Testing fuel pressure is an essential part of fuel injection system troubleshooting. A fuel pump is a critical component of a car's powertrain system, transferring petrol or diesel from the fuel tank to the engine's injectors. A malfunctioning fuel pump can cause a lack of power output from the engine and, in some cases, show signs of failure before a complete breakdown. To test fuel pressure, you will need to park your vehicle, apply the parking brake, and allow the engine to cool down. Then, locate the fuel pressure test port and install a pressure tester. Turn on the ignition and run the engine at a specific RPM. Check the pressure reading and compare it to the manufacturer's specifications. A typical port-injected vehicle requires fuel pressure between 30 and 80 PSI, but this can vary depending on the engine and vehicle. If the fuel pressure drops over time, it indicates a leak in the fuel system. If the fuel pump doesn't meet the required pressure specifications, it may be failing to pump fuel to the engine, and you should consult an expert mechanic.

| Characteristics | Values |

|---|---|

| Engine type | Throttle-body injected systems, multi-port injection, LT1 V8, LS1 V8, port-injected vehicle, direct injection fuel systems, regular pressure fuel injection system, GM, Ford, Chrysler, throttle body injection (TBI), central fuel injection (CFI) |

| Fuel pressure reading | Between 10-60 psi, depending on the engine. LT1 V8 in the 1996 Corvette: 40-42 psi. LS1 V8: 58 psi. Port-injected vehicle: 30-80 PSI. Direct port injection systems: 45-58 psi. Throttle body injection: 13-17 psi. |

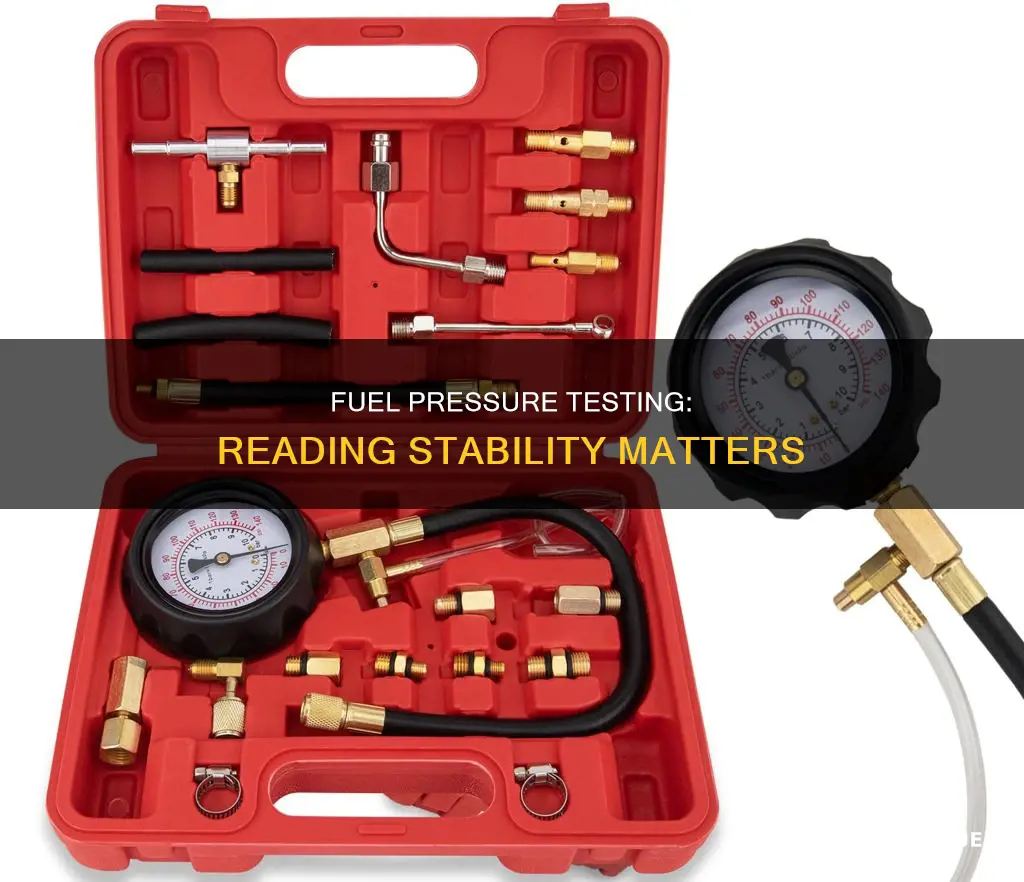

| Fuel pressure tester | A gauge attached to a fuel hose and multiple fittings. |

| Fuel system components | Fuel pump, fuel pressure regulator, fuel injectors, pressure line, return line |

| High fuel pressure readings | Faulty fuel pressure regulator, restrictions in return line, faulty fuel line couplings at the fuel tank |

| Low fuel pressure readings | Clogged or restricted fuel filter, restriction in pressure line, faulty fuel pump relay, bad fuel pump fuse, faulty fuel pump wiring, clogged or restricted fuel pump filter, faulty fuel pressure regulator, leaking fuel injectors, faulty fuel line couplings at the fuel tank |

| Fuel pressure test | Start the car and let it idle. Install a fuel pressure gauge, run the pump, and note the pressure reading. Compare it to the manufacturer's specification. |

What You'll Learn

Safety precautions when testing fuel pressure

Testing fuel pressure can be dangerous, so it is important to take safety precautions. Here are some detailed safety precautions to follow when testing fuel pressure:

Wear Protective Gear:

- Always wear safety glasses and gloves to protect your eyes and skin from fuel and debris.

- Consider wearing a long-sleeved shirt and pants to avoid direct skin contact with fuel.

- Ensure you are in a well-ventilated area to avoid inhaling fumes.

Prevent Fires and Spills:

- Disconnect the negative battery cable before beginning any testing or repairs to prevent sparks.

- Release the pressure in the fuel lines and relieve residual fuel pressure before starting.

- Wipe up any fuel spills immediately, especially on engine surfaces, as they can ignite when the car is running.

- Keep a Class B fire extinguisher nearby, as fuel fires cannot be extinguished with water.

Handle Fuel Lines and Fittings Carefully:

- Wrap a shop towel around fuel line fittings before loosening them to absorb any leaking fuel.

- Use two wrenches when loosening or tightening fuel line fittings to minimise stress on the lines.

- Inspect O-rings and replace them if worn.

- Do not replace fuel pipes with fuel hoses or equivalent components.

Store Excess Fuel Properly:

- Use containers approved by Underwriters Laboratories for storing fuel.

- Ensure the containers are airtight and will not react chemically with the fuel.

Additional Precautions:

- Do not smoke or have any sources of sparks or flames nearby when working with fuel.

- Check the manufacturer's manual for specific safety instructions related to your vehicle.

- Be cautious when working with high-pressure fuel systems to prevent fuel from penetrating your skin.

The Benefits of Pressure Vacuum Fuel Caps

You may want to see also

How to test fuel pressure

Testing fuel pressure is a simple process that can help identify fuel-related issues with your car. Here is a step-by-step guide on how to test fuel pressure:

Step 1: Prioritise Safety

Fuel under pressure can be dangerous, so safety should be the top priority. Wear safety gear such as gloves and goggles, and work in a well-ventilated area to minimise the risk of fire and injury. Do not smoke or do anything that could create a spark.

Step 2: Check Fuel Pressure

Start by checking the fuel pressure. Start your car and let it idle. Install a fuel pressure gauge and run the pump to get a pressure reading. Compare this reading to the manufacturer's specifications. If the pressure is low, you may need to address potential issues. If the pressure is sufficient, you can move on to the next step.

Step 3: Perform a Fuel Volume Test

To ensure the proper amount of fuel is being delivered to the fuel injectors, perform a fuel volume test. Use a flowmeter for the most accurate results. If you don't have access to a flowmeter, you can perform a timed fuel delivery test using a glass measuring container.

Start the car and collect a fuel sample for a specified duration (e.g., five seconds) with the pump running. Compare the amount of fuel delivered to the manufacturer's specifications to determine if the correct amount is being delivered. You may need to convert units (e.g., milliliters per second to gallons per hour) for this comparison.

Step 4: Understand Fuel Pressure Readings

Zero fuel pressure indicates that the pump is not functioning due to a lack of power. Check the fuel pump fuse and verify power to the pump using a multimeter. If power is present, replace the fuel pump.

Low fuel pressure can be caused by a clogged fuel filter or a failing pump. Replace the fuel filter if it is a serviceable type. It could also be due to improper tank venting or a loose gas cap. Check the gas cap gasket for damage and tighten it securely.

High fuel pressure may be caused by a clogged or kinked fuel return line, a faulty fuel pump driver module, or a powertrain control module. These issues often trigger a "check engine" light and store a code. High fuel pressure can also result from a faulty fuel pressure regulator.

Step 5: Take Necessary Actions

Based on your fuel pressure readings and the identified issues, take the necessary actions. This may involve replacing the fuel pump, fuel filter, or other relevant components. If you are unsure or uncomfortable performing these tasks yourself, consult a professional mechanic for assistance.

Understanding Fuel Injection: Defining Normal Injection Pressure

You may want to see also

Interpreting fuel pressure readings

- Zero fuel pressure: This usually indicates that the fuel pump is dead or not receiving power. Check the fuel pump fuse, verify power to the pump with a multimeter, and replace the pump if necessary.

- Low fuel pressure: Low fuel pressure can be caused by a clogged fuel filter or a failing pump. It could also be due to improper tank venting or a loose gas cap. Start by checking the fuel filter and changing it if necessary. Also, ensure the gas cap is tight and the cap gasket is not damaged.

- High fuel pressure: High fuel pressure can be caused by a clogged or kinked fuel return line, a faulty fuel pump driver module, or a powertrain control module. It could also be due to a faulty fuel pressure regulator. Check for any stored codes and look for a "check engine" light.

- Fluctuating fuel pressure: If the fuel pressure reading fluctuates significantly, such as by 20% or more, it could indicate an issue with the fuel system. However, it is important to note that electric fuel pumps and regulators rarely lose pressure and usually fail altogether.

- Manufacturer specifications: Always refer to the manufacturer's specifications for the required fuel pressure for your specific vehicle. The required pressure can vary significantly depending on the engine and vehicle. For example, older throttle-body injected systems may need as little as 10 psi, while multi-port injection systems can see up to 60 psi.

- Fuel gauge accuracy: Several factors can impact the accuracy of your fuel gauge readings, including driving habits, road conditions, weather, and vehicle maintenance. Regularly check and maintain your vehicle to ensure optimal fuel efficiency.

- Fuel system troubleshooting: If you are experiencing fuel-related issues, it is important to check the entire fuel system, including the fuel pump, fuel filter, fuel lines, and fuel injectors. Fuel pressure testing can help identify potential problems and ensure the smooth performance of your engine.

Fuel Rail Pressure Drop: Causes and Solutions

You may want to see also

What to do if fuel pressure is low

When testing fuel pressure, the reading is supposed to hold. If the pressure is low, there are several steps you can take to address the issue.

Firstly, it is important to identify the potential causes of low fuel pressure. This can include a clogged fuel filter, a failing pump, improper tank venting, or a leaking fuel injector. In some cases, low fuel pressure may be due to a defective fuel pressure regulator or a loose gas cap. It is also possible that the fuel tank is empty, so ensure that there is fuel in the tank before proceeding.

If you suspect that the issue is related to the fuel pump, there are several tests you can perform. Begin by verifying that the fuel pump is operational. To do this, locate the fuel tank and have an assistant turn the ignition switch to "On." Listen for a two-second whir, hum, or series of rapid clicks, which indicates that the fuel pump is pressurizing the fuel line to the engine. If no sound is heard, check the fuel pump fuse and relay. If both are functional, inspect the wiring to the pump and ensure that voltage is present when turned on.

If the fuel pump appears to be functioning properly, the next step is to test the fuel pressure. This can be done using a fuel pressure tester or a fuel pressure gauge. Connect the tester or gauge to the Schrader valve fitting on the fuel rail, ensuring a leak-proof fit. Turn the ignition to "On" and observe the pressure reading. A steady fuel pressure that is within a few psi of the recommended pressure indicates that the fuel system is functioning properly.

If the fuel pressure is still low, there are a few additional steps you can take. Check the manufacturer's manual for specific instructions on pressure testing the fuel pump, as some vehicles may require testing with the engine running at a particular RPM. You can also refer to a repair manual or the internet to find the recommended fuel pressure range for your vehicle. If the fuel pump is unable to meet the required pressure specifications, it may be failing and should be inspected by a mechanic.

In summary, addressing low fuel pressure involves identifying potential causes, testing the fuel pump and fuel pressure, and referring to manufacturer guidelines. If issues persist, it is recommended to consult a professional mechanic for further diagnosis and repair.

Understanding Fuel Rail Pressure Sensor: Circuit High Input Meaning

You may want to see also

What to do if fuel pressure is high

High fuel pressure can cause issues with your car's engine and performance. If you suspect your car is experiencing high fuel pressure, there are several steps you can take to address the problem and prevent further damage.

Firstly, it is important to recognise the symptoms of high fuel pressure. These can include:

- Black smoke coming from the exhaust pipe

- A strong smell of unburned fuel

- Poor fuel economy

- Rough idling or stalling

- Engine misfires

- Check Engine Light is on

If you notice any of these symptoms, it is recommended to take your car to a trusted mechanic or auto repair shop specialising in fuel systems. A qualified mechanic will have the necessary tools and expertise to diagnose and resolve the issue.

However, if you want to try and diagnose the issue yourself, there are some potential causes of high fuel pressure that you can check. One common cause is a faulty fuel pressure regulator. The fuel pressure regulator is responsible for maintaining consistent fuel pressure, and if it malfunctions, it can lead to excessive pressure. Another possible cause is a clogged or restricted fuel filter, which can obstruct the flow of fuel and increase pressure. A malfunctioning fuel pump or a restricted fuel return line can also lead to high fuel pressure.

To fix the issue, you may need to replace or repair the faulty component. For example, if the issue is a clogged fuel filter, replacing it may resolve the problem. However, it is important to note that working on fuel systems can be dangerous, and you should always put safety first. Make sure to wear appropriate protective gear, work in a well-ventilated area, and avoid any sources of sparks or flames.

Duramax LMM Fuel Rail Pressure: Too Much?

You may want to see also