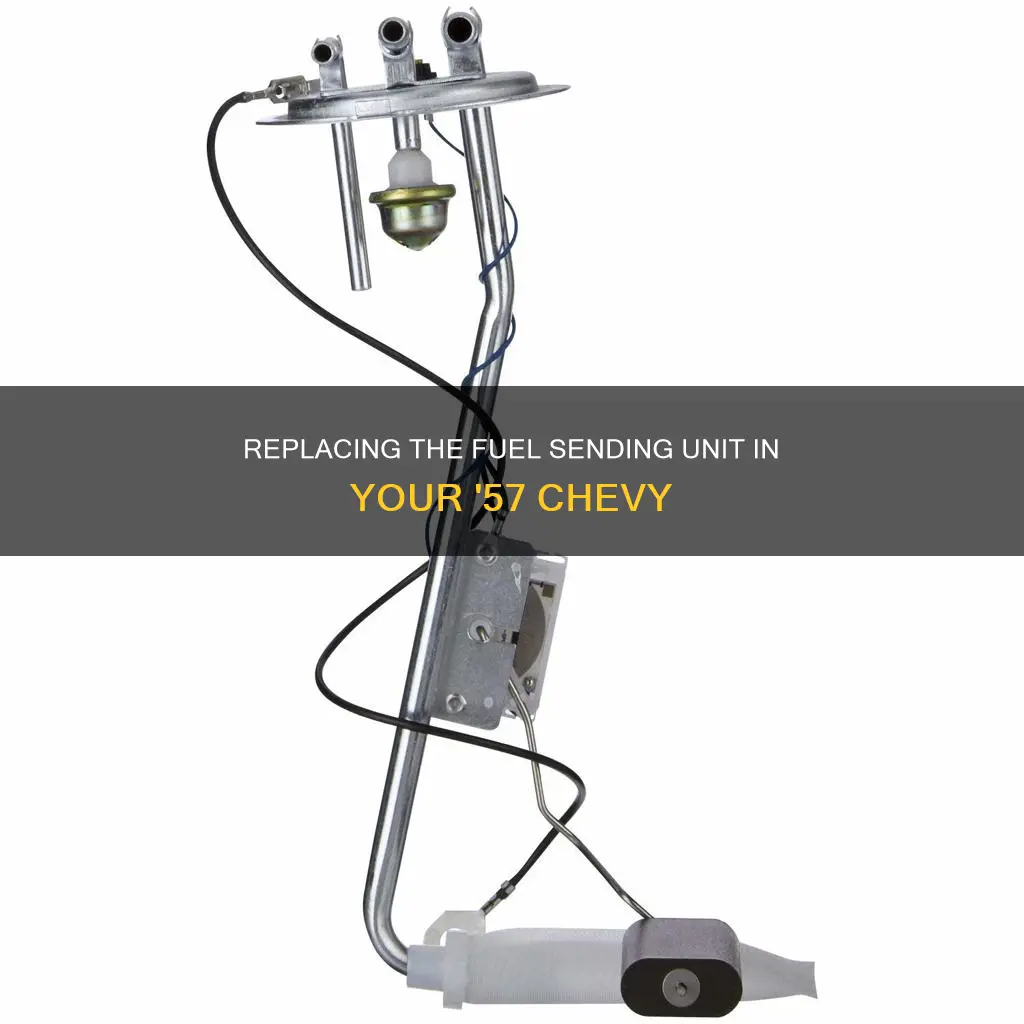

Replacing the fuel sending unit in a '57 Chevy is a common task for owners and enthusiasts of these classic cars. The fuel sending unit, or fuel gauge sending unit, is prone to failure and can cause issues with the fuel gauge reading. It is recommended to replace this unit to keep the fuel gauge reading correctly and avoid being stranded on the side of the road. The process of replacement can be done without dropping the gas tank, although some suggest that it is easier to replace the unit when the tank is out. When replacing the unit, it is important to use a cork gasket instead of a rubber gasket as the latter is prone to leaking. Additionally, it is recommended to use new screws and copper washers, and to be careful not to bend the float rod when installing the new unit.

| Characteristics | Values |

|---|---|

| Whether to drop the tank | Sources suggest it is possible to replace the fuel sending unit without dropping the tank, but it is easier if you do drop the tank. |

| Gaskets | Cork gaskets are recommended over rubber gaskets, which are likely to leak. |

| Other parts to replace | The O-ring, filter sock, and screws. |

| Other recommendations | Use copper washers under the screw heads, and run a separate ground wire from the unit to some bare steel. |

What You'll Learn

Whether to drop the tank or not

Whether or not to drop the tank when replacing the fuel sending unit in a '57 Chevy is a matter of some debate. Some people claim that it is possible to replace the sending unit without dropping the tank, while others argue that dropping the tank makes the job easier and only takes a few extra minutes.

Those who say it is possible to replace the sending unit without dropping the tank recommend using a cork gasket instead of the rubber gasket that typically comes with the unit. They suggest that the rubber gasket can lead to leaks. Additionally, they advise being careful not to knock the filter sock into the tank when removing the old sending unit.

On the other hand, those who recommend dropping the tank argue that it makes the job easier and provides better access to the sending unit. They suggest that dropping the tank allows for a more secure connection between the fuel line and the sending unit, reducing the risk of leaks. They also recommend using a cork gasket, new screws, and copper washers to ensure a tight seal.

Ultimately, the decision of whether or not to drop the tank when replacing the fuel sending unit in a '57 Chevy depends on factors such as the condition of the tank, the accessibility of the sending unit, and the preference of the mechanic. Both methods can be successful, but careful attention to detail and the use of high-quality parts are crucial to prevent leaks and ensure a proper fuel gauge reading.

Replacing the Fuel Pump in Your 2007 BMW X3

You may want to see also

Using a cork gasket

When replacing the fuel sending unit in a 57 Chevy, it is important to use a cork gasket. The cork gasket will not compress and deform as much as a rubber gasket, making it less prone to leaks. It is also recommended to use new screws and copper washers to secure the gasket in place. This will help ensure a tight seal and further reduce the risk of leaks.

When installing the cork gasket, it is important to be careful not to over-tighten the screws. Over-tightening can cause the gasket to pull and gap, leading to potential leaks. It is also important to ensure that the gasket is clocked correctly, as the screw hole pattern is indexed and not evenly spaced. This means that the gasket will only fit one way, and improper alignment can lead to installation issues.

Additionally, when working with the fuel tank and sending unit, it is recommended to use a fuel-resistant sealant, such as Permatex No. 3, to help create a strong seal and prevent leaks. This sealant should be applied to both surfaces of the gasket and allowed to dry before installation.

When replacing the fuel sending unit, it is also a good idea to consider upgrading to a plastic float, as the brass floats that come with some units have been known to split and fill with fuel, affecting the accuracy of the fuel gauge. A plastic float will provide a more durable and reliable option.

By following these recommendations and using a cork gasket, new screws, copper washers, and a fuel-resistant sealant, you can help ensure a successful and leak-free installation of the fuel sending unit in your 57 Chevy.

Replacing the Fuel Pump Relay in a '98 Mitsubishi Mirage

You may want to see also

Using a plastic float

To replace the fuel sending unit in a 57 Chevy, you'll first need to disconnect the negative battery cable to ensure no electrical sparks are possible. You should also work in a well-ventilated area to prevent breathing in fumes.

The fuel tank sending unit is located at the top of the fuel tank and is accessible under the back seat or in the trunk. It will be protected by an access cover, which you'll need to remove.

Once the access cover is removed, you'll see the fuel tank sending unit. It will have a wiring harness plugged into the top, which tells the gas gauge how much fuel is in the tank. Unplug the wiring harness and move it to the side.

If your fuel tank sending unit is screwed or bolted in place, remove the screws or bolts. If it's a twist-lock type, you'll need to use a sturdy, flat-head screwdriver to gently tap it counter-clockwise to loosen it.

Now you can remove the fuel tank sending unit. Attached to it is a long rod with a float at the end, so you might need to try a few different angles to get it out.

When installing the new unit, make sure to use a plastic float instead of a brass one as these are known to be faulty. You can purchase a plastic float from GMC Paul, O'Reillys, or try the float from a Jeep or Ford.

Be sure to plug in the new sender when installing, or it won't work! It's also recommended to replace the fuel filter at the same time if it's located in the tank.

Replacing Lawnmower Fuel Pumps: A Step-by-Step Guide

You may want to see also

Grounding the unit

Firstly, it is important to confirm that the issue is indeed related to grounding. You can do this by performing a simple test using a wire. Connect one end of the wire to the sending unit and touch the other end to a bare metal ground location on the vehicle. If the gauge starts working properly, it confirms a grounding issue.

Now, let's move on to the grounding process:

- Materials Required: You will need a piece of wire, preferably 20-gauge wire, and some basic tools like wire cutters, wire strippers, and crimping tools. You may also want to get some heat shrink tubing and a heat gun to insulate and protect your connections.

- Disconnect the Battery: Before you begin any work, it is important to disconnect the negative terminal of the battery to avoid any electrical shorts.

- Remove the Fuel Tank: While it is possible to access the sending unit without dropping the fuel tank, it will make the grounding process easier if you have the tank out. This will give you more room to work and ensure you can reach the sending unit and its connections comfortably.

- Prepare the Ground Wire: Cut a length of wire that is long enough to reach from the sending unit to a suitable grounding location. Strip both ends of the wire to expose the copper. If you are using heat shrink tubing, slide it onto the wire now, before making any connections.

- Connect to Sending Unit: At one end of the wire, attach a ring terminal that fits the terminal bolt on the sending unit. You can crimp and solder this connection for a secure joint. If using heat shrink tubing, slide it into place and shrink it with the heat gun to insulate the connection.

- Grounding Location: Now, you need to find a suitable grounding location. Look for a clean, bare metal surface on the vehicle's frame or body. It should be free of paint, undercoating, or any other coatings that might hinder electrical conductivity.

- Connect to Ground: Attach the other end of the wire to the chosen grounding location. You can use a bolt or screw that is already in place, ensuring it makes good contact with the metal surface. Again, crimp and solder this connection and use heat shrink tubing if desired.

- Reassemble: Once your connections are secure and insulated, you can reassemble the fuel tank and any other components you removed. Be careful not to pinch or damage the ground wire during this process.

- Test the Gauge: Reconnect the battery and start the vehicle. Test the fuel gauge by adding fuel to the tank or moving the float in the sending unit manually. The gauge should now respond accurately.

By following these steps, you will have successfully grounded the fuel sending unit in your 1957 Chevy, ensuring accurate fuel gauge readings.

Replacing Fuel Pump on Big Cam 400: Step-by-Step Guide

You may want to see also

Extending the gauge wire

When extending the gauge wire, you will need to splice in a length of new wire to reach the new sending unit. To do this, you can use a double crimp butt connector with shrink tubing to join the old and new wires together. This will ensure a secure connection that is protected from corrosion and moisture.

Firstly, cut the old wire to the desired length, stripping the insulation from the ends. Take the same length of new wire and strip the insulation from both ends. You will now have two wires with exposed ends that can be joined together.

Next, take the double crimp butt connector and insert the stripped ends of the old and new wires into it. Use a crimping tool to securely crimp the connector around the wires. This will create a strong mechanical bond between the connector and the wires.

Now, take a piece of heat shrink tubing and slide it over the connector. Apply heat to the tubing with a heat gun or hair dryer to shrink it around the connector. This will provide insulation and protection from the elements.

You now have a secure and insulated extension of the gauge wire. You can connect this to the sending unit using a ring terminal. Strip the insulation from the end of the new wire and crimp on a ring terminal that matches the size of the post on the sending unit. Again, you can use heat shrink tubing to insulate this connection.

Finally, it is recommended to run a separate ground wire from the sending unit to the vehicle's frame for a better ground connection.

Replacing the Fuel Pump in a Classic 1965 Ambassador

You may want to see also

Frequently asked questions

No, you don't need to drop the tank to replace the fuel sending unit in your 57 Chevy. However, be careful not to knock the filter sock off into the tank when pulling the sender out of the hole.

You should use a cork gasket when replacing the fuel sending unit in your 57 Chevy. Do not use the rubber gasket that comes with the sending unit.

Be careful not to bend the float rod when installing the new sending unit, as this can cause the float to only drop to 1/2, never registering below that.