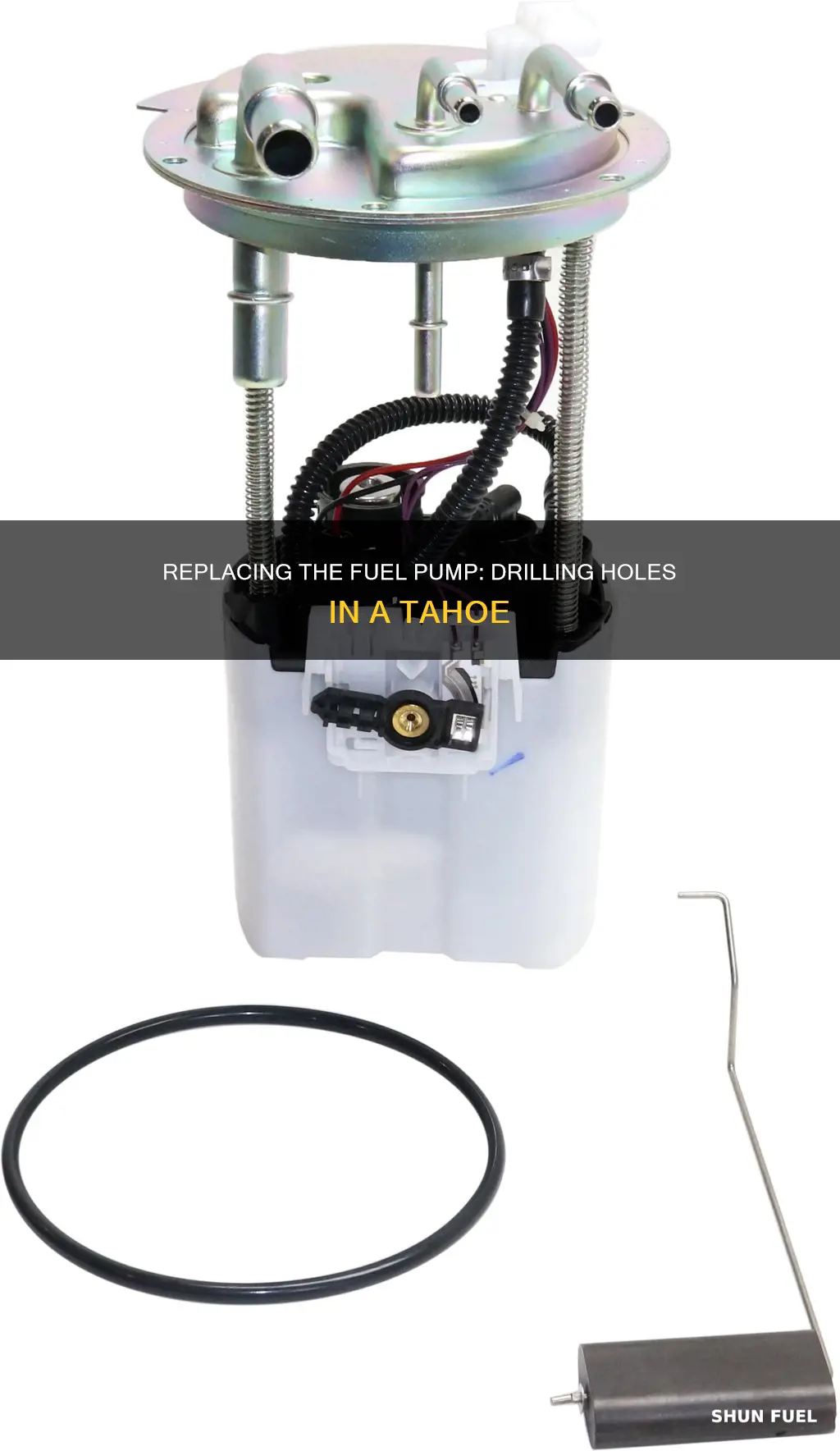

Replacing the fuel pump in a Chevy Tahoe can be a challenging task. While some people opt to drop the fuel tank to access the pump, others choose to cut a hole in the floor of the vehicle. This method requires careful measurement and execution to avoid damaging fuel lines or the fuel tank itself. It is essential to wear safety gear, such as safety goggles, work gloves, and a respirator, when cutting into the vehicle's structure. Some people choose to create a removable access panel, while others simply leave the hole open or cover it with a piece of metal or carpet. It is crucial to consider the potential risks and take the necessary precautions when attempting to replace the fuel pump in a Chevy Tahoe.

| Characteristics | Values |

|---|---|

| Vehicle type | Chevy Tahoe, GMC Yukon, Jeep, S-10, Camaro, Astro van |

| Tools | Angle grinder, cordless drill, tin snips, Skilsaw, safety goggles, hammer, screwdriver, tape measurer, etc. |

| Fuel pump location | Under the rear seat, in the floor, in the bed, spare tire well |

| Fuel pump replacement process | Drop the fuel tank, cut an access door/hole/panel in the floor, cut the spare tire well, cut the bed |

| Challenges | Risk of cutting fuel lines, difficulty dropping the fuel tank, rust, bolts snapping off |

What You'll Learn

Cutting a hole in the floor of your vehicle to access the fuel pump

Planning:

Before you begin, it is crucial to gather the necessary tools and materials, including safety gear such as safety goggles and work gloves. You will also need a power drill, a saw (a Skilsaw or a sabre saw), a hammer, a flat-head screwdriver, a tape measure, and a permanent marker. Additionally, it is recommended to have tin snips, a vacuum cleaner, and a pick tool or a small Phillips-head screwdriver.

Step 1: Remove the Rear Seat:

Start by removing the lower portion of the rear seat. Push in on the front, lower side of the seat to locate and disengage the hook and bar assembly on each side. The seat has the bar, while the floor panel has the hook.

Step 2: Roll Back the Sound Deadening Material and Carpet:

Roll back the sound deadening material and use the center adjustable seat belt to clip it up. Then, roll back the carpet and tuck it out of the way.

Step 3: Measure and Mark the Cutting Area:

Measure and mark the cutting area on the floor. For a Tahoe, measure from the center of the lower weather stripping on the passenger side rear door. Make a mark at 21" and another at 30". Additionally, measure from the edge where the floor pan rolls downward and make marks at 1" and 8". These marks will serve as a template for your cutting.

Step 4: Create Pilot Holes:

Using your power drill, create pilot holes at the corners of the template you marked. These holes will allow you to insert your saw blade and begin cutting.

Step 5: Cut Along the Template:

PUT ON YOUR SAFETY GOGGLES. Adjust the blade depth of your saw so that only a small portion (roughly 1/16" of the blade) is showing. Start cutting along the lines of your template, being extremely cautious not to cut too deeply. Cut along the three sides of the rectangle, leaving the rear section uncut unless you plan to create a separate door.

Step 6: Peel Back the Floor Plate:

Using your flat-head screwdriver and work gloves, carefully pry back the floor plate. You should now see the fuel lines and the electrical connector for the fuel pump.

Step 7: Clean the Area:

Use a vacuum cleaner to remove any metal shavings and dirt that could fall into the hole and onto the fuel tank.

Step 8: Disconnect the Fuel Lines and Electrical Connector:

Use your screwdriver to lightly tap on the little lips or edges that stick up on the outer ring of the fuel pump hanger. Keep rotating to loosen it evenly. Once the ring is removed or loosened, disconnect the fuel lines and the electrical harness from the fuel pump.

Step 9: Remove the Fuel Pump:

With the fuel lines and electrical connection disconnected, the fuel pump hanger can now be pulled out. Guide it around the ballast tank inside the fuel tank as you remove it.

At this point, you have successfully accessed the fuel pump through the hole in the floor and can proceed with the replacement. Once the replacement is complete, you can seal the hole using a combination of the cut-out metal piece, screws, high-temperature RTV, and/or insulation batting.

Should You Replace the Strainer When Installing a New Fuel Pump?

You may want to see also

How to cut a hole in the floor of your car

If you need to cut a hole in the floor of your car, it's likely that you're trying to access the fuel pump for a replacement. This is a tricky procedure, so it's important to be careful and take the necessary precautions. Here's a step-by-step guide on how to cut a hole in the floor of your car:

Step 1: Prepare the Car

Before you start cutting, you need to make sure the car is prepared properly. This includes removing any fire hazards, such as carpet and upholstery. Cover anything flammable with a fireproof blanket. You will also need to measure and mark the area where you plan to cut the hole. Make sure you know the exact location of the fuel pump and any surrounding components to avoid accidental damage.

Step 2: Gather the Right Tools

Make sure you have the right tools for the job. You'll need a grinder with a cutting wheel, safety goggles, work gloves, a hammer, a screwdriver, a tape measure or ruler, and a sharpie or marker to make your measurements and marks. You may also want to use tin snips or a Skilsaw for cutting, but proceed with caution.

Step 3: Cut the Hole

Start by making small pilot holes with a drill. This will help guide your cuts and reduce the risk of cutting too deep. Use your tools to carefully cut along the marked lines. If using a Skilsaw, adjust the blade depth to ensure you don't cut too deep. Remember that you're cutting through thin metal, so take your time and be precise.

Step 4: Access the Fuel Pump

Once you've cut three sides of the rectangle, use a flat-blade screwdriver and work gloves to pry back the floor plate. You should now see the fuel lines and electrical connector. Use a vacuum to clean up any metal shavings or dirt that could fall into the hole.

Step 5: Remove the Fuel Pump

Locate the fuel pump hanger and use a screwdriver to lightly tap around the outer ring to loosen it. Disconnect the fuel lines and electrical harness from the pump hanger. Now, you can pull the fuel pump hanger out and replace the fuel pump as needed.

Step 6: Repair the Hole

After you've finished your repairs, you'll need to repair the hole in the floor. Cut a patch of sheet metal that is slightly larger than the hole, then weld it into place. Make sure to alternate sides while welding to prevent the floor from warping. Apply a rubberized undercoating to the outside of the patch and a spray primer to the inside for added protection. Finally, you can reinstall the carpet and upholstery.

Remember to always put safety first when working on your vehicle. Cutting a hole in the floor of your car can be dangerous if not done properly, so take your time and follow the instructions carefully.

Replacing Toro Lawn Mower Fuel Filter: A Step-by-Step Guide

You may want to see also

Safety considerations when cutting a hole in your car

When cutting a hole in your car, there are several safety considerations to keep in mind. Here are some detailed safety precautions to ensure your safety and protect your vehicle:

Work Area and Tool Preparation:

- Choose a well-ventilated work area, preferably outdoors or in a spacious garage.

- Keep your work area clean and organized. Remove any clutter, and ensure there is enough space to move around safely.

- Inspect and prepare your tools before starting. Ensure blades are sharp, electrical tools are in good condition, and safety features like guards are functioning properly.

Personal Protective Equipment (PPE):

- Wear safety goggles or a full-face welding mask to protect your eyes from flying debris and sparks.

- Use ear protection, such as earplugs or earmuffs, to safeguard your hearing from loud noises.

- Put on cut-resistant gloves to prevent cuts and protect your hands from sharp metal edges.

- Wear long-sleeved tops and full-length trousers to shield your skin from sparks and metal chips.

- Don steel-toed boots to protect your feet from falling objects or hot debris.

Cutting Technique and Awareness:

- Always cut away from your body to reduce the risk of injuries.

- Use clamps to secure the material you are cutting to prevent slipping and for a more stable cutting process.

- Maintain a stable stance and good balance while cutting to avoid accidental slips or falls.

- Be mindful of your surroundings. Ensure no flammable materials are nearby, and check for other people in the work area.

Fuel System Precautions:

- Before cutting, ensure the fuel tank is empty or nearly empty to minimize spillage and fuel-related hazards.

- Identify the location of fuel lines and the fuel pump. Mark the cutting area carefully to avoid cutting into these components accidentally.

Vehicle Integrity and Structural Considerations:

- Cutting into the vehicle's structure can affect its integrity. Keep the cut as small as possible, and consider the potential impact on the vehicle's strength and safety in the event of a collision.

- If you plan to cut a larger access panel, consult a professional or seek advice from a mechanic to understand the structural implications and how to reinforce the vehicle appropriately.

Post-Cutting Clean-up and Maintenance:

- After cutting, clean up any metal shavings, debris, or dirt that could fall into the fuel tank or other vehicle components.

- Regularly inspect and maintain your vehicle after the repair to ensure no issues arise due to the modification.

Remember to work cautiously and deliberately, taking your time to avoid accidents. Cutting into your car can be a delicate process, but with proper safety measures, you can successfully replace your fuel pump while minimizing risks to yourself and your vehicle.

Replacing Fuel Tank Straps on a Dodge Ram: A Step-by-Step Guide

You may want to see also

Fixing the hole after replacing the fuel pump

First, decide on the method for cutting the hole. Some people choose to cut an access panel, while others opt for a flap or a simple hole. If you're cutting an access panel, you can reuse the existing sheet metal or cut a new piece to fit. It's important to ensure a tight seal by using rubber foam weather stripping and fasteners. Welding or panel bonding adhesive can also be used to secure the access panel.

If you've cut a simple hole, you can create a flap by cutting three sides and peeling back the metal. This method requires careful measurement and tools like tin snips or a Skilsaw to make precise cuts. After cutting the hole, vacuum any metal shavings and dirt to prevent them from falling into the fuel tank.

Once the fuel pump is replaced, you can close the flap or cover the hole with the access panel. Ensure that everything is securely fastened to prevent any fuel leaks or carbon monoxide seepage.

If you've opted for a simple hole without a flap or access panel, it's crucial to seal it properly. You can use a piece of sheet metal and screws, along with high-temperature RTV to create a tight seal. This method helps to maintain the integrity of the vehicle's structure and prevent fuel leaks.

Remember to always put safety first when working with fuel systems. Consult a professional mechanic if you're unsure about any part of the process.

Replacing the Fuel Sending Unit in a 2001 Grand Prix

You may want to see also

Alternative methods to cutting a hole

Drop the Fuel Tank:

This method involves removing the fuel tank to access the fuel pump. While it can be challenging to do this alone, it is a safer option that doesn't require cutting into the vehicle's structure.

Create an Access Door:

Some people choose to cut an access door into the floor of their Tahoe, usually measuring around 8" by 8". This provides easier access to the fuel pump without fully cutting away the floor. Ensure you don't cut too deeply to avoid damaging fuel lines or the tank.

Use a Transmission Jack:

This method involves using a transmission jack to raise the rear end of the car and provide better access to the fuel tank. By undoing the fill tube brace and fuel cap location, you can create more play and avoid damaging the tank when lowering it.

Roll Back the Carpet and Sound Deadening Material:

Before attempting any fuel pump replacement, it's essential to roll back the carpet and sound deadening material in the vehicle. This provides better access to the area and ensures you're working with a clean space.

Use a Dremel Tool:

Instead of a Skilsaw or tin snips, consider using a Dremel tool with a 2" cutting wheel. This method is slower but provides more precision and reduces the risk of cutting too deeply.

Seal the Hole:

If you do decide to cut a hole, ensure you seal it properly afterward. Use a piece of sheet metal with screws and high-temperature RTV to cover the hole, preventing dust and water intrusion.

Remember to take the necessary safety precautions when performing any fuel pump replacement and always work in a well-ventilated area to avoid inhaling fumes.

Replacing Fuel Pump in 98 Caravan: Step-by-Step Guide

You may want to see also

Frequently asked questions

Dropping the fuel tank to replace the fuel pump is not an easy job for one person in a driveway. There are several YouTube videos where people cut an access door into the floor of their pre-2007 Tahoe to reach and replace the fuel pump. You will need to remove the lower portion of the rear seat, roll back the sound-deadening material and carpet, and then measure and mark where to cut. You can then use a screwdriver and hammer to make small holes, and cut along your lines with tin snips.

You will need a 12" flat-blade screwdriver, a hammer, a Sharpie permanent marker, a tape measurer, tin snips, a Skilsaw, safety goggles, work gloves, a small pick tool, a straight edge to make lines, a power drill and assorted drill bits, and a vacuum to clean up.

It is very important to make sure the blade is not too far down—you do not want to cut too deep. You should also wear safety goggles and be mindful when cutting—don't try to do the whole side at once, just take your time.