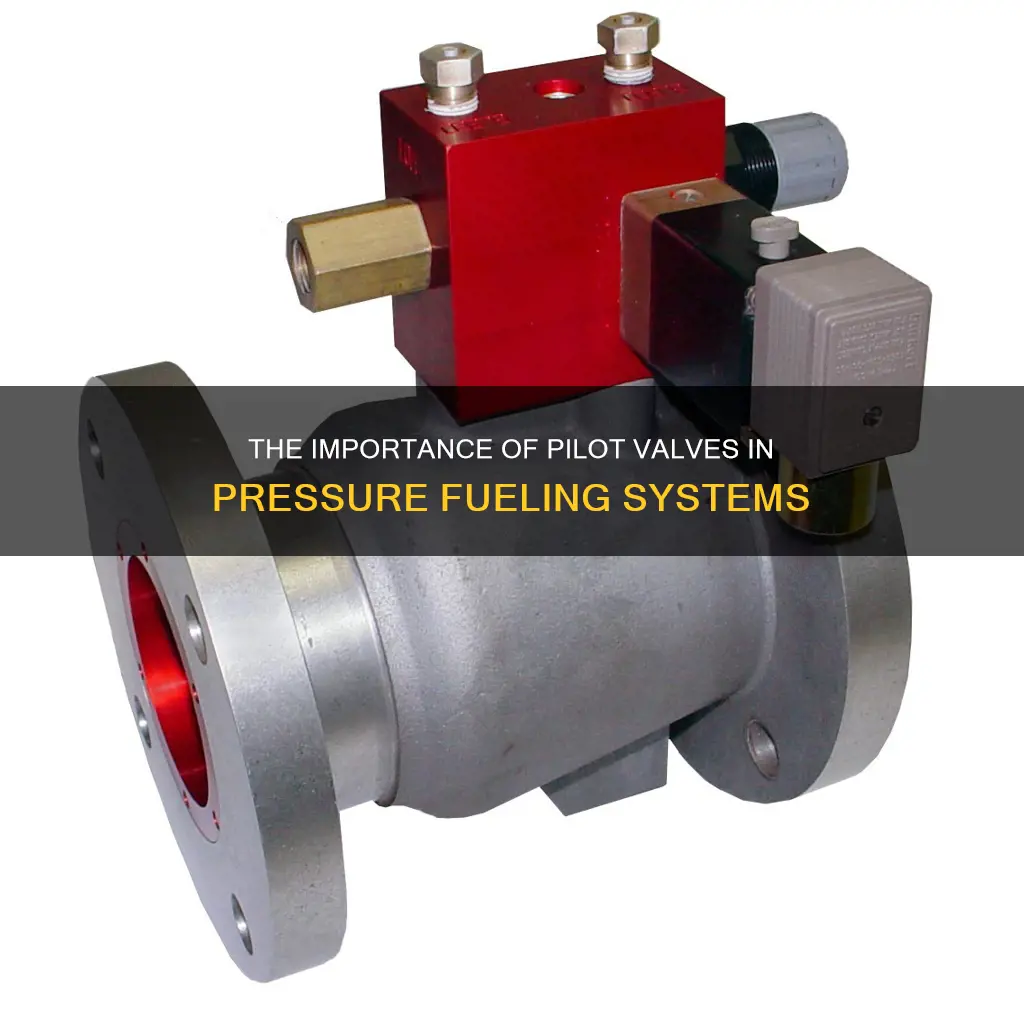

A pilot valve is a small valve that controls a limited-flow feed to a separate valve, which in turn controls a high-pressure or high-flow feed. Pilot valves are used in a variety of applications, including emergency controls, refrigeration plants, and engines. They are particularly useful in systems where a small and easily operated feed needs to control a much higher-pressure or higher-flow feed, such as in a pressure fueling system. In this context, a pilot valve can be used to control the flow of fuel, ensuring safe and efficient operation.

| Characteristics | Values |

|---|---|

| Definition | A small valve that controls a limited-flow control feed to a separate piloted valve. |

| Use | To control a high-pressure or high-flow feed. |

| Advantages | Allows a small and easily operated feed to control a much higher pressure or flow feed. |

| Use Cases | Critical applications, emergency and SIS controls, large refrigeration plants, hydraulic pistons, engines, and safety controls. |

| Types | Gas (using air) and liquid (using hydraulic oil). |

| Performance | Can withstand high pressures up to thousands of psi and allow flows of up to 40-50 gallons per minute. |

| Safety | Does not require electricity to operate, making it safer than electrical systems in certain contexts. |

| Installation | Can be mounted remotely and added to standard in-line valves of various sizes. |

What You'll Learn

Pilot valves are used in emergency situations

Pilot valves are also used in critical applications, such as emergency controls, and are human-operated. They can be set up as a push-to-activate or dead man's switch.

In an emergency, a pilot valve can be used to control a high-pressure or high-flow feed. It allows a small and easily operated feed to control a much higher pressure or flow, which would otherwise require a much larger force to operate. This makes it useful in situations where there is a significant pressure drop and the capacity to modulate is needed.

Pilot valves are often used in fluid flow systems to transfer from small control to a large load, similar to how relays are used in electrical systems. In fluid systems, this is accomplished using a pilot valve, which can be controlled by the external flow of a fluid. This is important for safety, as fluids can reach dangerous pressures of thousands of pounds per square inch and can cause serious injury or fatality.

Pilot valves are also beneficial in situations where electricity is not readily available, such as in remote or vehicle systems. For example, on a large dump truck, the main hydraulic cylinder may be controlled by a smaller fluid flow running from the cab's switches to the hydraulic valve near the back.

Understanding NG Fuel Pressure: Performance and Safety

You may want to see also

They are add-ons to the in-line valve

Pilot valves are add-ons to the in-line valve, which means they can be attached to a standard in-line valve to add extra functionality. They are small valves that control a limited-flow feed to a separate, larger piloted valve. This allows a small and easily operated feed to control a much higher pressure or flow feed, which would otherwise require a much larger force to operate.

Pilot valves are used in a range of applications, from refrigeration plants to hydraulic pistons, and are particularly useful in critical applications such as emergency controls. They are also often used in the oil and gas industry, especially in offshore applications, due to their ability to withstand high backpressure and improve system stability.

In a pilot-operated relief valve (PORV), the pilot valve controls the pressure to the main valve dome, which is the upper part of the main valve. When the pressure reaches the set point, the pilot valve opens and releases the pressure from the dome, allowing the piston to open and the main valve to exhaust the system fluid.

Pilot valves can be added to a large in-line valve in two ways. Firstly, an external thermal element can be added to control an injection, causing the valve to function as an expansion valve. Secondly, a pressure control valve can be added to ensure that the evaporating pressure does not fall below a certain temperature. These additions are relatively easy and inexpensive, and pilot valves come in standard sizes that can be attached to in-line valves of various sizes.

Fuel Pump Pressure: Factors Affecting Performance and Efficiency

You may want to see also

Pilot valves are used in refrigeration plants

A pilot valve is a small valve that controls a limited-flow control feed to a separate piloted valve. Typically, the piloted valve controls a high-pressure or high-flow feed. Pilot valves are useful because they allow a small and easily operated feed to control a much higher pressure or flow feed, which would otherwise require a much larger force to operate. Pilot valves are often used in critical applications and can be human-operated.

Pilot valves are often used in larger refrigeration plants with many consumers. They are an add-on to the in-line valve, enabling a small force to operate the larger valve, like in a hydraulic piston. The pressure inside the temperature sensor and coil enable the main valve to operate. The control is mechanical.

Two pilot valves can be added to a large in-line valve. One is an external thermal element for controlling an injection, which makes the valve work as an expansion valve. The other is a pressure control valve, ensuring that the evaporating pressure does not fall below a certain temperature.

Pilot-operated solenoid valves can be installed in return lines (liquid/vapour) and pressure-equalizing lines. They are used in all types of refrigeration systems and are suitable for low-pressure suction lines. Pilot valves are also used in large industrial refrigeration systems with ammonia or fluorinated refrigerants.

Ford F350 Fuel Pressure: Specifications and Performance

You may want to see also

Pilot-operated valves are pressure relief valves

A pilot valve is a small valve that controls a limited-flow control feed to a separate piloted valve. Typically, this separate valve controls a high-pressure or high-flow feed. Pilot valves are useful because they allow a small and easily operated feed to control a much higher-pressure or higher-flow feed, which would otherwise require a much larger force to operate.

Pilot-operated valves are used for emergency relief during overpressure events, for example, when a tank gets too hot and the expanding fluid increases the pressure to dangerous levels. They are also called pilot-operated safety valves (POSV), pilot-operated pressure relief valves (POPRV), or pilot-operated safety relief valves (POSRV), depending on the manufacturer and application.

In a pilot-operated valve, the major relieving device (main valve) is combined with and controlled by a self-actuated auxiliary pressure relief valve called a pilot valve. The pilot valve senses the system pressure and uses this pressure to control the closing force on the main valve disc. As the inlet valve pressure increases, so does the closing force until the pilot valve opens. Pressure is relieved at a designated set point as the process media is allowed to discharge through the main valve.

Pilot-operated valves are ideal for higher operating pressure gaps compared to spring-loaded valves. They can also offer much greater capacity compared to standard bores with comparable valve sizes. This allows operators to save on valve costs and associated piping investment due to reduced piping diameters.

Pilot-operated valves are used in many industries, including power generation, refining/petrochemical, chemical, midstream oil and gas, upstream oil and gas, and pulp and paper. Some unique applications include high-pressure applications, reducing emissions in high-operating pressure applications, offshore drilling, and production platforms in deep well applications.

Fuel Pressure Regulators: Linked to Engine Performance and Control

You may want to see also

Pilot valves are used for safety

Pilot valves are also used for safety in electrical systems, where they are known as 'solenoids'. In these systems, electricity is used to control the direction and flow of fluids, rather than a separate smaller fluid flow as in pilot valves. Solenoids are necessary when the control signal originates from a PLC, as they can handle higher current flows than pilot valves.

Pilot valves are beneficial for safety as they do not require any electricity to operate, meaning they will still function even if power is lost. This makes them ideal for use in remote and vehicle systems where electricity may not be readily available. For example, in a large dump truck, the main hydraulic cylinder may be controlled by a smaller fluid flow running from the cab's switches to the hydraulic valve near the back, ensuring safety and efficient operation.

Additionally, pilot valves offer excellent performance for overpressure protection. They are designed to withstand higher backpressure than spring-loaded valves and can optimize valve selection. Their compact design and ability to handle high pressures and flow rates make them a popular choice for ensuring safety in various industries.

Ideal Fuel Pressure for Holley 4150 Carb Performance

You may want to see also

Frequently asked questions

A pilot valve is a small valve that controls a limited-flow control feed to a separate piloted valve.

Pilot valves enable a small force to operate a larger valve, like in a hydraulic piston. The pressure inside the temperature sensor and coil enables the main valve to operate.

Pilot valves are useful because they allow a small and easily operated feed to control a much higher pressure or higher flow feed, which would otherwise require a much larger force to operate. They are often used for safety, especially in critical applications such as emergency and SIS controls.

Pilot valves are commonly used in the oil and gas industry, especially in offshore applications. They are also used in refrigeration plants, dump trucks, and engines.