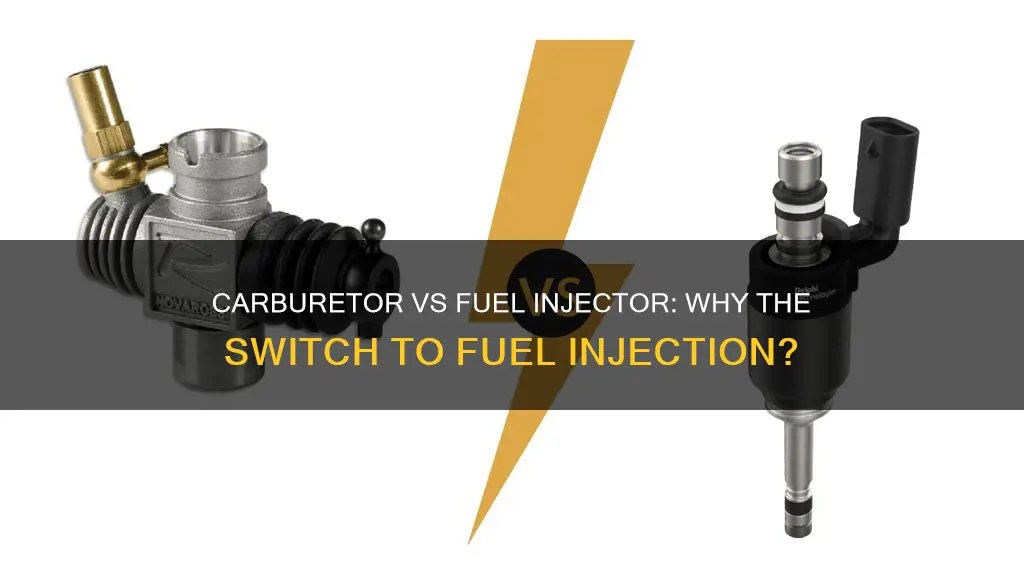

Carburettors and fuel injectors are two types of fuel delivery systems used in cars, motorcycles, and planes. Carburettors were the most common method until the 1980s and 90s when fuel injection systems became more popular. The primary benefits of fuel injection systems are more power, better fuel efficiency, and increased reliability. Fuel injection systems are more precise, allowing for a more efficient use of fuel, reduced consumption, and lower emissions. They can also account for changes in air or fuel temperature and atmospheric pressure, resulting in improved performance and fuel delivery that matches driver demand. Additionally, fuel injection systems require less maintenance since they don't need to be tuned like carburettors.

| Characteristics | Values |

|---|---|

| Cost | Fuel injection systems are more expensive than carburetor systems |

| Complexity | Carburetor systems are purely mechanical, while fuel injection systems are more complex and require more sensors |

| Maintenance | Carburetor systems require more maintenance and tuning than fuel injection systems |

| Fuel Efficiency | Fuel injection systems provide better fuel efficiency and reduced fuel consumption |

| Emissions | Fuel injection systems produce fewer emissions |

| Power | Fuel injection systems provide higher power and torque |

| Performance | Fuel injection systems provide better performance, as they can be tuned to match driver demand |

| Precision | Fuel injection systems offer greater precision in delivering the correct air-fuel ratio |

| Response | Fuel injection systems have a sharper throttle response |

| Customisation | Carburetor systems can be customised for power or mileage |

| Reliability | Fuel injection systems are more reliable than carburetor systems |

What You'll Learn

- Fuel injection systems are more precise, resulting in less fuel wastage and better fuel efficiency

- They are more reliable and can be adjusted to reduce emissions, optimise power or improve fuel economy

- They are better at accounting for changes in air or fuel temperature and atmospheric pressure

- They require less maintenance

- They are easier to start in cold and hot weather

Fuel injection systems are more precise, resulting in less fuel wastage and better fuel efficiency

Fuel injection systems are more precise than carburetors, resulting in less fuel wastage and better fuel efficiency. This is because fuel injection systems use an electronically controlled system to regulate the fuel-air mixture, achieving the correct stoichiometric ratio.

The stoichiometric mixture is the ideal ratio of air to fuel for maximum engine efficiency. For gasoline, this ratio is about 14.7:1. Fuel injection systems can constantly tweak the balance of this mixture depending on the engine's needs, resulting in reduced fuel consumption and improved fuel efficiency.

The electronic system also allows for more precision in metering the fuel, as sensors in a fuel injection system can account for changes in air or fuel temperature, or atmospheric pressure. This accuracy in fuel delivery can be tuned to match driver demand, resulting in improved power and performance.

Additionally, the sealed nature of the fuel injection system means that less raw fuel is allowed to evaporate from the engine when it is shut off, further reducing fuel wastage and overall pollution. This also results in a cleaner combustion process, leading to fewer pollutants and lower emissions.

The increased precision and efficiency of fuel injection systems mean that fuel is burned more completely, improving fuel efficiency and reducing wastage.

Replacing the Fuel Pump in a 1994 YJ Jeep

You may want to see also

They are more reliable and can be adjusted to reduce emissions, optimise power or improve fuel economy

Fuel injection systems are more reliable than carburetors and can be adjusted to reduce emissions, optimise power or improve fuel economy.

Fuel injection systems are more reliable than carburetors because they do not need to be tuned and require less maintenance. They are also less sensitive to changes in weather conditions, which improves engine starting performance.

Fuel injection systems can be adjusted to reduce emissions by achieving a more efficient use of fuel and lower fuel consumption. This is done by constantly tweaking the balance between air and fuel depending on the engine's needs, resulting in less wasted energy and better fuel efficiency. The electronic system can also account for changes in air or fuel temperature or atmospheric pressure, leading to more precision.

To optimise power, fuel delivery can be tuned to match driver demand. This results in higher power and torque than a carbureted version of the same engine.

Finally, fuel injection systems can improve fuel economy by optimising the air-fuel ratio, ensuring that every drop of fuel counts and reducing fuel wastage.

Replacing the Fuel Pump in Your 1994 Infiniti QX4

You may want to see also

They are better at accounting for changes in air or fuel temperature and atmospheric pressure

Fuel injectors are better at accounting for changes in air or fuel temperature and atmospheric pressure. This is because they use sensors to account for these changes and adjust the fuel-air mixture accordingly. Carburettors, on the other hand, are mechanical devices that do not rely on electronics to mix air and fuel. As a result, they cannot account for changes in temperature or atmospheric pressure as accurately as fuel injectors.

Fuel injectors use an electronically-controlled system to regulate the fuel-air mixture, achieving the correct stoichiometric ratio. This means that the air-fuel mixture can be constantly tweaked depending on the engine's needs, resulting in less wasted energy and better fuel efficiency. The electronic system can also calculate the optimum air-fuel mixture based on the exact conditions, improving starting performance in cold and hot weather.

Sensors in a fuel injection system can detect changes in air or fuel temperature and atmospheric pressure and adjust the fuel delivery accordingly. This results in a more precise and accurate fuel delivery system that can match driver demand. The accuracy of fuel injection and modern electronic controls lead to improved fuel delivery that matches the driver's demand.

Overall, the ability of fuel injectors to account for changes in air or fuel temperature and atmospheric pressure through the use of sensors and electronic controls results in improved fuel efficiency, performance, and reliability when compared to carburettors.

Replacing Fuel Water Separator: ISX15 Step-by-Step Guide

You may want to see also

They require less maintenance

Fuel injectors require less maintenance than carburetors. This is because they maintain an optimum air-to-fuel ratio, eliminating random engine stoppages and oiled spark plugs. Fuel injection systems also do not need to be tuned like carburetors, which require frequent adjustments to the air-fuel ratio to stay balanced. Carburetors are also vulnerable to blockages if dust enters the chamber.

Fuel injection systems are more reliable than carburetors, and their increased accuracy means that fuel delivery can be fine-tuned to match driver demand. Sensors in a fuel injection system can account for changes in air or fuel temperature or atmospheric pressure, which a carburetor cannot. This results in a more efficient use of fuel, reduced fuel consumption, and lower emissions.

The increased efficiency of fuel injection systems also means that fuel is burned in a cleaner way, leading to fewer pollutants. This is particularly important as emission controls and fuel economy are highly regulated by governments.

While fuel injection systems are more complex than carburetors and often require more sensors to operate, they are a clear improvement on the old technology. For the modern driver, the improved power, fuel economy, and lower emissions are all that is needed.

Replacing Fuel Sending Unit in Isuzu Rodeo: Step-by-Step Guide

You may want to see also

They are easier to start in cold and hot weather

Fuel injection systems are easier to start in cold and hot weather because they are designed to meet or exceed emissions regulations and can deliver fuel more precisely, even when accounting for elevation and temperature changes. They can also adjust to changes in altitude automatically, maintaining engine performance without manual adjustments.

Fuel injection systems are computer-controlled and use sensors to account for changes in air or fuel temperature or atmospheric pressure. This means that when you turn the key, the car is going to start. In contrast, carburetors are more sensitive to changes in weather and elevation, and do not adjust autonomously. They are also less precise in fuel delivery, which can make it harder to start the engine in cold or hot weather.

The sealed nature of the fuel injection system also means that less raw fuel is allowed to evaporate from the engine when it is shut off, reducing overall pollution. This is especially beneficial in hot weather, where vapour lock might give carburetors trouble.

Additionally, fuel injection systems deliver fuel that is already atomized by the injectors. This means that as long as the system is functioning and there is gas in the fuel line, the engine will start in just about any weather.

Replacing Chainsaw Fuel Lines: A Simple Trick to Try

You may want to see also

Frequently asked questions

Fuel injection systems replaced carburetors in the 1980s and 90s due to their ability to deliver more power, better fuel efficiency, and increased reliability.

Fuel injection systems offer several benefits over carburetors, including:

- Reduced emissions

- Improved fuel economy

- Increased power and performance

- More precise control of the air-fuel ratio

- Less maintenance required

- Better starting performance in cold and hot weather conditions

While fuel injection systems offer improved performance and efficiency, they are more complex and costly than carburetors. They also require specialized tools and expertise for tuning and repairs.