Checking your car's fuel system is an essential part of vehicle maintenance to ensure optimal performance and longevity. Whether you're a DIY enthusiast or prefer professional assistance, knowing where to inspect your fuel system can save you time and money. This guide will provide an overview of the key areas to check, including the fuel tank, fuel lines, and the fuel pump, as well as when and how to perform these inspections. Understanding these components and their locations will empower you to take control of your vehicle's health and address any potential issues before they become major problems.

| Characteristics | Values |

|---|---|

| Automotive Repair Shops | Professional mechanics can diagnose and repair fuel system issues. They have specialized tools and knowledge to identify problems with fuel pumps, injectors, and other components. |

| Dealerships | Authorized dealerships often have access to manufacturer-specific diagnostic equipment and can provide accurate diagnoses and repairs for fuel system problems. |

| Specialized Fuel System Repair Shops | These shops focus exclusively on fuel system issues and may offer specialized services like fuel pump testing, injector cleaning, and fuel pressure testing. |

| Online Resources | Websites and forums can provide general information and troubleshooting tips for common fuel system problems. However, for complex issues, professional help is recommended. |

| DIY (Do-It-Yourself) | Some fuel system checks can be performed at home, such as inspecting hoses for cracks, checking fuel filter replacement intervals, and using fuel system cleaner. |

| Fuel System Specialists | Experts in fuel system technology can offer advanced diagnostic services and repairs for complex fuel system malfunctions. |

What You'll Learn

- Under the Hood: Inspect fuel lines, pump, and filter for leaks and damage

- Fuel Tank: Check for corrosion, debris, and proper ventilation

- Fuel Injectors: Verify proper spray patterns and cleanliness

- Engine Bay: Look for signs of fuel leaks or contamination

- Diagnostic Tools: Use OBD-II scanner to read error codes related to fuel system

Under the Hood: Inspect fuel lines, pump, and filter for leaks and damage

Checking the fuel system of your car is an essential part of routine maintenance to ensure optimal performance and prevent potential issues. While it's not a task for the faint-hearted, it is certainly something that can be accomplished with some knowledge and the right tools. Here's a step-by-step guide to inspecting the fuel lines, pump, and filter for any leaks or damage:

Locate the Fuel System Components: Start by familiarizing yourself with the location of the fuel system under the hood. The fuel lines, pump, and filter are typically found in close proximity to the engine. Locate the fuel tank, which is usually a small, rectangular or oval-shaped component, and identify the fuel lines that run from the tank to the engine. The fuel pump, responsible for sending fuel from the tank to the engine, is often located near the tank or along the fuel lines. The fuel filter, designed to remove contaminants from the fuel, is typically found close to the engine.

Inspect for Leaks: Begin your inspection by looking for any signs of fuel leaks. Check the connections between the fuel lines and the fuel pump, as well as the connections to the engine. Look for any wet spots or stains around these areas, which could indicate a leak. Inspect the fuel lines for any visible damage, such as cracks, punctures, or corrosion. Even small leaks can lead to engine misfires, reduced performance, and potential damage to other engine components. If you notice any leaks, it's crucial to address them immediately to prevent further issues.

Examine the Fuel Pump: The fuel pump is a critical component that ensures a steady supply of fuel to the engine. Inspect the pump for any visible signs of damage or wear. Check for any loose connections or corrosion around the pump's electrical terminals. If the pump is accessible, you can also listen for any unusual noises, such as grinding or whining, which could indicate internal damage. In some cases, you may need to remove the pump to access certain areas for a thorough inspection.

Check the Fuel Filter: The fuel filter plays a vital role in maintaining the cleanliness of the fuel. Inspect the filter for any signs of clogging or excessive dirt accumulation. If the filter appears dirty or clogged, it may need to be replaced. Check for any leaks or damage around the filter housing. Over time, the filter can become restricted, leading to reduced fuel flow and potential engine performance issues. Regularly replacing the fuel filter is essential to keep the fuel system clean and efficient.

Use a Fuel Pressure Gauge (Optional): For a more comprehensive inspection, you can use a fuel pressure gauge to measure the pressure in the fuel lines. This tool will help you identify any issues with the fuel pump or restrictors in the lines. Compare the readings to the manufacturer's specifications to determine if the fuel system is functioning correctly.

Remember, regular maintenance and inspections can help prevent costly repairs and ensure your car's fuel system operates efficiently. If you're unsure about any part of this process, it's always best to consult a professional mechanic who can provide expert guidance and ensure the job is done safely and correctly.

Jerking Engine: Fuel Filter's Fault or Something Else?

You may want to see also

Fuel Tank: Check for corrosion, debris, and proper ventilation

Checking the fuel tank is an essential part of maintaining your car's fuel system. Over time, the fuel tank can accumulate corrosion, debris, and other contaminants, which can lead to performance issues and potential damage to the engine. Here's a step-by-step guide on how to inspect your fuel tank for these common problems:

Accessing the Fuel Tank: Start by locating the fuel tank, which is typically a large, cylindrical structure mounted beneath the vehicle. It is usually made of steel or a composite material. You might need to raise the car on a jack stand to access the tank, ensuring you follow proper safety procedures. Once you have access, you can begin the inspection.

Checking for Corrosion: Corrosion inside the fuel tank can be a significant concern. Look for any signs of rust or oxidation on the tank's interior walls. This corrosion can lead to fuel contamination and potentially damage the fuel pump and injectors. If you notice any corrosion, it may be necessary to clean or replace the tank to ensure optimal performance. Use a flashlight to get a clear view of the interior, especially in hard-to-reach areas.

Inspecting for Debris: The fuel tank should be free from any debris or contaminants. Over time, dirt, rust, and other particles can accumulate, reducing fuel quality and potentially causing blockages. Remove the fuel tank's filler cap and inspect the area around the opening. If you find any debris, use a small brush or a specialized fuel tank cleaner to remove it gently. Ensure that no debris enters the fuel lines during this process.

Ventilation and Breathing: Proper ventilation is crucial for the fuel system's health. Check the fuel tank's breathing system, which allows air to enter the tank to facilitate the evaporation of fuel vapor. This system helps prevent fuel vapor buildup, which can lead to engine performance issues and potential safety hazards. Ensure that the ventilation ports are clear of any obstructions and that the breather cap is secure. If the ventilation system is compromised, it may require professional attention to restore proper function.

By regularly checking the fuel tank for corrosion, debris, and proper ventilation, you can maintain a healthy fuel system and ensure your car's engine operates efficiently. Remember, if you encounter any issues during this inspection, it is advisable to consult a professional mechanic for further assistance.

Fuel Filters: A Universal Car Component?

You may want to see also

Fuel Injectors: Verify proper spray patterns and cleanliness

When it comes to maintaining your car's fuel system, one crucial aspect often overlooked is the health and functionality of fuel injectors. These small but mighty components play a vital role in delivering the right amount of fuel to your engine, ensuring optimal performance and fuel efficiency. Here's a comprehensive guide on how to verify the proper spray patterns and cleanliness of your fuel injectors.

Start by understanding the basics of fuel injectors. These devices are responsible for spraying a precise amount of fuel into the engine's cylinders, creating a controlled combustion process. Over time, fuel injectors can become clogged or malfunction, leading to poor engine performance. Therefore, regular maintenance and inspection are essential.

To verify the spray patterns, you'll need a fuel pressure gauge and a spray pattern tester. The fuel pressure gauge will help you measure the pressure of the fuel being delivered to the injectors, while the spray pattern tester allows you to visually inspect the fuel's dispersion. Begin by disconnecting the fuel line from the injector and attaching the fuel pressure gauge. Ensure the engine is off and allow a few minutes for the fuel system to stabilize. Then, slowly increase the engine speed using a manual or automatic transmission, and monitor the fuel pressure. The ideal pressure range varies by vehicle, so consult your car's manual for specific guidelines. If the pressure is within the recommended range, proceed to the next step.

Now, it's time to inspect the spray patterns. Remove the fuel injectors one by one and attach the spray pattern tester to each. Start with a clean and dry environment to avoid any interference from dirt or moisture. Operate the engine at a steady speed, and observe the fuel spray through the tester. The ideal spray pattern should be a smooth, consistent stream of fuel without any clumps or irregularity. If you notice any deviations from this pattern, such as uneven spray or clumping, it may indicate a clogged or malfunctioning injector.

In addition to spray patterns, it's crucial to check the cleanliness of the fuel injectors. Over time, fuel can accumulate contaminants, leading to blockages and reduced performance. Start by removing the injectors and examining them for any signs of dirt, debris, or corrosion. You can use a fuel injector cleaner and a high-pressure water jet to thoroughly clean the injectors. Ensure that you follow the manufacturer's instructions for the cleaning process. After cleaning, reattach the injectors and test the engine to verify that the issues have been resolved.

Regular maintenance and inspection of fuel injectors are essential to keep your car running smoothly and efficiently. By verifying the proper spray patterns and cleanliness, you can identify potential issues early on and take the necessary steps to address them. Remember, a well-maintained fuel system contributes to better engine performance, improved fuel economy, and reduced emissions.

The Surprising Truth: Does Your Car's Fuel Expire?

You may want to see also

Engine Bay: Look for signs of fuel leaks or contamination

When inspecting your car's fuel system, the engine bay is a crucial area to examine for any potential issues. This is where you can often find visible signs of fuel leaks or contamination, which could indicate a more serious problem. Start by opening the hood and taking a comprehensive look around the engine bay. Look for any wet or discolored spots on the engine block, as these could be indicative of a fuel leak. Fuel leaks can occur at various points in the system, including the fuel pump, lines, or injectors. If you notice any unusual stains or wet patches, it's essential to investigate further.

Check the fuel lines for any visible damage or cracks. Over time, fuel lines can deteriorate due to heat, vibration, or chemical degradation, leading to potential leaks. Inspect the lines for any signs of wear and tear, especially where they connect to the fuel pump and injectors. Additionally, pay attention to the fuel pump itself. A malfunctioning pump can cause fuel to leak or spray out of the system when the engine is running. Look for any signs of corrosion or damage around the pump and ensure that the fuel filter is securely attached and free from any blockages.

Contamination is another critical aspect to consider. Fuel contamination can occur when water or other substances enter the fuel system, leading to potential engine damage. Check for any signs of water accumulation in the engine bay, especially in areas where fuel lines or components are located. If you notice any water, it's crucial to address the issue promptly to prevent further contamination. Moreover, inspect the fuel tank for any visible signs of corrosion or damage. The fuel tank is a critical component, and any issues here can lead to contamination and potential engine problems.

In addition to visual inspections, it's essential to trust your senses. If you notice any strange odors coming from the engine bay, it could be a sign of fuel leaks or contamination. Fuel has a distinct smell, and any unusual scent could indicate a problem. Also, pay attention to the engine's performance. If you notice any changes in acceleration, idling, or fuel efficiency, it might be a result of fuel system issues.

Remember, regular maintenance and inspections are key to keeping your car's fuel system in good condition. By thoroughly examining the engine bay and being vigilant for any signs of leaks or contamination, you can identify potential issues early on and ensure your vehicle's optimal performance.

Can You Swap Car Fuel Filters for Motorcycles? A Guide

You may want to see also

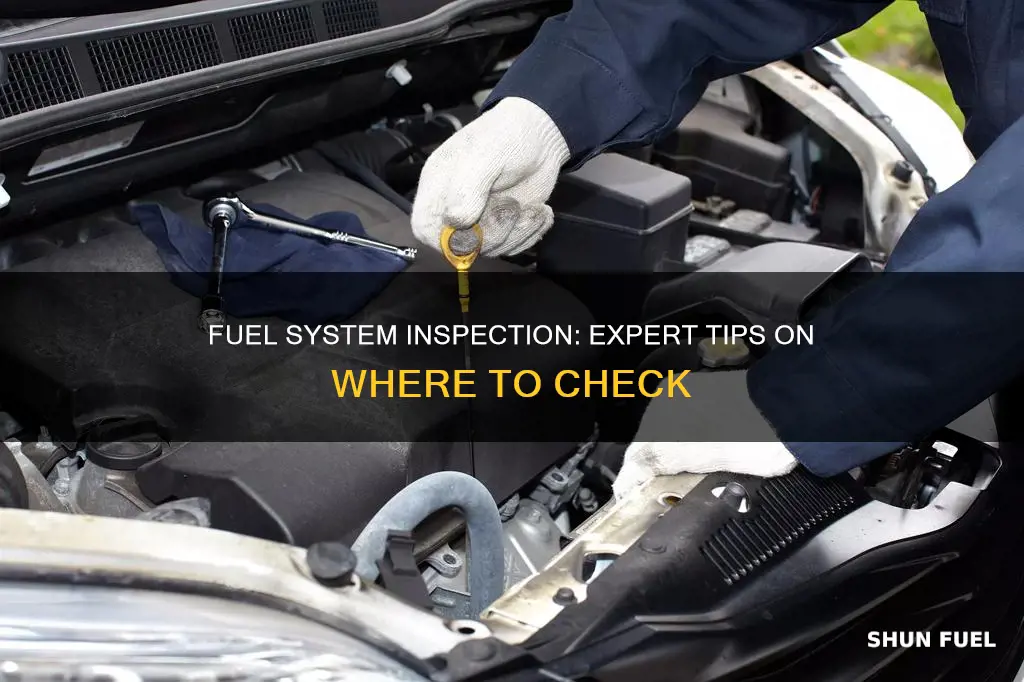

Diagnostic Tools: Use OBD-II scanner to read error codes related to fuel system

The On-Board Diagnostics (OBD-II) system is a powerful tool for car owners and mechanics alike, offering a wealth of information about a vehicle's performance and health. When it comes to diagnosing issues with the fuel system, an OBD-II scanner can be an invaluable asset. This technology allows you to access and interpret diagnostic trouble codes (DTCs) related to fuel system problems, providing a clear path to resolving the issue.

Here's a step-by-step guide on how to use an OBD-II scanner for fuel system diagnostics:

- Locate the OBD-II Port: Most modern cars have an OBD-II port, typically located under the dashboard on the driver's side. It is a small, rectangular connector with a few pins. Ensure you have the correct scanner that is compatible with your vehicle's OBD-II system.

- Connect the Scanner: Plug the OBD-II scanner into the port. It will establish a connection with the vehicle's computer system. Turn on the scanner and follow the manufacturer's instructions to initialize it.

- Read Error Codes: Once the scanner is connected and initialized, you can read the error codes stored in the vehicle's computer. Look for codes related to the fuel system, such as those related to fuel pump issues, fuel injectors, or fuel pressure regulators. These codes will provide specific information about the problem.

- Interpret the Codes: Each DTC has a specific meaning. For example, a code related to the fuel pump might indicate a malfunction in the pump's operation. Research the codes to understand the potential causes and the affected components. This step is crucial in narrowing down the problem area.

- Clear Codes (Optional): After diagnosing the issue, you can use the OBD-II scanner to clear the error codes. This process involves erasing the trouble codes from the vehicle's memory, which can help you perform further tests or drive the car without the warning lights being triggered.

Using an OBD-II scanner is a cost-effective and efficient way to troubleshoot fuel system problems. It empowers car owners to take a proactive approach to vehicle maintenance, potentially saving money on costly repairs. By following these steps, you can quickly identify and address fuel system issues, ensuring your vehicle runs smoothly and efficiently. Remember, proper maintenance and timely repairs can extend the lifespan of your car and improve overall performance.

Clogged Fuel Filter: The Hidden Culprit Behind Your Car's Failure to Start

You may want to see also

Frequently asked questions

You can inspect your fuel system at various points. Start by checking the fuel tank for any signs of corrosion or contamination. Then, locate the fuel filter, which is usually positioned near the engine or under the car. Inspect it for any blockages or signs of wear. Additionally, you can check the fuel lines for any cracks or leaks, especially where they connect to the engine and the fuel pump.

It is recommended to inspect your fuel system regularly, at least once a year or every 10,000 miles. More frequent inspections are advised if you notice any unusual behavior, such as reduced engine performance, strange noises, or frequent stalling. Regular maintenance can help prevent fuel system issues and ensure optimal engine operation.

Yes, you can perform a basic check on the fuel pump. Start the car and listen for any unusual noises coming from the engine compartment. A healthy fuel pump should produce a steady humming sound. If you hear a high-pitched whining or a lack of sound, it could indicate a failing fuel pump. However, for a thorough inspection, it's best to consult a professional mechanic who has the necessary tools and expertise.

A clogged fuel filter can lead to reduced engine performance and fuel efficiency. Signs of a clogged filter include engine misfires, difficulty starting the car, reduced power, and increased fuel consumption. If you notice any of these symptoms, it's essential to have your fuel filter inspected and replaced if necessary.

Regular maintenance is key to preventing fuel system problems. This includes using the recommended grade of motor oil, changing the oil at the specified intervals, and keeping the engine properly lubricated. Additionally, using high-quality fuel and fuel additives can help maintain the fuel system's health. Regularly checking for and addressing any fuel leaks or issues will also contribute to a well-maintained fuel system.