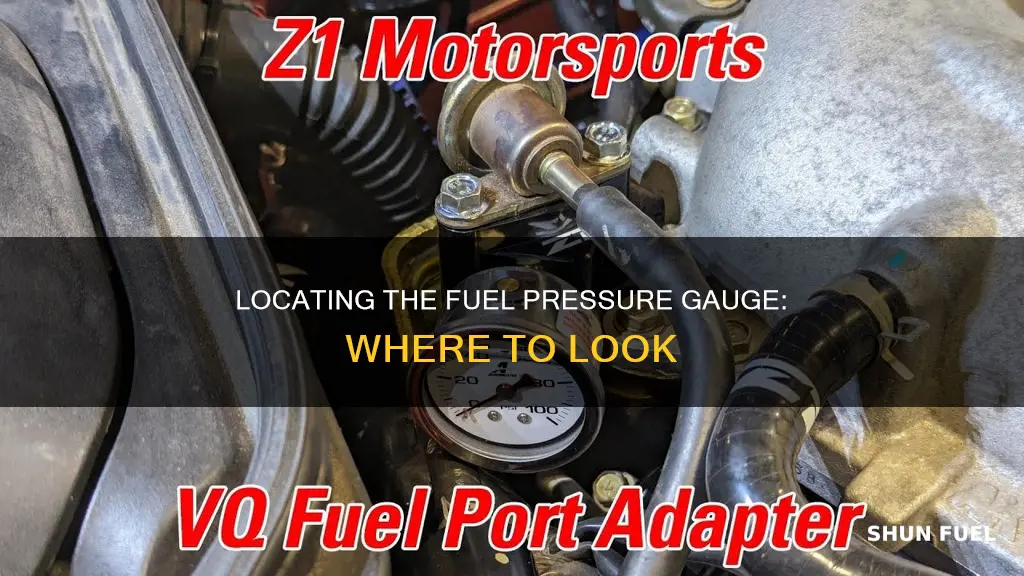

The fuel pressure gauge is an important component that helps monitor the fuel pressure in a vehicle. It is usually installed near a fuel line in the engine bay, with the mechanical gauge typically located close to the carburetor. For safety reasons, it is crucial to mount the gauge outside the driver's compartment to prevent fuel from entering and posing a fire hazard. This guide will explore the different types of fuel pressure gauges and their ideal placement for optimal functionality and safety.

| Characteristics | Values |

|---|---|

| Installation | A fuel pressure gauge can be installed near a fuel line in the engine bay. |

| Compatibility | A fuel pressure gauge is intended for carbureted engines, with readings of 0 to 15 psi. |

| Compatibility | Engines with fuel injection may require higher pressures, with indicators reading between 0 and 100 psi. |

| Placement | A mechanical fuel pressure gauge is usually located near the carburetor. |

| Placement | An electronic fuel pressure gauge can be placed anywhere, even on the dashboard. |

| Safety | A fuel line should not be plumbed into the passenger compartment due to safety risks. |

| Safety | An isolator can be used to transmit the fuel pressure reading into the passenger compartment while keeping fuel outside. |

| Usage | A fuel pressure gauge allows you to monitor fuel pressure while the engine is under load, helping to identify problems. |

| Function | A fuel pressure gauge measures the pressure of gasoline delivered to the engine, usually reported in psi. |

What You'll Learn

Fuel pressure gauge types: mechanical vs electrical

Fuel pressure gauges are used to measure the pressure of the gasoline delivered to the engine, usually in pounds per square inch (psi). They are especially important for carbureted engines, as the reading is only 0 to 15 psi. For engines with fuel injection, the indicator will read between zero and 100 psi.

There are two main types of fuel pressure gauges: mechanical and electrical. Mechanical gauges are full sweep, meaning they have 270 degrees of needle movement. They must be connected by tubing to the engine bay and are usually plumbed directly before the carburetor. There are two varieties of mechanical gauges: wet and dry. A wet gauge uses a dial filled with clear oil, such as glycerin, to dampen the effects of the needle's movements and prevent damage to the delicate parts. However, the temperature of the oil can be affected by the engine's warmth, potentially impacting the reading. To mitigate this, some manufacturers provide a relief valve to equalize the pressure within the indicator. Dry gauges lack this fluid, potentially providing more accurate readings, but they are more susceptible to wear from engine vibrations and typically do not last as long.

On the other hand, electrical gauges are short sweep, with 90 to 180 degrees of needle movement. They take measurements from a sensor installed in the engine bay and are connected via wires, allowing for more placement flexibility. Electrical gauges provide more precise readings and have fewer moving parts, making them more durable.

When deciding between a mechanical and electrical fuel pressure gauge, it is important to consider the specific needs and constraints of your vehicle. Both types have their advantages and can provide valuable information about your car's fuel pressure.

Understanding the Fuel Rail Pressure in Your Vehicle

You may want to see also

Where to install a fuel pressure gauge

Installing a fuel pressure gauge is a straightforward process, but it is important to take a systematic approach. Here is a step-by-step guide on where and how to install a fuel pressure gauge:

Step 1: Choosing the Location

The fuel pressure gauge should be installed near a fuel line in the engine bay. For a mechanical gauge, this is usually near the carburetor, although this location makes it difficult to see while driving. An alternative location is near the cowl, depending on your hood design.

It is important to note that plumbing a mechanical gauge into the passenger compartment is not recommended, as it is unsafe to have a fuel line inside the car. Instead, an "isolator" can be purchased to safely transmit the fuel pressure reading, but this adds another component that can fail.

For an electronic gauge, the signal is sent via wires, so it can be placed anywhere, even on the dashboard.

Step 2: Gathering the Tools and Materials

To install the fuel pressure gauge, you will need the following:

- A fuel pressure gauge (60 or 100 psi)

- A gauge fitting for a 3/8-inch fuel hose (the fuel lines are typically 5/16-inch inside diameter hoses, but the 3/8-inch gauge fitting will fit)

- Two 3/8-inch hose clamps

- Teflon tape

- A cutter for cutting the fuel hose

- A sizable rag

Step 3: Installing the Gauge

Begin by wrapping the gauge's threads with two wraps of Teflon tape, ensuring that the tape does not extend below the threads. Use a large wrench or vise to hold the fitting and a small wrench to screw in the gauge. Hand-tightening will not be sufficient.

Next, place the rag under the visible rubber hoses around the engine, as part of the fuel filtration process. This will catch any leaking fuel when you cut the fuel line.

Use the cutter to cut the fuel line and clamp each end of the cut fuel line using the hose clamps. Insert one open end of the fuel pressure gauge over one cut end of the fuel line. Slide the hose clamp holding the cut fuel line over the point where the line has been forced onto the gauge and tighten it by turning the screw of the clamp in a clockwise direction. Repeat this process with the other end of the cut fuel line. Now you should have the fuel line clamped at both ends on the two openings of the fuel pressure gauge.

Step 4: Testing the Gauge

Start the engine. The fuel pressure gauge should start giving readings within seconds, but the initial readings may be unsteady. Start and stop the engine at least twice, for a few minutes each time. Then, start the engine again and keep it running for two to three minutes. The reading on the fuel pressure gauge should now be the correct reading.

Fuel Pump: Understanding Pressure-Induced Auto-Shutoff

You may want to see also

How to install a fuel pressure gauge

A fuel pressure gauge is important for ensuring that your engine is receiving the right amount of fuel. It's usually straightforward to install, and can be done by following these steps:

Firstly, ensure you have the right parts. You will need a 60 or 100 psi gauge, a gauge fitting for a 3/8 inch fuel hose, and two 3/8 inch hose clamps. The fuel lines are actually 5/16 inch inside diameter hoses, but the 3/8 inch gauge fitting will fit. You can order these parts from specialist retailers.

Next, prepare the fuel line. The fuel line you want to tap into is the one closest to the oil dipstick. It is a rubber hose that connects to a metal pipe near the engine. Before you start cutting the hose, you must release the fuel pressure to avoid spraying fuel. Once the pressure is released, cut the fuel line and use a rag to prevent fuel from spraying. Have two 5/16 inch plugs ready to stop the fuel flow – two Bic pen-type caps will work. The fuel lines have an insulation tube that makes them look larger than 5/16 inches, so this will need to be removed to get the clamps on the hose.

Now you can install the gauge. Put two wraps of Teflon tape on the gauge's threads and screw it into the gauge fitting, ensuring the tape doesn't extend below the threads. Use a wrench to tighten the fitting. You can then prime the fuel system and start the engine, checking for any fuel leaks.

If you are installing an electric pressure gauge, you can install the pressure sender in the same place and then route the output wire through the firewall to the gauge.

There are a few different locations you can choose for your fuel pressure gauge. A mechanical gauge is usually plumbed along the fuel line, often located near the carburetor. This can make it difficult to see while driving, so you may want to put it near the cowl, depending on your hood design. It is not safe to have a fuel line inside your car, so if you want to place the gauge in the cockpit, you will need to use an isolator or an electrical gauge with a separate pressure sender. An electronic gauge can be placed anywhere, even on the dashboard, as the signal is sent via wires.

Finally, check the reading on your gauge. A normal idle fuel pressure is 28-32 psi, and most carburetors recommend fuel pressure between 5 and 8 psi. If your engine seems erratic, check the fuel pressure gauge and, if the pressure is low, look for a clogged fuel filter or a collapsed fuel line.

Fuel Pressure Maintenance: Carburetor Secrets Revealed

You may want to see also

How to test fuel pressure

Testing fuel pressure can help you diagnose issues with your car's fuel pump, fuel filter, or fuel return line. Here's a step-by-step guide on how to test fuel pressure:

Step 1: Check the Fuel Level and Fuel Gauge

First, check that there is enough fuel in the tank. Even if the fuel gauge shows a full tank, it could be faulty. Add at least two gallons of fuel and try starting the car. If it starts, the issue may be an internal failure of the fuel gauge.

Step 2: Verify the Fuel Pump is Working

Go to the fuel tank and ask an assistant to turn the ignition switch to "On." Listen for a two-second whirring, humming, or series of rapid clicks, which indicates that the fuel pump is pressurizing the fuel line to the engine. If you don't hear any noise, the pump may not be getting power or it may have failed. Check the fuel pump fuse and relay, and if they are intact, check the wiring to the pump.

Step 3: Connect a Fuel Pressure Tester

Safety Warning: Fuel vapors are highly flammable, so ensure you perform these steps in a well-ventilated area with a fire extinguisher nearby.

With the engine cold, open the hood and locate the Schrader valve fitting on the fuel rail. Remove the Schrader valve cap and attach the appropriate fuel pressure tester fitting. Ensure it is threaded on properly for a leak-proof fit.

Step 4: Check the Fuel Pressure Reading

Turn the ignition to "On," not "Start," and observe the psi reading on the fuel pressure tester. A drop in psi over 5-10 minutes indicates a leak in the fuel system. If the pressure remains steady, the system is holding pressure well.

Step 5: Start the Engine and Observe

Start the engine and let it idle. The fuel pressure should remain steady, within a few psi of the recommended pressure for your engine. Once the engine is warmed up, slowly rev the engine and observe whether the fuel pressure rises with the RPMs. If the fuel pressure holds steady and rises with engine speed, your engine problem is likely not fuel-related.

Understanding Fuel Pressure Readings

Zero Fuel Pressure

This indicates that the fuel pump is dead or not receiving power. Check the fuel pump fuse, verify power to the pump with a multimeter, and if necessary, replace the fuel pump.

Low Fuel Pressure

Low fuel pressure can be caused by a clogged fuel filter or a failing fuel pump. If it is a serviceable type filter, replace the fuel filter. It could also be due to improper tank venting or a loose gas cap. Check the gas cap gasket for damage and tighten it securely.

High Fuel Pressure

High fuel pressure can be caused by a clogged or kinked fuel return line, a faulty fuel pump driver module, or a faulty fuel pressure regulator. It could also be due to a bad powertrain control module, which would likely trigger a "check engine" light.

By following these steps, you can effectively test and diagnose fuel pressure issues in your vehicle.

Fuel Pressure Fundamentals for 60 Series Detroit Engines

You may want to see also

What to do if your fuel pressure is too high or too low

A fuel pressure gauge is usually installed near a fuel line in the engine bay. For a mechanical gauge, this is often located near the carburetor, making it difficult to see while driving. If you want to be able to view the gauge while on the road, you could put it near the cowl, depending on your hood design.

An electronic gauge, on the other hand, can be placed anywhere due to its wired signal, even on the dashboard.

Now, if your fuel pressure is too high or too low, there are a few things you can do to address the issue:

If your fuel pressure is too high, your vehicle's engine may be overfuelled, leading to symptoms such as a rough-running engine, poor fuel economy, and black smoke from the exhaust. In this case, the best course of action is to take your car to a trusted mechanic to diagnose and resolve the root cause of the issue, which is typically a bad fuel regulator or a clogged return line.

On the other hand, if your fuel pressure is too low, your vehicle may experience a lack of horsepower, slow starting, an inability to start the engine, or stalling. To address this, you should first check for a clogged fuel filter or a collapsed fuel line. If the pressure remains low, you may need to look at your fuel pump and confirm that it is flowing at the rated pressure.

It is important to maintain correct fuel pressure to ensure your vehicle runs efficiently and to prevent damage and low performance.

Understanding Fuel Pressure: Location and Functionality Explored

You may want to see also

Frequently asked questions

The fuel pressure gauge is usually installed near a fuel line in the engine bay.

A mechanical fuel pressure gauge must be installed outside the driver's compartment, as bringing fuel inside is a major safety hazard. Most people install it just in front of the windshield, where the driver can still see it.

An electrical fuel pressure gauge can be mounted anywhere you find it most convenient.

The source for your readings can be tapped at any point along either fuel rail, as long as the source for your readings is at the same pressure as your fuel injectors.

The fuel pump test point is usually beside the fuel injectors.