Despite the advancements in automotive technology, cars still lack seamless fuel doors, which is an intriguing aspect of vehicle design. This feature, which allows easy access to the fuel tank without the need for manual opening, has not yet been widely adopted. The absence of seamless fuel doors can be attributed to various factors, including safety concerns, cost implications, and the complexity of integrating such mechanisms into existing vehicle structures. Understanding these reasons provides insight into the challenges and trade-offs in automotive engineering, highlighting the ongoing pursuit of innovation and user convenience.

What You'll Learn

- Cost and Complexity: Current fuel doors are expensive to manufacture and install, requiring intricate designs

- Safety Concerns: Fuel doors might pose risks if not properly sealed, leading to potential fuel leaks and fires

- Reliability: Mechanical fuel doors can malfunction, causing fuel spills and engine issues

- Design Limitations: Current designs lack innovation, failing to meet modern vehicle aesthetics and functionality

- Regulatory Barriers: Fuel door regulations hinder innovation, requiring extensive testing and compliance

Cost and Complexity: Current fuel doors are expensive to manufacture and install, requiring intricate designs

The primary reason cars have not yet adopted seamless fuel doors is the significant cost and complexity associated with their design and installation. Current fuel doors are intricate and require precise engineering to ensure both functionality and security. The manufacturing process involves multiple components, including the door itself, the locking mechanism, and the associated wiring and electronics. Each component must be carefully crafted and assembled to meet strict safety standards, which drives up production costs.

The complexity of the design is a major factor. Seamless fuel doors would need to incorporate advanced locking systems that can withstand tampering and provide robust security. This includes the use of high-quality materials, such as durable alloys or advanced composites, to ensure the door's strength and resistance to prying. The intricate nature of these designs often requires specialized tools and equipment, further increasing manufacturing expenses.

Furthermore, the installation process adds to the overall cost. Current fuel doors are typically designed with a specific vehicle model in mind, requiring custom-made components and precise fitting. This customization increases the time and skill needed for installation, making it a more expensive and time-consuming process. Seamless fuel doors, with their advanced features and potential for integration with existing vehicle systems, would likely demand even more specialized installation techniques, further elevating costs.

Despite the challenges, there is ongoing research and development in the automotive industry to address these issues. Engineers are exploring ways to streamline the manufacturing process, reduce costs, and simplify the installation of fuel doors. This includes the use of advanced manufacturing techniques, such as 3D printing, to create custom components with reduced material waste. Additionally, the development of more user-friendly locking mechanisms and improved security features is an ongoing focus to make seamless fuel doors a viable and cost-effective option for vehicle manufacturers.

In summary, the high cost and complexity of current fuel door designs are significant barriers to the widespread adoption of seamless fuel doors. However, with advancements in manufacturing technology and a continued focus on research, these challenges can be overcome, potentially leading to more efficient and secure fuel door systems in the future.

Garry's Mod VCMod: Ultimate Guide to Car Fueling

You may want to see also

Safety Concerns: Fuel doors might pose risks if not properly sealed, leading to potential fuel leaks and fires

The concept of seamless fuel doors, while appealing for aesthetic and functional reasons, raises significant safety concerns that have prevented their widespread adoption in the automotive industry. One of the primary issues is the potential for fuel leaks, which can have severe consequences. Fuel is a highly flammable substance, and any leak, even a small one, can lead to dangerous situations. If a seamless door is not properly sealed, it could create a pathway for fuel to escape, especially during accidents or when the vehicle is subjected to extreme temperatures. This risk is further exacerbated by the fact that fuel tanks are often located in areas that are more susceptible to damage, such as the underbody or rear of the vehicle.

In the event of a collision or a sudden impact, the fuel door's integrity becomes crucial. A poorly designed or sealed door might not withstand the force, leading to a breach in the fuel tank. This could result in fuel spilling onto hot engine components, creating a fire hazard. The risk of fire is a critical safety concern, as it can quickly escalate and pose a threat to both the vehicle and its occupants. Moreover, the release of fuel vapor into the air can contribute to air pollution and potentially affect the environment.

To address these safety concerns, automotive engineers have developed various sealing mechanisms and designs for fuel doors. These include multiple seals, gaskets, and locking mechanisms to ensure a tight closure. The goal is to create a robust and reliable system that can withstand various conditions without compromising safety. For instance, some fuel doors are designed with a double-locking mechanism, ensuring that the door remains securely closed even during extreme maneuvers or accidents.

Additionally, manufacturers are implementing advanced materials and technologies to enhance the overall safety of fuel systems. This includes using high-quality, flexible materials that can adapt to temperature changes without compromising the seal. By incorporating these innovations, carmakers aim to minimize the risks associated with fuel leaks and fires, making seamless fuel doors a safer option for modern vehicles. Despite the challenges, the automotive industry continues to explore and refine these designs, ensuring that vehicles remain safe and efficient.

Funny Cars vs. Top Fuel Dragsters: Who's Faster?

You may want to see also

Reliability: Mechanical fuel doors can malfunction, causing fuel spills and engine issues

The reliability of mechanical fuel doors in vehicles is a critical aspect that cannot be overlooked. These doors, designed to control the flow of fuel into the engine, are susceptible to various malfunctions that can lead to hazardous situations. One of the primary concerns is the potential for fuel spills, which can occur due to worn-out gaskets, damaged seals, or faulty door mechanisms. Over time, the constant opening and closing of the fuel door can cause these components to degrade, leading to leaks and potential fires. For instance, a simple issue like a loose or damaged gasket can result in fuel seeping out when the door is closed, posing a significant risk to both the vehicle and its occupants.

In addition to fuel spills, mechanical fuel doors can also cause engine issues. When these doors malfunction, they may not properly close, leading to an exposed fuel tank. This exposure increases the risk of fuel evaporation, which can attract static electricity and potentially ignite, causing engine misfires or even more severe engine damage. Furthermore, a poorly functioning fuel door might not secure the fuel tank tightly, allowing air to enter and contaminate the fuel, leading to performance problems and reduced engine efficiency.

To address these reliability concerns, automotive engineers are constantly exploring innovative solutions. One approach is to incorporate advanced materials and designs that enhance the durability and longevity of fuel door components. For example, using high-quality seals and gaskets that are resistant to wear and tear can significantly reduce the likelihood of fuel leaks. Additionally, implementing self-closing mechanisms or automatic fuel door systems can minimize the risk of human error and ensure that the fuel door remains securely closed at all times.

Another strategy to improve reliability is through the integration of smart technology. Sensors and actuators can be employed to monitor the fuel door's position and functionality, alerting drivers to any issues. For instance, a sensor can detect if the fuel door is not properly closed and trigger a warning light on the dashboard, prompting the driver to take action. Such a system can prevent potential accidents and engine damage caused by neglected fuel door malfunctions.

In summary, while mechanical fuel doors have been a standard feature in vehicles for decades, their reliability remains a concern. Malfunctions can lead to fuel spills, engine issues, and potential safety hazards. By implementing advanced materials, innovative designs, and smart technology, automotive manufacturers can enhance the durability and safety of fuel doors, ensuring a more reliable and efficient driving experience. It is through continuous innovation and a focus on reliability that the automotive industry can address the question of why seamless fuel doors have not yet become a standard feature in modern vehicles.

A Step-by-Step Guide to Draining Your Car's Fuel Tank Safely

You may want to see also

Design Limitations: Current designs lack innovation, failing to meet modern vehicle aesthetics and functionality

The concept of seamless fuel doors has been a topic of interest for automotive enthusiasts and designers alike, as it presents an opportunity to enhance both the aesthetics and functionality of vehicles. However, despite the potential benefits, current designs in the automotive industry have fallen short of achieving this seamless integration. One of the primary design limitations is the lack of innovation in this specific area. Over the years, fuel doors have remained largely unchanged, with traditional designs often featuring bulky, protruding mechanisms that disrupt the sleek lines of modern vehicles. This lack of creativity has resulted in a missed opportunity to create a visually appealing and streamlined solution.

Modern car manufacturers strive to produce vehicles that are not only efficient but also aesthetically pleasing, catering to the diverse preferences of consumers. The current fuel door designs, however, often clash with the sleek and minimalist aesthetics that are prevalent in the automotive market. Designers face the challenge of integrating a functional component, such as a fuel door, without compromising the overall visual appeal. This is particularly crucial in an era where consumers demand vehicles that are not just functional but also visually stunning.

Furthermore, the functionality of current fuel door designs is often limited. Many traditional fuel doors require manual operation, which can be cumbersome and inconvenient. The process of opening and closing the fuel door might involve complex mechanisms, making it less user-friendly. In contrast, seamless fuel doors could offer a more intuitive and efficient solution, allowing for quick and easy access to the fuel tank. This improvement in functionality would not only enhance the user experience but also contribute to the overall convenience of vehicle ownership.

Addressing these design limitations requires a shift in approach, encouraging automotive engineers and designers to think outside the box. By incorporating innovative materials and advanced engineering techniques, it is possible to create fuel doors that are both aesthetically pleasing and highly functional. For instance, utilizing lightweight yet sturdy materials can ensure the structural integrity of the fuel door while also reducing its overall weight, contributing to a more seamless integration. Additionally, implementing smart technologies could enable automatic or remote-controlled fuel door operations, further enhancing convenience and security.

In summary, the lack of innovation in fuel door design has led to a disconnect between functionality and modern vehicle aesthetics. By embracing new materials, engineering solutions, and user-centric design principles, the automotive industry can overcome these limitations. Seamless fuel doors have the potential to revolutionize the way vehicles are designed and experienced, offering a harmonious blend of form and function that meets the expectations of contemporary car enthusiasts.

F1 Fuel Efficiency: Unlocking the Secrets of Race Day Consumption

You may want to see also

Regulatory Barriers: Fuel door regulations hinder innovation, requiring extensive testing and compliance

The automotive industry is often a complex web of regulations and standards, and one area where these rules can significantly impact innovation is in the design of fuel doors. While the concept of a seamless fuel door, which would eliminate the need for a separate access point, might seem appealing for both aesthetic and functional reasons, the reality is that regulatory barriers make such advancements challenging. These barriers are primarily in place to ensure safety, security, and compliance with industry standards, but they often act as a bottleneck for innovation.

One of the primary regulatory hurdles is the requirement for extensive testing. Fuel systems, including the doors, must undergo rigorous safety assessments to ensure they can withstand various conditions, from extreme temperatures to potential crash scenarios. This process is essential for public safety but can be a significant barrier for manufacturers wanting to introduce new designs. The testing requirements are often stringent and time-consuming, requiring multiple iterations and modifications to meet the necessary standards. For instance, a seamless fuel door design might need to prove its ability to prevent fuel leaks under various conditions, a challenging task that could delay product launch by months or even years.

Compliance with industry standards is another critical aspect. Fuel door regulations are set by various bodies, such as the National Highway Traffic Safety Administration (NHTSA) and the Environmental Protection Agency (EPA), among others. These standards dictate the materials, construction methods, and performance criteria that fuel doors must meet. For innovative designs, such as seamless fuel doors, manufacturers must navigate these complex regulations, ensuring that their products not only meet but exceed the required standards. This process often involves extensive documentation, testing, and sometimes even third-party audits, all of which can be costly and time-consuming.

Furthermore, the regulatory environment can vary significantly across different regions, adding another layer of complexity. A seamless fuel door design that complies with regulations in one country might not meet the standards in another, requiring manufacturers to tailor their products for specific markets. This customization adds to the overall cost and time required for development, potentially discouraging smaller manufacturers from investing in such innovations. As a result, the automotive industry might miss out on the benefits of seamless fuel doors, including improved fuel efficiency, enhanced vehicle aesthetics, and increased customer satisfaction.

In summary, while the idea of seamless fuel doors is appealing, the regulatory barriers present significant challenges. These barriers are essential to ensure safety and compliance, but they also hinder innovation by making it difficult and costly for manufacturers to introduce new designs. Overcoming these regulatory hurdles requires a deep understanding of the rules, significant investment in testing and compliance, and a commitment to meeting or exceeding industry standards. Until these barriers are addressed, the automotive industry may continue to grapple with the challenge of integrating seamless fuel doors into mainstream vehicles.

Boost Your Car's Fuel Efficiency: Tips for Petrol Vehicle Owners

You may want to see also

Frequently asked questions

The primary reason is a combination of practicality and safety concerns. Seamless fuel doors, while aesthetically pleasing, can pose challenges in terms of security and maintenance. The fuel door acts as a protective barrier, preventing accidental spills and unauthorized access to the fuel tank. It also helps to maintain the structural integrity of the vehicle by providing a secure closure for the fuel filler area.

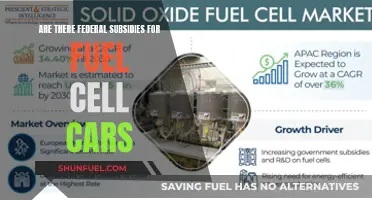

While there is ongoing research and development in the automotive industry, seamless fuel doors are not yet a standard feature. Manufacturers are constantly exploring innovative designs and materials to improve vehicle efficiency and aesthetics. However, the current focus is on ensuring that fuel systems are reliable, safe, and easily accessible for maintenance.

Seamless fuel doors can enhance the overall appearance of a vehicle, providing a sleek and modern look. They can also improve the user experience by offering a more seamless and integrated fuel system. Additionally, seamless fuel doors could potentially reduce the risk of fuel leaks and improve the overall safety of the vehicle, especially in emergency situations.