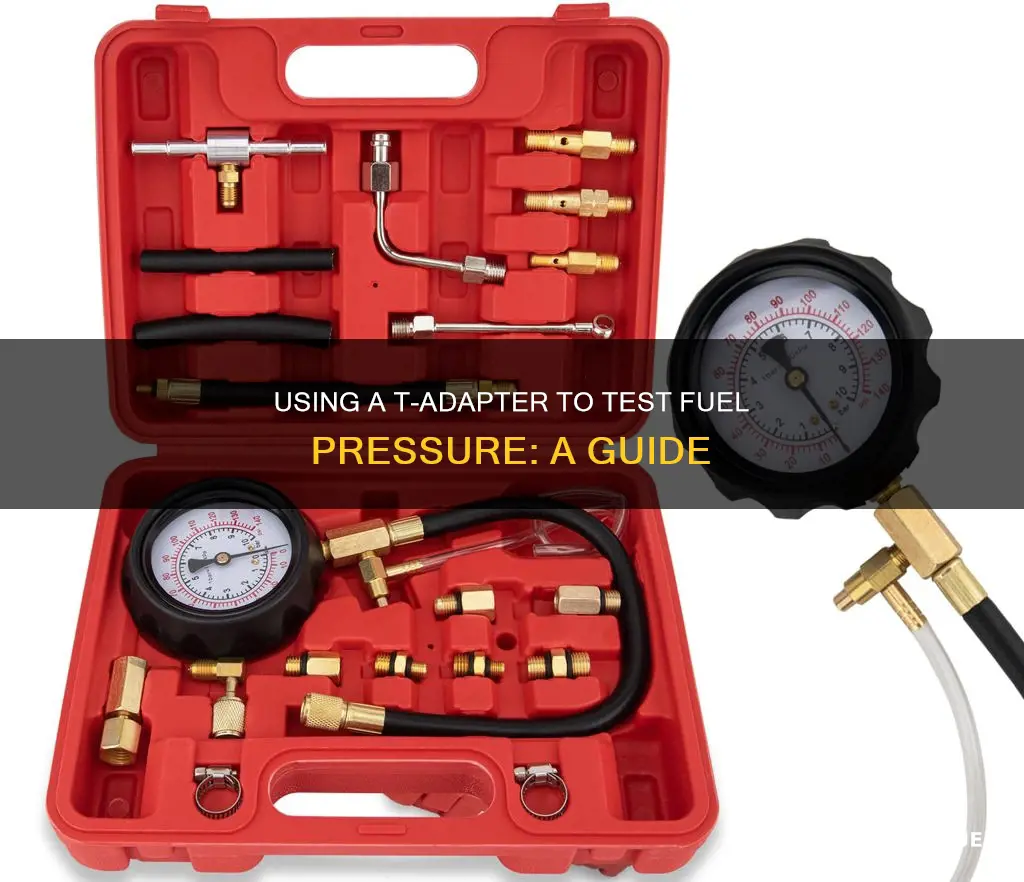

A fuel pressure tester is a simple tool that can help you diagnose car issues. It consists of a gauge attached to a fuel hose with multiple fittings, which can connect to the fuel system of almost any vehicle. To use a fuel pressure tester, you need to connect it to the fuel system and pressurise the system. The tester will then display the pressure in psi, allowing you to verify whether your fuel pressure is too high or too low, which could be causing issues such as a slow startup, low performance, misfires, and stalling.

To test fuel pressure, you will need a fuel pressure tester, which you can buy or rent. Before testing, check that your car has enough gas in the tank, as a faulty fuel gauge could be the issue. If there is gas in the tank, the next step is to verify that the fuel pump works. You can do this by listening for a two-second whir, hum, or series of rapid clicks as the fuel pump pressurises the fuel line to the engine when you turn the ignition switch to On. If there is no noise, this means the pump is not getting power or it has failed.

Once you have confirmed that you have gas in your tank and your fuel pump is working, you can connect the fuel pressure tester. With an entirely cold engine, pop the hood and find the Schrader valve fitting on the fuel rail. Remove the Schrader valve cap and attach the appropriate fuel pressure tester fitting, making sure it is leakproof. Then, turn the ignition to On and check the psi reading, waiting to see if there is a drop in pressure, which would indicate a leak in the system. If the pressure holds steady, start the engine and let it idle, and you should see steady fuel pressure.

If you are testing fuel pressure on a Ford 6.0L Powerstroke engine, you will need a specialised fuel pressure test kit. To attach the tester, you will need to remove the black top cap of the secondary fuel filter and install the aluminium lid supplied in the kit, making sure the o-ring is in place. Then, screw the aluminium fitting into the threaded hole and attach the black hose to the fitting. Finally, check that all connections are tightened and bleed the fuel system by turning the ignition to the On position for 30 seconds, repeating three times. With the engine idling, check the pressure level on the fuel pressure gauge.

If you are testing a TBI system, you will need a T-fitting, as there is no Schrader valve. You can buy a T-fitting or make your own, but be sure to use the correct thread pitch to avoid leaks.

| Characteristics | Values |

|---|---|

| Purpose | To test fuel pressure |

| Vehicle compatibility | Ford 6.0L Powerstroke Engines, 2003 - 2010 |

| Tools required | 36mm Socket, 6mm Allen Wrench, 24mm Sock or ½" Drive Ratchet, Fuel Pressure Test Kit |

| Fuel pressure with engine idling | 48psi |

| Fuel pressure with engine running | 35psi |

| Fuel pressure specification | 45psi or more |

| Fuel pressure gauge reading interpretation | Low pressure: leaking fuel injector, worn out or faulty fuel pump, clogged or restricted fuel filter, failed anti-drain valve, or bad FPR. High pressure: clogged or kinked fuel return line, bad fuel pump driver module, powertrain control module, or faulty fuel pressure regulator. |

What You'll Learn

How to test fuel pressure

Testing fuel pressure can be done in a few simple steps. First, you need to gather your tools. For testing fuel pressure, you will need a fuel pressure tester, which typically consists of a gauge attached to a fuel hose with multiple fittings. These fittings can be connected to the fuel system of almost any vehicle.

Next, you need to locate the Schrader valve on the fuel rail. This is usually found on the fuel rail, which holds the fuel injectors in place. Remove the Schrader valve cap and attach the appropriate fuel pressure tester fitting, ensuring a tight fit to prevent leaks.

With the fitting attached, turn the ignition to the "on" position, but do not start the engine. Check the psi reading on the fuel pressure tester and wait to see if there is any drop in pressure, which would indicate a leak in the system. If the pressure holds steady for 5-10 minutes, the system is sealed properly.

If the pressure drops, there is a leak in the fuel system. Leaks can be located by looking for drips underneath the vehicle. It is important to note that leaks can also occur internally from a faulty fuel injector.

Once any leaks have been addressed, start the engine and let it idle. The fuel pressure should remain steady, within a few psi of the recommended pressure for your specific engine.

If the fuel pressure is steady and rises with engine speed, your engine problem is likely not fuel-related. However, if you are still experiencing issues, further diagnostics may be required.

It is important to note that fuel vapors are highly flammable, so these steps should be performed in a well-ventilated area with a fire extinguisher nearby. Additionally, always refer to the repair manual for your specific vehicle for detailed instructions and specifications.

Finding the C4 Fuel Pressure Regulator: Where is it?

You may want to see also

How to connect a fuel pressure tester

To connect a fuel pressure tester, safety should be the first priority. Fuel vapours are highly flammable, so ensure you are working in a well-ventilated area and have a fire extinguisher nearby. You should also wear safety glasses and gloves.

With the engine entirely cold, pop the hood and locate the Schrader valve fitting on the fuel rail. These are present in most vehicles but may be hidden under a fuel rail cover or other plastic engine cover. Remove the Schrader valve cap and attach the appropriate fuel pressure tester fitting, ensuring that it is threaded on properly for a leak-proof fit.

Turn the ignition to "on", not start, and check the psi reading. Observe the reading over 5 to 10 minutes, watching for a psi drop which would indicate a leak in the system. If the pressure remains the same, the system is holding pressure well. If the fuel pressure drops, this indicates a leak in the fuel system.

Start the engine and let it idle. The fuel pressure should be steady, within a few psi of the recommended pressure. Once the engine is warmed up, slowly rev the engine, checking that the pressure rises with the RPMs. If the fuel pressure holds steady, rises with engine speed, and is at the recommended pressure, your engine problem is likely not fuel-related.

Testing Fuel Pressure in a 2004 Taurus: A Step-by-Step Guide

You may want to see also

Tools required for testing fuel pressure

Testing your vehicle's fuel pressure can be done in a few ways, depending on the vehicle. You can either use a fuel pressure tester or a fuel injection pressure tester.

- Fuel Pressure Tester Kit: This kit typically includes a gauge attached to a fuel hose and multiple fittings, allowing you to connect to the fuel system of most vehicles. It measures the pressure in psi, helping you diagnose any issues with fuel pressure.

- Fuel Injection Pressure Tester: This tester is designed to check the pressure in fuel injection systems. It usually includes various adapters and fittings to connect to different vehicles.

- T-Adapter: If you have a TBI (Throttle Body Injection) system, you may need a T-fitting to connect the fuel pressure tester to the fuel lines.

- Schrader Valve: Most vehicles have a Schrader valve fitting on the fuel rail, which the fuel pressure tester can be attached to.

- Multimeter: A multimeter can be used to verify power delivery to the fuel pump.

- Fire Extinguisher: It is important to have a fire extinguisher nearby when working with fuel systems, as fuel vapors are highly flammable.

- Repair Manual: To determine the correct fuel pressure specifications for your vehicle, refer to the repair manual.

- Fuel Pressure Gauge: A fuel pressure gauge is used to measure and display the fuel pressure.

It is important to note that some vehicles may require specific tools or adapters, so it is recommended to consult a professional or refer to vehicle-specific instructions for more detailed information.

Fuel Pressure Maintenance for 1995 Subaru Legacy

You may want to see also

How to test a fuel pressure regulator

Testing a fuel pressure regulator can be done in a few simple steps. Here is a detailed guide on how to do it:

Firstly, it is important to prioritise safety. Ensure you are wearing safety gear, including safety glasses and gloves, and work in a well-ventilated area. This is because releasing fuel under pressure can cause fires and injuries.

Now, you need to locate the fuel pressure regulator. It is usually found on one end of the fuel rail, which holds the fuel injectors in place. It is a small metallic cylinder with a thin vacuum hose connected on top. Depending on your vehicle's configuration, you may also see an incoming fuel line and a return fuel line connected to it. However, in newer vehicle models, the fuel pressure regulator may be placed inside the fuel tank as part of the fuel pump assembly, so you may not find it on the fuel rail.

Once you have located the fuel pressure regulator, check the vacuum hose for a tight connection. A loose hose will prevent the regulator from functioning properly. Inspect the hose for any signs of damage or wear, and then disconnect the vacuum line from the regulator. If there is fuel in the vacuum line, the diaphragm inside the pressure regulator is leaking, and you will need to replace the regulator.

The next step is to connect a fuel pressure gauge. Most modern fuel injection systems have a Schrader or test valve located on the fuel rail, similar to a tyre air valve. Connect your fuel pressure gauge to this valve or test port. If your system does not have this valve or has an older fuel system, refer to your vehicle's repair manual for the best way to connect the gauge. If there is no test port or you lack the correct adapter, you can either remove the test port valve and connect the gauge directly or disconnect the fuel inlet line and connect a T-adapter before reconnecting the fuel line and attaching the gauge to the T-adapter.

Now, you need to find the fuel system pressure specification for your specific vehicle model with the engine running and off. This information can be found in your car repair manual.

Start the engine and let it idle, or ask an assistant to crank the engine for a few seconds if it doesn't start. Then, turn off the engine. Observe the fuel pressure gauge during and after this process. The fuel pressure should hold to the specifications outlined in your repair manual. With the engine off, the pressure should remain stable for about five minutes.

Additionally, you can remove the vacuum line while the engine is running. If the pressure does not rise, there is an issue with the fuel pressure regulator.

For further confirmation, repeat the process of starting the engine and turning it off several times, noting the pressure gauge readings each time. Compare these readings to the specifications in your repair manual. If the readings are lower than the specified pressure while the engine is running, there could be an issue with the fuel injector, fuel pump, fuel filter, anti-drain valve, or the fuel pressure regulator itself.

If the fuel pressure begins to drop soon after shutting off the engine, a leaking injector, a faulty anti-drain valve, or problems with the fuel pressure regulator may be the cause.

By following these steps and observing the fuel pressure gauge readings, you can effectively test a fuel pressure regulator and identify any potential issues.

Gasoline vs Diesel: Vapor Pressure Differences Explained

You may want to see also

How to test for maximum pressure

Testing for maximum pressure is important to ensure your vehicle's fuel system is working optimally and to avoid issues such as excessive fuel consumption, black smoke from unburned gas, and catalytic converter overheating. Here's a step-by-step guide on how to test for maximum pressure:

- Safety First: Working with fuel can be dangerous, so put on safety gear such as gloves and safety glasses. Ensure you work in a well-ventilated area, and don't smoke or have anything nearby that could cause a spark.

- Check the Fuel Pressure: Start your car and let it idle. Connect a fuel pressure gauge to the fuel rail's Schrader valve. Turn the ignition to "on" and observe the psi reading. Compare this reading to the manufacturer's specifications. If the pressure is within the acceptable range, proceed to the next step. If it's higher or lower than specified, you may need to address issues with the fuel pump or fuel filter.

- Perform a Fuel Volume Test: Use a flowmeter if available, or perform a timed fuel delivery test. Collect a fuel sample for five seconds while the pump is running, and compare the amount of fuel delivered to the manufacturer's specifications. This step helps determine if the proper volume of fuel is reaching the fuel injectors.

- Understanding Fuel Pressure Readings: If you encounter issues with fuel pressure, there are several potential causes. High fuel pressure may be due to a faulty fuel pressure regulator, restrictions in the return line, or faulty fuel line couplings at the fuel tank. Low fuel pressure may be caused by a clogged fuel filter, restrictions in the pressure line, a faulty fuel pump relay, or issues with the fuel pump fuse, wiring, or filter. Refer to your vehicle's service manual for detailed diagnostic procedures.

- Address Any Issues: Based on your findings, take the necessary steps to resolve any problems with the fuel system. This may involve replacing or repairing faulty components, such as the fuel pump, fuel filter, fuel pressure regulator, or fuel line couplings.

- Re-test and Verify: After making any necessary repairs or adjustments, re-test the fuel pressure to ensure it is now within the manufacturer's specified range. This confirms that you have successfully addressed the issue and maximized the fuel pressure for your vehicle's optimal performance.

Remember to consult a professional mechanic if you are unsure about any part of the process or if you encounter complex issues with your vehicle's fuel system.

Fuel Tank Pressure: What's the Cause?

You may want to see also

Frequently asked questions

A fuel pressure test is used to diagnose starting or running issues with your car. It involves connecting a fuel pressure tester to the fuel system of your vehicle to verify that enough fuel pressure is getting to the injectors.

First, make sure your engine is entirely cold and pop the hood. Find a Schrader valve fitting on the fuel rail. Remove the Schrader valve cap and attach the appropriate fuel pressure tester fitting. Ensure it threads on properly for a leak-proof fit. Turn the ignition to "on", not start, and check the psi reading.

"Good fuel pressure" depends on the engine. Some older throttle-body injected systems need as little as 10 psi, while multi-port injection can see as high as 60. Check your repair manual for the specifications of your vehicle.

Low fuel pressure may cause a slow start-up, low performance, misfires, and stalling. High fuel pressure may cause excessive fuel consumption, black smoke from unburned gas, an overheating catalytic converter, and rough idle.

First, locate the fuel pressure regulator on one end of the fuel rail. Check the vacuum hose for a tight connection and disconnect it from the regulator. If you see any signs of fuel in the vacuum line, the diaphragm inside the pressure regulator is leaking and you need to replace the regulator. If not, connect your fuel pressure gauge to the Schrader valve or test port and observe the fuel pressure gauge while the engine is running and after shutting off the engine.