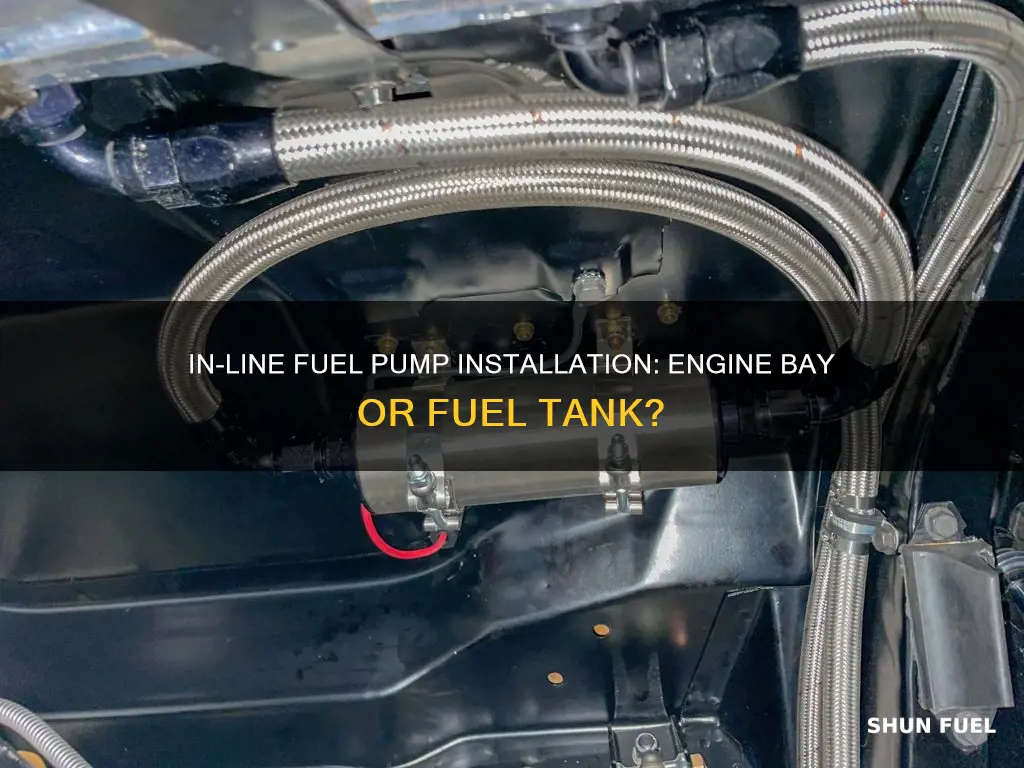

Installing an in-line fuel pump is a crucial step in ensuring the efficient operation of your vehicle's fuel system. This process involves placing the pump directly into the fuel line, typically between the fuel tank and the engine. The location is strategic, as it allows for precise control over the fuel flow, ensuring that the engine receives the required amount of fuel for optimal performance. Proper installation is essential to prevent issues such as fuel starvation or excessive pressure, which can lead to engine problems. Understanding the specific requirements of your vehicle and the type of pump being installed is key to a successful and safe installation process.

| Characteristics | Values |

|---|---|

| Installation Location | Engine compartment, typically near the fuel tank |

| Engine Type | Suitable for both gasoline and diesel engines |

| Placement | Inline with the fuel line, hence the name |

| Advantages | Improved fuel efficiency, reduced engine load, and better performance |

| Common Vehicles | Used in various cars, trucks, and motorcycles |

| Maintenance | Regular checks and replacements are recommended |

| Installation Difficulty | Can vary depending on the vehicle model and engine design |

| Cost | Installation costs can range from $50 to $200 |

| Safety | Proper grounding and wiring are essential to prevent electrical issues |

What You'll Learn

- Engine Bay: Install the pump in the engine compartment, typically near the fuel tank

- Under Hood: Choose a location with easy access and minimal interference with other components

- Fuel Tank: Some designs allow for direct installation inside the tank for compact systems

- Fuel Line: Ensure the pump is positioned to connect to the fuel line efficiently

- Safety Considerations: Avoid areas prone to heat or vibration to prevent damage

Engine Bay: Install the pump in the engine compartment, typically near the fuel tank

When installing an in-line fuel pump, the engine bay is a strategic location, offering both accessibility and proximity to the fuel source. This placement ensures that the pump can efficiently draw fuel from the tank and supply it to the engine without unnecessary strain or the need for extensive piping. The engine bay is often chosen due to its central position, allowing for a direct and straightforward connection to the fuel system.

The process begins with careful consideration of the engine's layout and available space. The fuel pump should be installed near the fuel tank, typically in the engine compartment, to ensure a short and direct path for the fuel flow. This proximity reduces the risk of fuel pressure drop and ensures optimal performance. It is crucial to select a suitable mounting location that provides easy access for maintenance and allows for proper ventilation to prevent overheating.

Once the ideal spot is identified, the installation process commences. Begin by disconnecting the fuel lines leading to the engine. Carefully remove any existing pump or strainer, if present, to create space for the new in-line pump. Ensure that all connections are properly sealed to prevent fuel leaks. Then, position the in-line pump securely, using the appropriate mounting hardware provided with the pump.

After the pump is in place, reattach the fuel lines, ensuring a tight and secure fit. Check for any signs of leakage and verify that the pump is functioning correctly. It is essential to test the system under various conditions to ensure it meets the required specifications. Proper installation and regular maintenance will contribute to the longevity of the fuel pump and overall engine performance.

Remember, the engine bay installation of an in-line fuel pump requires careful planning and attention to detail. By following manufacturer guidelines and best practices, you can ensure a successful and efficient fuel delivery system, enhancing the performance and reliability of your vehicle's engine.

Understanding Honda's Fuel Line Pulsation Dampener: A Comprehensive Guide

You may want to see also

Under Hood: Choose a location with easy access and minimal interference with other components

When installing an in-line fuel pump under the hood of a vehicle, one of the most critical considerations is choosing the right location. This decision will impact the pump's performance, longevity, and overall reliability. The ideal spot should offer easy access for maintenance and repairs while minimizing interference with other engine components.

Under the hood, there are several areas to consider for the fuel pump installation. Firstly, the front of the engine bay is often a popular choice due to its accessibility. This location allows for straightforward connections to the fuel tank and lines, making it convenient for maintenance. However, it's essential to ensure that the pump doesn't interfere with the engine's cooling system or other critical components.

Another potential spot is the side of the engine, which provides a more compact layout. This position might be more suitable for smaller engines or vehicles with limited space. By placing the pump here, you can avoid potential obstructions and maintain a clean, organized engine bay.

For those with larger engines, the rear of the engine bay could be an option. This location often provides more space and can accommodate larger fuel pumps without interference. However, it may require additional considerations for wiring and connections, ensuring they are securely routed to avoid damage.

In all these scenarios, it's crucial to consider the pump's orientation and any potential clearance issues. The pump should be installed in a way that allows for easy access during maintenance, with sufficient space to work on the connections and lines without strain. Additionally, ensuring that the pump is securely mounted to prevent vibration-induced damage is essential.

Choosing the Right Fuel Line for Your Lawn Mower: A Guide

You may want to see also

Fuel Tank: Some designs allow for direct installation inside the tank for compact systems

When considering the installation of an in-line fuel pump, one of the key factors to take into account is the design of the fuel tank. Some fuel tank systems are specifically engineered to accommodate the direct installation of an in-line pump, offering a compact and space-efficient solution. This approach is particularly useful in situations where space is limited, such as in smaller vehicles or boats.

Direct installation inside the fuel tank has several advantages. Firstly, it allows for a more streamlined design, as the pump can be positioned close to the fuel source, reducing the length of fuel lines required. This not only saves space but also minimizes the risk of fuel line leaks, as there are fewer connections to worry about. Additionally, having the pump inside the tank can help protect it from external damage, as it is shielded from potential impacts or vibrations that might occur during vehicle operation.

The process of installing an in-line pump within the fuel tank typically involves careful planning and precision. The pump must be securely mounted to ensure it operates reliably and efficiently. This often requires specialized brackets or adapters to hold the pump in place, ensuring it remains stable even when the vehicle is in motion. Proper sealing is also crucial to prevent fuel leaks, and this is usually achieved using high-quality gaskets or O-rings.

Furthermore, this installation method can contribute to improved fuel efficiency. By reducing the distance between the pump and the fuel, there is less resistance in the fuel line, allowing for smoother fuel flow. This can result in better engine performance and potentially longer engine life, as the engine receives a consistent and clean supply of fuel.

In summary, direct installation of an in-line fuel pump inside the fuel tank is a practical solution for compact systems. It offers space savings, reduced risk of leaks, and potential improvements in fuel efficiency. However, it requires careful consideration and precise installation techniques to ensure optimal performance and reliability.

Understanding Homelite 4620 Chainsaw Fuel Line Setup

You may want to see also

Fuel Line: Ensure the pump is positioned to connect to the fuel line efficiently

When installing an in-line fuel pump, it's crucial to consider the fuel line's position and configuration to ensure optimal performance and safety. The fuel line is a critical component in the fuel delivery system, and its placement directly impacts the pump's efficiency and the overall fuel flow. Here's a detailed guide on how to ensure a proper connection between the pump and the fuel line:

Location and Routing: The first step is to identify the ideal location for the in-line fuel pump. Typically, it should be installed close to the fuel tank but not directly on it. This placement ensures that the pump is not exposed to potential damage from the tank's movement during acceleration or deceleration. A common installation point is along the fuel line, just before the line splits to supply the engine. This position allows for easy access and maintenance. When routing the fuel line, ensure it is protected by a suitable shield or sleeve to prevent damage from road debris or vibrations.

Connection and Fitting: To connect the pump to the fuel line, use appropriate fittings and adapters. The goal is to create a secure and leak-free connection. Start by cleaning the fuel line and pump's inlet to ensure a proper seal. Then, use the correct size of fittings, typically made of durable materials like aluminum or brass, to join the pump and the fuel line. Tighten the connections securely, but be careful not to overtighten, as this can restrict fuel flow. Consider using a fuel line inspection tool to ensure the connections are made at the correct angles and are free from any kinks.

Pressure and Flow Considerations: The pump's position and connection should also take into account the fuel system's pressure and flow requirements. Ensure that the pump's outlet is connected to the fuel line with sufficient diameter to handle the expected fuel flow rate. A restricted connection can lead to reduced performance and potential engine issues. Additionally, check for any pressure regulators or fuel filters in the line and ensure they are positioned correctly to maintain optimal fuel pressure.

Testing and Verification: After the installation, it is essential to test the system thoroughly. Start the vehicle and monitor the fuel gauge to ensure the pump is supplying fuel correctly. Check for any leaks at the connections and verify that the engine runs smoothly without any fuel-related issues. This testing phase is crucial to identify any potential problems and make necessary adjustments.

By following these steps and paying close attention to the fuel line's connection, you can ensure that the in-line fuel pump is installed efficiently, providing reliable fuel delivery to the engine. Proper installation and maintenance of the fuel line will contribute to the overall performance and longevity of the vehicle's fuel system.

Arctic Cat 454 Fuel Line: The Ultimate Guide to Sizing

You may want to see also

Safety Considerations: Avoid areas prone to heat or vibration to prevent damage

When installing an in-line fuel pump, it is crucial to prioritize safety and ensure the pump's longevity. One of the primary safety considerations is the installation location. Avoid placing the pump in areas that are prone to excessive heat or vibration, as these factors can significantly impact its performance and durability.

Heat is a critical concern for fuel pumps. High temperatures can cause the pump's internal components to degrade faster, leading to reduced efficiency and potential failure. It is recommended to install the pump in a well-ventilated area with a temperature range suitable for the specific model. Engines, for example, generate a lot of heat, so placing the pump too close to the engine block or exhaust system can be detrimental. Instead, opt for a cooler location, such as the engine bay or a dedicated fuel tank compartment, ensuring the pump operates within the manufacturer's recommended temperature limits.

Vibration is another critical factor to consider. Fuel pumps are designed to withstand a certain level of vibration, but excessive movement can loosen connections, damage seals, and disrupt the pump's functionality. To prevent this, it is essential to secure the pump firmly. Use vibration-damping materials or mounts to absorb and reduce the impact of engine vibrations. Properly fastening the pump to a stable surface, such as a metal bracket or the fuel tank itself, can help minimize movement and ensure a secure installation.

Additionally, when choosing the installation site, consider the proximity to other components. Avoid areas where the pump might come into contact with sharp edges or protruding parts that could cause damage during engine operation. Proper insulation and the use of protective covers can further safeguard the pump from potential hazards.

By adhering to these safety guidelines and carefully selecting the installation location, you can ensure the in-line fuel pump operates reliably and efficiently, extending its lifespan and maintaining the overall performance of your vehicle's fuel system.

Jeep Grand Cherokee Fuel Line Sizes: A Comprehensive Guide

You may want to see also

Frequently asked questions

The ideal location for an in-line fuel pump is typically in the fuel tank, positioned directly after the fuel filter and before the engine's fuel injectors or carburetor. This placement ensures that the pump can efficiently draw fuel from the tank and deliver it to the engine when needed.

Yes, it is possible to install an in-line fuel pump outside the fuel tank, but it is generally not recommended. Placing the pump outside the tank may lead to increased fuel line pressure, potential leaks, and reduced fuel efficiency. It is best to keep the pump within the tank for optimal performance and safety.

In-line fuel pumps offer several advantages. They provide a consistent fuel supply to the engine, ensuring better performance and fuel efficiency. These pumps are also more compact and can be easily integrated into the fuel system without requiring extensive modifications. Additionally, in-line pumps often have longer lifespans compared to traditional external pumps.