A fuel solenoid valve, also known as a fuel shut-off valve, is an important component of a pressure washer. It controls the flow of diesel fuel into the burner fuel nozzle, where it is ignited by the electrodes. When the valve is energised, it opens to allow diesel fuel to flow, and when the power is cut, it stops the flow of diesel, preventing fuel from entering the pressure washer burn chamber when no spark is present. The electrical requirements for the fuel solenoid are typically stamped on the head of the valve and it is important to purchase the correct voltage for your power washer. This article will provide an overview of the fuel solenoid, its function, and the considerations for selecting the appropriate valve for your pressure washer.

| Characteristics | Values |

|---|---|

| Function | Controls the flow of diesel fuel |

| Operation | Opens when energised to allow diesel fuel to flow into the burner fuel nozzle |

| Closes when power is cut off to prevent fuel from being ported into the pressure washer burn chamber | |

| Electrical requirements | 110 volt, 220 volt or 12 volt DC |

| Compatibility | Can be used on nearly all brands of hot water pressure washers |

| Voltage | 110-120V, 115V, 12/24 VDC, 220-240V, 230V, 24 V |

| Colour | Gray, Black, Green, Blue |

| Coil | With cord, without cord |

| Delay | Non-delay |

What You'll Learn

- The fuel solenoid is a valve that controls the flow of diesel fuel

- Fuel solenoids are available in 110 volt, 220 volt and 12 volt DC

- A faulty fuel solenoid can be identified by a failure to shut off the fuel supply to the nozzle

- Fuel solenoids can be tested by checking if the coil is creating a magnetic field

- Fuel solenoids can be replaced with a cable setup

The fuel solenoid is a valve that controls the flow of diesel fuel

Fuel solenoid valves are available in 110V, 220V, and 12V DC and can be used on almost all brands of hot water pressure washers. The electrical requirements are usually stamped on the head of the fuel solenoid. It is important to purchase the correct voltage of the shut-off valve required for your power washer.

The fuel solenoid is an essential component in a pressure washer's fuel system, ensuring the controlled release of diesel fuel into the burner. It plays a vital role in regulating the flow of fuel, allowing for the ignition process to take place safely and efficiently.

The fuel solenoid valve is designed to work with specific voltages, and it is crucial to select the correct voltage for your power washer. Operating the valve at the wrong voltage can be unsafe and may impact its ability to function properly.

The fuel solenoid is an integral part of the pressure washer's fuel system and plays a critical role in controlling the flow of diesel fuel. By regulating the fuel supply, the solenoid ensures that the burner receives the necessary fuel for ignition, resulting in the production of hot water for various cleaning applications.

Finding the Fuel Pressure Relief Valve in 2004 Mustangs

You may want to see also

Fuel solenoids are available in 110 volt, 220 volt and 12 volt DC

Fuel solenoids, also known as fuel shut-off valves, control the flow of diesel fuel in pressure washers. They are an essential component of the pressure washer's fuel system, ensuring that fuel only flows into the burner when the correct conditions are met.

Fuel solenoids are available in a range of voltages, including 110-volt, 220-volt, and 12-volt DC options. This variety ensures compatibility with different power washer models and electrical setups. It is important to purchase the correct voltage for your specific power washer to ensure optimal performance and safety.

Suntec and Danfoss are two reputable manufacturers that offer fuel solenoids compatible with most hot water pressure washer brands. Their products are designed to meet diverse electrical requirements, and the voltage information is typically stamped on the head of the fuel solenoid for easy identification.

When purchasing a fuel solenoid, it is crucial to consider the voltage specifications of your pressure washer. Matching the correct voltage ensures proper functionality and helps prevent electrical issues or safety hazards. If you are unsure about the required voltage, it is recommended to consult with a professional or the pressure washer's manufacturer.

By selecting the appropriate fuel solenoid voltage, you can effectively manage the flow of diesel fuel in your pressure washer, ensuring safe and efficient operation.

Trailblazer Fuel Pressure: Getting the Right PSI

You may want to see also

A faulty fuel solenoid can be identified by a failure to shut off the fuel supply to the nozzle

A fuel solenoid valve, commonly known as a fuel shut-off valve, controls the flow of diesel fuel in a pressure washer. When activated, the solenoid draws a higher current from the batteries, causing the coil to magnetize and pull the solenoid plunger. This action results in the opening of the valve, allowing fuel to flow into the carburettor.

To identify a faulty fuel solenoid, you can perform the following steps:

- Begin by using a wrench to detach the solenoid from the carburettor.

- Securely attach the solenoid in a vice and attach the battery to the positive terminal of the solenoid.

- Touch the other end of the wire to the negative terminal of the solenoid.

- If the solenoid is functional, the solenoid's rubber pole should move in an upward and downward motion.

- If this movement does not occur, it indicates that the solenoid is defective and requires attention.

Additionally, you can test the solenoid with a multimeter. Here are the steps:

- Wear protective equipment, such as insulated gloves and eyewear, to protect against shock hazards.

- Disconnect the solenoid from any electrical connections or wiring.

- Check the solenoid manufacturer's specifications to determine its supply voltage (AC/DC).

- Connect the solenoid terminals to the required power source.

- Once the solenoid is connected, it should activate with a click. If there is no click, the solenoid is faulty and needs to be replaced.

- Use a multimeter to test the solenoid for resistance and voltage.

- Set the multimeter to measure resistance (Ω) and connect the probes to the solenoid terminals.

- Note the multimeter readings and compare them to the manufacturer's expected resistance value range.

- If the reading is 'OL' (infinite resistance), it signifies an incomplete circuit within the solenoid, and the solenoid needs to be replaced.

- Set the multimeter to measure voltage (AC/DC) and connect the probes to the solenoid terminals.

- Note the results. If the solenoid is operating normally, the multimeter should read a voltage that matches the rated voltage of the valve. Otherwise, the coil is faulty and needs to be replaced.

Understanding Fuel Pressure: The Sweet Spot for Performance

You may want to see also

Fuel solenoids can be tested by checking if the coil is creating a magnetic field

Fuel solenoids are an important component of a vehicle's fuel system, controlling the electric current that allows fuel to enter the combustion chamber. Testing the fuel solenoid is crucial to ensure optimal vehicle performance and can be done by checking if the coil is generating a magnetic field. Here's a detailed guide on how to perform this test:

Step 1: Understand the Basics

Before beginning the test, it's important to know that a fuel solenoid is a coil of wire that acts as an electromagnet. It converts electrical energy into mechanical energy by creating a magnetic field, which is then used to induce linear motion.

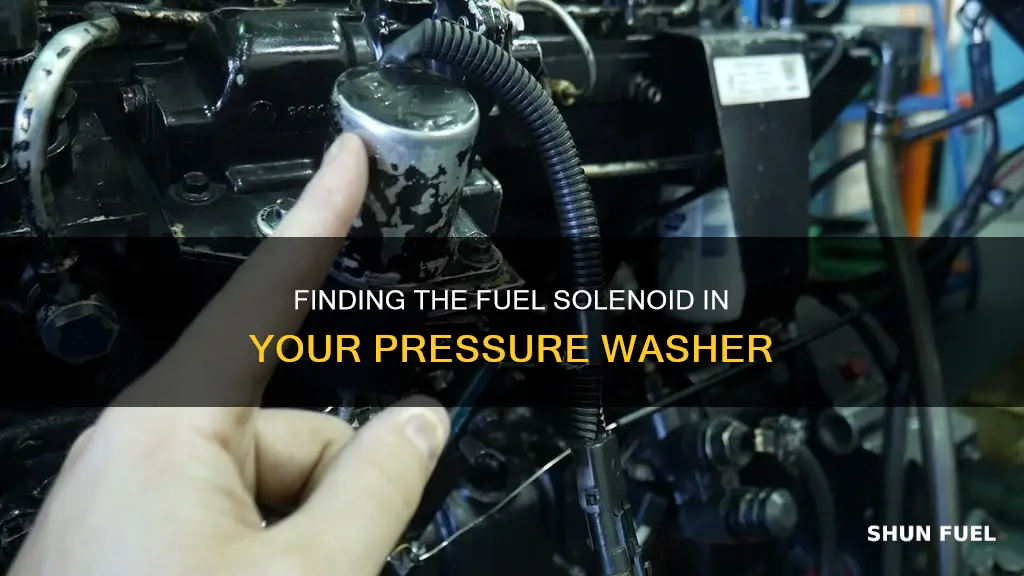

Step 2: Locate the Fuel Solenoid

The fuel solenoid is typically found near the fuel injector and fuel tank. It is usually cylindrical with a smaller cylinder attached, and there will be wires connecting it to the battery.

Step 3: Check Power Supply

Ensure that power is being supplied to the solenoid. You can do this by testing the voltage with a multimeter or voltmeter, or by connecting the coil directly to the power source. A properly functioning solenoid should receive a voltage within the operating range specified by the manufacturer.

Step 4: Remove the Coil

To access the coil, remove the retaining nut or screw that holds it in place on the valve. Once removed, you should see a small hole in the center.

Step 5: Test for Magnetic Field

With the coil energized, slowly insert a small screwdriver into the center hole. If the coil is functional, the magnetic force should pull the screwdriver towards it. If the screwdriver is not attracted to the coil, it needs to be replaced.

Step 6: Inspect the Valve Stem and Ball

If the coil is functional, the next step is to check the valve stem and ball for any issues. Remove the screws holding the rectangular plate on the valve body, and then pull out the valve stem. Inside the valve stem is a small ball that should move freely. If the ball is stuck, use a thin probe to free it.

Step 7: Reassemble and Test

Once you've checked and addressed any issues with the coil and valve, reassemble the components and test the operation of the fuel solenoid.

By following these steps, you can effectively test the fuel solenoid by checking for the presence of a magnetic field. This process helps ensure that your vehicle's fuel system is functioning correctly and can save you time and money by identifying potential issues early on.

Fuel Pressure Maintenance for 1999 Blazers: What You Need to Know

You may want to see also

Fuel solenoids can be replaced with a cable setup

A fuel solenoid is a valve that controls the flow of fuel to the burner. When the solenoid is energised, it opens and allows fuel to pass through to the burner, where it is ignited by electrodes. When power is cut, the solenoid closes, preventing fuel from entering the burn chamber.

There are a few things to consider if you're thinking of replacing your fuel solenoid with a cable setup. Firstly, you'll need to determine the type of fuel solenoid you have and ensure that you purchase the correct replacement. Fuel solenoids typically come in 12-volt, 110-volt, 220-volt, and 24-volt varieties, so it's important to get the right one for your machine.

Additionally, when replacing the fuel solenoid, it's important to follow safety precautions. Make sure the pressure washer is turned off and disconnected from any power source before beginning any work. You should also wear appropriate protective gear, such as gloves and eye protection.

- Purchase the correct replacement cable setup for your pressure washer.

- Turn off the pressure washer and disconnect it from any power source.

- Locate the fuel solenoid, typically found near the burner.

- Disconnect the fuel lines and electrical connections to the solenoid.

- Remove the mounting hardware securing the solenoid in place.

- Install the new cable setup according to the manufacturer's instructions.

- Reconnect the fuel lines and electrical connections.

- Test the pressure washer to ensure it is functioning properly.

By following these steps, you can safely replace the fuel solenoid with a cable setup, ensuring your pressure washer continues to operate effectively.

Fuel Pressure Regulator Vacuum Loss: Effects and Solutions

You may want to see also

Frequently asked questions

A fuel solenoid valve, commonly known as a fuel shut-off valve, controls the flow of diesel fuel.

When a pressure washer fuel solenoid valve is energised, it opens to allow diesel fuel to flow into the burner fuel nozzle, where it is ignited by the electrodes. When power to the fuel shut-off valve is cut, it generally stops the flow of diesel.

The fuel solenoid is the valve that is energised when the burner control switches allow current to flow to it.

First, establish that power is being supplied to the solenoid. Then, remove the coil from the valve by unscrewing the retaining nut. With the coil energised, slowly insert a small screwdriver blade into the centre hole – if the coil is functional, the magnetic force should pull the screwdriver blade towards it. If not, replace the coil.

Fuel solenoids are available from a variety of online retailers and pressure washer parts suppliers.