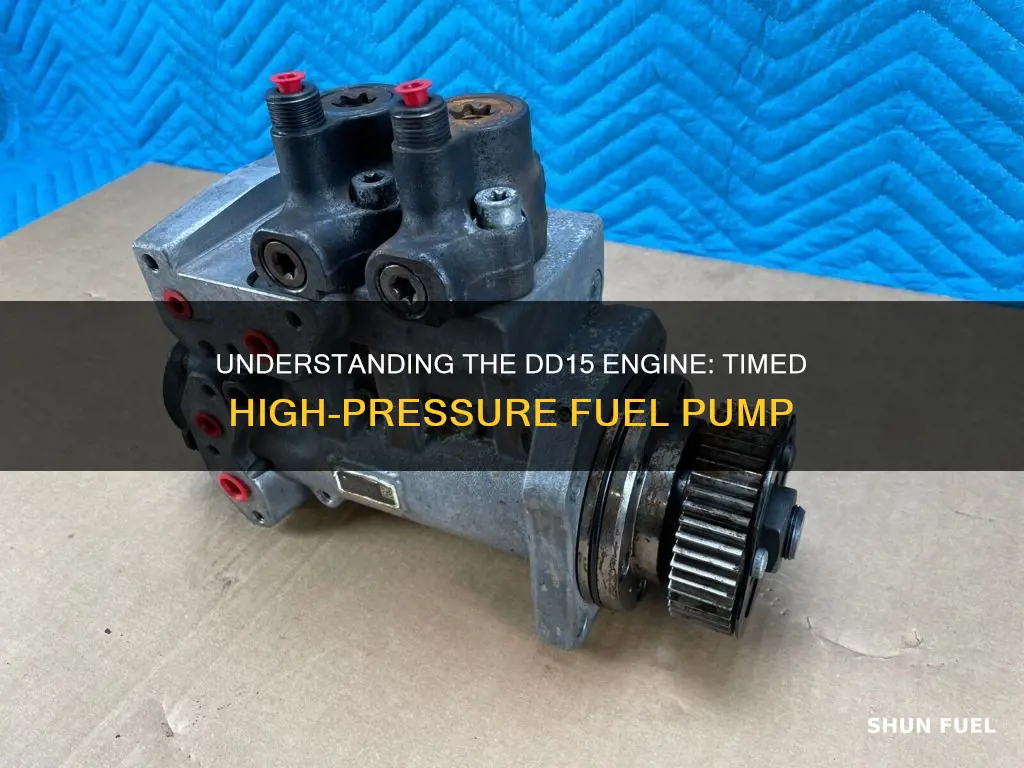

The high-pressure fuel pump is a vital component of the DD15 engine, responsible for delivering the right amount of fuel at the correct pressure to the engine for combustion. Located on the left side of the cylinder block, it is driven by the pinion gear drive. While some sources suggest that the pump needs to be timed, others argue that it does not need to be timed and that the issue may lie elsewhere. Mechanics advise setting the new pump to 12 o'clock for simplicity. Proper maintenance of the DD15 fuel pump is essential to ensure optimal engine performance and avoid potential breakdowns.

What You'll Learn

DD15 fuel pump replacement

The DD15 fuel pump is an important component of a diesel engine, delivering the right amount of fuel at the correct pressure to the engine for combustion. A failing DD15 fuel pump may cause engine misfires, reduced power, poor fuel economy, and engine stalling.

To replace the DD15 fuel pump, follow these steps:

Removal of High-Pressure Fuel Pump:

- Disconnect the batteries.

- Drain the coolant system.

- Install an engine barring tool in the flywheel housing and rotate the flywheel until the dot inside the tooth aligns with the edge of the pointer.

- Remove the coolant line from the module to the air compressor.

- Disconnect the fuel supply line to the doser block assembly.

- Disconnect the needle and amplifier return lines.

- Disconnect fuel lines from the fuel filter module on the manifold at the high-pressure pump.

- Remove the fuel filter module.

- Remove two high-pressure lines from the high-pressure fuel pump to the fuel rail.

- Remove the upper and lower fuel manifolds from the high-pressure fuel pump and discard the gaskets.

- Disconnect the electrical connector for the quantity control valve.

- Remove the bolts securing the high-pressure fuel pump bracket to the engine block, the high-pressure fuel pump to the bracket, and the high-pressure fuel pump to the cylinder block.

- Take out the high-pressure fuel pump.

Installation of High-Pressure Fuel Pump:

- Ensure the flywheel is positioned at top dead center (TDC) on cylinder number one.

- Inspect the high-pressure pump: if the driven gear is new or from the old pump, install it with a new high-pressure pump into a holding fixture, then install the key way and driven gear onto the shaft.

- Paint a mark on the gear to show the location of the key way.

- Install the nut and locking tooth, then torque to 250 N·m (184 ft·lb).

- Position the eyebrow plate over the gear, aligning the hash mark on the plate with the paint mark on the gear.

- Install the eyebrow mounting bolts and torque to 30 N·m (22 ft·lb).

- If the driven gear is factory-installed, skip the previous steps and proceed to the next step.

- Install the high-pressure pump and a new O-ring. Ensure the pump slides into the flywheel housing without binding, and the bolt holes align.

- If there is binding or misalignment, remove the pump, verify the timing mark, and reinstall.

- Use the correct bolt length (35 mm or 1.37 in.) when installing the high-pressure pump to avoid damage to the gear train.

- Secure the high-pressure pump to the flywheel housing and torque to 60 N·m (44 ft·lb).

- Secure the high-pressure fuel pump to the bracket and torque to 30 N·m (22 ft·lb).

- Secure the high-pressure fuel pump bracket to the block and torque to 100 N·m (74 ft·lb).

- Install new gaskets and torque the upper and lower fuel manifold bolts of the high-pressure fuel pump to 30 N·m (22 ft·lb).

- Connect the quantity control valve connector.

- Install the fuel lines on the fuel filter module.

- Torque the emergency lubrication line, fuel inlet and return for the high-pressure pump, and fuel inlet and return for the low-pressure pump to their specified values.

- Install the banjo bolts (version four only).

- Torque the amplifier and needle return fittings at the fuel inlet for the low-pressure and high-pressure pumps, respectively, to 35 N·m (26 ft·lb).

- Torque the fuel supply line to the doser block assembly to 40 N·m (30 ft·lb).

- Install two high-pressure lines from the high-pressure pump to the fuel rail and torque to 40 N·m (30 ft·lb).

- Install the fuel filter module and coolant line for the air compressor.

- Fill the coolant system and prime the system using a fuel priming valve or hand primer.

- Start and run the engine. Once it reaches operating temperature (140° F or 60° C), observe the pump for any performance issues or leaks.

Note: It is not necessary to time the fuel pump. However, ensure that the piece on the end of the pump is in the correct position, as improper positioning may affect the fit of the pump in the block.

Understanding Common Rail Diesel Fuel Pressure Performance

You may want to see also

DD15 engine troubleshooting

Troubleshooting a DD15 engine can be a complex task and it is recommended that you consult a certified mechanic. However, here is some general information and guidance on common issues with the DD15 engine.

One issue that has been reported by DD15 engine owners is the presence of coolant in the oil. This can be caused by a leaking bottom O-ring on the liner, which is a common problem with this type of engine. In this case, it is recommended to perform an inframe, which may include replacing the cylinder head gasket, injectors, injector harnesses, and fuel quantity valve.

Another issue that has been reported is related to the high-pressure fuel pump. It is important to note that the high-pressure fuel pump does not need to be timed, but it is crucial to ensure that it is installed correctly. When replacing the high-pressure fuel pump, make sure to follow the installation instructions carefully, including proper torque specifications for bolts and fittings.

Additionally, the DD15 engine has a number of sensors and control modules that may require troubleshooting. For example, a fault code SPN 602 (CPC) indicates an erratic or missing Cruise Control Accelerate Switch signal. In this case, you may need to refer to the EPA07 DD15 Troubleshooting Guide for further diagnosis and repair instructions.

Furthermore, issues with the fuel system, such as low fuel pressure or faulty injectors, can also occur. It is important to check for fault codes and refer to the DD15 Fuel System Technician's Guide for specific diagnosis and repair procedures.

When troubleshooting a DD15 engine, it is important to prioritize safety and always work in a well-ventilated area to avoid inhaling toxic engine exhaust fumes.

Finding the Fuel Pressure Sensor in a D12 Engine

You may want to see also

DD15 fuel pump maintenance

The DD15 fuel pump is an essential component of modern diesel engines, delivering the right amount of fuel at the correct pressure to ensure efficient combustion and optimal engine performance. To maintain the DD15 fuel pump and keep the engine running smoothly, regular inspection and maintenance are crucial. Here are some detailed instructions and tips for DD15 fuel pump maintenance:

Understanding the DD15 Fuel Pump

The DD15 fuel pump is responsible for pumping fuel to the engine with precision and efficiency. It plays a crucial role in maintaining the optimal fuel-to-air ratio, enabling the engine to generate power efficiently. Any disruptions or malfunctions in the fuel pump can lead to a decrease in engine performance and potential breakdowns. Therefore, it is important to recognize the importance of proper maintenance and care to prolong the lifespan of the fuel pump.

Maintenance Intervals and Procedures

To ensure optimal performance and longevity of the DD15 fuel pump, regular maintenance is essential. Here are some recommended maintenance intervals and procedures:

- Regular Inspections: It is crucial to regularly inspect the DD15 fuel pump for any signs of wear, leaks, or damage. Check for unusual noises or changes in engine performance that could indicate a problem with the fuel pump.

- Fuel Filter Replacement: Follow the manufacturer's recommendations for fuel filter replacement to prevent debris and contaminants from reaching the fuel pump. Clogged filters can restrict fuel flow and strain the pump, affecting its performance.

- Engine Oil and Filter Change: Perform engine oil and filter changes at the intervals specified in the maintenance schedule, such as adjusting at 100,000, 500,000, and then every 500,000 miles thereafter.

- Valve Lash Adjustment: Adjust the valve lash at specific intervals, such as 100,000, 500,000, and then every 500,000 miles thereafter.

- Diesel Particulate Filter Change: Change the diesel particulate filter when the check engine light illuminates, indicating that ash removal is required. This is usually recommended at intervals of 550,000 to 630,000 miles.

- DEF Pump Filter Change: Replace the DEF pump filter every 3 years or 500,000 miles, whichever comes first.

Signs of a Failing DD15 Fuel Pump

Recognizing the signs of a failing DD15 fuel pump is crucial to prevent potential engine issues and maintain optimal performance. Some common symptoms of a failing fuel pump include:

- Engine misfires

- Reduced power and performance

- Poor fuel economy

- Engine stalling or difficulty starting the engine

Maintenance Tips for the DD15 Fuel Pump

In addition to regular inspections and maintenance intervals, here are some specific maintenance tips for the DD15 fuel pump:

- Keep the fuel filters clean and replace them as per the manufacturer's recommendations. Dirty or clogged filters can affect fuel flow and engine performance.

- Use high-quality fuel that meets the specifications recommended for your engine. Contaminated or low-quality fuel can damage the fuel pump and engine components.

- Regularly check the fuel system for any air leaks or blockages, as obstructions in the fuel lines can disrupt fuel delivery and impact engine performance.

- Consider scheduling routine maintenance with a qualified technician to ensure optimal performance and identify any potential issues early on.

- When upgrading or replacing the DD15 fuel pump, choose components that are compatible with your vehicle's engine specifications and fuel system requirements.

High-Pressure Fuel Pump Replacement

If the high-pressure fuel pump needs to be replaced, here are some additional considerations:

- Disconnect the batteries and drain the coolant system before beginning the replacement process.

- Ensure that the engine has been shut down for a minimum of 10 minutes before servicing any component within the high-pressure circuit to prevent the escape of high-pressure fuel.

- Follow the detailed installation steps provided in the repair manual for the DD15 engine, including torque specifications for bolts and fittings.

- Prime the system using a fuel priming valve or hand primer after installing the new high-pressure fuel pump.

- Start and run the engine after the replacement to observe pump performance and check for any leaks.

Fuel Pressure Relief Valves: Where Are They Needed?

You may want to see also

DD15 fuel pump function

The DD15 fuel pump is an essential component of modern diesel engines, delivering fuel to the engine with precision and efficiency. It is often likened to the heart of the engine, pumping fuel throughout the system to keep it alive and running smoothly. The pump is driven by a pinion gear drive and is located at the rear on the left side of the cylinder block.

The high-pressure pump within the DD15 plays a crucial role in maintaining engine performance and power output. It pressurises the fuel before sending it to the injector system, ensuring atomised fuel for better combustion and engine efficiency. This pump operates at high pressures, with internal components such as pistons, cylinders, and valves working together to create the required pressure levels.

The injector system, another key part of the DD15 fuel pump, acts as the gateway for delivering fuel into the combustion chamber. The injector nozzle sprays fuel into the chamber at high pressure, with the injector solenoid regulating the fuel flow. The fuel rail completes this system, delivering pressurised fuel from the high-pressure pump to the injector nozzles and ensuring a consistent flow to each injector.

The control module is the electronic component that regulates the operation of the DD15 fuel pump. It ensures the fuel delivery process is optimised for maximum efficiency, monitoring and adjusting parameters to meet the engine's requirements.

To maintain the DD15 fuel pump, regular inspections are crucial. This includes checking for leaks, unusual noises, or changes in engine performance. Using high-quality fuel and regularly replacing fuel filters is also important to prevent damage to the pump and its components. Following the manufacturer's maintenance guidelines helps prevent unexpected breakdowns and ensures the pump operates efficiently, supporting the performance of the diesel engine.

Fuel Pressure Regulator: 90 W124 Mercedes 300E Location Guide

You may want to see also

DD15 fuel pump performance gains

The DD15 fuel pump is an integral component of diesel engines, delivering fuel to the engine with precision and accuracy. Its role is similar to that of a conductor in an orchestra, ensuring the right amount of fuel is delivered to each cylinder at the right moment. A well-maintained DD15 fuel pump can improve engine performance, fuel efficiency, and power output.

Performance Gains Through Upgrades

Upgrading the DD15 fuel pump can unlock the full potential of your engine. Aftermarket options and tuning strategies can enhance fuel delivery and increase horsepower. High-performance pumps deliver fuel more efficiently and at higher pressures, resulting in improved combustion and smoother engine operation. Tuning the fuel pump by adjusting injection timing, pressure, and duration can also improve throttle response, increase torque, and reduce fuel consumption.

Maintenance for Performance

Regular maintenance of the DD15 fuel pump is essential to ensure optimal performance and longevity. This includes regular inspections, timely replacement of fuel filters, and the use of high-quality fuel. Keeping the fuel filters clean and replacing them as recommended prevents clogging, which can restrict fuel flow and strain the pump. Additionally, using low-quality fuel can damage the fuel pump and other engine components, leading to costly repairs.

Troubleshooting Common Issues

Troubleshooting common issues with the DD15 fuel pump is crucial to prevent unexpected breakdowns. One common issue is a drop in fuel pressure, which can lead to engine misfires and reduced efficiency. Leaks in the fuel system, clogged fuel filters, and pump malfunctions should be checked. Another issue is fuel contamination, which can cause engine performance issues and component damage. Regularly replacing fuel filters, using high-quality fuel, and keeping the fuel system clean can prevent this.

Enhancing Fuel Efficiency

Maximizing fuel efficiency with the DD15 fuel pump involves proper maintenance, monitoring, and efficient driving practices. Ensuring the fuel pump is well-maintained, lubricated, and free from debris optimizes its performance. Adjusting the fuel injection timing can also improve fuel efficiency and reduce emissions. Implementing proper fuel management practices, such as monitoring fuel consumption and maintaining proper tire pressure, further enhances fuel efficiency.

In conclusion, the DD15 fuel pump is critical to engine efficiency and performance. Upgrading the fuel pump, regular maintenance, and troubleshooting common issues can all contribute to performance gains, ensuring the engine operates at its peak potential.

Measuring Fuel Pressure in a V6 Tacoma

You may want to see also

Frequently asked questions

No, the high-pressure fuel pump on the DD15 engine does not need to be timed.

Some common signs of a failing DD15 fuel pump include engine misfires, reduced power output, decreased fuel economy, and unexpected engine stalling.

The DD15 fuel pump ensures that the engine receives the right amount of fuel at the correct pressure for combustion, optimising engine performance and fuel efficiency.

Regular inspection and maintenance of the DD15 fuel pump are crucial. This includes checking for leaks, corrosion, or damage, as well as keeping fuel filters clean and replaced as per the manufacturer's recommendations.

The Detroit Diesel Engine Repair Manual provides detailed instructions on removing and installing the high-pressure fuel pump. It is a complex process that involves multiple steps and should be performed by a qualified technician.