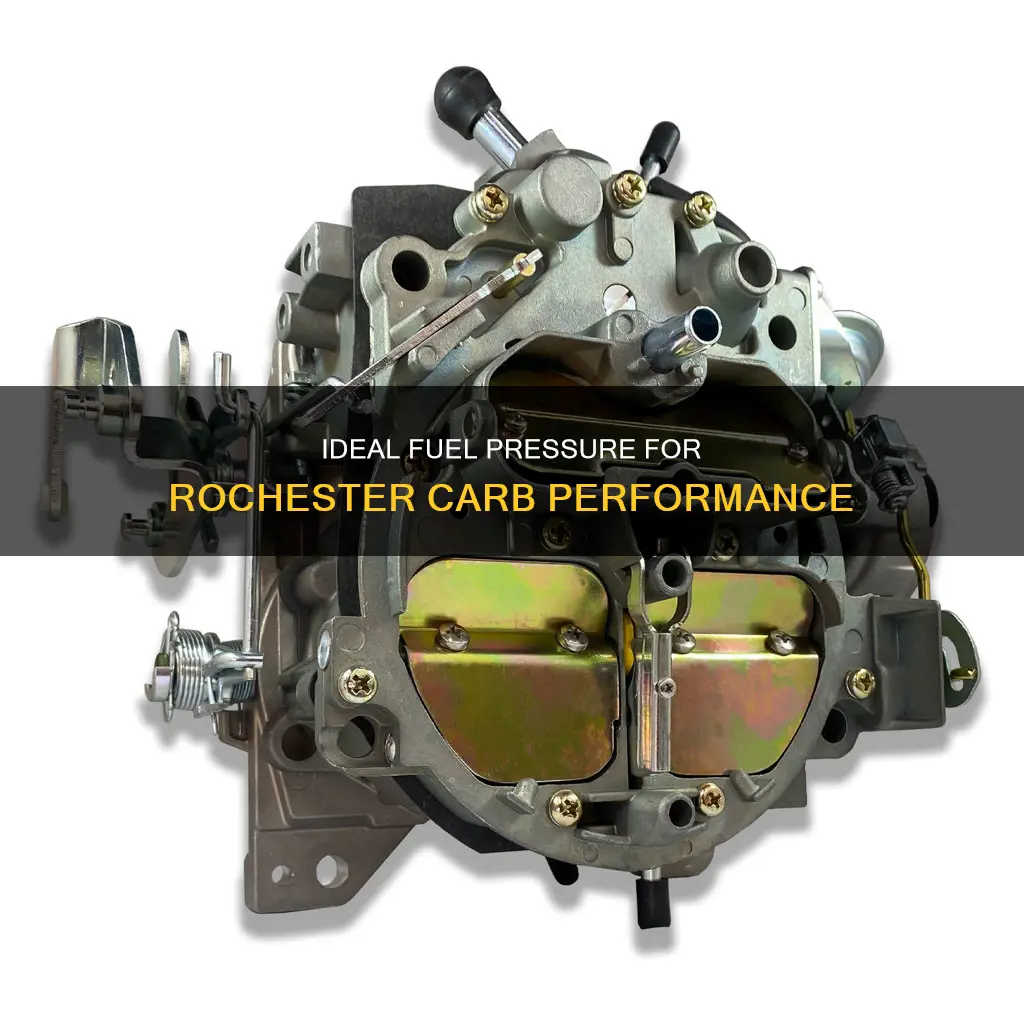

The Rochester Quadrajet carburetor has a small fuel bowl and requires a steady and plentiful supply of fuel to perform at its best. The recommended fuel pressure for most combinations is 6-7 lbs. However, it's important to note that each style of carburetor has a specific fuel pressure range where it performs optimally. The owner's manual for your carburetor will provide set-up and tuning instructions, but you can also use online resources as a basic guideline.

What You'll Learn

- The Rochester Quadrajet carburetor requires a steady and plentiful fuel supply

- lbs of fuel pressure is recommended for most combinations

- A fuel pressure regulator can be used to adjust and maintain consistent fuel pressure

- Low fuel pressure can cause the fuel bowls to run dry

- High fuel pressure can force too much fuel into the engine, causing fouled spark plugs

The Rochester Quadrajet carburetor requires a steady and plentiful fuel supply

To ensure an adequate fuel supply, it is advisable to install a mechanical fuel pressure gauge to monitor the fuel pressure during Wide Open Throttle (WOT) operation. The pickup point for the gauge should be as close to the carburetor fuel inlet fitting as possible. For rubber fuel line connections, a fuel pressure gauge pickup fitting can be spliced into the rubber line. Alternatively, for solid metal fuel lines, drilling and tapping the fuel inlet fitting allows for a temporary compression fitting installation to accommodate the gauge.

Maintaining constant fuel pressure at WOT is crucial. A drop in pressure indicates that the fuel system requires improvement, as it cannot keep up with the carburetor's demands. The fuel system encompasses various components, including the fuel tank, pickup, rubber hoses, steel fuel lines, pumps, and regulator, all of which play a role in delivering fuel to the carburetor.

For engines producing over 400 horsepower, an electric "pusher pump" should be installed near the fuel tank to supply fuel to the stock mechanical pump. The Mallory 110 pump is an excellent choice, as it does not require an external regulator. However, for engines generating 550 horsepower or more, the Mallory 140 pump and regulator are recommended to feed the mechanical fuel pump adequately.

It is important to note that both insufficient and excessive fuel pressure can lead to issues. Low fuel pressure can cause the fuel bowls to run dry, while high pressure can force too much fuel into the engine, resulting in fouled spark plugs and other problems. Therefore, it is essential to maintain the recommended fuel pressure range for optimal carburetor performance.

Exploring the Fuel Pressure Sensor in 04 Explorers

You may want to see also

6-7 lbs of fuel pressure is recommended for most combinations

The Rochester Quadrajet carburetor is a high-performance engine component that requires a careful balance of fuel pressure to operate optimally. While each carburetor style has its own unique fuel pressure range, the Rochester Quadrajet's small fuel bowl design necessitates a steady and abundant fuel supply.

For this reason, it is generally recommended to maintain a fuel pressure of 6-7 lbs for most combinations. This range ensures that the carburetor receives an adequate amount of fuel to perform effectively. Operating within this pressure range helps prevent issues that can arise from both insufficient and excessive fuel pressure.

For instance, if the fuel pressure is too low, the fuel bowls may run dry, leading to performance issues. On the other hand, if the fuel pressure is too high, it can force an excessive amount of fuel into the engine, resulting in fouled spark plugs and other complications. Therefore, maintaining the optimal fuel pressure of 6-7 lbs is crucial for the proper functioning of the Rochester Quadrajet carburetor.

To accurately monitor the fuel pressure, it is advisable to install a mechanical fuel pressure gauge. This gauge should be positioned as close to the carburetor fuel inlet fitting as possible to ensure precise readings. By regularly checking the fuel pressure, you can make any necessary adjustments to maintain the optimal pressure range for your Rochester Quadrajet carburetor.

In summary, the recommended fuel pressure of 6-7 lbs for most combinations is crucial for achieving the best performance from your Rochester Quadrajet carburetor. By following this guideline and regularly monitoring fuel pressure, you can help ensure the optimal functioning of your engine and avoid potential issues related to incorrect fuel pressure.

Understanding Fuel Pressure in the 1982 Corvette

You may want to see also

A fuel pressure regulator can be used to adjust and maintain consistent fuel pressure

A fuel pressure regulator is an essential component of any EFI system, ensuring the fuel rail builds up enough pressure to supply the injectors with the required amount of fuel. Without it, the fuel will simply flow through without reaching the injectors.

The regulator works by maintaining a steady fuel supply, even when there are dramatic changes in fuel demand. It consists of a diaphragm that controls the bypass valve, which can open and close to adjust for steady fuel delivery. When pressure is applied to the top of the regulator, a spring attached to the diaphragm forces it down, reducing excess fuel and making the fuel pumps work harder. This, in turn, increases fuel pressure.

The fuel pressure regulator diaphragm has two sides or chambers. One side is under pressure from the fuel rail, while the other is subject to vacuum or boost pressure from the inlet tract. The ideal ratio is 1:1, allowing the fuel injector to maintain the perfect ratio between fuel and boost.

To adjust the pressure, you can use a fuel pressure regulator. This is particularly important as too low fuel pressure can cause the fuel bowls to run dry, while too much pressure can force too much fuel into the engine, causing fouled spark plugs and other issues.

For the Rochester Quadrajet carburetor, it is recommended to run 6-7 lbs of fuel pressure for most combinations. It is also advised to install a mechanical fuel pressure gauge to verify fuel pressure during Wide Open Throttle (WOT).

Ideal Fuel Pressure for Chevy 350 TBI Engines

You may want to see also

Low fuel pressure can cause the fuel bowls to run dry

The Rochester Quadrajet carburetor has a small fuel bowl and requires a steady and plentiful fuel supply to perform at its best. If the fuel pressure is too low, the fuel bowls can run dry.

One solution to this issue is to install an electric fuel pump, which will fill the carburetor before starting the engine. This may not be a stock option, but it is an effective solution. Another solution is to regularly drive the car, as this was how people avoided this issue in the past.

Additionally, a return line can help keep fuel cooler and maintain pressure. Blocking the return line can also increase fuel pressure, but this should be verified with a fuel pressure gauge to ensure it is beneficial.

It is important to maintain the fuel system, including the fuel pickup, rubber hoses, steel fuel lines, pumps, and regulator, to ensure optimal performance and prevent issues with low fuel pressure.

Fuel Pressure: Getting the Right PSI for Your Engine

You may want to see also

High fuel pressure can force too much fuel into the engine, causing fouled spark plugs

Carburetors require a specific fuel pressure range for optimal performance. The Rochester Quadrajet carburetor, for instance, is recommended to run on 6-7 pounds of fuel pressure for most combinations. However, if the fuel pressure is too high, it can lead to adverse effects on the engine.

High fuel pressure can force an excessive amount of fuel into the engine, resulting in what is known as "spark plug fouling." Fouled spark plugs are unable to ignite the air-fuel mixture in the cylinder reliably, disrupting the combustion process. This, in turn, leads to a range of issues, including engine misfires, rough idling, and a decrease in fuel economy.

Spark plug fouling occurs when the spark plug tip becomes coated or covered with deposits of excessive fuel, oil, or combustion residue. This coating prevents the spark plug from firing reliably, causing the engine to hesitate, misfire, or run unevenly. The combustion process is critical for engine performance, and any interruption can significantly impact the vehicle's overall performance.

To avoid spark plug fouling due to high fuel pressure, it is essential to maintain the recommended fuel pressure range for your specific carburetor. Each carburetor style has its own optimal fuel pressure range, and this information can typically be found in the owner's manual or by consulting a professional mechanic. By ensuring that the fuel pressure is properly adjusted and regulated, you can help prevent issues related to spark plug fouling and keep your engine running smoothly.

Additionally, regular maintenance and inspections of the spark plugs can help identify any signs of fouling or wear and tear. By promptly addressing any issues, you can prevent them from escalating into more serious and costly problems. Therefore, it is crucial to pay close attention to any changes in your vehicle's performance and take the necessary steps to ensure optimal engine health.

The High-Pressure Fuel Pump: Powering Your Car's Performance

You may want to see also

Frequently asked questions

The Rochester Quadrajet carburetor requires a steady and plentiful supply of fuel to perform at its best. It is recommended to run 6-7 lbs of fuel pressure for most combinations.

If your fuel pressure is too low, you may run the fuel bowls dry. If the pressure is too high, it can force too much fuel into the engine, causing fouled spark plugs and other issues.

To adjust and maintain consistent fuel pressure, use a Fuel Pressure Regulator.

Install a mechanical fuel pressure gauge to verify fuel pressure during Wide Open Throttle (WOT).