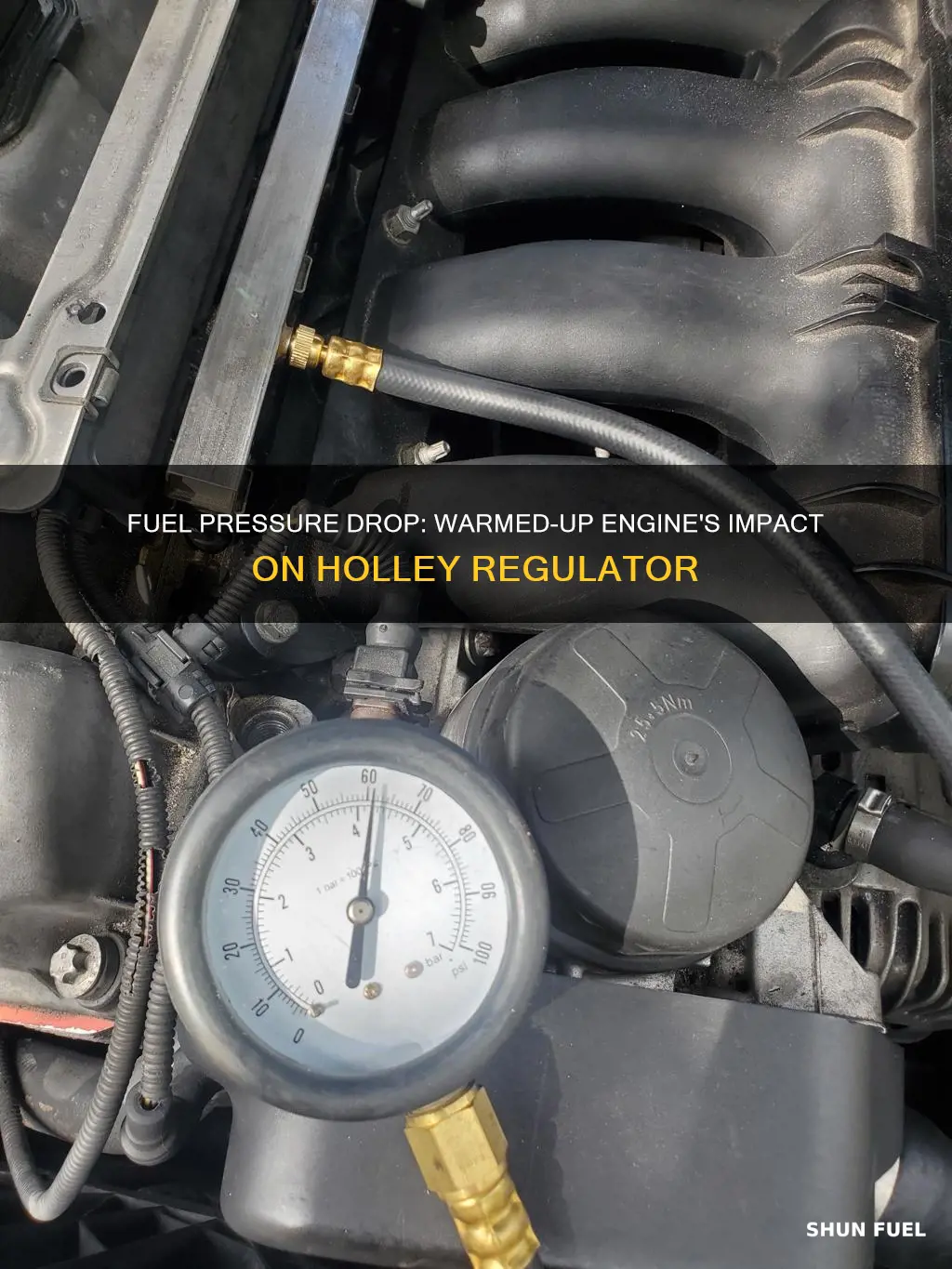

When the engine of a car warms up, the fuel pressure drops. This issue can be caused by a faulty fuel pressure regulator. Fuel pressure regulators are designed to maintain the appropriate fuel pressure for either carbureted or EFI engines. However, not all fuel pumps require a pressure regulator. Low-pressure electric fuel pumps, for instance, can feed a mild carbureted application without the need for a regulator.

In the case of a faulty fuel pressure regulator, there are a few troubleshooting steps that can be taken. First, check the fuel lines for any restrictions or blockages. This includes ensuring that the lines are not too close to the exhaust or any other heat sources. If the fuel lines appear clear, the next step is to check the fuel pump. It is possible that the fuel pump is not delivering enough pressure or volume to the regulator. Adjusting the fuel pressure regulator may also be necessary. This can be done by loosening the lock nut and turning the adjusting Allen stud.

It is important to note that fuel pressure regulators are designed to operate within specific pressure ranges, and using a regulator outside of its specified range can lead to issues. Additionally, the type of regulator used (deadhead or return style) can also impact fuel pressure. Deadhead regulators are normally open, while return-style regulators are normally closed until the pressure limit is reached.

In conclusion, a drop in fuel pressure when the engine warms up can be caused by a faulty fuel pressure regulator, restrictions in the fuel lines, or issues with the fuel pump. By following the troubleshooting steps outlined above, the root cause of the issue can be identified and addressed.

| Characteristics | Values |

|---|---|

| Fuel pressure | 7 lbs at idle |

| Fuel pressure when warmed up | Drops to 4 lbs or 3 lbs |

| Fuel filter when pressure drops | Does not fill completely, sometimes just pulses and bubbles |

| Pressure drops to | Zero sometimes |

| Engine | 440/493, MP 528 cam, 2" headers, 3" exhaust, Holley mechanical pump |

| A/F tuned | With a wideband gauge |

| Fuel line connections | Secure |

| Gas tank and sender | New in 2003 |

| Car behaviour when cruising | Runs fine |

| Car behaviour when at WOT | Stumbles sometimes |

| Previous pump | Carter pump |

| Previous pump reading | 11 lbs at idle |

| Return line | 1/4" vent line |

| Fuel line | 3/8" |

Fuel line heat

To prevent fuel line heat, it is essential to ensure that the fuel lines are properly insulated and routed away from potential heat sources. This can be done by using heat shields or sleeves, which are available in a variety of materials such as aluminium, stainless steel, and basalt. These shields can be placed around the fuel lines to reflect and absorb heat, preventing it from reaching the fuel.

Another solution to fuel line heat is to use an inline fuel heater, which preheats the fuel before it reaches the injection pump. This can improve fuel burn, increase power, and reduce smoke. Additionally, some fuel heaters can also help prevent fuel gelling, which occurs when fuel reaches low temperatures and wax crystals form, blocking the flow of fuel.

In some cases, a return-style fuel delivery system may be advantageous. This system returns excess fuel to the tank, reducing fuel temperature and minimising the risk of vapor lock. This type of system is often used in high-horsepower, carbureted drag cars to prevent temporary pressure drops on the starting line.

When dealing with fuel line heat, it is crucial to monitor fuel pressure and make adjustments as needed. This can be done using a fuel pressure gauge, which can be temporarily tee'd in or permanently plumbed into the fuel line. By making these adjustments, you can ensure that your engine receives the optimal fuel pressure for its specific requirements.

Fuel Filter Element: High-Pressure Performance and Maintenance

You may want to see also

Vapor lock

Most modern engines are equipped with fuel injection and have an electric submersible fuel pump in the fuel tank, which helps prevent vapor lock since the entire fuel delivery system is under positive pressure and the fuel pump runs cooler. For this reason, some carbureted engines are retrofitted with an electric fuel pump near the fuel tank.

To prevent vapor lock, it is recommended to isolate fuel lines from sources of heat, such as long-tube headers, and to use a fuel with a lower Reid Vapor Pressure (RVP), which is a measure of a fuel's propensity to evaporate.

Fuel Pressure Maintenance for Peterbilt Trucks

You may want to see also

Fuel pump push rod

A fuel pump push rod is a component of an engine that helps to maintain the fuel pressure and ensure the smooth flow of fuel to the carburetor or fuel injectors. In some cases, issues with the fuel pump push rod can lead to a drop in fuel pressure when the engine warms up.

A fuel pump push rod is a vital component of the fuel delivery system in an engine. It connects the fuel pump to the engine's fuel system, enabling the pump to deliver fuel at the required pressure. The push rod is typically made of durable materials such as chromoly or blended carbon polymer, ensuring it can withstand the high pressures and temperatures in the engine compartment.

When choosing a fuel pump push rod, it is important to select one that is compatible with your vehicle's specific make and model. Push rods come in various lengths and diameters to fit different engines. It is also essential to consider the tip material, which can be made of bronze or steel to withstand the constant contact with the camshaft.

In some cases, a worn-out or faulty fuel pump push rod can lead to a drop in fuel pressure, especially when the engine warms up. As the push rod wears down, it may not provide the necessary force to maintain the fuel pressure, resulting in a decrease in performance. Additionally, a faulty push rod can cause the fuel pump to work harder, leading to potential overheating issues and reduced fuel efficiency.

To address a drop in fuel pressure due to a faulty fuel pump push rod, it is recommended to inspect the push rod for signs of wear and replace it if necessary. It is also crucial to refer to the vehicle's service manual or seek professional assistance to ensure the correct push rod is selected and installed properly.

Fuel Pressure Maintenance for 1999 Blazers: What You Need to Know

You may want to see also

Fuel tank venting

The fuel tank venting system typically consists of a vent valve or vent tube that connects the fuel tank to the atmosphere. This vent allows air to enter the tank as fuel is consumed, maintaining a balanced pressure. It also allows vapours from the fuel to escape, preventing a build-up of pressure that could lead to leaks or damage.

The venting system should be designed to prevent the release of fuel vapours into the environment, as they can be harmful and contribute to air pollution. Modern vehicles often employ carbon canisters or other vapour recovery systems to capture and store these vapours, ensuring they are not released directly into the atmosphere.

When choosing a fuel pressure regulator, it is important to consider the type of fuel delivery system in your vehicle. Holley offers a range of fuel pressure regulators for both carbureted and EFI fuel systems. For carbureted applications, you can choose between deadhead (or blocking) regulators and return-style regulators. Deadhead regulators are simpler and more cost-effective, while return-style regulators offer more precise fuel pressure control and are better suited for high-performance engines.

Return-style regulators are commonly used in EFI systems and feature a dedicated return port to circulate excess fuel back to the tank. This helps maintain fuel temperature and reduces the load on the fuel pump. It is important to note that blocking the return port on a return-style regulator can lead to dangerous fuel pressure spikes.

Cleaning Fuel Pump Pressure: Tips and Tricks

You may want to see also

Fuel hose collapse

A fuel hose collapse can be caused by a variety of factors. One of the main causes is the ethanol that is present in the fuel. The ethanol causes the rubber in the hoses to break down over time, leading to a softening of the hoses. This makes them more susceptible to collapsing under low pressure or when exposed to high temperatures. The breakdown of the rubber can also result in the formation of a thick, sticky substance that can clog fuel filters and other components.

Additionally, the design of the fuel hose itself can contribute to its collapse. If the hose is not installed correctly or becomes twisted, it can kink or collapse due to the suction created by the fuel pump. This is more likely to occur if the hose is old or made of soft material. To prevent this, it is recommended to install a spring inside the hose to provide internal support and ensure proper installation of all fuel system components.

Another factor that can lead to fuel hose collapse is a low coolant level in the cooling system. When the engine is warm, the cooling system pressure increases. However, when the system cools down, a vacuum is created, causing the hoses to collapse. Therefore, it is important to periodically inspect the cooling system and maintain adequate coolant levels.

In some cases, the fuel pump itself may be the cause of the problem. A faulty fuel pump can create a lot of suction, which can lead to the collapse of a soft or twisted hose. Regular maintenance and replacement of fuel hoses, especially in regions with ethanol-blended fuel, can help prevent issues related to fuel hose collapse.

Fuel Pressure in Audi S5: How Much is Needed?

You may want to see also

Frequently asked questions

A return line is required for a bypass-type regulator. A deadhead regulator does not use one. A deadhead regulator is ok for street use. If you do a lot of full-throttle driving, you will find a bypass type is the only way to keep the float bowl full all the time.

You need to have the fuel pressure gauge mounted where you can see it while driving. The Holley 12-804 (1-4 psi) and 12-803 (4.5-9 psi) regulators are the same except for the spring, so buying the repair kit 12-807 will give you both low and high-pressure springs along with a diaphragm. You cannot adjust the regulator without the engine running.

Carburetors are designed to operate on internal combustion engines using the vacuum created by the motor through venturi, as air flows through the carburetor's throttle body. Carburetors (unlike fuel injection) do not operate under pressure. The fuel supply to a carburetor only needs to fill and maintain the float bowl(s). Most carburetor’s normal inlet operating pressure is 3 - 5psi (pounds per square inch).