Checking fuel pressure is an important step in ensuring your car's fuel pump is working properly and that the correct amount of fuel is being delivered to the engine. A fuel pump transfers petrol or diesel from the fuel tank to the engine, and when it malfunctions, it can cause a lack of power output from the engine. Testing fuel pressure can help diagnose potential issues and ensure the smooth performance of the engine. This is done by attaching a fuel pressure gauge to the fuel pump test point and activating the engine. The pressure reading can then be compared to the manufacturer's specifications to determine if there is an issue.

| Characteristics | Values |

|---|---|

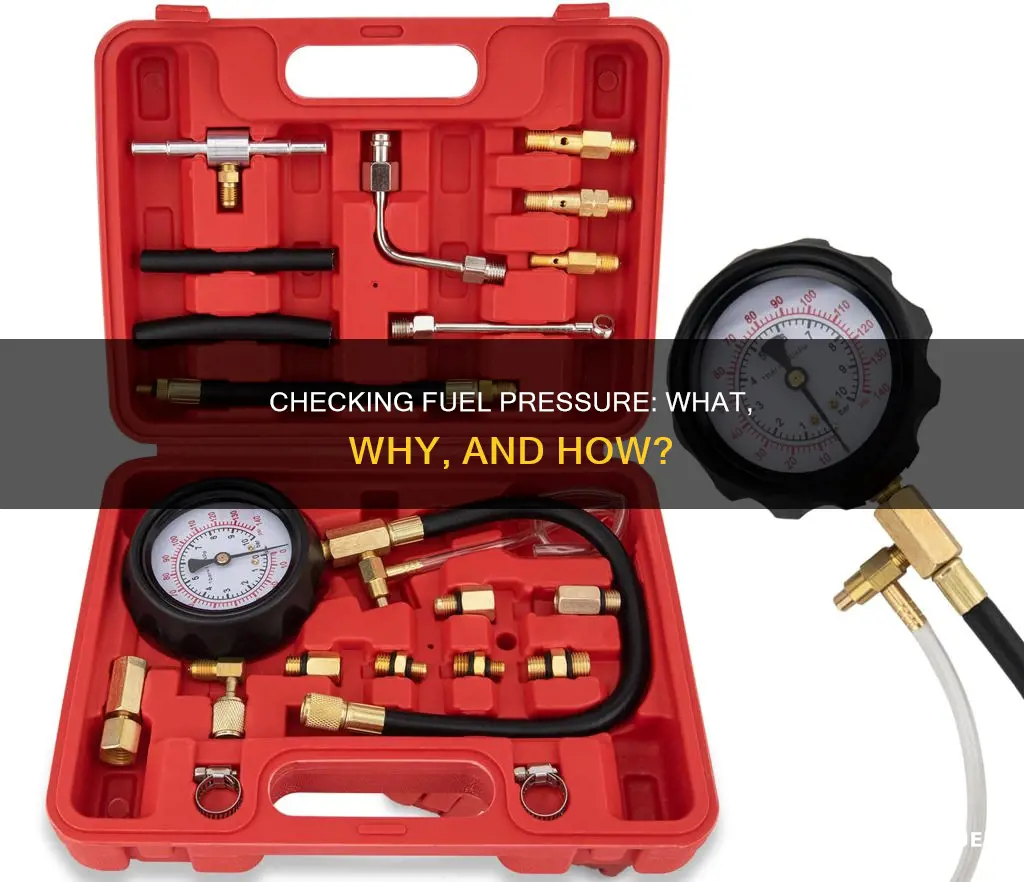

| Fuel pressure tester kits consist of | A fuel gauge and the fuel hose it is attached to |

| How to test fuel pressure | Attach the gauge to the fuel pump test point and activate your engine |

| Fuel pressure tester cost | $70 to $80 |

| Fuel pressure | Check the manufacturer specification |

| Fuel pump | Either mechanical or electric |

| Fuel injection system | Port or multi-port fuel injection, Throttle Body Injection (TBI) or Central Fuel Injection (CFI) |

| Fuel pump warning signs | Depressing the gas pedal, vehicle moving at a consistent speed and then surging forward, temperature of the car, frequency of fuelling up |

| Engine issues | Unable to ignite, sputters at high speeds, lack of power output |

| Fuel pump testing tools | Screwdriver, fuel pressure gauge, ratchets, sockets |

| Fuel pump testing steps | Park the vehicle, apply the parking brake, turn off the engine, locate the fuel pressure test port, install pressure tester, turn on the ignition and run the engine at a specific RPM, check for required pressure |

What You'll Learn

Safety precautions when checking fuel pressure

Checking fuel pressure can be dangerous, so it is important to take safety precautions. Fuel, especially gasoline, is highly flammable and can easily catch fire. It is also corrosive and poisonous. Therefore, it is crucial to take the necessary steps to ensure your safety and prevent accidents. Here are some safety precautions to follow when checking fuel pressure:

Personal Protective Equipment (PPE):

- Wear safety gear, such as gloves, safety goggles, and fire-resistant clothing. This will protect your skin, eyes, and body from fuel exposure and sparks or flames.

- Use safety footwear to protect your feet from any falling objects or spills.

Work Area Preparation:

- Ensure proper ventilation in the work area. Fuel vapors can be dangerous, so working in a well-ventilated area is crucial.

- Keep a Class B fire extinguisher nearby. Fuel fires cannot be extinguished with water, so a fire extinguisher containing dry chemicals is necessary to deprive the fire of oxygen.

- Have spill response kits nearby in case of any fuel leaks or spills.

- Use grounding equipment to prevent static electricity buildup, which could ignite fuel vapors.

Vehicle Preparation:

- Disconnect the negative battery cable before beginning any testing or repair procedures, unless they require electrical power. This helps prevent accidental sparks.

- Relieve the pressure in the fuel lines before working on the fuel system, including the fuel lines, fuel pump, and fuel injectors.

- Wrap a shop towel around the fitting on a fuel line before loosening it to absorb any leaking fuel.

- Wipe up any fuel spills immediately, especially from engine surfaces, as they can ignite when the car is running.

- Do not smoke or allow any sparks or open flames near the work area.

Fuel Storage and Handling:

- Use approved containers to avoid leaks. UL-approved fuel containers may be made of metal or plastic and will be airtight and chemically inert.

- Do not overfill fuel tanks or containers. Leave some space to prevent spills and overpressure.

- Store fuel in a safe area, away from exits or passages. Keep it tightly sealed and away from smoking areas.

- When transferring fuel, use a pump or hose instead of your mouth to start the siphon.

- Always follow the vehicle's operating manual for specific instructions and precautions.

Remember, safety should always be the top priority when working with fuel systems. By following these precautions, you can help protect yourself, your equipment, and the environment from potential hazards and accidents.

Understanding the Fuel Pressure Solenoid in Your 1999 Eclipse GSX

You may want to see also

How to test fuel pressure

Testing fuel pressure is a relatively straightforward process, but it's important to take safety precautions and understand the potential issues that can arise. Here's a step-by-step guide on how to test fuel pressure:

Step 1: Safety First

Fuel under pressure can be dangerous, so it's crucial to prioritise safety. Wear protective gear, such as safety glasses and gloves, and work in a well-ventilated area. Ensure there are no sources of ignition nearby, such as smoking or sparking.

Step 2: Check Fuel Pressure

Start by checking the fuel pressure in your vehicle. Start the car and let it idle. Install a fuel pressure gauge and run the pump to get a pressure reading. Compare this reading to the manufacturer's specifications. If the pressure is low, address this issue first. If the pressure is within the acceptable range, proceed to the next step.

Step 3: Perform a Fuel Volume Test

If the fuel pump is supplying sufficient pressure, perform a fuel volume test to ensure the proper amount of fuel is being delivered to the fuel injectors. This can be done using a flowmeter, or by performing a timed fuel delivery test with a glass measuring container. Collect a fuel sample for a specified duration (e.g., five seconds) and compare it to the manufacturer's specifications.

Step 4: Understand Fuel Pressure Readings

Different fuel pressure readings indicate different issues with your vehicle. Zero fuel pressure means the pump is likely dead or not receiving power. Low fuel pressure can be caused by a clogged fuel filter or a malfunctioning pump. High fuel pressure can be the result of a clogged or kinked fuel return line, a faulty fuel pump driver module, or a faulty fuel pressure regulator. Refer to your vehicle's repair manual or owner's manual to understand the specific fuel pressure requirements and potential causes of issues.

Step 5: Verify Fuel Pump Operation

Before concluding that there is an issue with fuel pressure, it's important to verify that the fuel pump is operational. Ensure there is fuel in the tank, even if the gauge indicates a full tank, as the gauge could be faulty. Have an assistant turn the ignition switch to "On" and listen for sounds indicating that the fuel pump is pressurising the fuel line. If no noise is heard, check the fuel pump fuse, relay, and wiring.

Step 6: Connect a Fuel Pressure Tester

To use a fuel pressure tester, locate the Schrader valve fitting on the fuel rail and remove the valve cap. Attach the appropriate tester fitting securely to ensure a leak-proof fit. Turn the ignition to "On" and monitor the psi reading. A stable reading indicates that the system is holding pressure well, while a drop in psi suggests a leak in the fuel system.

Step 7: Start the Engine and Observe

Start the engine and let it idle. You should observe steady fuel pressure within a few psi of the recommended pressure. Once the engine has warmed up, slowly rev the engine and ensure that the fuel pressure rises with the RPMs. If the fuel pressure holds steady and rises with engine speed, your engine problem is likely not fuel-related.

By following these steps, you can effectively test and diagnose fuel pressure issues in your vehicle. Remember to refer to vehicle-specific manuals and seek professional advice if you are unsure about any aspects of the testing process.

Ideal Fuel Pressure for GSR Engines at Idle

You may want to see also

Interpreting fuel pressure readings

Understanding the Basics:

Before interpreting the readings, it's essential to know that the fuel pressure reading should fall between 30-80 PSI for most engines. However, it's important to consult your vehicle's repair manual or manufacturer specifications for the correct range, as it can vary. For example, older throttle-body injected systems may need as little as 10 PSI, while multi-port injection systems can require up to 60 PSI.

Zero Fuel Pressure Readings:

If your fuel pressure gauge reads zero, it could indicate that the pump is dead or not operational. This could be due to a loose connection or a faulty fuel pressure gauge. To diagnose this issue, test for power and ground to the fuel pump to determine if it's genuinely broken or if there are other factors at play.

Low Fuel Pressure Readings:

Low fuel pressure readings can be caused by a malfunctioning fuel pump or a clogged fuel filter. Check for loose gas caps, as improper tank venting can also lead to low pressure. If tightening the gas caps doesn't resolve the issue, consider changing the fuel filter. Low fuel pressure can cause a significant drop in performance, making it harder to start the engine, and leading to frequent stalling.

High Fuel Pressure Readings:

High fuel pressure readings could indicate bad components, such as a failing fuel pump driver or a malfunctioning fuel pressure regulator. High fuel pressure can cause the engine to suffer in performance, with issues such as black smoke, rough running, and a strong fuel odour.

Interpreting Deviations:

Deviations from the specified pressure range may indicate underlying problems. For example, a faulty fuel pressure regulator, leaking fuel injectors, a clogged fuel filter, or a malfunctioning fuel pump can all cause pressure variations.

Safety Precautions:

It's important to prioritise safety when working with fuel systems. Wear appropriate protective gear, including safety glasses and gloves, to safeguard against potential fuel splashes or spills. Ensure the work area is well-ventilated to minimise the risk of fuel vapours accumulating and creating a fire hazard. Always avoid ignition sources and keep flammable objects away from the work area.

Fuel Pressure Sensor Location in 2003 Buick LeSabre

You may want to see also

Troubleshooting fuel pressure issues

Identifying the Problem:

Firstly, it's important to understand the symptoms of low fuel pressure. These may include an unresponsive throttle, difficulty starting the engine, a check engine light, misfires, or low engine performance. If you're experiencing any of these issues, it's likely that you have low fuel pressure.

Testing Fuel Pressure:

To confirm your suspicions, you'll need to test the fuel pressure. Here are the steps to do so:

- Put on safety gear: Safety first! Wear safety glasses and gloves, and work in a well-ventilated area to prevent any accidents.

- Check the fuel pressure: Start the car and let it idle. Install a fuel pressure gauge and run the pump, then note the pressure reading.

- Compare to specifications: Compare the pressure reading to the manufacturer's specifications for your specific car model. This information can be found in your vehicle owner's manual.

- Identify the issue: If the pressure is lower than specified, you've confirmed that you have low fuel pressure. If it's within the specified range, the issue may lie elsewhere.

Common Causes of Low Fuel Pressure:

If you've confirmed low fuel pressure, the next step is to identify the cause. Here are some common causes:

- Clogged fuel filter: The fuel filter may be clogged, preventing adequate fuel flow. This is a common issue, especially if the filter hasn't been replaced in a long time.

- Faulty fuel pump: The fuel pump may be malfunctioning or damaged, affecting its ability to provide sufficient fuel pressure.

- Faulty fuel pressure regulator: The regulator controls fuel pressure, and if it's faulty, it can cause either too low or too high of pressure.

- Stuck fuel injector: If a fuel injector is stuck open, it can cause low fuel pressure in the rail, leading to misfires.

- Damaged fuel lines: Driving on bumpy roads can cause damage to the fuel lines, resulting in low fuel pressure.

Resolving the Issue:

Once you've identified the cause of low fuel pressure, you can take steps to resolve the issue:

- Replace the fuel filter: If the issue is a clogged fuel filter, replace it with a new one. This is a relatively inexpensive and straightforward fix.

- Repair or replace the fuel pump: If the fuel pump is faulty, you may need to repair or replace it. This can be a more complex task, and you may need to consult a professional mechanic.

- Address other causes: Depending on the specific cause identified, you may need to repair or replace the faulty component, such as the fuel pressure regulator, fuel injector, or fuel lines.

Preventative Measures:

To avoid future fuel pressure issues, it's important to perform regular maintenance on your vehicle:

- Use high-quality fuel: Prevent contamination and clogging in the fuel system by using high-quality fuel.

- Regularly replace fuel filters: Follow the manufacturer's recommendations for replacing fuel filters to ensure optimal performance.

- Check for leaks: Regularly inspect the fuel system for any signs of leaks, as this can lead to a drop in fuel pressure.

- Clean the fuel system: Use recommended fuel system cleaners to prevent clogs and contamination.

- Perform regular diagnostics: Stay on top of any potential issues by performing regular diagnostics and addressing any problems early on.

By following these troubleshooting steps, you can effectively identify and resolve fuel pressure issues, ensuring the smooth and efficient operation of your vehicle's engine.

Locating Fuel Pressure Check Points in Your 240 Volvo

You may want to see also

When to seek expert help

While there are some DIY solutions to fuel pressure issues, it is generally recommended to seek professional help to address problems with your vehicle's fuel pressure. This is especially important if you are unsure about how to test your fuel pressure or interpret the results. Here are some signs that indicate when you should seek expert help:

- Unusual Fuel Tank Noises: If you hear a loud whining noise coming from your fuel tank instead of the usual low humming sound, it could indicate a malfunctioning fuel pump. Don't ignore these unusual noises and consult a mechanic if necessary.

- Struggling Car Starts: If your engine stumbles and makes popping sounds when you engage the accelerator pedal, it could be a sign of a problematic fuel pump. Consider seeking professional repair if your car fails to start or starts and then shuts off.

- Engine Sputtering: Engine sputtering, especially at higher speeds, could be due to a weak fuel pump not providing enough fuel to the engine. Inconsistent fuel delivery may also be caused by a worn-down fuel pump or a clogged fuel filter, which requires attention.

- Unexpected Stalling: Unexpected stalling while driving could be a sign of a failing fuel pump. An overheating fuel pump can lead to engine stall, indicating the need for immediate attention.

- Power Loss during Heavy Loads or Inclines: If you experience power loss while driving uphill or carrying a heavy load, it may suggest a bad fuel pump that cannot meet your vehicle's requirements. Don't ignore these symptoms as they could lead to more severe issues.

- Surging Engine Performance: Surging engine performance occurs when the fuel pump provides too much fuel to the engine, resulting in fluctuating vehicle speeds. This can be caused by a leaky fuel pressure regulator that is unable to maintain the necessary pressure.

- Decreased Fuel Efficiency: A decrease in fuel efficiency could be due to an excessive amount of fuel entering the fuel system because of a faulty valve within the fuel pump. This issue should be addressed to prevent long-term problems with your vehicle.

- Dead Fuel Pump: If your car won't start, there's a possibility of a dead fuel pump. However, it's important to rule out other potential issues such as electrical faults, problems with the ignition switch, faulty fuel injectors, or a malfunctioning fuel pressure regulator before concluding that the fuel pump is the culprit.

- Complex Repairs: Some fuel pressure issues may require complex repairs or replacements of specific components. In such cases, it is advisable to seek the expertise of a professional mechanic to ensure proper diagnosis and repair.

- Safety Concerns: If you are unsure about how to test fuel pressure or perform repairs safely, it is always best to consult a professional. Fuel acts as a coolant for the electric motor in your fuel pump, and improper handling can lead to overheating and potential safety hazards.

Remember, regular maintenance and timely inspections of your fuel system can help prevent major issues and ensure a smooth driving experience.

Fuel Rail Pressure Maintenance for Dodge Nitro Owners

You may want to see also

Frequently asked questions

It's important to remember that releasing fuel under pressure can cause fires and injuries. Therefore, you should wear safety glasses and gloves, work in a well-ventilated area, and avoid smoking or having anything around that could cause a spark.

First, make sure your vehicle is parked on flat ground with the emergency brake set and the engine off. Then, locate the fuel pressure test port and install the pressure tester. Turn on the ignition and run the engine at a specific RPM. Finally, check the pressure reading against the manufacturer's specifications.

Common signs of a malfunctioning fuel pump include low engine power delivery, hard starting, hesitation, low engine power, and frequent stalling.

If you suspect an issue with your fuel pump, it is recommended to take your vehicle to a mechanic or a shop to have it properly diagnosed and repaired.

To check fuel pressure, you will need a few tools, including a screwdriver, fuel pressure gauge, ratchets, and sockets. You may also need an adapter or a fuel pressure test kit, which you can borrow from auto parts stores in most cases.