A fuel pressure regulator is an essential component of a vehicle's fuel system, controlling the amount of fuel pressure delivered to each injector. A faulty regulator can cause a range of issues, from increased fuel consumption to engine misfires and complete failure to start. While it is a simple component to replace, with many vehicle models allowing for at-home replacement, it is important to take safety precautions when working with the fuel system, such as ensuring adequate ventilation and releasing system pressure to avoid injury from pressurized fuel. This article will provide a step-by-step guide on how to unstick and replace a fuel pressure regulator, as well as offer tips on cleaning and maintaining this crucial component to ensure optimal vehicle performance and avoid costly repairs.

What You'll Learn

Relieve system pressure

To relieve the system pressure of a fuel pressure regulator, there are a few steps you need to take. Firstly, park your vehicle in a well-ventilated area, away from any open flames or sources of ignition. The fumes released by the fuel system are highly combustible, so this is an important safety precaution.

Next, you will need to relieve the system pressure. For vehicles with Throttle Body Injection (TBI) systems, you can simply turn off the engine and wait a few seconds for the pressure to drop. If this does not work, you can remove the fuel pump fuse or relay and let the engine idle until it stalls. For multiport fuel injection systems, you will need to follow a similar process. Start by removing the fuel pump fuse or relay, then start the engine and let it idle until it stalls.

If your vehicle has an Electronic Fuel Injection (EFI) system, the process is slightly different. Locate the Schrader valve on the fuel rail and cover it with a rag. Carefully depress the valve with a screwdriver, using the rag to catch any released fuel. Then, loosen the fuel filler cap to relieve pressure from the gas tank.

Once you have completed these steps, you can proceed to disconnect the negative battery cable and begin working on the fuel system. It is important to relieve the system pressure before attempting any repairs or maintenance on the fuel pressure regulator to ensure your safety and avoid the risk of injury.

High-Performance BMW 335i: Choosing the Right Fuel Pump

You may want to see also

Disconnect the negative battery cable

Disconnecting the negative battery cable is a crucial step when relieving the fuel system's pressure before replacing the fuel pressure regulator. Here is a detailed guide on how to safely disconnect the negative battery cable:

Turn Off the Ignition: Before starting, ensure your car is turned off. Never attempt to disconnect the battery while the car is powered on.

Locate the Car Battery: Pop the hood of your car and locate the car battery. It is typically a large, block-like component located under the hood, near the engine bay's surface. If you are having trouble locating it, consult your car's owner's manual.

Identify the Negative Terminal: The negative terminal is marked with a "-" symbol and is usually black, often with a black plastic cap. It is crucial to distinguish the negative terminal from the positive terminal, marked with a "+" and typically red.

Loosen the Nut on the Negative Terminal: Remove any plastic caps covering the terminals. Find a wrench that fits the nut on the negative terminal and place it on the nut. Turn the wrench counterclockwise to loosen the nut.

Remove the Negative Connector: After loosening the nut, carefully remove the negative connector cable from the battery. Ensure that the cable is pushed aside and does not come into contact with the battery. It is essential to avoid letting the wrench touch both the negative and positive terminals simultaneously.

By following these steps, you can safely disconnect the negative battery cable, which is necessary when relieving fuel system pressure and performing maintenance on your vehicle's fuel pressure regulator.

Ford 351 Fuel Pressure: Maintaining Optimal Performance

You may want to see also

Remove the air cleaner assembly

To remove the air cleaner assembly, you'll need to follow these steps:

Firstly, locate the air cleaner assembly on your vehicle. It is usually found on the throttle body injection unit or the multiport fuel injection system. Once you have located it, you can begin the removal process.

Next, disconnect the negative (black) battery cable. This is an important safety precaution as it will prevent any accidental electrical discharge during the removal process. Ensure you are wearing protective gear, such as gloves and safety goggles, to prevent skin irritation and protect your eyes from fuel splashes.

Now, you can start to remove the air cleaner assembly. Loosen any screws or bolts holding the assembly in place, using the appropriate tools. Be careful not to misplace any small parts, such as screws, and keep them in a safe place. Slowly lift the assembly away from the throttle body injection unit or the multiport fuel injection system, whichever is applicable to your vehicle.

With the air cleaner assembly removed, you will now have access to the fuel pressure regulator. You can proceed with the next steps to unstick or replace the fuel pressure regulator.

It is important to note that working with fuel systems can be dangerous if not done correctly. If you are unsure about any part of the process, it is always best to consult a professional mechanic for assistance.

Best Places to Buy 855 Cummins Fuel Pressure Spring

You may want to see also

Remove the vacuum hose

Removing the vacuum hose from a fuel pressure regulator is a crucial step in maintaining or replacing this component. Here is a detailed guide on how to do it:

First, locate the vacuum hose. It is usually connected to the fuel pressure regulator, which can be found at the end of the fuel rail, connected to the injectors. Once you have located the regulator, you can proceed to the next step.

Next, carefully remove the vacuum hose from the regulator. It is important to be cautious during this step as, in some cases, there may still be pressure left in the fuel injectors. You may hear a low hiss as any remaining pressure is released. Be prepared for the possibility of fuel dripping from the hose or regulator. This could indicate a faulty fuel pressure regulator or injectors, so be sure to inspect the components for any signs of damage or defects.

After the vacuum hose is removed, set it aside and inspect the area for any fuel residue or leaks. Use a clean, white cloth to wipe up any excess fuel and ensure that the area is clean and dry before proceeding with any further maintenance or repairs.

Now, you can proceed to replace the fuel pressure regulator or perform other necessary maintenance tasks. It is important to consult a qualified mechanic or a repair manual specific to your vehicle's make and model for further guidance.

Remember to exercise caution when working with fuel system components, and always work in a well-ventilated area to avoid inhaling dangerous fumes.

Fuel Pump Pressure: Factors Affecting Performance and Efficiency

You may want to see also

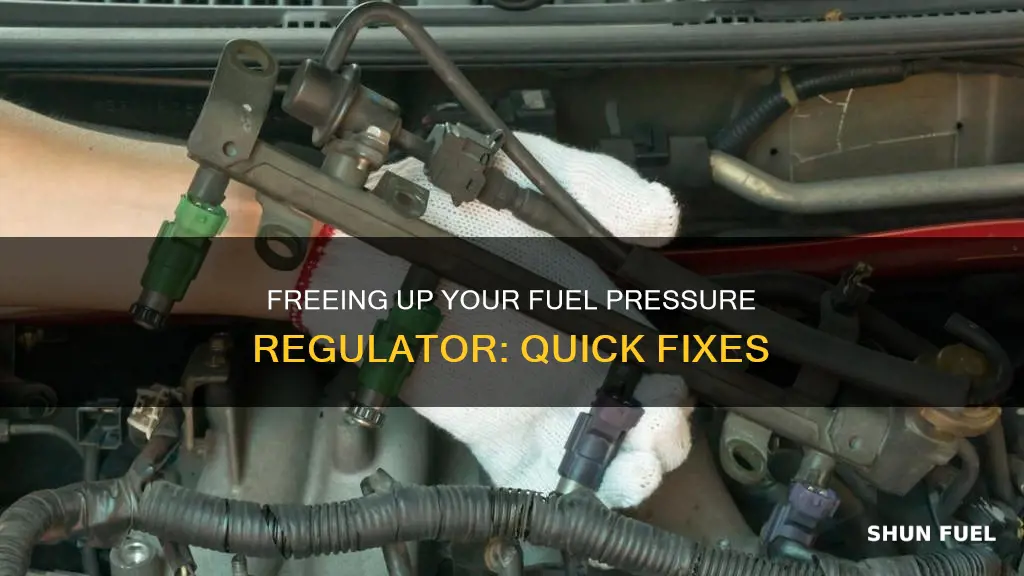

Clean the fuel pressure regulator

Cleaning a fuel pressure regulator is a relatively simple process, but it's important to be careful as the regulator is a sensitive component. Here is a step-by-step guide on how to clean your fuel pressure regulator:

Firstly, gather the necessary tools and safety equipment. You will need a fuel pressure regulator cleaner, a soft brush or cloth, safety glasses, and gloves. It is important to use a specific fuel pressure regulator cleaner as other harsh chemicals can damage the regulator.

Next, locate the fuel pressure regulator in your car. It is usually installed near the fuel injectors on the fuel rail. Once you have located it, remove any components attached to the regulator using the correct wrench or socket. Keep track of the position of O-rings and seals, as you will need to reinstall them later.

Now, you can begin cleaning the regulator. Use the soft brush or cloth and the cleaner to gently wipe away any dirt or buildup from the regulator. Be especially gentle around the diaphragm, as this is a delicate internal part. Once you have finished cleaning, move the diaphragm with your hand to ensure it is functioning correctly.

After cleaning, reinstall the regulator in the fuel line, ensuring it is properly aligned and the seals are correctly installed. Reconnect the fuel lines and test the car to ensure the regulator is working properly.

If, after cleaning, the regulator is still not functioning correctly, you may need to replace it. Fuel pressure regulators are relatively inexpensive, ranging from $20 to $200 or more, depending on the make and model of your car.

Remember, it is important to maintain your car and clean your fuel pressure regulator regularly to avoid build-up and corrosion, which can lead to a stuck regulator and other engine problems.

Testing Fuel Pressure Regulator in '99 Camry: A Step-by-Step Guide

You may want to see also

Frequently asked questions

If your engine is hard to start, this could be a sign of a faulty fuel pressure regulator. Other signs include misfires, reduced power and acceleration, and a drop in fuel efficiency. You can also check for internal leaks by closing or pinching the fuel return line and cycling the key a couple of times. If the pressure on the gauge doesn't increase, your fuel pressure regulator might be stuck or faulty.

First, relieve the fuel system pressure. On some TBI models, system pressure drops a few seconds after turning off the engine. For TBI models and multiport fuel injection systems, you can remove the fuel pump fuse or relay, start the engine, and let it idle until it stalls. Once the system pressure is relieved, you can proceed to replace the fuel pressure regulator. This process is relatively simple and can be done at home with common tools for most vehicle models.

A stuck or faulty fuel pressure regulator can cause a range of issues, from increased fuel pressure and emissions to insufficient fuel pressure, which can cause the engine to lose power, affect performance, or not start at all. A bad fuel pressure regulator can also lead to spark plug fouling or misfiring, so it is important to address the issue promptly and refer to a repair manual or mechanic if needed.