To check the pressure fueling system for proper operation, you must test the fuel pressure and flow. This can be done in four steps. Firstly, ensure safety precautions are in place, such as wearing safety glasses and gloves, and working in a well-ventilated area. Secondly, check the fuel pressure by starting the car and letting it idle, then installing a fuel pressure gauge and noting the pressure reading. Thirdly, perform a fuel volume test to determine if the proper amount of fuel is being delivered to the fuel injectors. Finally, collect a fuel sample for five seconds with the pump running to test fuel delivery.

| Characteristics | Values |

|---|---|

| How to check fuel pressure | Start the car and let it idle. Install a fuel pressure gauge, run the pump, and note the pressure reading. Then compare it to the manufacturer's specification. |

| How to check fuel volume | The most accurate way to test fuel delivery is by using a flowmeter. However, a reliable way to perform a test is to collect a fuel sample for five seconds with the pump running. The pump should deliver a specific amount of fuel within that time frame—check your manufacturer's specification to see if your pump is delivering the right amount and your system is working properly. |

| Safety precautions | Wear safety glasses and gloves, work in a well-ventilated area, and don’t smoke or have anything around that can cause a spark. |

| How to check for a clogged fuel filter | Remove the filter from the vehicle and drain excessive fuel from the filter. Use a short piece of rubber hose on the filter inlet. Blow through the filter inlet, paying attention to the resistance, which should be minimal. Inspect the screen for debris and replace the filter if necessary. |

| How to check for a clogged fuel injector | Check the psi reading. Wait and watch for a psi drop indicating a leak in the system. If it's still reading the same after 5 or 10 minutes, the system is holding pressure well. If the fuel pressure drops over 10 minutes, that means there is a leak in the fuel system. |

| How to check for a clogged fuel line | Check the pressure both at idle speed and at the rated speed listed in your pump specifications. If you don’t know the rated speed, just rev the engine and see how the pressure reacts. If you have a serious problem, the needle won’t go anywhere or goes down below specifications, meaning the fuel pump needs to be replaced. |

What You'll Learn

Check the fuel pressure

Checking your fuel pressure is a straightforward process that can help you diagnose any issues with your fuel system and engine. Here's a detailed guide on how to check your fuel pressure:

Step 1: Safety

Fuel under pressure can be dangerous, so safety should be your top priority. Wear protective gear, such as safety glasses and gloves, and work in a well-ventilated area to minimise the risk of fire and injury. Ensure there are no sources of ignition nearby, such as smoking or sparking.

Step 2: Check Fuel Level and Pump

Before investing in a fuel pressure tester, perform some initial checks. First, ensure there is fuel in the tank. If your fuel gauge indicates a full tank, don't rely on it solely as it could be faulty. Add a couple of gallons of fuel and try starting your car. If it starts, your fuel gauge may be faulty and should be replaced.

Next, verify that your fuel pump is working. Locate the fuel tank and ask an assistant to turn the ignition switch to "On." Listen for a two-second noise, such as a whir, hum, or rapid clicks, indicating that the fuel pump is pressurising the fuel line. If you don't hear any noise, check the fuel pump fuse and relay. If they are intact, inspect the wiring to the pump. If voltage is present, the pump has failed and needs to be replaced.

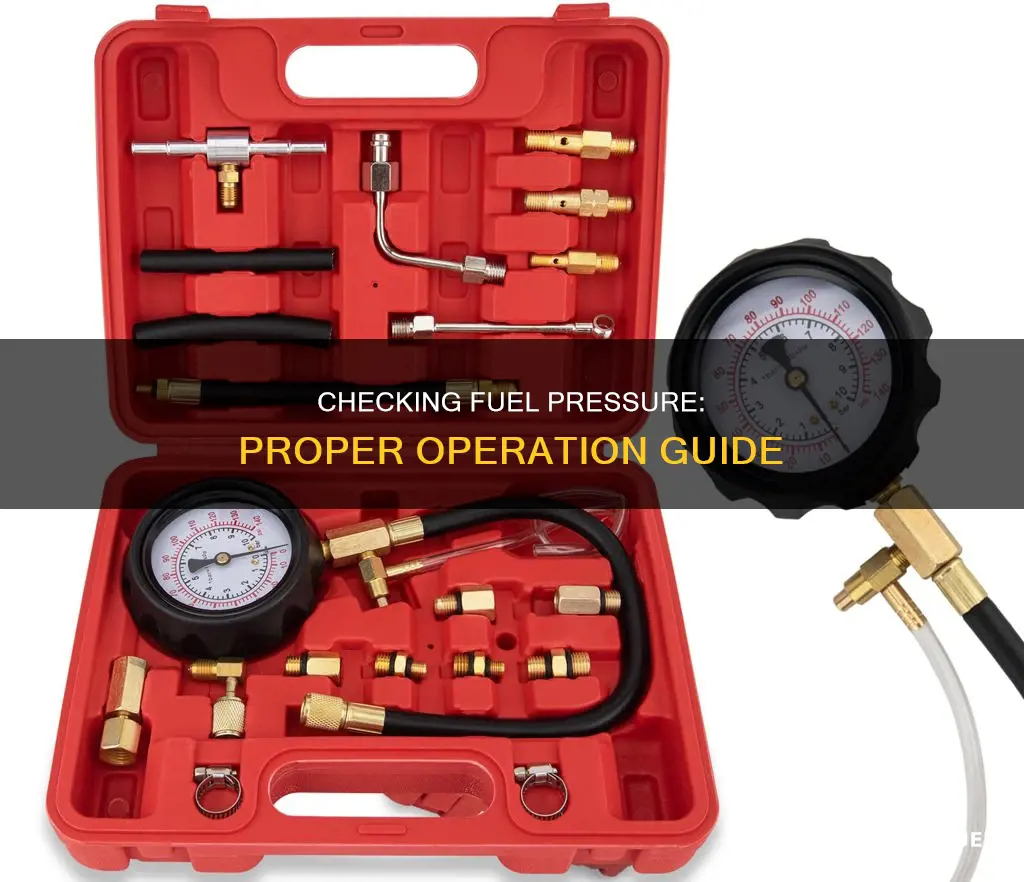

Step 3: Connect a Fuel Pressure Tester

Fuel pressure testers are simple devices that consist of a gauge attached to a fuel hose with multiple fittings. They connect to the fuel system of most vehicles. Ensure your engine is entirely cold before you begin. Locate the Schrader valve fitting on the fuel rail, which may be hidden under a cover. Remove the Schrader valve cap and attach the appropriate tester fitting securely.

Step 4: Test Fuel Pressure

Turn the ignition to "On" and observe the psi reading on the tester gauge. A stable reading after 5-10 minutes indicates that the system is holding pressure well. If the pressure drops significantly during this time, it suggests a leak in the fuel system. Check for drips underneath to pinpoint the location. Keep in mind that it could also be an internal leak from a faulty fuel injector.

Step 5: Start the Engine

Start your engine and let it idle. The fuel pressure should remain steady, within a few psi of the recommended pressure. Once the engine is warmed up, slowly rev it and observe whether the pressure rises with the RPMs. If your fuel pressure is stable, increases with engine speed, and is within the recommended range, your engine issue is likely not fuel-related.

Understanding Fuel Pressure Readings

Zero fuel pressure means the pump is not functioning or isn't receiving power. Check the fuel pump fuse, verify power with a multimeter, and replace the pump if necessary.

Low fuel pressure can be caused by a clogged fuel filter or a failing pump. Replace the fuel filter if it's a serviceable type, as it's a quick and inexpensive fix. It could also be due to improper tank venting or a loose gas cap. Check the cap gasket for damage and tighten it securely.

High fuel pressure may be caused by a clogged or kinked fuel return line, a faulty fuel pump driver module, or a powertrain control module. These issues should trigger a "check engine" light. High fuel pressure can also result from a faulty fuel pressure regulator.

Geo Tracker Fuel Pump: Pressure and Performance

You may want to see also

Compare pressure to manufacturer specifications

To check the pressure in a fuelling system, you will need to use a fuel pressure tester. This consists of a gauge attached to a fuel hose and multiple fittings. The tester will display the pressure in psi on a large gauge visible from inside the vehicle.

The pressure reading will depend on the engine. Older throttle-body injected systems may need as little as 10 psi, while multi-port injection can see as high as 60. You should consult a repair manual or the manufacturer's specifications to determine the correct pressure for your vehicle.

Once you have obtained a pressure reading, you should compare it to the manufacturer's specifications. If the pressure is within the specified range, the fuelling system is operating correctly. If the pressure is below the specified range, there may be a problem with the fuel pump or a clogged fuel filter. If the pressure is above the specified range, there may be a problem with the fuel pressure regulator or a clogged or kinked fuel return line.

It is important to note that releasing fuel under pressure can be dangerous, so it is crucial to take safety precautions when performing any diagnostic tests. Always work in a well-ventilated area and avoid any sources of ignition, such as smoking or open flames.

Understanding Negative Fuel Pressure and Its Impact on Engines

You may want to see also

Test fuel volume

Testing the fuel volume in a fuel system is an important step in diagnosing fuel delivery problems. It is necessary to perform a volume test in addition to a pressure test because low fuel volume can cause a drop in fuel pressure under high load, which a pressure test at idle might not reveal.

Step 1: Safety

Fuel under pressure can cause fire and injury, so safety should be the top priority when performing any diagnostic tests. Wear safety gear such as gloves and safety glasses, work in a well-ventilated area, and avoid smoking or any potential sources of sparks.

Step 2: Check Fuel Pressure

Start by checking the fuel pressure. Start the car and let it idle. Install a fuel pressure gauge, run the pump, and note the pressure reading. Compare this reading to the manufacturer's specifications. If the pressure is low, address this issue first. If the fuel pump is supplying sufficient pressure, proceed to the fuel volume test.

Step 3: Fuel Volume Test

The most accurate way to test fuel volume is by using a flowmeter. However, if you don't have access to a flowmeter, you can perform a timed fuel delivery test. Use a glass container to collect a fuel sample (for safety reasons, as fuel can corrode or fog up plastic). Start the car and let it idle, then collect the fuel sample for a specified amount of time (typically five seconds). Compare the amount of fuel delivered within this time frame to the manufacturer's specifications. You may need to convert the units (e.g. milliliters per second to gallons per hour) to make this comparison.

Step 4: Interpret Results

If the pump is delivering the right amount of fuel within the specified time frame, your system is working properly. If the pump is not delivering enough fuel, there could be a problem with the fuel pump or another component in the fuel system. A clogged fuel filter, a defective pressure regulator, a restricted fuel supply line, or a weak pump could all be potential causes of low fuel volume.

Ford F350 Fuel Pressure: Specifications and Performance

You may want to see also

Check for leaks

Checking for leaks in a pressure fueling system is an important step in ensuring the proper operation of the system. Here are some detailed instructions on how to check for leaks:

First, it is crucial to prioritize safety. Fuel under pressure can cause fires and injuries, so wear protective gear such as safety glasses and gloves. Work in a well-ventilated area, and ensure there are no sources of sparks or flames nearby.

Before performing any tests, it is recommended to consult the manufacturer's specifications for your vehicle to determine the expected fuel pressure levels. This information can usually be found in a repair manual.

To check for leaks, start by installing a fuel pressure gauge on the fuel rail. Ensure that the car is turned on but not started. Observe the pressure reading on the gauge and look for any drops in pressure, which could indicate a leak in the system. If the pressure remains stable, the system is likely holding pressure well.

If there is a suspected leak, you can perform a more comprehensive test by running the engine and allowing it to idle. You should see steady fuel pressure, within a few psi of the recommended pressure. Once the engine is warmed up, slowly rev it and observe if the pressure rises with the RPMs.

If you continue to suspect a leak, there are a few additional steps you can take. One method is to use a black light to inspect the injectors and fuel lines for signs of leakage. You can also try using a flowmeter or a glass measuring container to collect a fuel sample and test the fuel delivery. Compare the amount of fuel delivered within a specific timeframe to the manufacturer's specifications.

In some cases, a leak may be due to a faulty fuel pump or a clogged fuel filter. If you suspect this, you can test the fuel pump by listening for a whirring, humming, or a series of rapid clicks when the ignition switch is turned on. If no noise is heard, check the fuel pump fuse, relay, and wiring.

It is important to note that there are different types of fuel systems, and the testing procedures may vary slightly. Additionally, always refer to the specific guidelines and safety precautions for your vehicle's make and model.

Understanding Fuel Pressure Requirements for a Quadrajet Carburetor

You may want to see also

Check the fuel pump

Checking the fuel pump is a vital part of ensuring your car's fuel system is operating correctly. Here is a detailed, step-by-step guide on how to do it:

Firstly, it is important to note that the fuel pump may not always be the cause of a non-starting car. Some vehicles can still run, albeit poorly, with a malfunctioning fuel pump. However, driving with a faulty pump can cause damage to your vehicle, so it is best to check and address any issues promptly.

The fuel pump is responsible for delivering fuel from the tank to the engine. A faulty pump can cause issues with starting the car, or it may start but then sputter, stutter, or stall. To check the pump, you can perform the following tests:

Electrical Test:

- Check the fuel pump fuse in the fuse box. Refer to your owner's manual to locate the fuse box and identify the fuel pump fuse.

- Inspect the fuse for signs of failure, such as burning or breakage.

- If the fuse is blown, replace it with one of the proper amp rating. Do not use a fuse with more amps than necessary.

- If the fuse is intact, check the voltage at the pump itself. Consult your vehicle's service manual to find the correct procedure and location for this check.

- Perform a drop test using a voltmeter. Ensure the power wire shows the full voltage, and the grounding wire is properly grounded.

- If this electrical test does not reveal any issues, it is likely the fuel pump needs to be replaced. However, for a more thorough diagnosis, you can also perform a fuel pressure test.

Fuel Pressure Test:

- Eliminate the fuel filter as a possible cause. Remove the filter and drain excess fuel. Use a rubber hose on the filter inlet and blow through it, checking for resistance. Inspect for debris and replace the filter if necessary.

- Obtain a fuel pressure gauge from an auto parts store. These are usually available for a reasonable price and can be borrowed from some machine or auto shops.

- Locate the fuel pump test point, typically near the fuel injectors, and the pump's connection to the filter injector rail.

- Attach the pressure gauge to the test point or port. Refer to your owner's manual for specific instructions, as locations and procedures may vary depending on your vehicle.

- Start the engine and let it warm up slightly.

- With the engine idling, check the pressure on the gauge. Then, rev the engine and check the pressure again.

- Compare the pressure readings to the specifications in your repair manual. If the pressure is below the specified range or doesn't increase with engine speed, it indicates a problem with the fuel pump, and it likely needs to be replaced.

Remember to always put safety first when working on your vehicle's fuel system. Wear appropriate protective gear, ensure good ventilation, and keep a fire extinguisher nearby.

Fuel Pressure Secrets: Building the WRX Powerhouse

You may want to see also

Frequently asked questions

You can check the pressure in your fuel system by using a fuel pressure tester. This device consists of a gauge attached to a fuel hose with multiple fittings that can connect to the fuel system of nearly any vehicle. Once connected and the fuel system is pressurised, the tester will display the pressure in psi on a large gauge.

"Good fuel pressure" depends on the engine. Older throttle-body injected systems may need as little as 10 psi, while multi-port injection can see as high as 60. You can find the specifications for your vehicle in a repair manual.

Low fuel pressure can cause a slow start-up, low performance, misfires, and stalling.

You can test your fuel pump by checking the fuel pump fuse and voltage, performing a drop test using a voltmeter, and/or performing a fuel pressure test with a fuel pressure gauge.