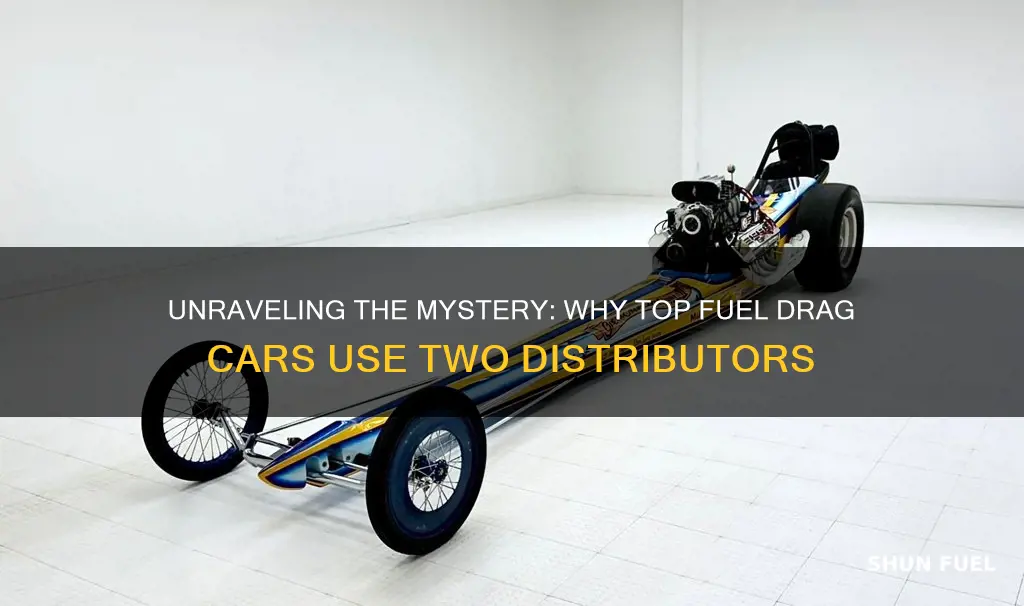

Top Fuel drag cars, known for their incredible speed and power, utilize a unique engine configuration that includes two distributors. This design choice is primarily due to the high-performance nature of these engines, which require precise timing and synchronization of fuel injection and spark. The two distributors are strategically positioned to ensure that each cylinder receives the optimal amount of fuel and spark, allowing for the rapid acceleration and powerful performance that these cars are renowned for. This setup is a critical component of the car's performance and is a key factor in the success of Top Fuel drag racing.

| Characteristics | Values |

|---|---|

| Engine Type | V8 |

| Power Output | Over 1,300 horsepower |

| Fuel | Methanol |

| Ignition System | 2-stage ignition (primary and secondary distributors) |

| Distributor Purpose | To route high-voltage spark energy from the battery to the spark plugs at precise timing |

| Advantages | Improved performance, reliability, and ease of maintenance |

| Disadvantages | Complex setup, potential for mechanical failure, and high cost |

| Alternatives | Electronic ignition systems, which are more reliable and easier to manage |

| Regulations | Top Fuel drag cars are required to use 2-stage ignition systems due to the extreme power and fuel requirements |

What You'll Learn

- Engine Power: Two distributors increase power output by firing spark plugs simultaneously

- Fuel Injection: Distributors work with fuel injectors to optimize fuel-air mixture for combustion

- Performance: Dual distributors enhance performance by providing precise timing for maximum speed

- Reliability: Redundancy ensures reliable ignition even if one distributor fails

- Customization: Top Fuel cars can be fine-tuned with different distributor settings for specific needs

Engine Power: Two distributors increase power output by firing spark plugs simultaneously

Top Fuel drag cars are renowned for their incredible power and speed, and a key component in achieving this performance is the use of two distributors in their engines. This setup is a strategic choice to maximize power output and ensure optimal performance during the short duration of a drag race.

The primary advantage of having two distributors is the ability to fire spark plugs simultaneously. In a typical engine, a single distributor controls the timing of spark plug ignition. However, in Top Fuel cars, the use of two distributors allows for a more precise and powerful ignition sequence. When the two distributors are synchronized, they can deliver a double spark, or a more intense spark, to the combustion chamber at the exact moment the piston is at the top of its compression stroke. This double spark provides a more robust and rapid combustion process, resulting in a significant increase in power output.

The power gain is achieved through the principle of 'double-firing'. Each distributor is responsible for controlling the spark plug in its respective cylinder. When both distributors are engaged simultaneously, they create a more aggressive and rapid firing sequence. This rapid firing process compresses the air-fuel mixture more efficiently, leading to a more powerful explosion and, consequently, a substantial increase in horsepower. The additional power is crucial for Top Fuel cars, as it enables them to accelerate rapidly and reach their top speed in a fraction of a second.

This dual-distributor system is a sophisticated engineering solution to optimize engine performance. It requires precise timing and coordination to ensure that the spark plugs fire in perfect harmony. The engineers and mechanics responsible for these cars' setups must carefully calibrate the distributors to achieve the desired power output without compromising the engine's reliability.

In summary, the use of two distributors in Top Fuel drag cars is a strategic design choice to enhance engine power. By firing spark plugs simultaneously, the double-distributor system creates a more aggressive combustion process, resulting in increased horsepower and the ability to accelerate rapidly. This innovative approach showcases the engineering prowess required to build these high-performance vehicles.

Camshafts in Fuel-Injected Engines: Unlocking Power and Efficiency

You may want to see also

Fuel Injection: Distributors work with fuel injectors to optimize fuel-air mixture for combustion

In the world of high-performance drag racing, Top Fuel cars are renowned for their incredible power and speed. One of the key components that contribute to their performance is the fuel injection system, which plays a crucial role in optimizing the fuel-air mixture for combustion. This is where the concept of distributors comes into play, specifically the use of two distributors in these powerful machines.

Distributors are essential in managing the timing and delivery of fuel to the engine. In a conventional internal combustion engine, the distributor's primary function is to route the high-voltage spark from the ignition coil to the correct cylinder at the precise moment of ignition. However, in Top Fuel dragsters, the challenge lies in the extreme power and speed, which demand a more sophisticated approach to fuel injection. This is where the second distributor comes into the picture.

The use of two distributors in Top Fuel cars is a strategic design choice. The primary distributor, as in standard engines, controls the spark timing for the engine's cylinders. However, the second distributor is dedicated to fuel injection. This additional distributor works in conjunction with the fuel injectors to ensure a precise and optimized fuel-air mixture. By having a separate distributor for fuel injection, engineers can fine-tune the fuel delivery, allowing for a more efficient and powerful combustion process.

The fuel injectors in these high-performance cars are designed to deliver a precise amount of fuel directly into the combustion chamber. The second distributor ensures that the fuel is injected at the exact moment when the air-fuel mixture is most receptive to ignition. This timing is critical for achieving the highest power output and ensuring that the engine operates efficiently under the extreme conditions of drag racing. The additional distributor provides the flexibility to adjust the fuel injection timing independently, allowing for a more tailored and precise fuel-air mixture.

In summary, the use of two distributors in Top Fuel drag cars is a sophisticated approach to fuel injection. The primary distributor manages spark timing, while the second distributor works with the fuel injectors to optimize the fuel-air mixture. This setup enables engineers to fine-tune the combustion process, resulting in the incredible power and speed that make Top Fuel racing so thrilling. It showcases the intricate engineering required to harness the full potential of these powerful machines.

Unveiling the Green Lie: Electric Car Batteries' Fossil Fuel Connection

You may want to see also

Performance: Dual distributors enhance performance by providing precise timing for maximum speed

Top Fuel drag cars are renowned for their incredible performance and speed, and a key component contributing to this is the use of dual distributors. These cars operate under strict rules and regulations, and their engines are finely tuned to deliver maximum power over a very short duration. The primary reason for employing two distributors is to achieve precise timing, which is crucial for achieving the highest possible speed during the brief window of acceleration.

In the context of these high-performance vehicles, timing is everything. When a Top Fuel drag car launches, it needs to generate an immense amount of power in a fraction of a second. The dual distributor setup ensures that the spark plugs receive the right amount of fuel and spark at the exact moment required. This precise timing allows for optimal combustion, resulting in a powerful burst of speed that propels the car forward.

The two distributors work in tandem, each responsible for controlling the spark for one cylinder bank. This setup provides independent timing for the front and rear banks, allowing for a more nuanced and precise control of the engine's performance. By having separate distributors, the engineers can fine-tune the timing for each bank, ensuring that the power is delivered efficiently and effectively. This level of control is essential for achieving the extreme speeds these cars are capable of.

During the initial stages of the race, the dual distributors play a critical role in managing the engine's performance. As the car accelerates, the distributors adjust the spark timing to match the increasing speed and load. This dynamic adjustment ensures that the engine operates at its peak efficiency, providing the necessary power to overcome the drag and build up speed. The precision offered by dual distributors is vital for maintaining control and stability, especially at the higher speeds reached during the race.

In summary, the use of dual distributors in Top Fuel drag cars is a strategic design choice to enhance performance. By providing precise timing for maximum speed, this setup allows the engine to deliver an incredible amount of power in a very short time. The independent control offered by two distributors enables engineers to fine-tune the engine's performance, ensuring optimal combustion and a powerful launch. This technology is a testament to the ingenuity and engineering prowess required to build these high-performance vehicles.

Unleash the Power: Strategies to Spark Hydrogen Car Awareness

You may want to see also

Reliability: Redundancy ensures reliable ignition even if one distributor fails

In the high-octane world of Top Fuel drag racing, every millisecond counts, and reliability is paramount. One of the key factors that contribute to the success of these powerful machines is their ignition system, specifically the use of two distributors. This design choice is not arbitrary but a strategic decision to ensure optimal performance and reliability in the most extreme conditions.

The primary reason for employing two distributors in Top Fuel drag cars is redundancy. Each distributor is responsible for firing the engine's cylinders, and having two of them means that even if one fails, the other can still provide the necessary spark to ignite the fuel and propel the car down the track. This redundancy is crucial because it eliminates the risk of a complete loss of ignition, which could result in a failed race or, worse, a dangerous situation during the race.

The reliability offered by this setup is essential for several reasons. Firstly, it ensures that the engine continues to operate at peak performance even under immense stress. Top Fuel cars produce astonishing power, and the ignition system must be able to handle this without faltering. With two distributors, the engine can maintain its power output even if one distributor is compromised, providing a consistent and reliable spark.

Secondly, the use of two distributors allows for a more robust and fault-tolerant system. In the event of a distributor failure, the car's engine control unit (ECU) can quickly switch to the backup distributor, ensuring that the race continues without significant performance degradation. This quick response time is vital in racing, where every second counts, and a well-maintained system can make all the difference.

Furthermore, this design choice also accounts for the extreme conditions that Top Fuel cars operate in. The high-speed, high-load environment of drag racing puts immense stress on all components, and the ignition system is no exception. By having two distributors, the car's engineers can ensure that the ignition system is more likely to withstand the rigors of the sport, providing a reliable spark even in the most challenging circumstances. This level of reliability is a testament to the meticulous planning and engineering that goes into building these high-performance machines.

Car Qwest Fuel Pumps: Unlocking Performance and Reliability

You may want to see also

Customization: Top Fuel cars can be fine-tuned with different distributor settings for specific needs

Top Fuel drag racing cars are highly customized machines, and one of the key areas of customization is the distributor setup. These cars often feature a unique and intricate system that involves two distributors, which is a significant departure from the standard single-distributor setup found in most vehicles. The primary reason for this configuration is to optimize power delivery and fine-tune the engine's performance for the specific demands of drag racing.

The two-distributor system in Top Fuel cars is a result of extensive engineering and performance enhancements. Each distributor is responsible for firing the engine's cylinders in a precise and timed manner, ensuring optimal power output during the brief but intense race. By having two distributors, engineers can fine-tune the timing and power delivery for different stages of the race. This setup allows for a more aggressive and powerful engine response, crucial for the short, high-speed runs typical of Top Fuel racing.

Customization of distributor settings is a critical aspect of Top Fuel car preparation. Mechanics and engineers can adjust the timing, advance, and retard settings of each distributor independently. This fine-tuning process ensures that the engine's power is maximized at the right moment, providing a powerful burst of acceleration when the car leaves the starting line. The ability to adjust these settings allows for a tailored approach, optimizing the car's performance for various track conditions and weather scenarios.

One of the key advantages of this customization is the ability to adapt to different track lengths and conditions. Top Fuel cars race on various drag strips, each with unique characteristics. By adjusting the distributor settings, teams can ensure that the engine's power delivery matches the specific requirements of each track. This level of customization is essential for maintaining competitiveness and achieving the fastest possible times.

Furthermore, the two-distributor setup enables engineers to experiment with different timing curves and advance angles. This experimentation allows for the creation of unique power bands, where the engine delivers its peak power at specific RPM ranges. Such customization ensures that the car's performance is tailored to the driver's skill and the car's capabilities, providing an edge over competitors. In the highly competitive world of Top Fuel drag racing, every fraction of a second counts, and these fine-tuned distributor settings can make a significant difference in race outcomes.

Parking: Fuel Efficiency and Car Consumption Explained

You may want to see also

Frequently asked questions

Top Fuel dragsters use two distributors to achieve a high-performance ignition system, which is crucial for their short-duration, high-rpm engines. Each distributor is responsible for firing the spark plugs in two separate banks of cylinders, allowing for a more efficient power delivery and improved performance during the brief but intense race.

The dual-distributor setup ensures that the spark is delivered precisely at the right time for each cylinder, optimizing the combustion process. This results in a more powerful and controlled explosion, enabling the car to accelerate rapidly and achieve high speeds. The second distributor provides an additional spark, which can be particularly beneficial during the initial stages of the race when the engine needs an extra boost.

Yes, having two distributors offers some design flexibility. It allows for independent control of the spark timing for each cylinder bank, which can be advantageous for fine-tuning the engine's performance. Additionally, in the event of a failure in one distributor, the other can still provide ignition, ensuring the car can still complete the race, albeit with reduced power.