If you're looking to test the fuel pressure on your 2007 BMW 335i, there are a few methods you can use. One way is to use a digital volt-ohm meter (DVOM) to check the voltage at the fuel pump electrical connector. You can access the fuel pump electrical connector and terminals under the rear seat cushion, below an access panel. Another way is to use a BMW scan tool to monitor the fuel delivery pressure. You can also use a mechanical pressure gauge to test the fuel pressure, but this requires a special tool or an in-line pressure gauge fabricated for this purpose. Additionally, you can check the fuel pressure sensor, which can be found on the steel fuel line under the intake, sticking up near the high-pressure pump.

| Characteristics | Values |

|---|---|

| Year | 2007 |

| Model | 335i |

| Fuel Pressure | 5 bar (72.5 psi) |

| Fuel Pressure Drop | No more than 0.5 bar in 15 minutes |

What You'll Learn

Using a DVOM to check for correct voltage

To test the voltage of your 2007 BMW 335i's fuel pump using a DVOM, you will first need to access the fuel pump electrical connector and terminals. These can be found under the rear seat cushion, below an access panel.

Now, follow these steps to check for correct voltage:

- Set up your DVOM: Plug the black probe into COM and the red probe into mAVΩ.

- Connect the DVOM to the fuel pump electrical connector terminals: Connect the black probe to the negative terminal and the red probe to the positive terminal.

- Check the voltage: Press the Start Stop key as if you wanted to start the engine. If the engine doesn't start, the DVOM should read around 10 volts. If no voltage is found, check the ground to the fuel pump and the fuel pump fuse F70 in the junction box.

- Load test: Connect the DVOM across the fuel pump electrical connector terminals and take a reading. It should read battery volts when the key is turned on. Then, connect an incandescent bulb-style test light to the battery ground and touch the test light probe tip to the positive wire you are back-probing with the DVOM. Your reading should hold steady, with a maximum voltage drop of 0.5 volts.

- Confirm the pump can supply fuel pressure to the fuel rail: Use a fused jumper lead set to battery positive (+) and battery negative (-) and run the pump.

- Check the wiring diagram: Use the DVOM in conjunction with a wiring diagram to determine the correct terminals for testing.

Replacing Fuel Pressure Regulator in Your 3800 V6 Engine

You may want to see also

Locating the fuel pump electrical connector and terminals

First, you will need to locate the fuel pump module, which is positioned behind the right rear seat back cushion on the C-pillar. To access it, carefully remove the rear seat cushion by pulling it up and detaching the locking tabs. Once you have accessed the rear of the vehicle's interior, you will need to peel back the carpet on the right side of the rear seat cushion area.

Next, you will find four 10mm nuts securing an access panel. Remove these nuts and lift the access panel to expose the electrical connector on the fuel pump module. This is where you will find the fuel pump electrical connector and terminals.

It is important to note that the fuel pump is located on the right side of the fuel tank. Additionally, the fuel pump control module is used in place of the fuel pump relay in E90 models.

If you are having trouble locating the fuel pump electrical connector and terminals, there are a few aftermarket performance companies that sell OEM fuel pump connectors with terminals, which you can use to create a custom pump.

Furthermore, when testing the fuel pump, it is recommended to use a digital volt-ohm meter (DVOM) to confirm that the pump is receiving the correct voltage. You can also use a BMW scan tool to activate the fuel pump control module for testing.

Setting Fass Fuel Pump Pressure: Optimal Performance Tips

You may want to see also

Using a BMW scan tool to activate the fuel pump module

To test the fuel pump, you will need to use a BMW scan tool to activate the fuel pump module. This will allow you to test the fuel pressure and volume. Here is a step-by-step guide on how to do this:

Step 1: Remove the fuel test port cap.

Step 2: Install the fuel pressure gauge, making sure that all test hoses are installed and routed properly.

Step 3: Start or attempt to start the engine. The fuel pressure should be 5 bar (72.5 psi). Once you have tested the pressure, recharge the fuel system by cycling the key or running the fuel pump, and note the fuel pressure.

Step 4: Allow the fuel system to sit under pressure for 15 minutes. The pressure should drop no more than 0.5 bar in that time. If it drops, you may have a faulty fuel pump check valve or a leak in the fuel system.

Step 5: Working in the rear of the vehicle interior, grab the corner of the rear seat cushion and pull it up to detach the locking tabs. Then, pull the seat cushion up and out of the vehicle.

Step 6: Peel back the carpet from the seat cushion area of the body.

Step 7: Remove the four 10mm nuts from the access panel.

Step 8: Remove the access panel lid by lifting it up and moving it out of the way to access the electrical connector on the fuel pump module.

Step 9: Disconnect the fuel pump electrical connector by sliding the locking tab and pulling the connector off the fuel pump module.

Step 10: Connect a digital volt-ohm meter (DVOM) across the fuel pump terminals. Turn the key on, and the DVOM should read battery volts (around 12 volts). If no voltage is found, check the relay and fuel pump fuse. With the key on, the fuel pump will receive voltage for 3-5 seconds if the engine doesn't start.

Step 11: Load testing using a test light and a DVOM is suggested. Connect the DVOM across the fuel pump electrical connector terminals and take a reading; it should read battery volts when the key is turned on. Then, connect an incandescent bulb-style test light to the battery ground and touch the test light probe tip to the positive wire you are back-probing with the DVOM. Your reading should hold steady, with a maximum drop in voltage of 0.5 volts being acceptable.

Step 12: To confirm that the pump can supply fuel pressure to the fuel rail, you can manually activate the fuel pump using a fused jumper lead set to battery positive (+) and battery negative (-). The green arrow points to where the positive (+) lead goes, and the yellow arrow points to where the negative (-) lead goes.

Fuel Pressure Regulator: Understanding the Right Line Placement

You may want to see also

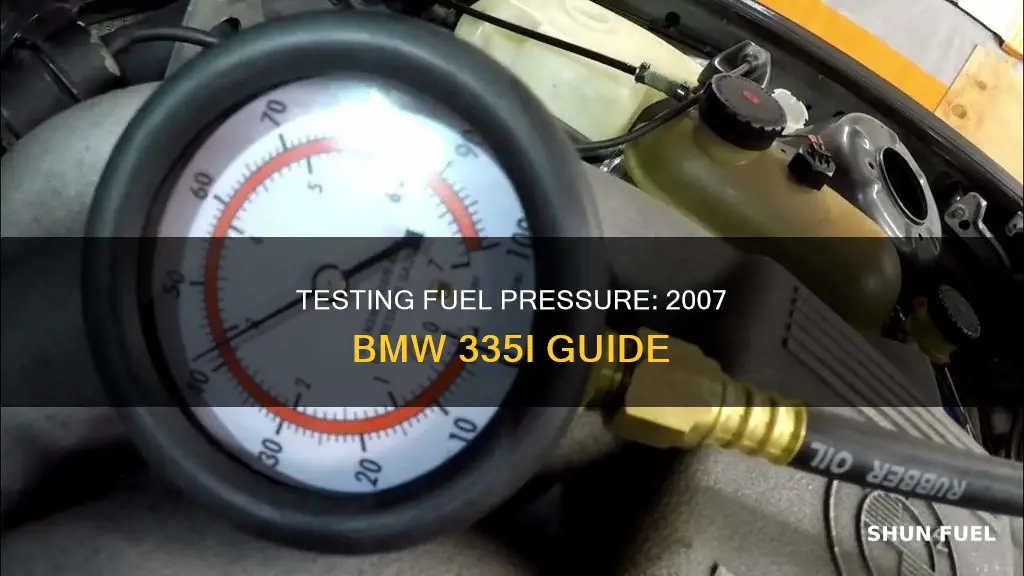

Using a mechanical gauge to check for pressure drop

To check for a pressure drop using a mechanical gauge, you will need to install the gauge in the pipe. There is a special tool for this, or you can fabricate an in-line pressure gauge for connection there.

First, you will need to remove the fuel test port cap. Then, install the fuel pressure gauge connecting line. Be sure that all test hoses are installed and routed properly. Then, install the fuel pressure gauge.

Next, start or attempt to start the engine. Fuel pressure should be 5 bar (72.5 psi). Once you test the pressure, recharge the fuel system by cycling the key or running the fuel pump, note the fuel pressure. Then, allow the fuel system to sit under pressure for 15 minutes. Pressure should drop no more than 0.5 bar in that time period. If it drops, you could have a faulty fuel pump check valve or a leak in the fuel system.

You can also manually activate the fuel pump. Use a fused jumper lead set to battery positive (+) and battery negative (-) and run the pump.

Replacing Fuel Pressure Regulator Spring on C15 Acert Engines

You may want to see also

Checking the ground to the fuel pump

To check the ground to the fuel pump, you will need to access the fuel pump electrical connector and terminals under the rear seat cushion, below an access panel.

First, remove the fuel test port cap. Next, install the fuel pressure gauge connecting line and then the fuel pressure gauge. Start or attempt to start the engine. The fuel pressure should be 5 bar (72.5 psi).

Now, access the fuel pump electrical connector and terminals. Connect your DVOM to the terminals by backprobing. Connect the positive lead to the green arrow and the black lead to the yellow arrow. Press the Start Stop key as if you wanted to start the engine. Allow the engine to crank if it doesn't start. The DVOM should read around 10 volts. If no voltage is found, check the ground to the fuel pump and the fuel pump fuse F70 in the junction box. Double-check the fuse number with your model-specific information. When the Start button is pressed, the fuel pump will receive voltage for 3-5 seconds, if the engine doesn't start.

Finding the Fuel Pressure Sensor in Audi A4s

You may want to see also

Frequently asked questions

You can test fuel pressure using a mechanical gauge. You will need to install the gauge in the pipe. There is a special tool for this, or you can fabricate an in-line pressure gauge for connection.

The fuel pump is located in the right side of the fuel tank.

You can confirm the fuel pump is receiving the correct voltage when commanded on by the fuel pump control module using a digital volt ohm meter (DVOM). If the correct voltage is present but the pump does not activate, it is likely faulty.

The normal fuel pressure is 5 bar (72.5 psi).