The Yamaha OX66 engine is known for frequently requiring low-pressure fuel pump replacements. This is due to the engine's design, which causes the low-pressure fuel pumps to run dry until they can get enough fuel to start working, leading to increased wear and tear on the pumps. Replacing these pumps can be a complex task, and it is recommended to seek advice from Yamaha mechanics or experts who are familiar with the OX66 engine. Online forums provide a wealth of information and guidance on this topic, with users sharing their experiences, suggestions, and step-by-step instructions on how to tackle the replacement process.

What You'll Learn

Check for leaks in fuel lines and filters

To check for leaks in the fuel lines and filters of a Yamaha OX66, begin by inspecting the fuel lines for any signs of cracks, wear, or damage. Look for any wet spots or stains that could indicate a fuel leak. Next, check the fuel filter and its connections for any signs of leaks. If the fuel filter has a clear housing, you can inspect the fuel level and quality. Make sure there is an adequate amount of fuel in the filter and check for any water contamination or debris that could be causing an issue.

If you suspect a leak, you can perform a pressure test to confirm. This involves attaching a fuel pressure gauge to the Schrader valve and monitoring the pressure. With the key turned to the "on" position but the engine not running, the fuel pressure should be around 35 psi. If the pressure is lower than expected or gradually drops, there may be a leak in the system.

Additionally, you can listen for the sound of the high-pressure fuel pump when you turn the key to the "on" position. If the pump is running, you should be able to hear it. If there is no sound, this could indicate an issue with the fuel pump or a potential leak in the fuel lines.

It is also recommended to check for voltage at the pump wires on the VST (Vapor Separation Tank). This can help determine if there is an electrical issue affecting the fuel pump's operation, which may be causing leaks or affecting fuel delivery.

If you find any leaks in the fuel lines or filters, it is important to replace or repair the affected components to ensure proper fuel delivery and engine performance.

Understanding Fuel Pressure: 1:1 Ratio Regulators Explained

You may want to see also

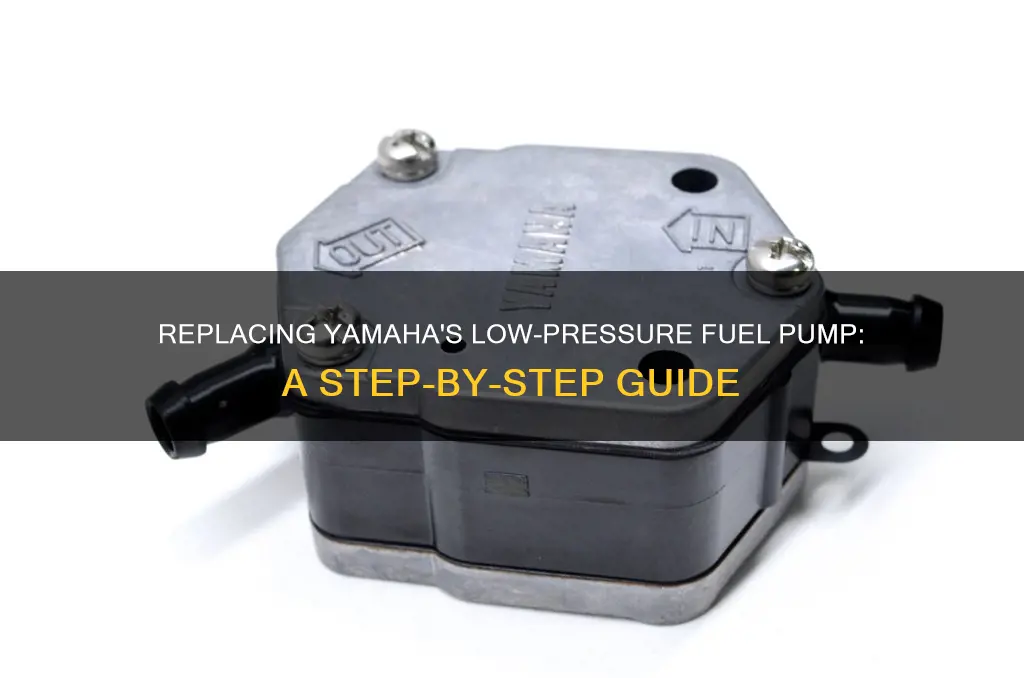

Prime the primer bulb until hard before the first start of the day

To replace the low-pressure fuel pump on a Yamaha OX66 engine, you will need to purchase a new fuel pump that is compatible with your specific Yamaha model. Before beginning the replacement process, ensure that you have the necessary tools and safety equipment, such as gloves and eye protection.

Now, to the priming process. Priming the primer bulb until hard before the first start of the day is a crucial step when replacing the low-pressure fuel pump on a Yamaha OX66 engine. This is what you need to do:

First, locate the primer bulb on your Yamaha OX66 engine. It is usually found near the fuel tank or the carburetor. Once you have located the primer bulb, press it firmly and repeatedly until it becomes hard. This process may take several pumps, so be patient and persistent. The goal is to fill the carburetor with the correct amount of fuel and create the necessary fuel pressure to ensure a smooth start.

As you are priming the bulb, pay attention to its condition. If the primer bulb is cracked, damaged, or unable to maintain pressure, it may need to be replaced. You can find Yamaha primer bulb replacements at authorized dealers or online. Refer to your engine's manual for specific instructions and safety precautions before starting any maintenance work.

After you have successfully primed the bulb until hard, proceed with the rest of the replacement procedure for the low-pressure fuel pump. Ensure that all fuel lines and connections are secure, and there are no signs of damage or leaks. If everything looks good, you can now attempt to start the engine.

Turn the key or pull the starter cord to crank the engine. If the engine turns over and runs smoothly, congratulations! You have successfully primed the primer bulb and replaced the low-pressure fuel pump. If the engine struggles to start or stalls, there may be other issues at play, such as a clogged fuel filter or a faulty spark plug. In this case, further troubleshooting and diagnostics may be required.

Remember to always exercise caution when working with fuel and engines. Work in a well-ventilated area and avoid any potential sources of ignition. Refer to Yamaha's safety guidelines and your engine's manual for detailed instructions on replacing the low-pressure fuel pump and any other maintenance tasks.

Beckett Burner Pressure Washers: Fuel Flow Factors

You may want to see also

Turn the key to the 'on' position and wait a few seconds

Turning the key to the 'on' position and waiting a few seconds is a crucial step in the process of replacing a low-pressure fuel pump in a Yamaha OX66 engine. This step ensures that the high-pressure fuel pump has built up sufficient pressure before starting the engine. Here is a detailed explanation of this step:

When you turn the key to the "on" position, you initiate the high-pressure fuel pump, which begins to draw fuel from the VST (Vapor Separation Tank) tank. This tank is essentially a small, built-in petrol tank inside the engine. The high-pressure pump works to lift the fuel rail pressure to the desired level, typically around 35 PSI.

During this process, the low-pressure fuel pumps are not yet primed and, therefore, run dry. They will remain in this state until they can draw enough fuel to start functioning. There is usually enough fuel in the VST tank to accommodate this process. Additionally, there are crankcase pulses that assist in priming the low-pressure pumps.

By waiting a few seconds after turning the key, you allow the high-pressure pump to build up the necessary pressure, and the low-pressure pumps to prime themselves. This simple step can help prolong the life of your low-pressure fuel pumps and improve the overall performance of your Yamaha OX66 engine.

It is worth noting that some users have reported similar issues with their Yamaha OX66 engines, and this step has proven beneficial in addressing those issues as well. Ensuring that there are no air leaks in the fuel lines or filters and regularly priming the primer bulb are also recommended practices to maintain the health of your fuel system.

Pontiac Sunfire: Electric Fuel Pump Pressure for Carb Performance

You may want to see also

Check the pressure at the Schrader valve

Checking the pressure at the Schrader valve is a crucial step in diagnosing fuel pump issues in your Yamaha OX66 engine. Here is a detailed guide on how to perform this task:

Step 1: Understand the Schrader Valve

The Schrader valve is a type of valve commonly found on car tyres and fuel lines. It consists of a valve stem, a core, and a spring. The core is depressed when the valve is opened, allowing air or fuel to escape. When the valve is closed, the spring pushes the core back up, sealing the valve and preventing leakage.

Step 2: Locate the Schrader Valve on Your Yamaha OX66

The Schrader valve on your Yamaha OX66 engine is typically located on the fuel rail or fuel line. It is usually easily accessible and identifiable by its distinctive shape, which resembles a car tyre valve.

Step 3: Prepare the Necessary Tools

To check the pressure at the Schrader valve, you will need a fuel pressure gauge and, in some cases, a Schrader valve adapter. Ensure that your fuel pressure gauge is compatible with the Schrader valve. If it is not, you may need to purchase an adapter to ensure a proper fit.

Step 4: Relieve the Fuel System Pressure

Before checking the pressure, it is essential to relieve the fuel system pressure. This can be done by opening the Schrader valve and allowing the fuel to flow into a suitable container. Be extremely cautious during this step, as the fuel can be dangerous if it comes into contact with your skin or eyes. Ensure proper ventilation in the work area.

Step 5: Connect the Fuel Pressure Gauge

Once the fuel system pressure is relieved, close the Schrader valve. Now, connect your fuel pressure gauge to the Schrader valve. Ensure that the connection is secure and tight to prevent any fuel leakage during the pressure check.

Step 6: Check the Fuel Pressure

With the fuel pressure gauge connected, you can now check the pressure at the Schrader valve. Turn the ignition key to the "on" position but do not start the engine. Observe the reading on the fuel pressure gauge. The pressure should be within the specified range for your Yamaha OX66 engine, typically around 35 PSI.

Step 7: Interpret the Results

If the fuel pressure is significantly below the specified range, it indicates a potential issue with the fuel pump or fuel filter. Low fuel pressure can lead to engine performance problems, such as difficulty starting the engine or stalling. If the pressure is within the acceptable range, other components, such as the fuel injectors or fuel lines, may be the cause of the engine issues.

Step 8: Further Troubleshooting

If you suspect a problem with the fuel pump, there are additional tests you can perform. Listen carefully for the sound of the high-pressure fuel pump when you turn the ignition key to the "on" position. If you don't hear the pump running, there may be an issue with the fuel pump relay or a blown fuse. Consult a Yamaha service manual or a qualified technician for further guidance on troubleshooting fuel pump issues.

Remember to exercise caution when working with fuel systems, and always refer to the Yamaha service manual or seek professional assistance if you are unsure about any steps.

Understanding Fuel Pressure in the 94 Sanoma: Performance and Maintenance

You may want to see also

Check for voltage at the pump wires

Checking for voltage at the pump wires is a crucial step in diagnosing electrical issues with your Yamaha OX66 engine. Here's a detailed guide on how to do it:

Before you begin, ensure you have a basic understanding of electrical safety and the differences between AC and DC electricity. It's important to work with a qualified marine electrician or seek expert advice if you're unsure. Now, let's get started:

Prepare Your Multimeter:

Get a multimeter to measure voltage. Set the multimeter to the correct voltage setting. For a 12-volt DC system, select the DC voltage setting, typically denoted as "DCV" on the multimeter. Make sure the voltage range is appropriate for your boat's electrical system.

Identify the Pump Wires:

Locate the pump wires on the VST (Vapor Separation Tank) of your Yamaha OX66 engine. These wires will be connected to the positive and negative terminals of the fuel pump.

Connect the Multimeter:

Connect the positive lead (usually red) of the multimeter to the positive pump wire. Then, connect the negative lead (usually black) of the multimeter to the negative pump wire. Ensure you don't touch the leads together to avoid a short circuit.

Take Voltage Readings:

With the multimeter connected, turn on the ignition switch to activate the electrical system. Observe the voltage reading on the multimeter display. A typical fully charged 12-volt battery should read around 12.5 volts or higher. If the voltage is significantly lower, it may indicate a problem with the electrical system or the battery itself.

Interpret the Results:

If there is no voltage or the voltage is low, it could suggest an issue with the wiring, a blown fuse, or a faulty connection. Check the wiring for any signs of damage or corrosion. Ensure the fuses are intact and functioning. If the voltage is within the normal range, but the fuel pump is not operating, the issue may lie elsewhere, such as a faulty fuel pump or a clogged filter.

Remember to exercise caution when working with electricity, and if you're unsure, consult a qualified marine electrician for assistance.

Ideal Fuel Pressure for Chevy 350 TBI Engines

You may want to see also

Frequently asked questions

Check for voltage at the pump wires on the VST. If there is voltage, the issue is likely with the fuel relay. If there is no voltage, the problem is likely with the high-pressure pump.

Symptoms of low-pressure fuel pump failure include power loss, bogging down, and rhythmic cycling between running and bogging down.

It depends on whether you are replacing the low-pressure fuel pumps or the high-pressure pump located in the VST housing. The low-pressure pumps are easier to access and can be replaced by unbolting them and checking for leaks. The high-pressure pump is located inside the VST housing and may require additional steps for replacement.