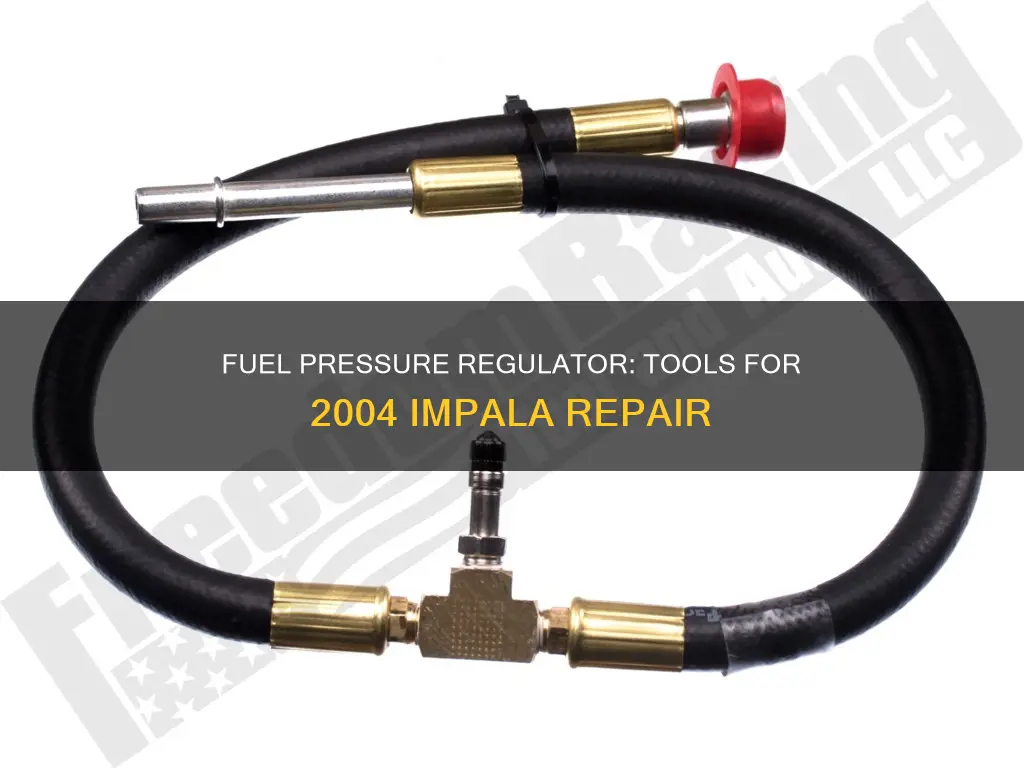

To replace the fuel pressure regulator on a 2004 Chevrolet Impala, you will need a few tools. These include a Torx bit set, a fuel line tool, and a rag to catch any spilled fuel. Additionally, you may want to use some Vaseline or engine oil to lubricate the O-rings on the new regulator. It is also recommended to relieve the fuel system pressure before beginning any work. This can be done by removing the fuel pump relay and allowing the engine to run out of fuel. You may also need to remove the upper intake manifold to access the fuel pressure regulator, which will require additional tools such as wrenches and sockets.

| Characteristics | Values |

|---|---|

| Tools needed | Torx bit set, fuel line tool, shop towel, new gasket, Loctite 262, Lisle or OEM plastic/metal quick disconnect fuel line tool, adjustable wrench, screwdriver, clean shop cloth, new pressure regulator O-ring, vacuum line, wrenches |

| Steps to replace the fuel pressure regulator | 1. Disconnect the negative battery cable. 2. Relieve the fuel system pressure. 3. Remove the upper intake manifold assembly. 4. Disconnect the vacuum line from the pressure regulator. 5. Remove the regulator retaining screw and remove the retainer bracket. 6. Using a clean shop cloth to catch fuel spillage, carefully pull the regulator from the fuel rail. 7. Twist the regulator slightly while removing to ease removal. 8. Discard the O-ring. 9. Clean all parts well. 10. Lubricate a new pressure regulator O-ring with clean engine oil and install on the regulator inlet. 11. Install the fuel return pipe to the regulator. 12. Install a new retainer and spacer bracket into the slot on the fuel rail and install the pressure regulator to the fuel rail. 13. Tighten the fuel return line nut to 13 ft. lbs. (17 Nm). 14. Connect the vacuum line to the pressure regulator and install the retainer screw. 15. Tighten to 76 inch lbs. (8.5 Nm). 16. Inspect and verify that the retainer and spacer bracket is engaged in the slots in the fuel rail. 17. Grasp and pull on the regulator to ensure that it is properly seated. 18. Install the upper intake manifold. 19. Connect the negative battery cable. 20. Inspect for leaks. |

What You'll Learn

Disconnect the negative battery cable

Disconnecting the negative battery cable is one of the first steps to take when replacing the fuel pressure regulator on a 2004 Chevrolet Impala. Here is a detailed, step-by-step guide on how to do this:

Firstly, ensure that your car is turned off before beginning any work. This is extremely important for your safety. It is also recommended that you wear safety equipment, such as gloves and goggles, when working on your car.

Next, locate your car's battery. This is usually located under the hood of your car, which you can open using the release mechanism in your car's cabin or under the hood itself. Car batteries are large, block-like components with two large cables attached to them near the engine bay's surface. If you are having trouble locating it, consult your owner's manual.

Once you have found the battery, identify the negative terminal. This should be clearly marked with a "-" symbol and is usually black in colour. It may also have a black plastic cap. The positive terminal, in contrast, will be marked with a "+" and will be red, with a red plastic cap.

Now that you have identified the negative terminal, it is time to loosen the nut that holds the cable in place. First, remove any plastic caps that may be present. Then, use a wrench to loosen the nut. There is no universal size for terminal hardware, so you may need to try a few different wrench sizes before finding the right fit. Turn the wrench counter-clockwise to loosen the nut.

Once the nut has been loosened, carefully remove the negative connector cable from the battery. Be sure to push it far aside and out of the way, ensuring that it does not come into contact with the battery again until you are ready.

Finally, repeat the same process for the positive terminal. Again, make sure that you push the cable well away and that it cannot come into contact with the battery.

And that's it! You have now successfully disconnected the negative battery cable on your 2004 Chevrolet Impala. Remember to always follow proper safety protocols when working on your vehicle.

Understanding the Role of Fuel Pressure Relief Valves

You may want to see also

Relieve the fuel system pressure

To relieve the fuel system pressure on a 2004 Impala, first remove the fuel pump relay and allow the engine to run out of fuel. You can also relieve the pressure by pushing the middle of the valve on the port, which looks like a tire stem.

The Evolution of Pressure: Rubber Fuel Hose Explained

You may want to see also

Remove the upper intake manifold assembly

To remove the upper intake manifold assembly from a 2004 Impala, you will need the following tools:

- Metric Socket set (7mm to 18mm)

- Socket wrench

- Several sizes of extensions

- A swivel socket (or a crow's foot)

- Torque Wrench (Foot pounds) (Inch Pounds if you have it, but not necessary)

- Flatblade Screwdriver

- Phillips screwdriver

- Pry Bar (you can use the screwdriver if you want)

- Duct tape

- Q-Tips

- Channel Locks

- Electrical Tape

- Metric Tap and Die set (just in case)

- Droplight/flashlight

- Oil Drain Pan

- A container to catch the coolant from your car

- Wire Brush

- Putty knife or scraper

- RTV Gasket Maker (ULTRA BLACK) (I also used High Temp Red)

- Degreaser

- Extra Coolant (I used the green 50/50 mix that goes with any type of coolant)

- A helper (optional)

- Disconnect the negative terminal of your car battery.

- Place a container under the car by the water pump (driver's side) to catch the coolant.

- Use a flat-blade screwdriver or channel locks to remove the hose from the water pump. Allow the coolant to drain completely.

- Remove the air filter and sensors on the air intake. If you have a stock air filter, loosen the hose clamps with a screwdriver and pull the air filter off the mass airflow sensor.

- Remove the spark plug wires. It is recommended to number them to avoid confusion during reassembly.

- Remove the hoses connected to the MAP sensor and fuel system.

- Remove the two 10mm bolts on the throttle body bracket.

- Disconnect the throttle body sensor by pulling outward on the plastic tab while pulling the harness outward. Do this for all harnesses plugged into sensors on the throttle body and nearby areas.

- Disconnect the harness to the EGR valve and any remaining sensors in this area. Be gentle, as the plastic and wires may be brittle.

- Loosen/move the hose clamps under the throttle body. Some coolant may come out.

- Remove the hose connected to the upper intake manifold on the passenger side. Loosen the hose clamp and pull the hose off. If it's stubborn, use WD40 and a screwdriver wrapped in electrical tape to avoid damage.

- Time to remove the MAP sensor: There is one 10mm bolt holding the MAP sensor bracket onto the manifold on the passenger side. The two bolts holding the MAP sensor in place are 7mm. After removing the bolts, pull up and outward to remove the sensor and rubber hose.

- Unplug the harnesses connected to the ignition coil packs. On the driver's side, there are two plugs: the top one can be unplugged directly, while the bottom one should be taped to the trans dipstick to avoid losing it.

- Remove the ignition coil packs. They are bolted to a steel plate, which is attached to the upper intake manifold with two 10mm bolts and two 13mm nuts.

- Remove the other half of the air intake hose, which is behind the driver's side of the engine.

- Remove a sensor and the EGR valve. There is one 10mm bolt holding the sensor, and two 10mm bolts holding the EGR valve. Remove these bolts and parts.

- Keep the EGR valve and sensor attached to the upper intake manifold for now, as it is easier to take them off once the manifold is removed.

- Remove the bolts holding the upper intake manifold: six 10mm bolts and one 13mm nut connected to a stud and bracket that holds the alternator.

- With all bolts and harnesses unplugged, carefully pull up and back, then push up to remove the hoses connected to the throttle body.

- Place the upper intake manifold assembly in a container for disassembly and cleaning.

- Remove the speed nuts holding the coolant return tank on the strut tower (7mm).

- Remove the temp sending sensor harness.

- On the driver's side of the manifold, near the valve cover, move the hose clamp holding the soft line to the hard line back onto the rubber part of the hose.

- Remove the 8mm bolt on the hard line opposite the rubber hose and pull that part up and out of the water pump.

- There is a 13mm nut holding the fuel lines to a bracket on the driver's side. Remove this.

- Remove the two 10mm bolts holding the fuel injectors/rail to the lower intake manifold.

- Use a screwdriver or pry bar to lift the tabs on each corner of the lower intake manifold and carefully pull up on the injectors, rotating the assembly to sit upside down on the manifold.

- At this point, you can choose to replace the lower fuel injector O-rings. Pinch and push the O-ring forward, then use needle-nose pliers to grab the excess rubber and pull upwards.

- To access the main harness, you will need to remove the serpentine belt, alternator, and power steering pump. Loosen the serpentine belt by placing a socket into the tensioner pulley and setting the wrench to loosen.

- Remove the alternator: three 15mm bolts, one bracket, one 13mm nut, and a harness. The last bolt is behind the alternator.

- The alternator bracket has two pieces that need to be duct-taped together for easier reassembly.

- Remove the power steering pump: three 13mm bolts. The first two are easy to access, while the bottom one is more challenging. Once the bolts are removed, pull up the pump and detach the hard lines from their clips.

- Remove the valve covers: four 8mm bolts on each side. Be careful with the stud that holds the coil pack assembly, which is in front of the last bolt.

- Clean the valve covers and prepare them for new gaskets.

- Remove the last hard line going into the engine on the driver's side. It may be attached to the same bracket as the fuel rail hard lines. Remove the nut or bolt holding the bracket, then twist and pull the line out.

- Remove the bolts holding the lower intake manifold: two on the sides and four on the top (all 10mm). One of each side bolt will require a swivel+extension or a crow's foot.

- Carefully lift the lower intake manifold, being cautious not to crack it.

- Clean the mating surfaces of the gaskets and engine.

- Reassemble the upper intake manifold, ensuring all sensors and components are securely attached and plugged in.

- Reinstall the upper intake manifold assembly, following the torque specifications provided in the repair manual.

Fuel Pressure Woes: Bad Pressure, Bad Performance

You may want to see also

Disconnect the vacuum line from the pressure regulator

To disconnect the vacuum line from the pressure regulator of a 2004 Impala, you must first relieve the fuel system pressure. This can be done by removing the fuel pump relay and allowing the engine to run out of fuel.

Once the fuel system pressure has been relieved, you can then proceed to disconnect the vacuum line from the pressure regulator. This step is necessary to ensure that there is no fuel pressure left in the system before you begin working on the regulator.

It is important to note that you should have a shop towel or a rag handy to catch any spilled fuel during this process, as there may be a small amount of fuel that leaks out when you remove the regulator.

Additionally, you will need a Torx socket to loosen the screw that holds the regulator in place. This is mentioned in one source as being a T-30 Torx for the fuel pressure regulator attaching screw and a T-25 Torx for the fuel outlet retainer clip.

Overall, disconnecting the vacuum line from the pressure regulator is a straightforward task, but it is important to take the necessary precautions and have the right tools on hand to ensure a safe and successful outcome.

Fuel Pressure Requirements for LS1 Engines: How Much is Needed?

You may want to see also

Remove the regulator retaining screw

To remove the regulator retaining screw, you will need a Torx socket. The screw holds the regulator in place, so it is important to have the right tool for this step.

First, relieve the fuel system pressure. Remove the fuel pump relay and allow the engine to run out of fuel. Then, disconnect the vacuum line from the pressure regulator.

Next, you can remove the regulator retaining screw. Place a clean shop cloth underneath the regulator to catch any fuel spillage. After removing the screw, carefully pull the regulator from the fuel rail, twisting the regulator slightly to ease removal.

Once the regulator is removed, you can discard the old O-ring and clean all parts. Do not use shop compressed air to test or clean the fuel pressure regulator. If the filter screen is contaminated, it should be removed and the pressure regulator replaced.

Fuel Pressure Maintenance for 1987 300ZX Performance

You may want to see also

Frequently asked questions

You will need a 7/8 nut, a #40 torx, a fuel line tool, a rag, and some Vaseline for the O-ring on the new regulator.

First, relieve the fuel system pressure. Remove the Fuel Pump relay and allow the engine to run out of fuel. Disconnect the vacuum line from the pressure regulator. Remove the regulator retaining screw and remove the retainer bracket. Using a clean shop cloth to catch fuel spillage, carefully pull the regulator from the fuel rail. Twist the regulator slightly while removing to ease removal. Discard the O-ring. Clean all parts well but do not use shop compressed air to test or clean the fuel pressure regulator. If the filter screen has been contaminated, it should be removed and the pressure regulator replaced. Lubricate a new pressure regulator O-ring with clean engine oil and install it on the regulator inlet. Install the fuel return pipe to the regulator. Install a new retainer and spacer bracket into the slot on the fuel rail and install the pressure regulator to the fuel rail. Tighten the fuel return line nut to 13 ft. lbs. (17 Nm). Connect the vacuum line to the pressure regulator and install the retainer screw. Tighten to 76 inch lbs. (8.5 Nm). Inspect and verify that the retainer and spacer bracket is engaged in the slots in the fuel rail. Grasp and pull on the regulator to ensure that it is properly seated.

Remove the Fuel Pump relay and allow the engine to run out of fuel.