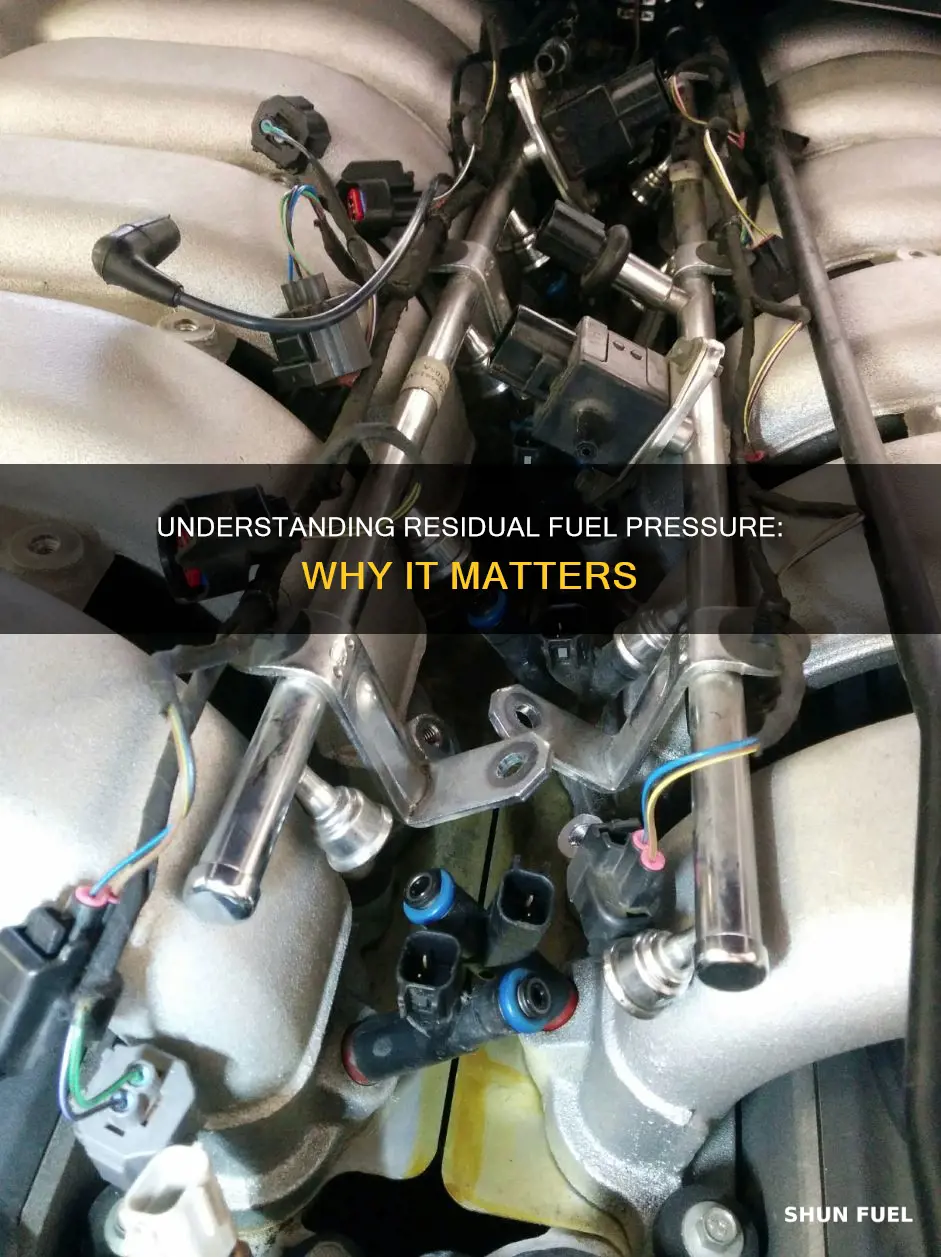

Residual fuel pressure is the pressure that remains in the fuel injectors when the engine is shut off. This pressure is required to keep the fuel injectors pressurised, and if it leaks away while the engine is off, air may enter the fuel injectors and cause hard starting. All systems lose residual pressure over time, and the rate at which this happens can cause issues. A loss of residual pressure could be caused by a leaking injector, pressure regulator, or fuel pump check valve.

What You'll Learn

- Residual fuel pressure is required to keep fuel injectors pressurised when the engine is off

- If residual pressure leaks away, air may enter the fuel injectors and cause hard starting

- A ruptured regulator diaphragm will pass fuel into the intake manifold

- A leaking check valve in the fuel pump may cause a loss of residual pressure

- Residual pressure specifications include a minimum pressure to be maintained for a specific time

Residual fuel pressure is required to keep fuel injectors pressurised when the engine is off

Residual fuel pressure is the pressure that remains in a fuel injection system when the engine is off. It is required to keep the fuel injectors pressurised when the engine is off, which helps with cold and hot engine starting.

Residual fuel pressure specifications usually include a minimum pressure that should be maintained for a specific time. For example, a Porsche following the spec book of CIS requires at least 1.2 bar of residual pressure after 20 minutes of shutting down the engine. If residual pressure cannot be maintained for the specified time, there may be a leak in the fuel lines, fuel injectors, fuel pressure regulator, or check valve in the fuel pump.

There are several causes of loss of residual fuel pressure, including external leaks, leaking injectors, leaking fuel pressure regulators, or a leaking check valve in the fuel pump. The latter is the most common and means the pump needs replacing. The check valve holds fuel pressure in the system and, once running, the pump pressure pushes the ball off the seat and allows fuel to flow. Contaminants, a worn ball seat, a pitted ball, or a weak spring are reasons why the check valve may not be sealing.

To prevent fuel leaks and aid hot and cold engine starting, fuel injection systems must maintain residual fuel pressure when the engine is off.

How Fuel Pressure Testing Keeps Your Vehicle Running

You may want to see also

If residual pressure leaks away, air may enter the fuel injectors and cause hard starting

Residual fuel pressure is the pressure that remains in the fuel system when the engine is turned off. This pressure is necessary to keep the fuel injectors pressurised and prevent air from entering the system. If residual pressure leaks away, air may enter the fuel injectors, leading to hard starting, especially when the engine is cold.

There are several potential causes of residual pressure loss, including leaking injectors, a faulty pressure regulator, or a defective fuel pump check valve. To identify the root cause, a series of tests can be performed to isolate different components of the fuel system. This typically involves pressurising the fuel system and monitoring the pressure over time, either with a fuel pressure gauge or by performing a leak-down test.

One method to isolate the issue is to perform a leak-down test. This involves hooking up a fuel pressure gauge and taking readings while the engine is running. After shutting off the engine, observe the pressure reading. It should hold steady for at least 30 minutes, with only a slight drop when the engine is first turned off. If the pressure continues to drop steadily, it indicates a leak in the system.

To determine if the leak is in the fuel tank or the fuel rail, a similar test can be performed by pinching off the return line and feed line going back to the tank when the engine is shut off. If the leak goes away and the pressure stabilises, the problem is likely in the tank, possibly due to a faulty check valve in the fuel pump. If the problem persists, the issue is in the fuel rail, which could be a leaking injector or a faulty fuel pressure regulator.

Another way to isolate the fuel injectors is to remove the fuel rail and observe the injectors after pressurising the fuel rail. This can help identify any external leaks, but caution must be exercised as the injectors may not be securely held in place without the fuel rail. Alternatively, a power balance test can be performed to isolate a problem cylinder, as a leaking fuel injector may cause a wet or sooty spark plug on the affected cylinder.

In some cases, the issue may not be immediately apparent, and further investigation may be required. For example, a leaking fuel injector may not always show signs of leakage when cold but may start to drip when heated. Therefore, it is important to consider the operating temperature and conditions when performing diagnostics.

Once the root cause of the residual pressure loss is identified, appropriate repairs or replacements can be made. This may include replacing faulty injectors, repairing or replacing the fuel pressure regulator, or addressing issues with the fuel pump check valve.

Fuel Pressure and Tuning: More Pressure, More Power?

You may want to see also

A ruptured regulator diaphragm will pass fuel into the intake manifold

Residual fuel pressure is the pressure that is maintained when the engine is off. It is required to keep the fuel injectors pressurised so that the engine can start after cooling off. If residual pressure leaks away, air may enter the fuel injectors and cause hard starting.

To isolate the regulator, pressurise the fuel system, then pinch off the fuel return line with pliers or clamps. If the residual pressure continues to drop, the cause lies elsewhere.

Understanding Dead Head Pressure: Fuel Pump Performance and Optimization

You may want to see also

A leaking check valve in the fuel pump may cause a loss of residual pressure

Residual fuel pressure is the pressure that is maintained in the fuel system when the engine is off. This pressure is required to keep the fuel injectors pressurised and ready to go when the engine is started. If the residual pressure leaks away, air may enter the fuel injectors and cause hard starting, especially after the engine cools off.

To test whether the check valve in the fuel pump is leaking, isolate the pump close to the fuel injector rail, then pressurise the system. No fuel pressure should reach the injectors or the pressure regulator during this test. If the fuel line pressure rapidly drops to zero, the residual fuel pressure is leaking past the fuel pump check valve or through a fuel line fitting.

If you suspect a leaking check valve, there are a few things you can do to diagnose the problem. First, check the fuel pressure with a fuel pressure gauge. When the engine is cold, the pressure should jump up to full-rated pressure, then the pump shuts off until you try starting it. If the pressure drops low and remains low, this could indicate a problem with the pressure regulator or the pump itself.

Another way to test for a leaking check valve is to perform a leak-down test. Shut down the engine and watch the fuel pressure gauge. Pressure should not fall below a certain level (specified by the manufacturer) for a specified amount of time. A quick loss of pressure usually indicates a defective check valve in the filter/regulator. A slow loss of pressure usually indicates a defective check valve in the electric fuel pump.

If you determine that the check valve in the fuel pump is indeed leaking, you may need to replace the fuel pump assembly. This can be a tricky job, especially if the fuel pump is located inside the fuel tank. It is important to follow recommended safety procedures when working with fuel pumps to avoid the risk of fire or explosion.

Fuel Pressure Requirements for Fitech Systems Explained

You may want to see also

Residual pressure specifications include a minimum pressure to be maintained for a specific time

Residual fuel pressure is the pressure that is maintained in a fuel injection system when the engine is shut off. This pressure is required to keep the fuel injectors pressurised, and if it leaks away, it may lead to hard starting once the engine cools off.

Residual pressure specifications include a minimum pressure that should be maintained for a specific time. For example, the spec book for CIS systems requires at least 1.2 bar of residual pressure to be maintained for 20 minutes after shutting down the engine. If residual pressure cannot be maintained for the specified time, there may be a leak in the fuel lines, fuel injectors, fuel pressure regulator, or check valve in the fuel pump.

The check valve in the fuel pump is a common source of residual pressure loss. It consists of a ballpoint pen-type spring that holds a ball onto a seat when the engine is off, creating residual pressure in the system. When the engine is running, the pump pressure pushes the ball off the seat, allowing fuel to flow. However, contaminants, a worn ball seat, a pitted ball, or a weak spring can cause the check valve to malfunction and allow residual pressure to leak into the fuel tank.

To isolate the cause of residual pressure loss, various parts of the fuel system can be pressurised and observed for pressure loss. For example, the fuel return line can be pinched off to isolate the regulator, and if the residual pressure continues to drop, the issue lies elsewhere. This process can be repeated to isolate the injector rail. Additionally, the fuel pump can be isolated close to the fuel injector rail, and the system pressurised. If fuel pressure reaches the injectors or the pressure regulator during this test, it indicates that the residual fuel pressure is leaking past the fuel pump check valve or through a fuel line fitting.

Fuel-Injected Cars: Maintaining Optimum Fuel Pressure

You may want to see also

Frequently asked questions

Residual fuel pressure, also known as "rest fuel" pressure, is the pressure that remains in the fuel injectors when the engine is shut off.

Residual fuel pressure is important because it keeps the fuel injectors pressurised when the engine is off. If residual pressure leaks away while the engine is shut off, air may enter the fuel injectors and cause hard starting after the engine cools off.

The causes of loss of residual fuel pressure include external leaks, leaking injectors, leaking fuel pressure regulators, or a leaking check valve in the fuel pump.