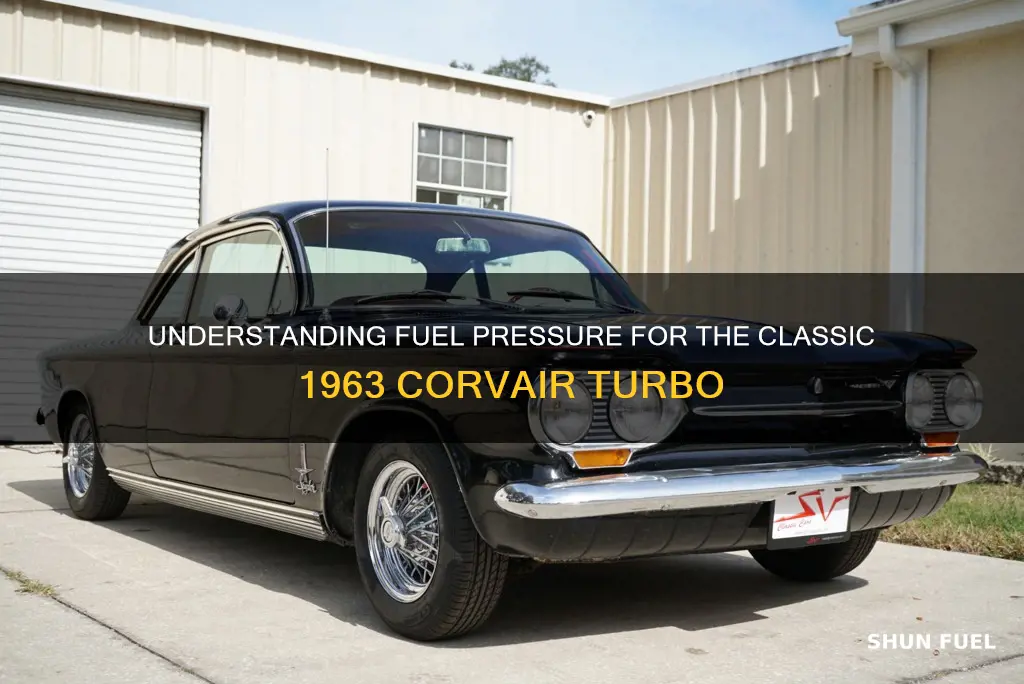

The 1963 Chevrolet Corvair is a rear-engined economy sedan introduced in 1959 to compete with the Volkswagen Beetle. A turbocharged version of the Corvair was released in 1962, making it one of the first mass-market turbocharged cars. The turbocharged Corvair was equipped with a 150 hp engine, which provided a significant boost in performance over the naturally aspirated model. The turbocharger was supplied by Thompson-Ramo-Wooldridge Inc. (later known as TRW) and was capable of spinning at up to 70,000 rpm. To prevent pre-ignition, the Corvair's compression ratio was lowered to 8.0:1, and a diaphragm on the distributor provided a pressure retard function to control timing. The 1963 Corvair Turbo is considered a pioneering vehicle in the history of turbocharged cars, and its influence can still be seen today as manufacturers increasingly adopt turbocharged engines across their model lines.

What You'll Learn

- The 1963 Corvair Turbo's fuel pressure was affected by the carburettor

- The Corvair's carburettor was a Carter YH

- The Corvair's turbo was built by TRW

- The Corvair's turbo muffler was used as an aftermarket muffler for V8 performance cars

- The Corvair's turbo was the first to expose the masses to the joys of turbo boost

The 1963 Corvair Turbo's fuel pressure was affected by the carburettor

The Corvair's turbo was built by TRW, and hid under a chrome bullet-shaped cover on the right. A side-draft 1½” Carter YH carb fed the turbine, in a “suck through” system. The Spyder engine received many heavy-duty parts, such as a special alloy-steel forged crank, stronger connecting rods, special pistons and rings, and tougher valves and seals, among others. Output jumped to 150 hp (gross), at 4,400 rpm from the 102 hp up-rated 145 cubic inch naturally aspirated engine. Torque jumped by 64%, to 210 lb.ft. @ 3200-3400 rpm. Chevy claimed that “usable power” increased by 90%, up to 3000 rpm; that would be after the turbo spooled up, of course.

The Carter YH carburettor has a well-known problem with fuel control, often due to excessive fuel pressure. If your fuel pump pressure is high, you might consider adding a fuel pressure regulator between the pump outlet and the carburettor inlet. The Holley 12-804 fuel pressure regulator features 3/8" NPT in/out ports. The Holley regulators are pre-set at the factory at 2.8 PSI so there is no guesswork when first installing the regulator.

Exploring the Fuel Pressure Sensor in 04 Explorers

You may want to see also

The Corvair's carburettor was a Carter YH

The Carter YH carburettor was placed before the turbocharger in the 1963 Corvair Turbo. This was a draw-through arrangement, which limited the boost to what air could be pulled through the relatively small carburettor.

The Carter YH carburettor was specifically designed for the Corvair Turbo. It was a single side-draft carburettor, which replaced the multiple-carburettor intake system of the naturally aspirated engine. The carburettor was placed before the turbocharger, drawing air through and then compressing it into the long intake runner that spanned the aluminium cylinder heads on opposite sides of the flat-six engine.

The Corvair Turbo was the first turbocharged car in volume production, and the Carter YH carburettor was an integral part of this engineering achievement. The carburettor was designed to work with the turbocharger, which was made by the Thompson Valve Division of Thompson-Ramo-Wooldridge Inc. The turbocharger weighed 13.5 lb and had a 3-inch diameter impeller, capable of spinning at up to 70,000 rpm.

The Corvair Turbo engine did not use a wastegate to limit boost pressure. Instead, boost pressure was controlled by the exhaust system, which was designed to create back pressure. To prevent the engine from running too lean, a metering rod and jet were selected to supply an over-rich mixture when at full throttle.

The Carter YH carburettor was an important component of the Corvair Turbo, allowing it to achieve a power output of 150 hp and a torque of 210 lb-ft. This represented a 47% increase in power and a 58% increase in torque compared to the naturally aspirated engine.

Fuel Pressure Regulators: Linked to Engine Performance and Control

You may want to see also

The Corvair's turbo was built by TRW

The Corvair's turbocharger was made by the Thompson Valve Division of Thompson-Ramo-Wooldridge Inc., which became TRW in 1965. The model selected weighed 13.5 lb (6.1 kg). It had a 3-inch diameter impeller and was capable of spinning at up to 70,000 rpm. The turbocharger was joined by a hose connection to the induction pipe, which tied into the two intake manifolds. The unit was mounted approximately 4-inches off-centre, to allow space between the exhaust pipes and the interior heater ductwork.

The Corvair's turbo was not marketed under the Turbo-Air name, being listed initially as the Super Charged Spyder engine. The turbocharged Corvair was the first car to expose the masses to the joys of turbo boost. The turbo revolution started with the Corvair Spyder, beginning in 1962.

Fuel Pressure Fundamentals for Chevy Carb Enthusiasts

You may want to see also

The Corvair's turbo muffler was used as an aftermarket muffler for V8 performance cars

The Corvair is a rear-engined economy sedan introduced by Chevrolet in 1959. A turbocharged version of the car was released in 1962, and the turbocharger was made by the Thompson Valve Division of Thompson-Ramo-Wooldridge Inc.

The Corvair's turbo muffler was the first of its kind, and it was soon adopted by hot rodders who were unbothered by the louder noise. The Corvair's turbo muffler was also used as an aftermarket muffler for V8 performance cars. The term "turbo muffler" was coined because of the turbocharger's ability to muffle the exhaust sound, allowing for less restrictive but louder mufflers. The Corvair's turbo muffler was also larger and heavier than most other mufflers at the time.

Fuel Pressure Regulator Hose: Understanding the Basics

You may want to see also

The Corvair's turbo was the first to expose the masses to the joys of turbo boost

The Corvair was a rear-engined economy sedan introduced by Chevrolet in 1959, and was the first car to expose the masses to the joys of turbo boost. The 1962 Jetfire had a similar displacement and was rated at 215 hp, but it used a high 10.25:1 compression ratio, which required the use of a water-methyl alcohol injection system to cool the fuel mixture as a deterrent to dangerous pre-combustion. The Jetfire quickly became a maintenance and reliability nightmare, and many were converted by dealers to conventional four-barrel induction.

Chevrolet took a more conservative approach with turbocharging its air-cooled Corvair engine. Compression ratio was lowered to 8.0:1, which helped reduce the chance of pre-ignition. Maximum turbo boost was 10psi, not insignificant, and was essentially limited by the design of the exhaust system, which featured a very throaty low-restriction muffler and short and fat 9″ tailpipe. The Corvair’s turbo was built by TRW, and hid under that chrome bullet-shaped cover on the right. A side-draft 1½” Carter YH carb fed the turbine, in a “suck through” system. The Spyder engine received many heavy-duty parts, such as a special alloy-steel forged crank, stronger connecting rods, special pistons and rings, and tougher valves and seals, among others. Output jumped to 150 hp (gross), at 4,400 rpm from the 102 hp up-rated 145 cubic inch naturally aspirated engine. Torque jumped by 64%, to 210 lb.ft. @ 3200-3400 rpm. Chevy claimed that “usable power” increased by 90%, up to 3000 rpm; that would be after the turbo spooled up, of course.

The turbocharged Corvair was released one month after the turbocharged Turbo-Rocket engine in the Oldsmobile F-85 Jetfire, making it just the second turbocharged car in volume production. This engine was not marketed under the Turbo-Air name, being listed initially as the Super Charged Spyder engine.

Fuel Pressure Fundamentals for Nitrous Users

You may want to see also

Frequently asked questions

The fuel pressure for a 1963 Corvair Turbo is 2-3 PSI.

The fuel pressure for a 1964 Corvair Turbo is the same as the 1963 model, 2-3 PSI.

The fuel pressure for a 1965 Corvair Turbo is not known, but it is likely to be the same as the previous models.

The fuel pressure for a 1966 Corvair Turbo is not known, but it is likely to be the same as the previous models.

The fuel pressure for a 1967 Corvair Turbo is not known, but it is likely to be the same as the previous models.