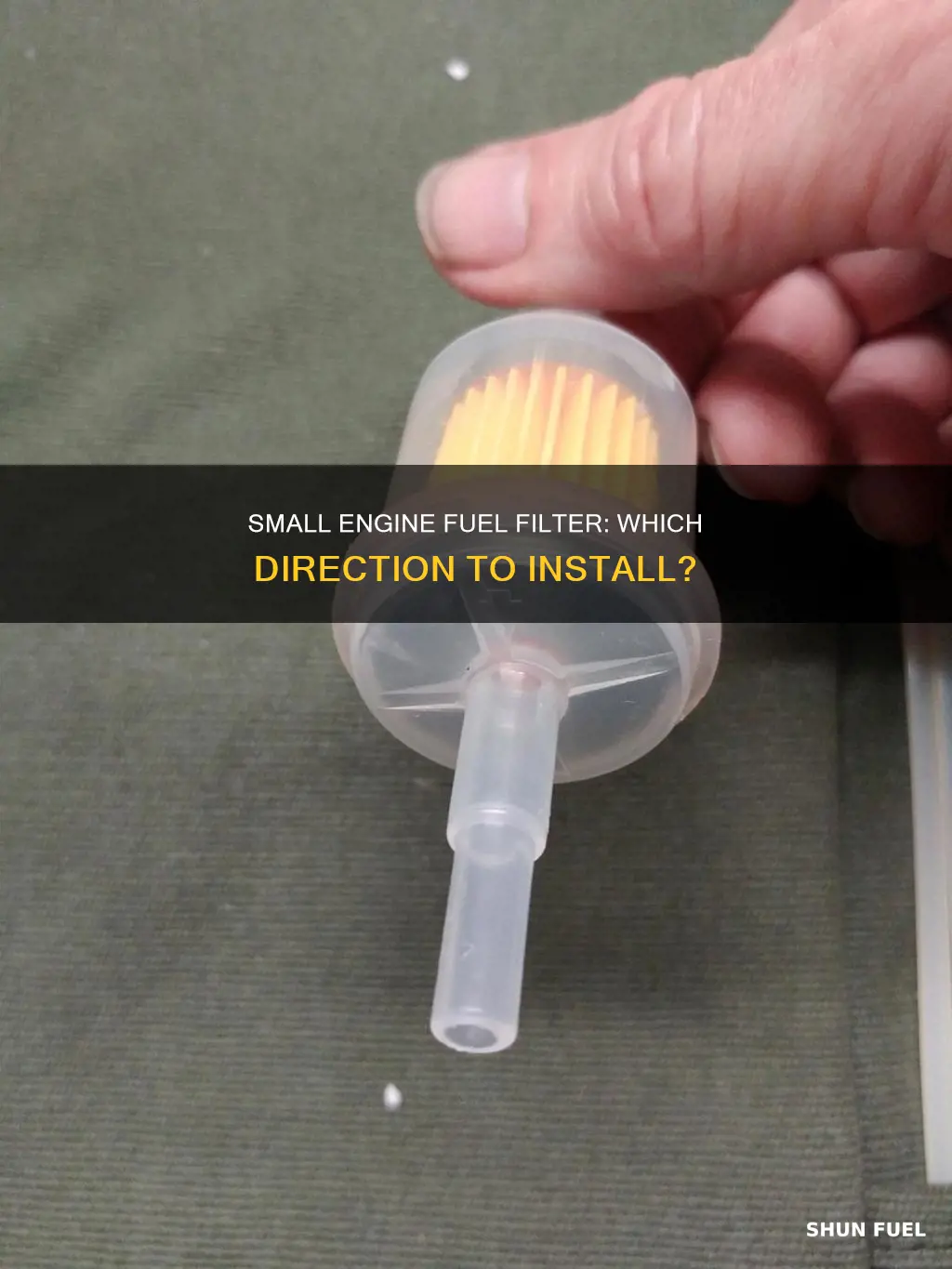

Fuel filters are an essential component in small engines, ensuring the engine is safe from harmful wreckage by screening out impurities. When replacing a fuel filter, it is important to know which direction to install it. Some filters have a direction of flow arrow on them, which must be followed for proper operation. For filters without an arrow, advice varies. Some sources suggest that the larger end should be installed nearer to the fuel tank, while others state that the conical side or large end should be installed towards the carburettor. However, some people argue that it does not matter which direction the filter is installed, as long as it is done consistently.

What You'll Learn

Fuel filter replacement benefits

Fuel filters play a critical role in maintaining the health and performance of your vehicle's engine. Replacing your fuel filter regularly offers several benefits, including:

Improved Engine Performance

The fuel filter is responsible for removing contaminants such as dirt, rust, and debris from the fuel before it reaches the engine. Over time, these contaminants can clog the fuel filter, leading to reduced fuel flow and engine performance issues such as sluggish acceleration and engine misfires. Regular replacement ensures unobstructed fuel flow, allowing the engine to run optimally.

Increased Fuel Efficiency

A clogged fuel filter can cause the engine to work harder to draw fuel, resulting in increased fuel consumption. By replacing the fuel filter, you maintain proper fuel flow, improving fuel efficiency and maximising fuel economy. This not only saves you money at the pump but also extends the driving range per tank of fuel.

Extended Engine Life

Regular fuel filter replacement helps extend the life of your engine. A clogged fuel filter can cause the engine to run poorly, leading to increased wear and tear. By ensuring a consistent and efficient fuel supply, you can enhance engine performance and longevity.

Protection against Contaminants

A properly functioning fuel filter acts as a barrier, capturing harmful particles such as rust, sediment, and debris, and preventing them from entering the engine. Regular replacement ensures the filter remains effective in removing contaminants, safeguarding the engine against potential damage.

Prevention of Fuel Injector Damage

Fuel injectors deliver the correct amount of fuel to the engine's combustion chambers. Contaminants in the fuel can cause blockages or malfunctions in the fuel injectors. Regular fuel filter replacement helps protect the fuel injectors, ensuring accurate and efficient fuel delivery. This maintains engine performance and avoids costly repairs or replacements of fuel injectors.

Prevention of Fuel System Corrosion

Moisture and impurities in the fuel tank can lead to corrosion within the fuel system. A clean fuel filter helps prevent these contaminants from reaching critical components such as fuel lines and injectors, reducing the risk of corrosion. Regular replacement contributes to the overall health and longevity of your vehicle's engine and fuel system.

Direction of Flow

It is important to note that some fuel filters have a direction of flow arrow on them. When replacing the filter, ensure that it is installed correctly, with the arrow pointing in the direction of fuel flow, to ensure proper operation.

Replacing the Fuel Tank in Your 1996 Ford F150 Pickup

You may want to see also

Fuel filter location

Fuel filters are essential components in small engines, ensuring that impurities in the fuel do not reach the engine and cause damage. The location of the fuel filter in a small engine depends on the engine's design.

Fuel filters can be found either inside the fuel tank or fitted into the fuel line between the tank and the fuel pump. Some fuel tanks have internal, non-serviceable fuel filters. If you are unsure about the location of your fuel filter, it is recommended to refer to the engine operator's manual for guidance.

There are three main types of fuel filters commonly used in small engines:

- In-line Disk filters: These are small disks that contain a filter screen. They come in two versions: red, with 150-micron screens, used for gravity-fed fuel systems, and white, with 75-micron screens, used for systems with fuel pumps.

- In-line Paper Cone Filters: These are plastic conical filters with an internal paper or felt filter. They are translucent, with an arrow indicating the fuel flow direction. This design allows for easy inspection of captured debris and facilitates timely replacement.

- In-tank Fuel Filters: These are small cylindrical filters commonly used for 2-cycle engines on trimmers, blowers, and chainsaws. They are inserted directly into the fuel tank and have a higher micron rating to prevent the fuel-oil mixture from causing engine burnout.

It is important to note that fuel filters should be replaced regularly to ensure optimal engine performance. Clogged or dirty fuel filters can lead to various issues, including difficulty starting the engine, uneven operation, diminished performance, and even engine damage.

Replacing Fuel Pump Strainer: Step-by-Step Guide for Beginners

You may want to see also

Fuel filter selection

Fuel filters are essential for small engines as they help to strain the gas before it reaches the carburetor in your lawnmower, snow blower, or other equipment. Dirty fuel filters can cause the engine to run too lean, leading to diminished performance and uneven operation. When choosing a fuel filter, it is important to consider the engine's design and select a filter that is compatible with the fuel pressure and flow rate of your engine.

There are two main types of fuel filters: screen filters and paper filters. Screen filters use a fine mesh screen made of woven monofilament plastic or metal wires to capture particles. They are physically smaller than paper filters and are useful when space is limited. Paper fuel filters, on the other hand, use filter elements made of polymer resin (phenolic resin)-treated cellulose or polyester felt sheets. They have higher working surface areas and greater mechanical strength, which increases flow through the filter while reducing flow restriction and pressure drop.

When selecting a fuel filter, it is important to consider the micron rating, which specifies the filter's particle-capturing capabilities. For example, a micron rating of 39 can capture particles as small as 0.000039 inches. For pre-pump filters, a micron rating between 75 and 150 is generally recommended, while finer filters with micron ratings of 10 or lower are used to capture smaller particles and protect sensitive fuel system components.

It is also important to pay attention to the direction of the flow arrow on the filter. The arrow indicates the direction in which the fuel flows and the filter must be installed correctly for proper operation. Additionally, fuel filters should be replaced regularly, typically every two years or after every 30,000 to 60,000 miles, to ensure optimal performance and prevent clogging.

Replacing the Fuel Filter in Your 2006 ML 350: Step-by-Step Guide

You may want to see also

Fuel filter replacement process

Fuel filters are essential components in small engines, as they help to purify the fuel by screening out impurities that could damage the engine. It is important to replace fuel filters periodically to ensure optimal engine performance and prevent clogging in the fuel system. Here is a step-by-step guide on how to replace a fuel filter in a small engine:

Step 1: Locate the Fuel Filter

The first step in the replacement process is to locate the fuel filter. In small engines, the fuel filter is typically located either inside the fuel tank or fitted into the fuel line between the tank and the fuel pump. If you are unsure of its location, refer to your engine's operator's manual for guidance.

Step 2: Prepare for Replacement

Before beginning the replacement process, ensure you are in a safe area with no open flames or fire sources nearby. Wear safety eyewear to protect your eyes from liquid fuel or fuel vapors. Have a dry cloth handy to catch any dripping fuel during the process.

Step 3: Drain the Fuel Tank (if necessary)

If the fuel filter is installed inside the tank, you will need to drain the tank before removing the filter. Shut the fuel valve, if your tank has one. If there is no valve, use a fuel line clamp to clamp the gas line. Do not pinch the fuel line as this could cause damage.

Step 4: Remove the Old Fuel Filter

If your filter is installed in the fuel line, use needle-nose pliers to remove the metal clips on each side of the filter. Then, slide the filter out of the fuel line. If the filter is inside the tank, refer to your operator's manual for specific removal instructions.

Step 5: Inspect and Clean the Old Filter

Shake the old filter over a clean cloth to displace any remaining fuel. Use the cloth to wipe away any residue from the outside of the filter. Keep the filter at a safe distance from your face and inspect the inside for debris. If the mesh screen, pleated paper, or casing is clogged with debris, it's time to replace the filter.

Step 6: Install the New Fuel Filter

Obtain a new replacement fuel filter that is compatible with your engine. When installing the new filter, ensure that it is oriented in the correct direction. Some filters have a direction of flow arrow that must be followed for proper operation. Reconnect the metal clips on both sides of the filter.

Step 7: Reopen the Fuel Line or Valve

Once the new fuel filter is securely in place, remove the clamp on the fuel line or reopen the fuel valve. Check for any leaks. Do not operate the engine if leaks are detected.

Step 8: Dispose of the Old Fuel Filter Properly

Finally, dispose of the old fuel filter properly according to your local waste management guidelines.

By following these steps, you can ensure a safe and effective fuel filter replacement process for your small engine. Always refer to your engine's operator's manual for specific instructions and safety precautions.

Kia Optima Fuel Cover: Easy DIY Replacement Guide

You may want to see also

Fuel filter maintenance

Fuel filters are an essential component of any small engine, ensuring that dirt, dust, and debris do not enter the combustion chamber and clog the engine's fuel system. They are usually located either inside the fuel tank or fitted into the fuel line between the tank and the fuel pump.

Maintenance

Maintaining your fuel filter is simple but important. All small engine manufacturers recommend changing the fuel filter annually or after about 200 hours of use. If you notice any of the following issues related to the fuel system, you should inspect the filter and change it earlier:

- Engine cranking longer and struggling to start

- Engine sputtering when turning the ignition

- Stuttering and stalling at low speeds

- Misfiring due to uneven fuel distribution and low fuel pressure

- Poor performance, especially at high speeds or under load

- A loud straining sound from the fuel pump

Replacement

Before replacing your fuel filter, refer to your engine operator's manual to determine the correct replacement filter and its location. When replacing the filter, be sure to:

- Wear safety eyewear to protect your eyes from liquid fuel or fuel vapors

- Have a dry cloth handy to hold the filter and catch any dripping fuel

- If the filter is inside the tank, drain the tank before removing the filter

- Shut the fuel valve or, if your tank is not equipped with a valve, clamp the gas line using a fuel line clamp

- If your filter is installed in the fuel line, remove the metal clips on each side of the filter using needle-nose pliers and slide it out of the fuel line

- Shake the filter over a clean cloth to displace any remaining fuel, then wipe away any residue from the outside

- Check for debris clogging the mesh screen, pleated paper, or the inside of the casing. If debris is present, replace the old filter with a new one, ensuring that any direction of flow arrows are pointing in the correct direction

- Reopen the fuel valve or remove the clamp on the fuel line and check for leaks. Do not operate the unit if any leaks are found

Auto Fuel's Rise: Hydrogen Peroxide's Demise?

You may want to see also

Frequently asked questions

It is recommended that fuel line filters be replaced every two years or after every 30,000 to 60,000 miles. However, for a more precise guideline, you may consult the car manual or instructions provided by the brand.

If fuel line filters are left clogged, the vehicle may not start or there may be a sudden and loud noise from the fuel pump, indicating potential hardware damage.

A small engine fuel filter's job is to prevent dirt, dust, and debris from entering the combustion chamber of the engine. It filters impurities of various sizes from the fuel before it enters the carburetor.

If you haven’t changed your filter at regular intervals, you might notice some odd engine behavior, such as engine sputtering when you turn the ignition, or the engine struggling to start.

The arrow on the filter indicates the direction of flow. The arrow should point towards the carburetor since the fuel pump fills the carburetor.