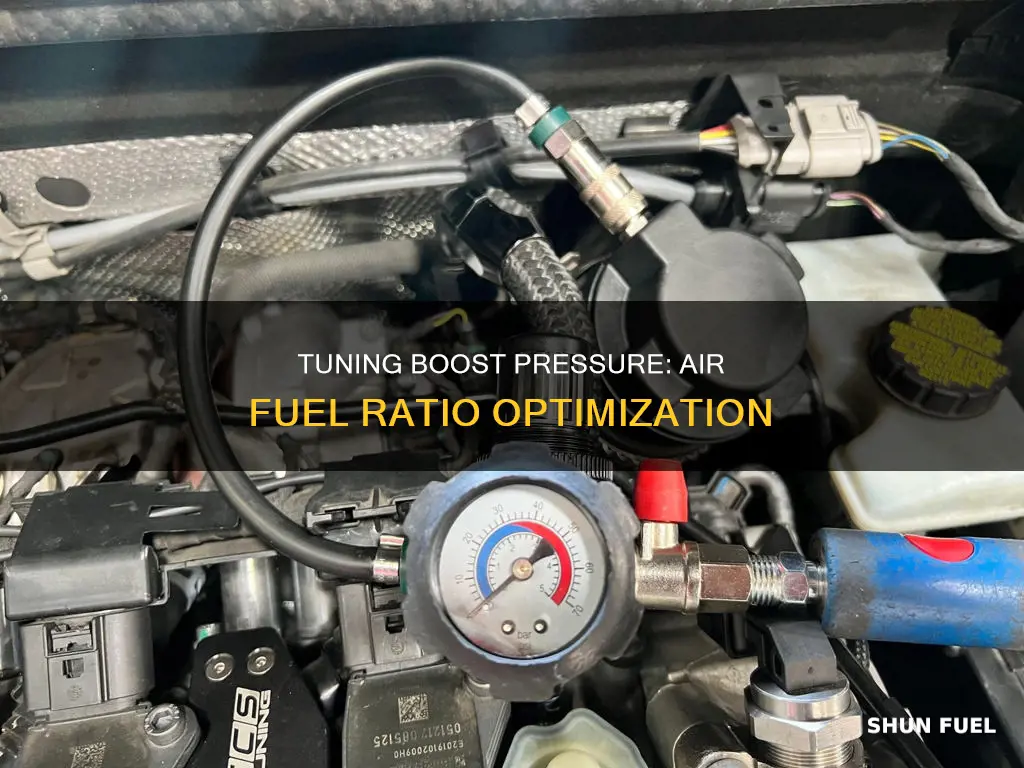

Tuning turbocharged engines can be a daunting task, even for experienced tuners. One of the key concepts to understand is boost pressure and its effect on airflow, which in turn influences fuel and ignition requirements. Boost pressure is the amount of air forced into the cylinders by the turbocharger, and as it increases, so does airflow. This has two main effects: firstly, it leads to more fuel and air being combusted, resulting in higher temperatures, and secondly, it affects ignition timing. To manage these effects, a richer air-fuel ratio target is required as boost pressure and airflow increase. This involves adding a small amount of extra fuel, which helps to cool the combustion charge temperature by passing through the combustion chamber unburned. Additionally, as boost pressure rises, ignition timing needs to be retarded, or started later in the engine cycle, to prevent knock. Understanding these relationships is crucial for creating a reliable tune and optimising engine performance.

What You'll Learn

The impact of boost pressure on airflow

Boost pressure and airflow are not the same. Boost pressure is a function of airflow vs the restriction of the engine's intake path. The amount of airflow and power produced is dependent on the engine's restriction. The more restriction, the higher the pressure differential (boost pressure) needs to be to overcome the restriction.

The turbocharger is used to force more air into the cylinders. This has two effects on tuning requirements: fuel delivery and ignition timing. As more fuel and air are combusted in the cylinder, more heat is created. Therefore, as the airflow and boost pressure increase, a richer air-fuel ratio is required to prevent the engine from overheating or suffering from knock.

Additionally, as more fuel and air are combusted in the cylinder, the combustion process happens faster. This means that less ignition advance is needed to reach MBT (Maximum Best Torque). As a result, more boost requires ignition timing to be retarded, or started later in the engine cycle.

When tuning a turbocharged engine, it is important to monitor various temperatures such as engine coolant temperature, intake air temperature, and oil temperature. This helps to ensure that the engine does not overheat and get damaged.

In summary, boost pressure results in airflow, and it is the airflow that determines the engine's fuel and ignition requirements. A larger turbocharger will produce more airflow and power at the same boost pressure compared to a smaller turbocharger. Therefore, when tuning a turbocharged engine, it is crucial to consider the impact of boost pressure on airflow to optimize fuel delivery and ignition timing for maximum power and engine reliability.

Fuel Pressure Regulator Issues: Code or No Code?

You may want to see also

The role of fuel type in AFR

The type of fuel used in your engine will have a significant impact on the ideal air-fuel ratio (AFR). While the ideal ratio for normal petrol engines is generally accepted to be 14.7:1 (14.7 parts air to 1 part fuel), this can vary depending on the type of fuel used.

For example, when using pump fuel, your engine will likely be knock-limited, meaning that advancing the timing towards maximum brake torque (MBT) will result in engine knock before MBT is reached. Knock can quickly destroy an engine, so it's important to understand how the AFR can be used as a knock deterrent.

Using higher octane fuel, such as race fuel or super unleaded, can increase an engine's resistance to knock. Race fuel, for instance, often has an octane rating of 120+ RON, which is significantly higher than the 97-99 RON of super unleaded. With these higher octane fuels, you can run leaner mixtures while still maintaining resistance to knock.

On the other hand, alternative fuels like nitromethane or liquefied petroleum gas (LPG) are incredibly resistant to detonation, even with richer mixtures. Nitromethane, in particular, is popular for drag racing cars as it provides increased power and resistance to detonation while remaining incredibly cold, often negating the need for an intercooler.

It's important to note that the ideal AFR will also depend on factors such as engine speed, load, and temperature, and may vary from engine to engine. As such, it's crucial to consult a qualified tuner and use proper tools and training when adjusting your AFR to avoid potential engine damage.

Understanding Fuel Rail Pressure in X15 Engines

You may want to see also

Tuning for fuel economy vs. power

Tuning for fuel economy and tuning for power are two very different things. This is because the air-fuel ratio (AFR) that is best for fuel economy is not the same as the AFR that generates the most power.

Tuning for Fuel Economy

For optimum fuel economy, a ratio of 16-17:1 is usually best. Any leaner than this and the car will begin to misfire.

Tuning for Power

Maximum power is usually found with an AFR between 12-14:1. However, this may be too lean for safety on many engines. For maximum reliability at full power, AFRs from 10.5-12.5:1 are considered best, depending on the engine. Richer than around 10.5:1 and you will start to get noticeable black smoke from the exhaust.

Tuning for Both

To get a good overall car, you need to have a mixture of these AFRs. This should depend on how the car is being driven at any moment in time. Thankfully, that’s what modern fuel injection can supply you with, provided the car has been mapped properly.

Replacing ISX15 High-Pressure Fuel Pump: Step-by-Step Guide

You may want to see also

The science behind AFR

Tuning turbocharged engines can be a daunting task, even for experienced tuners. The process involves optimising the fuel delivery and ignition timing to achieve maximum torque and power while maintaining reliability. One of the key aspects of tuning is understanding the science behind Air-Fuel Ratios (AFR).

The AFR is the proportion of air to fuel in the combustion chamber. The ideal AFR, also known as the stoichiometric ratio, for gasoline engines is around 14.7:1, which means 14.7 parts air to 1 part fuel. This ratio ensures complete combustion, maximising power and fuel efficiency while minimising emissions.

Deviating from the stoichiometric ratio can have significant effects on engine performance and fuel economy. A lean mixture, or a ratio with more air and less fuel, can lead to higher combustion temperatures, potentially causing engine damage, misfires, and detonation or "knock". On the other hand, a rich mixture, with more fuel and less air, results in unburned fuel, wasting fuel and reducing engine efficiency. It can also cause bore wash, oil dilution, and damage to exhaust components.

When tuning an engine, it is crucial to adjust the AFR based on various factors such as engine speed, load, and temperature. For example, engines running at low speeds can operate with leaner mixtures without adverse effects, while high-power engines require richer mixtures to prevent damage. Additionally, cold engines or those with low vacuum require richer mixtures for smooth operation.

The AFR also plays a crucial role in mitigating knock, a phenomenon where the air-fuel mixture ignites spontaneously without the spark plug, leading to severe engine damage. By enriching the fuel mixture, the combustion temperature and cylinder pressure are reduced, deterring knock.

In summary, understanding the science behind AFR is essential for successful engine tuning. It involves fine-tuning the AFR to achieve optimal combustion, balancing power, fuel efficiency, and engine reliability while preventing issues such as knock and detonation.

Fuel Pressure Regulator: Setting the Optimal PSI

You may want to see also

How to set your fuel pressure

Setting the fuel pressure correctly is crucial to the performance and longevity of your engine. Incorrect air-fuel ratios can lead to engine failure, so it's important to get it right.

Step 1: Understanding Air-Fuel Ratios

Firstly, you need to understand the basics of air-fuel ratios (AFR). The ideal ratio for normal petrol engines is 14.7:1, which is known as the stoichiometric mixture or Lambda 1.0. This is the amount of air required for the complete combustion of the fuel. A ratio with more air is considered lean, while a ratio with less air is considered rich.

Step 2: Determining the Target AFR

Several factors will influence the target AFR for your engine:

- Fuel Type: Different fuels have different ideal mixtures. For example, gasoline (91-94 octane) typically has an AFR of around 14.7:1.

- Camshaft Overlap and Duration: Camshafts with high overlap, long durations, and aggressive ramp rates are suitable for high engine speeds but sacrifice idle quality. Engines with low vacuum require richer AFRs for smooth idling.

- Engine Power: Engines can be leaned at idle without issues, but high-power engines running lean can lead to serious damage, including melted pistons, knock, and cylinder wall damage.

- Knock Threshold: Understanding knock is complex, but it is important to know that the air-fuel ratio has a significant relationship with the knock threshold on knock-limited fuels.

- Engine Speed: Engines at low speeds can run leaner than high-speed engines as they undergo fewer combustion cycles.

- Engine Load: As engine load increases, engine temperature rises significantly. To control the temperature, richer AFRs are required.

- Engine Coolant Temperature: Cold engines require more fuel to run smoothly due to poor fuel atomization at low temperatures.

- Cylinder Wall Temperature: During cold or hot starts, cylinder wall temperatures change rapidly, and the AFR required to run properly will also change.

- Idle Stability: The camshaft design, valve overlap, and injector performance all influence idle stability and can affect the AFR.

Step 3: Setting the Fuel Pressure

Now that you have determined the target AFR for your engine, you can adjust the fuel pressure accordingly. The process for doing this will depend on the specific fuel system and vehicle you are working on.

For example, when setting the fuel pressure for a Holley Terminator TBI system, you need to ensure the fuel pressure is properly adjusted, and the "Actual System Pressure" is accurately entered in the Engine Parameters. The fuel pressure can be checked during the "Fuel Pump Prime" time or by temporarily wiring the system relay to keep the pump running continuously.

For other fuel systems, you may need to refer to the instruction manual or seek advice from a qualified individual. It is important to note that tuning should only be performed by qualified individuals using proper tools and training.

Fuel Pressure Regulator Location in the MK4 Supra

You may want to see also

Frequently asked questions

The ideal ratio is generally around 14.7:1, which is also known as the stoichiometric mixture or Lambda 1.0. This is the amount of air required for the complete combustion of the fuel.

When a car is running lean, it means there is excess air and not enough fuel. This can lead to engine damage due to misfires and overheating. Conversely, a rich mixture means there is excess fuel and not enough air, resulting in lower engine efficiency and potential damage to exhaust components.

Tuning complicates air-fuel ratios as varying compression ratios, camshafts, boost pressures, and other factors affect the ideal ratio at any given time. This highlights the importance of remapping the car's ECU as tuning components are added.

The best way is to consult a trusted and reliable tuner who can ensure your ratios are safe for your specific engine. It is recommended to get things checked every six months to ensure everything is still optimal.