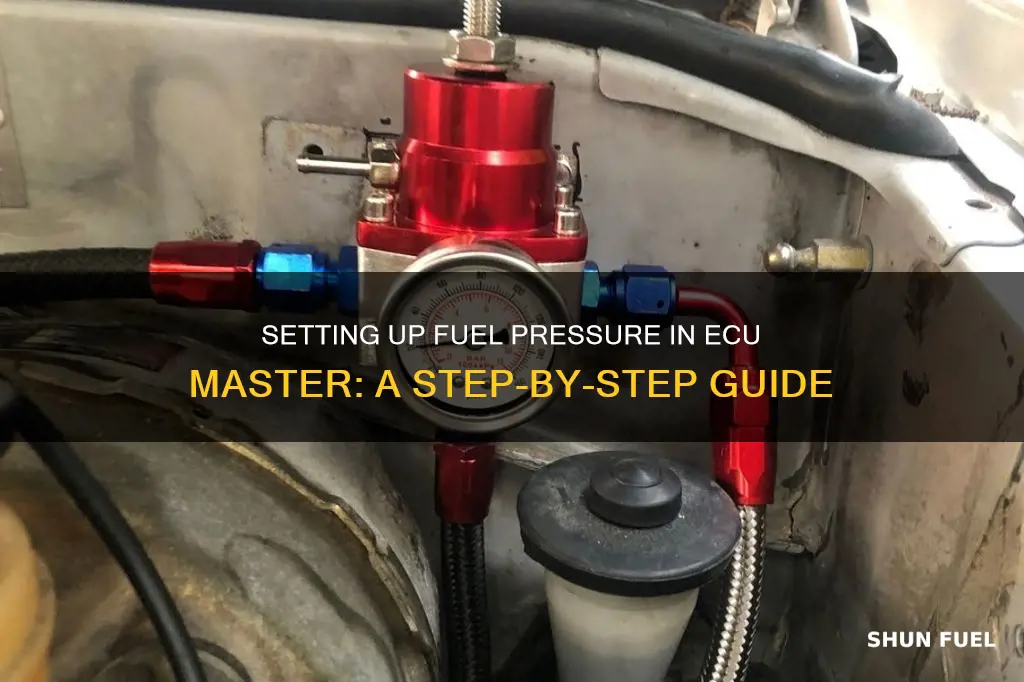

Setting up fuel pressure in an ECU master involves adding a fuel pressure sensor to the system. This sensor helps to monitor fuel pressure and increase the reliability and safety of the engine. It is important to choose the right sensor for your specific ECU package, as this will make a significant difference in the performance of the engine. The sensor should be installed in the fuel rail, and it is important to follow the installation instructions carefully to ensure a tight seal and trouble-free operation.

| Characteristics | Values |

|---|---|

| Pressure Range | 0-7 Bar Gauge Pressure (0-100 PSI) or 0-10 Bar Gauge Pressure (0-150 PSI) |

| Sensor Body Material | 304 Stainless Steel |

| Thread Type | NPT |

| Accuracy | Within 0.5% |

| Connector | Delphi |

| Installation | Comes with installation instructions |

| Sealing | Reliable sealing with wrench flats |

What You'll Learn

ECU Master Sensor: Fluid Pressure 10 bar (150psi)

The ECU Master Sensor is a fluid pressure sensor with a range of 0-10 bar (or 0-150 psi). It is designed for automotive applications, such as oil and fuel pressure monitoring. The sensor is built to custom specifications in an ISO9001 Certified facility, ensuring its quality and performance.

The compact design of the ECU Master Sensor makes it easy to install, even in cramped engine bays and chassis. The sensor body is crafted from 304 Stainless Steel, ensuring durability and reliable sealing. It also features CNC-cut threads and wrench flats, which facilitate trouble-free installation.

The ECU Master Sensor provides accurate pressure measurements within 0.5%. It is compensated for temperature over a broad range, ensuring consistent performance. The sensor comes with a Delphi connector kit, installation instructions, and a tube of thread sealing compound, making it a comprehensive solution for automotive fluid pressure monitoring.

The specifications of the ECU Master Sensor: Fluid Pressure 10 bar (150 psi) include a linear pressure range of 0-10 bar (0-150 psi), with 0.5v corresponding to 0 bar (0 psi) and 4.5v corresponding to 10 bar (150 psi). This sensor is an ideal choice for automotive enthusiasts and professionals looking for a reliable and accurate solution for fluid pressure monitoring in their vehicles.

Fuel Pressure Readings: Volvo S60 Maintenance Guide

You may want to see also

WHP 7 BAR FUEL OR OIL PRESSURE SENSOR

The WHP 7 BAR Fuel or Oil Pressure Sensor is a highly versatile sensor that is ideal for automotive applications. It can be used for fuel pressure, oil pressure, and even exhaust backpressure. Its compact design and custom specifications make it a perfect fit for any ECU, easing installation in tight spaces.

The WHP 7 BAR Pressure Sensor is built with the latest sensor technology in an ISO9001 Certified facility. It offers accurate measurements within 0.5% and is compensated for temperature variations over a wide range. The sensor body is crafted from high-quality 304 Stainless Steel, ensuring durability and reliable sealing. The CNC cut threads and wrench flats further enhance the ease of installation.

The sensor's pressure range is 0-7 Bar Gauge Pressure, which translates to 0-100 PSI. It has 1/8" NPT threads and comes with a Delphi connector kit, installation instructions, and a tube of thread sealing compound. This comprehensive package ensures a trouble-free installation process.

When setting up fuel pressure in an ECU Master, it is recommended to use a 7 bar sensor for fuel pressure and a 10 bar sensor for oil pressure. The WHP 7 BAR Pressure Sensor is typically used for fuel pressure applications, as it can handle the standard operating range for fuel. For oil pressure, a 10 bar sensor is suggested as cold oil pressure can surpass 7 bar.

Relieving Fuel Pressure in Your E30: A Step-by-Step Guide

You may want to see also

Fuel Pressure Sensor Tuning

Fuel pressure sensors are an important component of an engine's performance and longevity. Monitoring fuel pressure can help increase the reliability and safety of your engine. This is how you can go about tuning your fuel pressure sensor.

Firstly, it is important to understand that fuel injectors flow a given amount of fuel at a set pressure. Therefore, more pressure results in more flow, and less pressure results in less flow. The difference between the fuel pressure in the fuel rail and the air pressure in the intake manifold is called the differential fuel pressure. This differential fuel pressure determines the amount of fuel an injector provides for a given pulse width.

When tuning your fuel pressure sensor, you must ensure that the fuel pressure is set correctly. The correct fuel pressure depends on the usage of the engine. For example, a road car will have a different fuel pressure compared to a drag engine. Typically, a return-less fuel system with a constant pressure will have a fuel pressure of 58 psi or 4 bar, while a manifold pressure-referenced fuel pressure regulator will have a fuel pressure of 43.5 psi or 3 bar.

It is also important to monitor the fuel pressure while the engine is being tuned. This can help diagnose problems with fuel delivery. Additionally, employing engine protection strategies, such as fuel pressure fail-safes and fuel pressure warnings, can help maintain engine safety.

When it comes to the installation process, you will need to carefully inspect all parts before reassembly. Ensure that all O-rings are in good condition and that there are no cracks or cuts. It is also important to leave the engine off during the initial test and just turn on the fuel pump to check for any leaks.

Lastly, always take the necessary precautions when working with the fuel system. Ensure that there is no pressure left in the fuel system before removing any fittings, and always correctly tighten and leak-test fittings when reassembling.

Best Fuel Options for Your Subaru Pressure Washer

You may want to see also

Fuel Injectors

The relationship between fuel pressure and injector flow is directly proportional; that is, as fuel pressure increases, the injector flow rate also increases, assuming a constant injector open time. For example, if you have a set fuel pressure and injector pressure differential of 50 PSI, and then six months later, a dirty pre-fuel pump filter causes the fuel pressure to drop, you will experience problems. This drop in pressure will result in reduced injector flow, leading to a lean condition that can damage the engine.

To address this, the ECU Master can be set up to monitor the fuel pressure sensor full time, adjusting the fueling to the engine based on any changes in fuel pressure or injector differential pressure. This "closed-loop" system ensures that if the fuel pressure drops due to a faulty pump or leak, the ECU will compensate by extending the injector opening time to maintain the desired fuel flow rate.

When choosing a fuel pressure sensor, it is important to select one that suits your specific application. For example, 7-bar sensors are typically used for fuel pressure, while 10-bar sensors are recommended for oil pressure as cold oil pressure can easily exceed 7 bar. Additionally, it is advisable to purchase a sensor with some excess range above your normal operating range for added flexibility.

By following these guidelines and properly setting up the fuel pressure in the ECU Master, you can ensure that your fuel injectors perform optimally, contributing to the overall performance and reliability of your engine.

Malibu Maintenance: Locating Fuel Pressure Sensors

You may want to see also

Fuel Pressure Setup & Tuning

The Fuel Pressure Sensor is one of the most overlooked sensors when it comes to tuning. Monitoring fuel pressure via a gauge is good practice, but adding a fuel pressure sensor to your ECU is one of the most effective ways to increase the reliability and safety margin of your engine.

Fuel injectors flow a given amount at a set fuel pressure; more pressure equals more flow, and less pressure equals less flow (assuming the same injector open time). Ideally, your fuel system will maintain a 1:1 ratio, raising fuel pressure with the boost, meaning your injector pressure differential remains the same. However, fuel pumps can fail, and leaks or other problems can cause fuel pressure to drop unexpectedly. If fuel pressure drops under high engine load and your ECU is not correctly set up with a fuel pressure sensor, you are almost guaranteed to cause engine damage.

For example, if your engine has been tuned to 50psi base fuel pressure/injector pressure differential, and six months later, your dirty pre-fuel pump filter starts to kill pump flow and fuel pressure drops fall off first at high RPM/high engine load. This is where the pump needs to flow the most fuel, and this is also the most vulnerable operating range for an engine, so any loss in fuel will quickly cause a lean condition leading to damage.

The solution is to incorporate a fuel pressure sensor into your calibration, or "ECU tune", in several helpful ways:

- Injector flow calculation: The ECU is set up to monitor the fuel pressure sensor full-time, adjusting fuelling to the engine based on any fuel pressure/injector differential pressure changes. This “closed-loop” system means that if pressure drops, the ECU will compensate by holding the injectors open longer to flow the same amount of fuel at a lower fuel pressure.

- Fuel pressure fail-safes: For forced induction engines, using the fuel pressure/injector pressure differential to dictate target boost pressure and/or RPM limit. If fuel pressure drops, this feature will effectively lower the target boost pressure and/or RPM limit, keeping the engine safe.

- Fuel pressure warnings: If the fuel pressure/injector pressure drops below the target, it is important that the system be serviced and faulty parts replaced. As the ECU compensates for the dropping pressure, it is important that a warning message is sent to the dash so that the driver is aware of the problem.

Restoring Fuel Pressure: A Comprehensive Guide to Success

You may want to see also

Frequently asked questions

A fuel pressure sensor is used to monitor fuel pressure via a gauge. It can also be added to your ECU to increase the reliability and safety margin for your engine.

Fuel injectors flow a given amount at a set fuel pressure. More pressure results in more flow, and less pressure leads to less flow, assuming the injector open time is constant.

The WHP 7 BAR and WHP 10 BAR PRESSURE SENSORS are both well-suited for automotive applications such as oil and fuel pressure. The 7 bar sensor is typically used for fuel pressure, while the 10 bar sensor is recommended for oil pressure.