If you're having trouble with your boat's fuel vent, you might need to replace it. This could be because it's old and made of plastic, or you might be experiencing issues with your engine starting and dying. Before you replace your fuel vent, it's important to identify the cause of the problem. It could be due to a failed or clogged fuel tank vent, or an issue with the vent line. You can try some troubleshooting steps such as opening the fuel cap to release pressure or checking for any leaks in the fuel tank. If you decide to replace the fuel vent, make sure to choose a suitable replacement that is designed to prevent water intrusion and create a trap for any water that might enter. You can also consider adding a clamshell cover to protect the fuel vent from heavy spray and water intrusion. When replacing the fuel vent, follow the instructions carefully and ensure that you have the correct tools and equipment.

What You'll Learn

Disconnecting the old vent

Step 1: Accessing the Vent

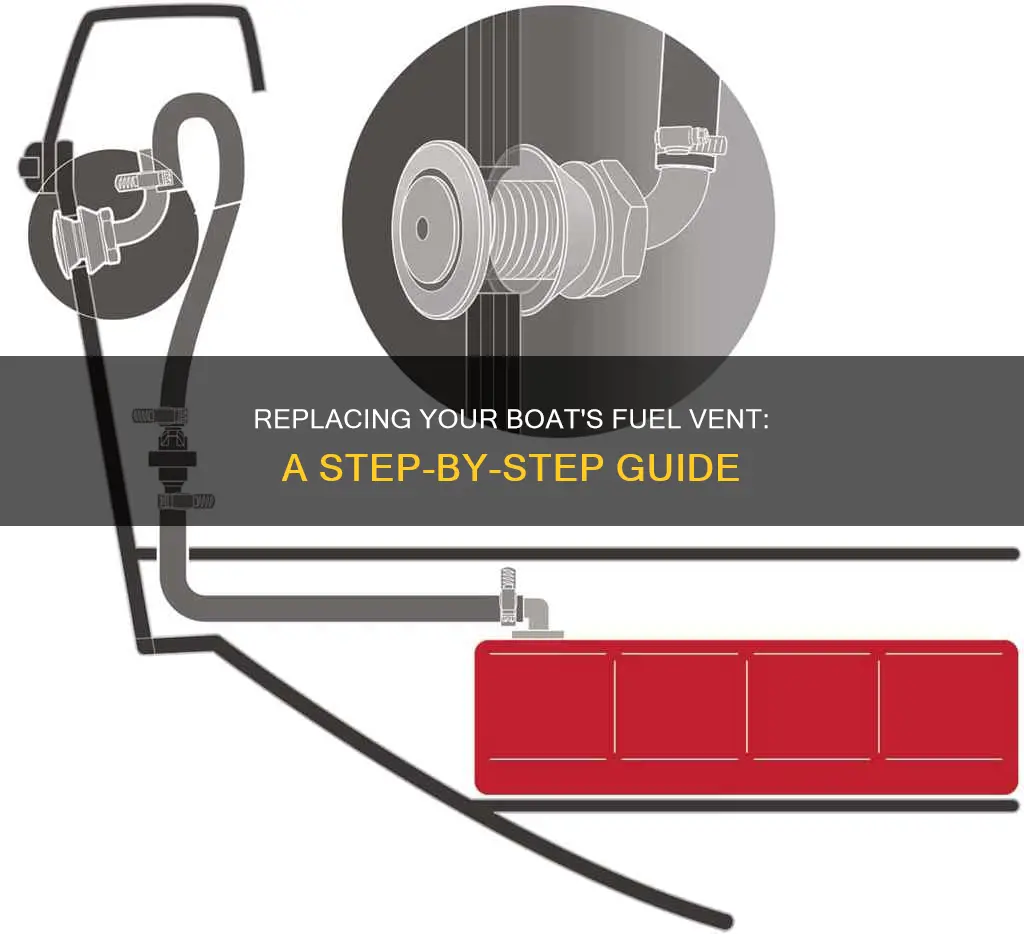

Begin by locating the fuel tank vent on your boat. It is usually found near the fuel tank, often with a vent hose running from the tank to the vent fitting on the hull side. You may need to remove any coverings or obstructions that are blocking access to the vent.

Step 2: Understanding the Vent Type

Before proceeding, it is important to identify the type of vent you have. Some common types include plastic vents, stainless steel vents, and through-hull vents. Each type may have unique disconnecting procedures, so understanding your vent is crucial.

Step 3: Removing the Vent Cap or Cover

If your vent has a cap or cover, carefully remove it. This will expose the inner workings of the vent and allow you to access the components that need to be disconnected. Place the cap or cover in a safe location to protect it from damage.

Step 4: Loosening the Vent Fittings

Most fuel tank vents have fittings that secure them to the hull or other components. Carefully loosen these fittings without applying excessive force. You may need to turn or unscrew specific parts to release the vent. Be cautious not to strip any threads or damage nearby components.

Step 5: Detaching the Vent Hose

The vent hose connects the fuel tank to the vent. To disconnect the old vent, carefully detach the hose from the vent. You may need to loosen any clamps or couplings holding the hose in place. Ensure that you do not damage the hose, as it will likely be reused with the new vent.

Step 6: Removing the Old Vent

Once the vent hose and any other connections are detached, carefully remove the old vent from the boat. This may require gently pulling or wiggling the vent to release it from its mounting. Be cautious not to damage the surrounding area or any nearby components.

Step 7: Cleaning the Area

After removing the old vent, take the time to clean the area. Use a soft cloth or brush to wipe away any dirt, debris, or residue that has accumulated. This will ensure that the new vent has a clean and secure mounting surface.

By following these steps, you can successfully disconnect the old vent on your boat's fuel tank. Remember to work carefully and methodically to avoid any damage to your boat or its fuel system. Always refer to your boat's specific instructions or seek professional guidance if you are unsure about any part of the process.

Replacing Fuel Pump in S10: Step-by-Step Guide

You may want to see also

Choosing a replacement vent

When choosing a replacement vent for your boat's fuel tank, there are several factors to consider to ensure optimal performance and safety. Here are some key guidelines to help you make an informed decision:

- Material: Stainless steel vents, such as those recommended by some boat owners, offer greater durability compared to plastic vents, which can be more susceptible to breakage if you brush against a dock or similar structure. Stainless steel is a stronger material that can provide longer-lasting performance.

- Vent Design: Opt for a vent design that minimises the risk of water intrusion. Some vents, like the Attwood 90-degree P-Trap Fuel Tank Vent, feature an upward bend in the hose fitting, creating a trap that prevents water from entering the tank. This design also makes it easier to clean the screen on your fuel vent, which is important for maintaining optimal airflow.

- Mounting Options: Consider a flush-mount vent, such as the Attwood Stainless Steel Flush-Mount Fuel Vent, to reduce the risk of damage from docks or pilings. This type of vent sits flush against the hull, keeping it safe from accidental impacts.

- Clamshell Cover: If your boat encounters heavy spray and you're concerned about water intrusion, consider adding a clamshell cover to your fuel vent. This cover can be angled aft and slightly downward to deflect oncoming water and rain, providing an additional layer of protection.

- Fuel Surge Protector: Incorporating a fuel surge protector, also known as a no-spill valve, can prevent fuel from spewing out of the vent during refuelling. It also helps to prevent fuel stains on the hull and is environmentally friendly by reducing fuel spillage.

- Compatibility: Ensure that the replacement vent you choose is compatible with your boat's fuel tank and vent line. Check the size of the hose and vent fittings to make sure they match. Some vents are designed for specific hose sizes, such as 5/8-inch or 3/4-inch hoses.

- Regulations: Stay compliant with Coast Guard and EPA regulations. Choose a vent that is Coast Guard approved to ensure it meets the necessary safety standards. Additionally, be mindful of EPA-mandated evaporative emissions regulations when selecting a replacement vent.

Craftsman Riding Mower Fuel Solenoid: Replacing the Right Way

You may want to see also

Avoiding water intrusion

Water intrusion is one of the biggest problems with through-hull vents. Here are some tips to avoid water intrusion when replacing your boat's fuel vent:

- Mount the vent fairly high so that it is not bathed in spray.

- Angle the vent opening aft and slightly downward to shield it from oncoming waves while underway and to prevent rain or dew from getting in.

- Use a 90-degree upward bend in the hose fitting. This allows you to create an upward loop in the line before securing it to the hose barb. Any water that splashes in tends to drain back out.

- Use a Perko through-hull vent, which includes an integral splash guard.

- Use Attwood's 90-degree P-trap fuel tank vent, which features a baffle chamber that traps any errant water and ushers it back out.

- When washing the boat, always point the spray nozzle aft while hosing down along the side of the boat to prevent water from shooting into the vent opening.

- Cover the fuel vent with a clamshell cover. Angle the clamshell aft and slightly downward to deflect oncoming seas as well as rain.

- Use a fuel surge protector (a.k.a. a no-spill valve) to keep fuel from spewing out of the vent when you fill the tank.

Replacing Fuel Pump on Big Cam 400: Step-by-Step Guide

You may want to see also

Cleaning the vent screen

Keeping your boat's fuel vent screen clean is essential for the proper functioning of your boat's fuel tank vent system. Here are some detailed instructions on how to clean the vent screen:

First, locate the fuel vent screen. It is usually found on the outside of the hull and can be identified by a black 'knob' portion that is threaded and can be unscrewed. If you are having trouble locating it, refer to your boat's manual or seek assistance from a marine mechanic.

Once you have located the fuel vent screen, inspect it for any signs of clogging or corrosion. If the screen looks clogged or corroded, it is time to clean it. You can use a small wire brush to gently scrub away any corrosion, salt crystals, or grime that has built up on the screen. Be careful not to apply too much pressure, as you do not want to damage the mesh of the screen.

If the screen is heavily corroded or the mesh has been eaten away, it is best to replace the entire vent instead of attempting to clean it. You can find replacement vents at marine supply stores or online. Make sure to choose a vent that is suitable for your boat and fuel type.

To clean the vent screen, you can use a mild solvent such as PB Blaster, which can help remove any corrosion or debris. Alternatively, you can use compressed air to blow out any debris or blockages in the vent screen. If you have access to an air compressor, set it to a low pressure setting and gently blow air through the vent screen, being careful not to damage the mesh.

Another method to clean the vent screen is to use a thin, flexible line, such as heavy monofilament or weed-whacker line, to snake through the vent hose and dislodge any blockages. Ensure that you round off and polish the tip of the line to prevent it from poking a hole in the vent tubing.

After cleaning the vent screen, reattach it to the boat and ensure that all connections are secure. Test the fuel vent system by filling up your boat's fuel tank and observing if there is any improvement in the venting. If the problem persists or you are unable to clean the vent screen effectively, consult a marine mechanic for further assistance.

Replacing the Fuel Pump in Your 1986 Buick Electra

You may want to see also

Installing the new vent

Once you have disconnected and removed your old fuel vent, it's time to install the new one.

First, you'll want to ensure you have the correct replacement part. Fuel vents come in a variety of materials, including stainless steel, plastic, and chrome-plated zinc. Stainless steel is a popular choice for its durability, but plastic vents are also common and usually cheaper. Consider the pros and cons of each material and choose the one that best suits your needs.

Next, inspect the new vent for any additional features or requirements. Some vents, like the Attwood 90 Degree P-Trap Fuel Tank Vent, are designed to be installed with the hose facing upward, creating a trap that prevents water from entering the tank. Others, like the Perko Gas Tank Vent, include a built-in splash guard to help shed water. Understanding the unique characteristics of your new vent will ensure a proper installation.

Now, you're ready to begin the installation process. Carefully feed the fuel hose through the hull, following the path of the previous vent. Ensure that the hose is securely attached to the vent and that there are no leaks or kinks in the line. If your vent has a removable bug screen, make sure to install it as well.

Finally, check that the vent is mounted securely and that all fittings are tight. Pay attention to the orientation of the vent, especially if it has specific features like a splash guard or a clamshell cover. The vent should be mounted fairly high to avoid constant spray, and the opening should be angled aft and slightly downward to deflect oncoming waves and rain.

Once the new vent is installed, take some time to inspect the fuel line for any sags or traps that could cause fuel to puddle. Ensure that the hose runs as straight as possible, allowing any fuel to drain back into the tank via gravity. A clear plastic vent line can be helpful in identifying and troubleshooting any potential issues.

Replacing Fuel Vapor Canister in Toyota Camry: DIY Guide

You may want to see also

Frequently asked questions

If your fuel tank vent is made of old plastic, be careful not to snap it. Try unscrewing the outside piece first. If it doesn't budge, you might need to apply more force, but be careful not to break anything.

You can choose between plastic and stainless steel fuel tank vents. Plastic vents are cheaper, but they are also more prone to breaking if you brush up against a dock. Stainless steel vents, like the Attwood 911526-1 Replacement Cover, are more durable and can be purchased with a flush mount to prevent damage.

When installing a new fuel tank vent, avoid creating sags or traps in the vent line, as these can cause fuel to puddle and block the vent. Keep the hose as straight as possible to allow fuel to drain back into the tank via gravity. Additionally, make sure to keep the screen on your fuel vent clean to prevent corrosion and grime from building up and impairing the vent's function.

One common issue with fuel tank vents is water intrusion, especially with through-hull vents. To mitigate this, mount the vent high and angle it aft and slightly downward to shield it from oncoming waves and rain. You can also consider using a clamshell cover, such as the Perko 2-inch-wide clamshell, to protect the vent from heavy spray.