Brake lines are an essential part of a car's braking system, converting the force from the brake pedal into stopping power. While they rarely get much attention, they are crucial for road safety. Rusted brake lines can be a potential risk and even cause the brake system to fail completely. Therefore, it is important to know when to replace them. This paragraph will discuss the signs that indicate it's time to replace rusted brake lines and provide an overview of the replacement process, ensuring that your vehicle remains safe and reliable on the road.

What You'll Learn

How to identify rusted brake lines

Rusted brake lines can be a serious safety hazard, so it's important to identify and address the issue promptly. Here are some detailed steps and guidelines on how to identify rusted brake lines:

Visual Inspection

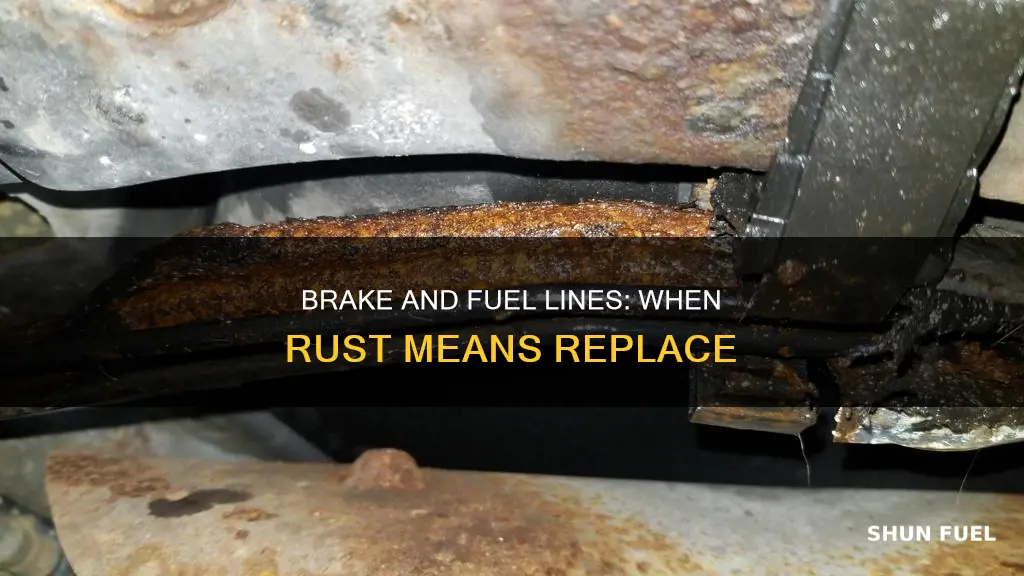

Start by visually inspecting your brake lines for any signs of rust or corrosion. Brake lines are typically located under the car, where they are susceptible to dirt, salt, and moisture, which can accelerate corrosion. Look for any discolouration, flaking, or pitting on the metal surfaces of the brake lines. In some cases, you may need to remove the wheels to access and inspect the brake lines more thoroughly.

Surface Rust vs. Serious Corrosion

It's important to distinguish between surface rust and serious corrosion. While surface rust is generally acceptable and can be treated, serious corrosion indicates a more advanced stage of deterioration and requires immediate attention. If you notice extensive pitting, deep cracks, or significant material loss, it's a clear sign that the brake lines need to be replaced.

Brake Fluid Leaks

Brake fluid leaks are a telltale sign of potential brake line rust and imminent failure. Inspect the areas around the brake lines for any signs of leaking fluid. Brake fluid is typically clear or slightly amber-coloured and may appear oily. If you notice any leaks, it's crucial to address them immediately, as they can compromise the braking system's performance.

Brake Performance and Pedal Feel

Pay attention to any changes in brake performance or the feel of the brake pedal. Rusted brake lines may cause a soft or spongy brake pedal, increased brake pedal travel, or poor braking performance. If you experience any of these symptoms, it could indicate that the brake lines are compromised and need to be inspected and potentially replaced.

Warning Lights

Modern vehicles are equipped with advanced warning systems. If you notice a warning light on your dashboard related to the braking system, don't ignore it. This could be an early indication of a problem, including potential issues with the brake lines. Have your vehicle diagnosed by a qualified mechanic to identify the exact cause.

Preventative Maintenance

Regular preventative maintenance can help identify rusted brake lines before they become a serious issue. Periodically inspect your brake lines, especially if you live in an area with cold winters or frequent rain, as these conditions can accelerate corrosion. Consider applying anti-rust coatings or spray paint to the brake lines to protect them from the elements. Additionally, regular brake fluid changes can help prevent internal corrosion within the brake lines.

Remember, rusted brake lines can compromise your safety and that of other drivers. If you suspect any issues with your brake lines, it's always best to have them inspected and addressed by a qualified mechanic or automotive specialist.

Replacing Fuel Pump Sending Unit: Step-by-Step Guide for Beginners

You may want to see also

The dangers of driving with rusted brake lines

Brake lines are an essential component of a car's braking system. They are designed to connect the brake system and run the length of the car, transferring the force from your foot on the brake pedal to the brake system itself. This system uses brake fluid to apply pressure to the brake calipers, creating friction between the rotor and the brake pads, which slows the car down and brings it to a stop.

Rusted brake lines can be extremely dangerous and even cause your brake system to fail completely. When brake lines corrode, they are susceptible to leaking brake fluid. This means that when you step on the brake pedal, there may not be enough pressure to activate the brake calipers and bring your car to a stop. This could result in a sudden loss of the ability to slow down or stop, which could lead to a collision or accident.

Brake lines are typically made of steel tubing or stainless steel, which is covered with plastic to prevent corrosion. However, they can still be susceptible to rust, especially in cold climates where salt is used on icy roads. The salt, combined with moisture, can accelerate the corrosion process. Abrasion is another common cause of rusted brake lines, as it can damage the outer protective layer, exposing the metal to air and external substances, leading to serious rust.

To prevent rusted brake lines, it is important to maintain and check them regularly, especially in winter. You can also coat the brake lines with anti-rust spray paint or use stainless steel or nickel-copper instead of steel, as these materials are more resistant to corrosion. Additionally, regularly changing the brake fluid and washing the undercarriage of your car during winter can help remove corrosive salts and reduce the risk of rust.

If you notice any signs of rust on your brake lines, it is crucial to address the issue immediately. Depending on the severity of the rust, you may need to replace the entire brake line or take your car to a repair shop for professional assistance. Driving with rusted brake lines is not only dangerous but can also put your safety and the safety of others at risk.

Replacing the Fuel Pump Relay in Your 2010 Acura RDX

You may want to see also

Steps to replace brake lines

Step 1: Source the Leak and Remove the Faulty Line

Use a jack to lift your car and fix all four corners. If there is a leak near a wheel, remove it. Inspect the brake lines to locate the corroded line and wear safety glasses to prevent debris from entering your eyes. Use a wrench to unscrew both ends of the brake line. If the nuts are rusted, spray some oil to make the process easier. Have a rag ready to wipe up any spilled liquid.

Step 2: Prepare the New Lines

Measure the length of the old brake lines with a ruler or measuring tape, being careful with the bends to ensure accuracy. Cut the new brake line to the required length, leaving about 1/4 inch for flaring.

Step 3: Bend the New Brake Lines

You can bend the new brake line by hand, based on the old line. For major bends, you may need a machine, especially if the brake line is made of tough materials like copper. Before bending, slide a new fitting onto the line and use crimping pliers to make the first bend.

Step 4: Flare the New Brake Line

Put on the fitting carefully before flaring the new brake line. Ensure the fitting meets the manufacturer's specifications. Choose a suitable adapter to match the size of the brake line. Tighten the clamp to prevent the brake line from slipping.

Step 5: Install the New Brake Line

Connect the new brake line to the coupler, matching the old and new lines with an adapter. Hold the link with an open-ended wrench and tighten each joint with a flare wrench.

Step 6: Bleed the System of Air

Fill the master cylinder reservoir with fluid and bleed the brake system of air. Ensure all connections are tight before driving your vehicle.

When to Replace Your Fuel Pump: Proactive Maintenance Tips

You may want to see also

How to prevent brake lines from rusting

Brake lines are made of steel tubing or stainless steel and are always covered with plastic to prevent corrosion. However, they are still susceptible to rust, especially in cold climates where salt is used on the roads. Here are some tips to help prevent your brake lines from rusting:

Use Anti-Corrosion Materials

Coat the brake lines with anti-rust spray paint or an anti-corrosion product like NH Oil Undercoating, which lifts and removes dirt, moisture, and contaminants while forming a protective layer on the metal. You can also use stainless steel or nickel-copper brake lines, as these materials are more resistant to corrosion than steel.

Regular Maintenance

Take your car to a service centre to have the underbody checked for rust periodically. It is recommended to wash and clean the undercarriage during winter to remove corrosive salts from the road. Additionally, consider changing the brake fluid every two years or sooner, as brake fluid accumulates deposits over time, which can cause internal corrosion.

Protective Coatings

Before applying any coatings, clean the brake lines with alcohol to remove dirt and contaminants. You can use a product like POR15, which bonds with and changes the metal, making it impervious to rust. However, be careful not to get it on the fittings, as it will weld the pieces together. You can also use a spray-on undercoating, which has been shown to protect brake lines from corrosion for many years.

Hydrogen: A Viable Alternative to Fossil Fuels?

You may want to see also

The importance of regular brake line checks

Brake lines are an essential component of a car's braking system. They connect the brake system and run along the length of the car, transferring the force from your foot on the brake pedal to the brake system itself. This force is what brings your car to a stop. Therefore, it is crucial to regularly check your brake lines for any signs of deterioration or damage, as a failing brake line can be extremely dangerous and even cause your brake system to fail completely.

Brake lines are made of metal, usually steel tubing or stainless steel, and are covered with plastic to prevent corrosion. However, they are still susceptible to rust and corrosion, especially in environments with salt or moisture. Over time, salt, heat, and moisture can accelerate the corrosion process, weakening the brake lines and making them prone to leaking brake fluid. A leaking brake line can lead to a sudden loss of braking ability, posing a significant safety risk to you and other road users.

To ensure your safety, it is recommended to periodically inspect your brake lines for any signs of corrosion or damage. Start by raising your vehicle to get a clear view of the underside. Check the brake lines and hoses for any dark stains or wetness, which could indicate leaking brake fluid. Also, pay close attention to the areas where the brake lines are fastened to the chassis and suspension, as these are common spots for rust to occur. If you notice any rust or suspect corrosion, carefully remove the affected section and inspect it further.

Even if there is no apparent leak, it is crucial to proactively address any signs of deterioration. Surface rust is normal, but if you notice deep pitting or softening of the brake line, it's time to replace it. Replacing a rusted brake line is a relatively straightforward process that can be done at home with the right tools and knowledge. However, if you are unsure or uncomfortable with the procedure, it is always best to consult a professional mechanic.

By conducting regular brake line checks and addressing any issues promptly, you can help ensure the safety and reliability of your vehicle's braking system, giving you peace of mind whenever you're behind the wheel.

Replacing Fuel Filter in 2004 Chevy Silverado: Step-by-Step Guide

You may want to see also

Frequently asked questions

Start by raising your vehicle to get a look at the underside. Check the brake lines and hoses for dark stains from dried brake fluid or wetness from actively leaking brake fluid. If there is a sudden drop in the reservoir fluid level, this generally indicates a fluid leak.

If you find rust or suspect that rust is eating at the line, pop the lines out of their body clips and inspect for corrosion. If there is notable deep pitting, it's time to replace your brake line.

Rusted or damaged brake lines can be a potential risk when you are behind the wheel and can even cause your brake system to fail completely.