Inline replaceable cartridge fuel filters are an essential component of any vehicle's fuel system, trapping contaminants to prevent engine damage and ensure optimal performance. When installing or replacing these filters, it is crucial to determine the correct direction of fuel flow. While some filters may have arrows indicating the direction, others might have distinct features, such as a larger cavity at one end. Generally, the fuel flows from the fuel tank towards the carburetor, with the arrow or larger end pointing towards the carburetor. However, it's important to refer to the vehicle's manual or seek expert advice for specific models.

What You'll Learn

- Fuel filters are designed to prevent contaminants from entering the fuel injector

- The direction of the fuel filter is indicated by an arrow

- Fuel filters are usually placed between the fuel tank and the carburetor

- Inline fuel filters are available in a variety of sizes and can be connected to most common AN fitting and line sizes

- Fuel filters should be replaced at the manufacturer's recommended intervals

Fuel filters are designed to prevent contaminants from entering the fuel injector

Fuel filters are typically made of pleated, porous materials that trap foreign particles and liquids. They are usually designed as cartridges containing filter paper, which can be replaced at regular intervals. By screening out these contaminants, fuel filters protect the fuel pump and injectors from damage and ensure the engine receives the necessary amount of fuel for proper combustion.

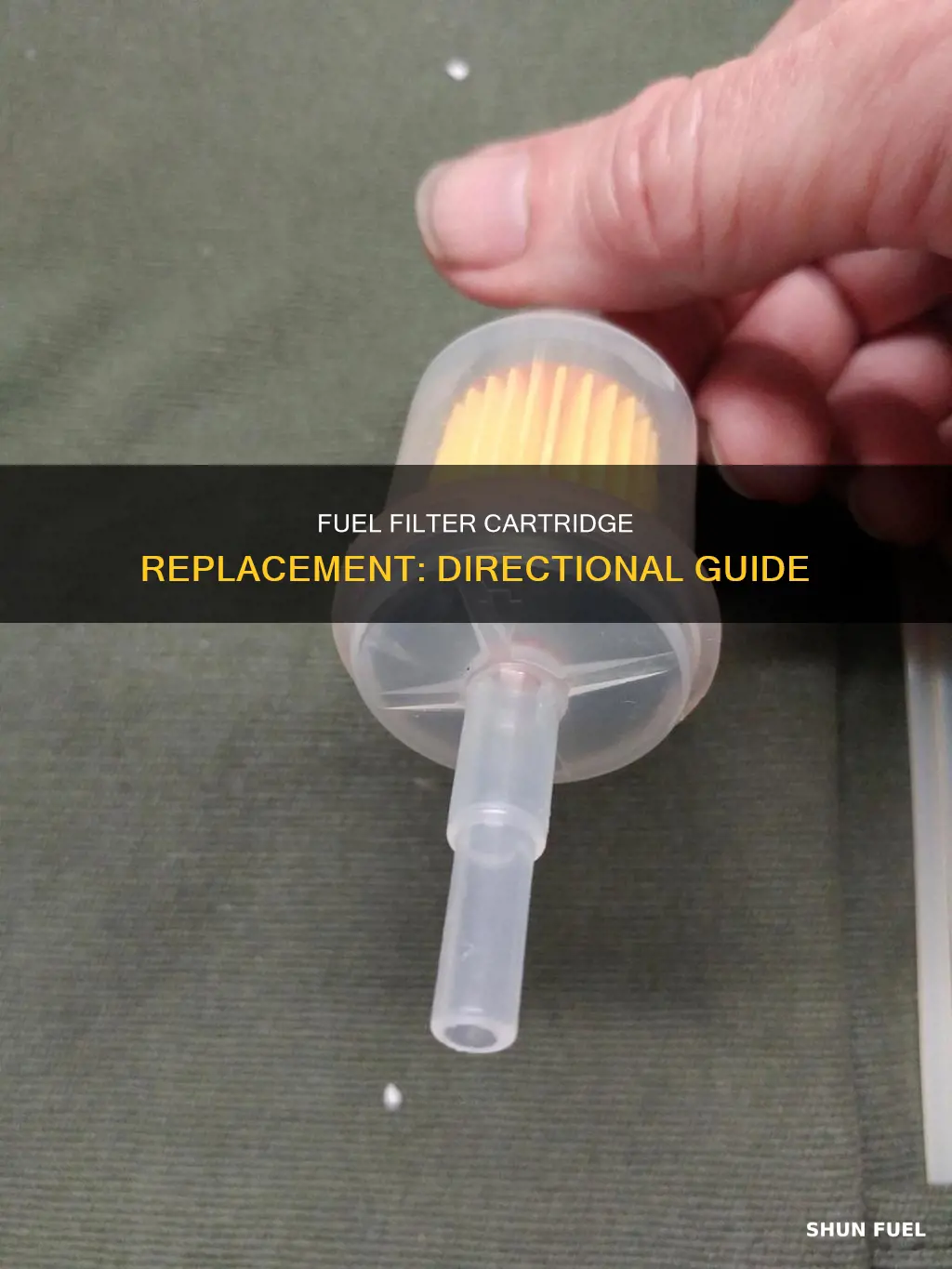

The direction of the fuel filter is important to ensure effective filtration. Most fuel filters are designed to have fuel flow from the outside-in, similar to an air filter. Clear fuel filters often have an arrow indicating the direction of fuel flow, with the arrow pointing in the direction of fuel travel from the tank to the carbs. This is important to ensure the filter is able to effectively trap contaminants and prevent them from entering the fuel injectors.

In some cases, the fuel filter may be placed before or after the fuel pump. While there is no definitive rule, some mechanics prefer to place the filter before the pump to catch any contaminants before they reach the pump. However, this setup may potentially pull air into the system due to the negative pressure created by pulling fuel through the filter. Placing the filter after the pump can help protect the pump itself, but may not provide the same level of protection for the fuel injectors. Ultimately, the specific setup and direction of the fuel filter can vary depending on the vehicle and the mechanic's preferences.

Game Fuel vs Kickstart: Who Will Win the Energy Drink Battle?

You may want to see also

The direction of the fuel filter is indicated by an arrow

In most cases, the arrow on the fuel filter will indicate that the fuel flows from the fuel tank to the carburetor. This is because the carburetor meters the fuel and air, mixes them, and then feeds the mixture into the combustion chamber. Therefore, the fuel filter should be installed with the arrow pointing towards the carburetor.

However, there may be some exceptions to this rule. In some vehicles, the fuel filter is located between the fuel tank and the engine, either under the vehicle or in the engine compartment. In this case, the arrow on the fuel filter may point towards the engine, indicating that the fuel flows from the tank to the engine.

It's important to refer to the vehicle's owner manual or a trusted mechanic to confirm the correct direction of the fuel filter installation. Additionally, some fuel filters may have other indicators of direction, such as a larger inlet or a threaded connection, which should be installed towards the fuel tank.

It's worth noting that not all fuel filters have arrows, and in some cases, the direction of the fuel filter may not matter, especially if it's a simple screen filter or a bi-directional filter. However, it's always best to check and install the fuel filter in the correct direction to ensure optimal fuel flow and engine performance.

Craftsman Leaf Blower: Replacing the Fuel Tank

You may want to see also

Fuel filters are usually placed between the fuel tank and the carburetor

Fuel filters are usually placed between the fuel tank and the carburettor. This is because the carburettor can be harmed by even relatively small particles, so the fuel filter helps to keep the engine running at peak performance.

In a fuel injection system, the fuel filter is placed after the fuel pump, to protect the pump and keep larger debris from clogging the post-pump filter. This is known as a pre-filter, and they are often placed in the fuel tank, where they are called "sock filters" or "fuel strainers".

In a carburettor system, the fuel filter is placed after the fuel pump, but before the carburettor. This is because the carburettor is more sensitive to particles than the fuel pump, so the fuel needs to be filtered after the pump to protect the carburettor.

The direction of the fuel filter is important, as fuel should flow from the outside-in, like an air filter. If the filter is clear, you can see how the fuel flows through it. If it's a metal body type, it should be marked with an arrow, have a larger or threaded inlet than the outlet, or be bi-directional.

When choosing a fuel filter, it's important to consider the micron rating and element type. A micron is a unit of measurement that is too small to be seen by the naked eye. The lower the micron rating, the smaller the particle the filter will be able to reliably filter out. However, a lower micron rating also means that the filter is more likely to clog up. For carburettor engines, a 40-micron filter is generally recommended, along with a 100-micron pre-filter before the pump.

It's also important to choose the right type of filter element. Paper filters, also known as cellulose filters, are usually disposable and should not be used with methanol or fuels containing more than 20% ethanol. Stainless steel filters are compatible with all fuels and can typically be cleaned and reused. Micro Glass filters are for post-pump use only and are disposable.

Brazil's Ethanol Revolution: Replacing Fossil Fuels

You may want to see also

Inline fuel filters are available in a variety of sizes and can be connected to most common AN fitting and line sizes

Inline fuel filters are an essential component of any vehicle, and they play a crucial role in ensuring the fuel that enters your engine is free of contaminants. These filters are available in a range of sizes to accommodate different vehicles and fuel types.

One key advantage of inline fuel filters is their compatibility with various fitting and line sizes. They are designed to connect seamlessly with most common AN fittings, which are often used in high-performance vehicles. This versatility makes them suitable for a wide range of applications.

The Evil Energy Inline Fuel Filter, for example, comes with 6AN, 8AN, and 10AN adapters, allowing it to accommodate different size applications. This universal fuel filter includes a mounting bracket that helps keep the engine bar stylish and clean. It is constructed with an aluminum alloy fuel filter can and a stainless steel filter element, ensuring durability and effective filtration.

The micron rating of a fuel filter is another important consideration. This rating indicates the filter's ability to capture and remove particles from the fuel. Evil Energy offers inline fuel filters with various micron ratings, including 10, 30, 40, and 100-micron options. The 10-micron filter, for instance, can capture particles as small as 10 microns, ensuring that your fuel is free of contaminants that could harm your engine.

In addition to the micron rating, the material of the filter is also crucial. Evil Energy's inline fuel filters are designed to handle various fuel types, including gasoline, diesel, and ethanol-based fuels like E85. The stainless steel filter element effectively captures fine debris and contaminants, ensuring that only clean fuel reaches your engine.

When choosing an inline fuel filter, it is essential to consider your vehicle's specific requirements, such as fuel type and pressure. By selecting a high-quality, compatible fuel filter and maintaining it through regular replacements, you can help ensure the optimal performance and longevity of your vehicle's engine.

Replacing Fuel Tank Shut-Off Valve: A Step-by-Step Guide

You may want to see also

Fuel filters should be replaced at the manufacturer's recommended intervals

Fuel filters play a critical role in ensuring your engine receives clean fuel and operates optimally. Over time, fuel filters can become clogged with dirt, debris, and other contaminants, leading to reduced engine performance and potential damage. Therefore, it is essential to replace them at the manufacturer's recommended intervals.

The recommended interval for fuel filter replacement varies between different vehicles and manufacturers. For older vehicles, it was generally recommended to replace the fuel filter every 20,000 to 30,000 miles. However, with advancements in fuel technology and vehicle design, newer vehicles can typically go longer between replacements. Today, many manufacturers suggest replacing the fuel filter every 60,000 miles.

It is important to note that some car manufacturers place the fuel filter inside the fuel tank, and these filters may not require regular replacement. For diesel vehicles, the replacement interval is typically shorter, ranging from 5,000 to 25,000 miles, depending on factors such as driving habits and vehicle type.

To determine the recommended replacement interval for your specific vehicle, it is best to consult your vehicle's owner's manual or seek advice from a trusted mechanic. By adhering to the manufacturer's recommendations, you can help ensure your engine receives clean fuel, maintain optimal engine performance, and prevent costly repairs associated with clogged or faulty fuel filters.

When replacing the fuel filter, it is important to install it in the correct direction. Most fuel filters are designed with a specific fuel flow direction, usually indicated by an arrow on the filter. Installing the filter correctly ensures that it effectively filters the fuel before it reaches the engine, preventing contaminants from causing damage.

Stihl 020AV Fuel Line Replacement: A Step-by-Step Guide

You may want to see also

Frequently asked questions

The arrow on the filter indicates the direction the fuel should flow. The arrow should face towards the carburetor, as the fuel pump fills the carburetor.

It is recommended to place the filter before the pump to catch any "crud" and keep the pump clean. However, placing the filter before the pump may cause air to be pulled into the system.

If there is no arrow, one end of the filter will have a larger cavity than the other. The larger end should be installed nearer to the fuel tank.