Fuel pressure regulators are an imperative component of any vehicle's fuel system, responsible for maintaining the proper pressure of fuel delivered to the engine. When referring to fuel pressure regulators, some vehicles have a crucial component that ensures the fuel delivered to the engine's injectors remains at the optimal pressure level. This component is called the fuel pressure regulator.

| Characteristics | Values | |

|---|---|---|

| Purpose of a fuel pressure regulator | To maintain a consistent fuel pressure within a vehicle's fuel system | To ensure the fuel delivered to the engine's injectors remains at the optimal pressure level |

| Function of a fuel pressure regulator | Ensure the right amount of fuel reaches the engine | Prevent issues like over-pressurization and under-pressurization |

| Types of fuel pressure regulators | Mechanical regulators, electronic regulators | Mechanical regulators are typically used in older vehicles, electronic regulators are found in modern fuel-injected engines |

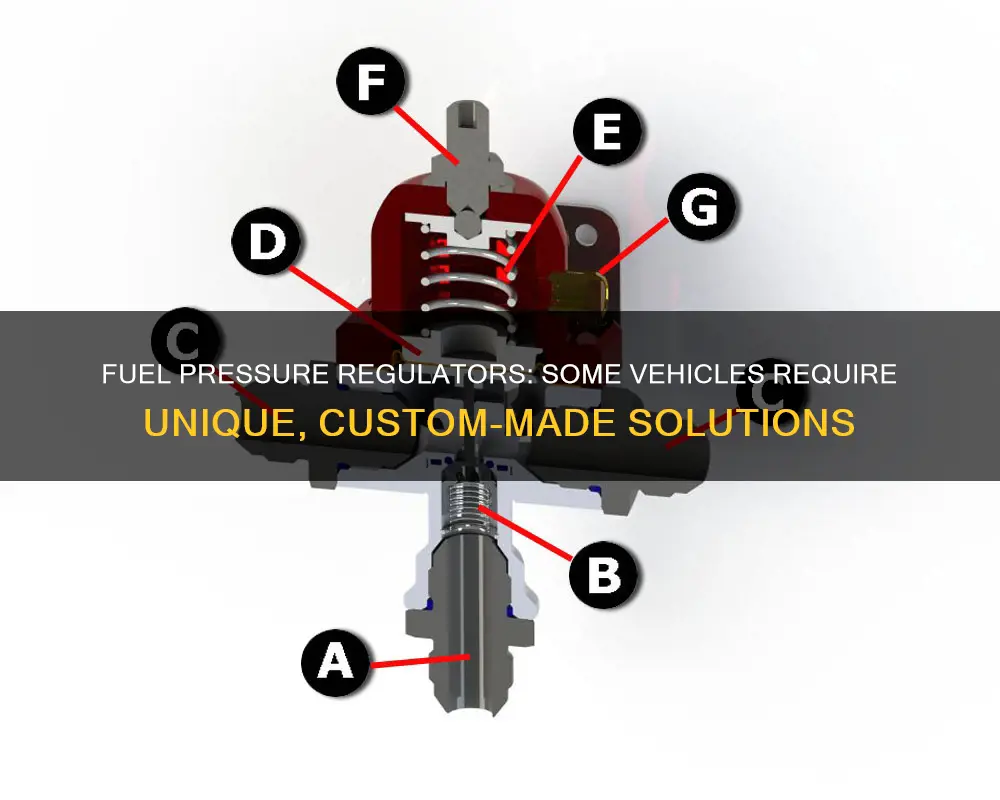

| Components of a fuel pressure regulator | Diaphragm, spring, valve, fuel inlet and outlet ports, adjustment screw (for adjustable regulators), vacuum port (in vacuum-referenced regulators), fuel return line (for return-type systems), housing | N/A |

What You'll Learn

- Are essential for maintaining fuel system stability and preventing performance issues?

- Ensure the engine receives the correct amount of fuel for optimal performance

- Are crucial for achieving proper air-fuel ratios, necessary for efficient combustion and engine performance?

- Prevent over-pressurisation, which can cause flooding, and under-pressurisation, which can lead to fuel starvation

- Come in two main types: mechanical and electronic

Are essential for maintaining fuel system stability and preventing performance issues

Fuel pressure regulators are essential for maintaining fuel system stability and preventing performance issues. They ensure that the fuel delivered to the engine's injectors remains at the optimal pressure level, allowing for efficient combustion and optimal engine performance.

The fuel pressure regulator controls the pressure by adjusting a valve that allows excess fuel to return to the fuel tank. This ensures that the engine always receives the correct amount of fuel, preventing issues such as over-pressurization or under-pressurization.

If the fuel pressure is too low, the engine can experience fuel starvation, leading to misfires and power loss. On the other hand, excessive fuel pressure can flood the engine, causing performance issues or even damage.

There are two main types of fuel pressure regulators: mechanical regulators and electronic regulators. Mechanical regulators are typically used in older or simpler systems, while electronic regulators are found in modern fuel-injected engines. Electronic regulators work in tandem with the engine control unit (ECU) to adjust fuel pressure based on real-time engine demands.

In summary, fuel pressure regulators play a critical role in ensuring a balanced and efficient fuel delivery system. By maintaining the right fuel pressure, they prevent performance issues and potential engine damage, contributing to a smooth-running and reliable vehicle.

Fuel Pump Pressure Essentials for the Classic 73Beetle

You may want to see also

Ensure the engine receives the correct amount of fuel for optimal performance

A fuel pressure regulator is a crucial component in any vehicle's fuel system. It ensures the engine receives the correct amount of fuel for optimal performance. Here are some key points to understand its function and importance:

Function of Fuel Pressure Regulators:

- Fuel pressure regulators maintain the correct fuel pressure within the fuel system, ensuring the engine receives the right amount of fuel.

- They control the pressure by adjusting a valve, allowing excess fuel to return to the fuel tank.

- This prevents issues like over-pressurization, which can cause flooding, and under-pressurization, leading to fuel starvation.

- The perfect ratio of fuel to air is 1:1, and fuel pressure regulators help maintain this balance.

Types of Fuel Pressure Regulators:

- There are two main types: mechanical regulators, commonly found in older vehicles, and electronic regulators in modern fuel-injected engines.

- Mechanical regulators use physical components like springs, diaphragms, and valves to control fuel pressure.

- Electronic regulators work with the Engine Control Unit (ECU) to dynamically adjust fuel pressure based on real-time engine demands.

Importance of Fuel Pressure Regulation:

- Optimized Combustion: Fuel pressure regulators ensure the right amount of fuel at the correct pressure, creating an optimal air-fuel mixture for efficient combustion.

- Smooth Acceleration: They adjust fuel flow during acceleration or deceleration, ensuring smooth transitions without power surges or lags.

- Fuel Efficiency: By maintaining proper fuel pressure, regulators reduce fuel consumption and emissions, improving fuel efficiency.

- Preventing Fuel Starvation and Over-Pressurization: Regulating fuel pressure prevents engine issues such as misfires, stalling, rough idling, and excessive fuel consumption.

- Engine Protection: Improper fuel pressure can lead to engine damage. Excessive pressure can wash away cylinder wall oil, increasing friction and wear. Insufficient pressure can cause lean conditions, leading to overheating and engine knocking.

Symptoms of a Failing Fuel Pressure Regulator:

- Engine misfires, poor fuel economy, hard starting, and stalling can indicate a faulty regulator.

- Fuel leaks, either externally or internally (fuel mixing with oil), may also be a sign.

- Black smoke from the exhaust and unusual noises during idling can be warning signs.

Adjusting and Replacing Fuel Pressure Regulators:

- Adjustable fuel pressure regulators allow fine-tuning of fuel pressure for optimal engine performance, especially in high-performance vehicles.

- It is important to replace a faulty regulator promptly to prevent engine problems and ensure the longevity of the fuel system.

- When choosing a replacement regulator, consider the vehicle's make and model, fuel system specifications, and fuel type to ensure compatibility and optimal performance.

Fuel Pressure Regulator Failure: Effects and Solutions

You may want to see also

Are crucial for achieving proper air-fuel ratios, necessary for efficient combustion and engine performance

Fuel pressure regulators are essential for maintaining the correct air-fuel ratio, which is crucial for efficient combustion and engine performance. By ensuring the fuel injectors receive the right amount of fuel at the correct pressure, the regulators play a vital role in achieving optimal engine performance and fuel economy.

The fuel pressure regulator is responsible for maintaining a consistent fuel pressure within the vehicle's fuel system. It ensures that the fuel delivered to the engine's injectors remains at the optimal pressure level, regardless of variations in engine demand or external conditions. This regulation is critical for achieving the proper air-fuel ratio, which is necessary for efficient combustion.

The regulator controls the pressure by adjusting a valve that allows excess fuel to return to the fuel tank. It operates based on the pressure within the fuel system, opening or closing as needed to maintain the right balance. This ensures that the engine always receives the correct amount of fuel, preventing issues like over-pressurization or under-pressurization.

There are two main types of fuel pressure regulators: mechanical and electronic. Mechanical regulators are typically used in older or simpler systems, relying on physical components like springs, diaphragms, and valves to control fuel pressure. On the other hand, electronic regulators are found in modern fuel-injected engines and work in tandem with the engine control unit (ECU) to dynamically adjust fuel pressure based on real-time engine demands.

The importance of fuel pressure regulation cannot be overstated. When the fuel pressure is too low, the engine can experience fuel starvation, leading to misfires and power loss. Conversely, excessive fuel pressure can flood the engine, causing performance issues or even damage. A properly functioning regulator maintains a balanced fuel delivery system, ensuring smooth engine operation and preventing costly repairs.

Additionally, fuel pressure regulators can be adjusted to optimize engine performance, especially in high-performance or tuned vehicles. Adjustable regulators allow for fine-tuning of fuel pressure to match specific engine needs, ensuring that the engine receives the correct amount of fuel for optimal combustion and performance.

Understanding Fuel Pressure: The Average Car Owner's Guide

You may want to see also

Prevent over-pressurisation, which can cause flooding, and under-pressurisation, which can lead to fuel starvation

A fuel pressure regulator is an essential component in a vehicle's fuel system, responsible for maintaining the correct pressure of fuel delivered to the engine. It ensures that the fuel injectors receive the right amount of fuel at the optimal pressure, preventing issues like over-pressurisation and under-pressurisation.

Preventing Over-Pressurisation and Flooding

When the fuel pressure is too high, the fuel pressure regulator relieves the excess pressure to prevent over-pressurisation, which can cause flooding in the engine. This is achieved by allowing the excess fuel to return to the fuel tank via a return line in a return-type system or by recirculating it in a returnless system. Over-pressurisation can lead to the fuel injectors receiving more fuel than they can handle, causing them to fail. Additionally, excessive pressure can result in the fuel injectors spraying more fuel than the engine can burn, leading to increased friction and potential engine wear or failure.

Preventing Under-Pressurisation and Fuel Starvation

On the other hand, when the fuel pressure is too low, the fuel pressure regulator ensures that the fuel flow to the injectors is not restricted, preventing under-pressurisation. Under-pressurisation can lead to fuel starvation, where the engine does not receive enough fuel, resulting in poor acceleration, engine misfires, and stalling. Maintaining the correct fuel pressure ensures that the engine always has sufficient fuel, preventing issues like fuel starvation and ensuring optimal engine performance.

The Role of the Diaphragm and Spring

The fuel pressure regulator achieves this balance by utilising a diaphragm and a spring. The diaphragm, a flexible membrane inside the regulator, reacts to changes in fuel pressure. When the fuel pressure increases, the diaphragm pushes against the spring, opening a valve and allowing excess fuel to return to the fuel tank. Conversely, when the pressure is too low, the spring holds the valve closed, ensuring that fuel flows to the injectors at the correct pressure. This mechanism ensures that the engine receives the right amount of fuel, preventing both over-pressurisation and under-pressurisation.

Types of Fuel Pressure Regulators

There are two primary types of fuel pressure regulators: mechanical and electronic. Mechanical regulators, commonly found in older vehicles, operate through physical components like springs, diaphragms, and valves. On the other hand, electronic regulators, used in modern fuel-injected engines, work in tandem with the engine control unit (ECU) to dynamically adjust fuel pressure based on real-time engine demands, providing greater precision.

In summary, the fuel pressure regulator plays a critical role in preventing both over-pressurisation and under-pressurisation, ensuring the engine operates smoothly and efficiently. By maintaining the correct fuel pressure, the regulator helps to avoid issues such as flooding and fuel starvation, contributing to optimal engine performance and fuel efficiency.

Fuel Pressure Sweet Spot for Elderbrook Carburetors

You may want to see also

Come in two main types: mechanical and electronic

When referring to fuel pressure regulators, some vehicles come in two main types: mechanical and electronic. Mechanical fuel pressure regulators are commonly found in older vehicles with simpler fuel systems and basic fuel injection systems. They are also used in high-performance and racing vehicles where specific fuel pressure adjustments are required for engine tuning. Mechanical regulators operate through physical components like springs, diaphragms, and valves. A spring-loaded diaphragm senses changes in fuel pressure, and when the pressure exceeds the set limit, the diaphragm pushes open a valve, allowing excess fuel to return to the tank. The advantage of mechanical regulators is their simplicity and reliability, and certain models allow for adjustable pressure. However, they offer limited precision compared to electronic systems and are less responsive to dynamic changes in engine load.

On the other hand, electronic fuel pressure regulators are widely used in modern vehicles with advanced fuel injection systems. They work in tandem with the vehicle's engine control unit (ECU) to make real-time adjustments based on engine demand. Sensors in these regulators monitor fuel pressure and communicate with the ECU, which then adjusts the fuel pressure electronically. This results in more precise fuel delivery across various engine operating conditions. Electronic regulators are ideal for high-efficiency or turbocharged engines where precise fuel control is critical for performance and emissions control. They offer several benefits, including extremely precise fuel pressure control, better fuel efficiency, and automatic adjustments based on engine conditions. However, they are more expensive and complex than mechanical regulators, making them more difficult to repair or replace.

Fuel Pressure Specifications for 1995 GMC G2500 Models

You may want to see also

Frequently asked questions

A faulty fuel pressure regulator can cause issues with the fuel injectors, such as causing them to fail if too much fuel is forced into them. This can lead to engine misfires, poor fuel efficiency, and other issues.

If the fuel pressure regulator allows too much fuel into the engine, it can cause flooding and performance issues. The engine may also consume more fuel than necessary, leading to increased fuel consumption and costs.

If the fuel pressure regulator is not maintaining the correct fuel pressure, it can lead to fuel starvation, resulting in misfires, power loss, and potential engine damage. Maintaining the right fuel pressure is crucial for efficient combustion and optimal engine performance.