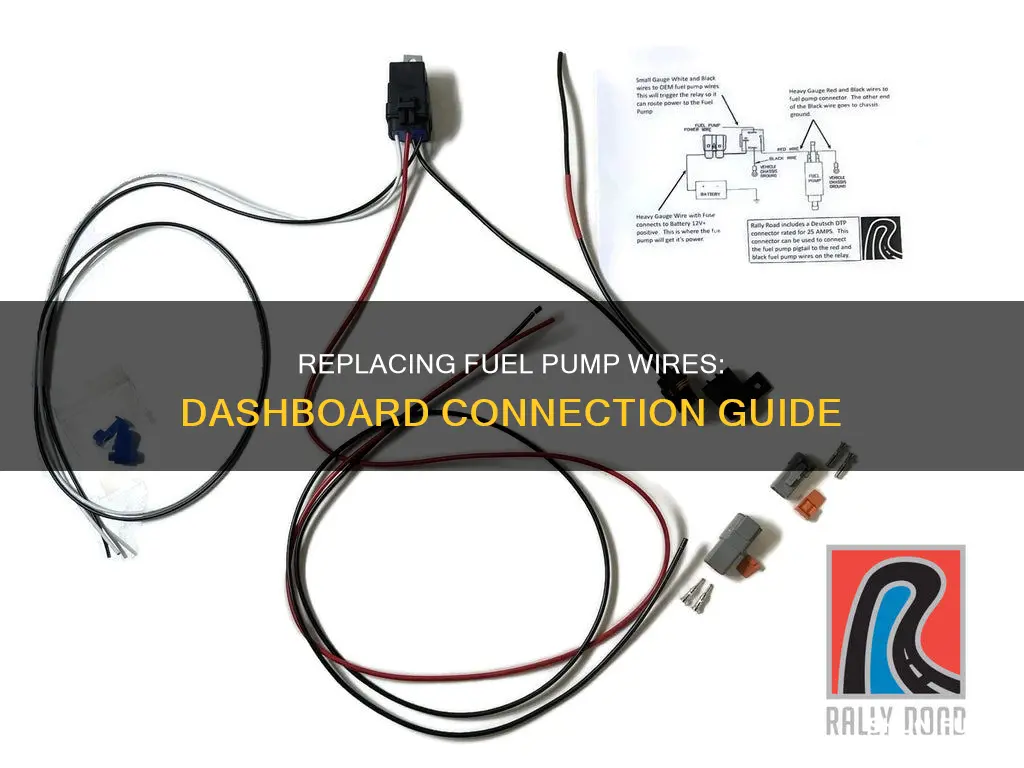

Replacing the fuel pump wires in your car is a complex task that requires careful preparation and a clear understanding of your vehicle's wiring system. This process involves disconnecting the negative battery terminal and fuel pump harness, properly cutting and stripping wires, and ensuring secure connections through crimping and insulation. Additionally, it is important to wear protective gear and have safety equipment nearby. For those seeking a more advanced modification, adding a switch to the fuel pump wires near the dashboard can serve as a theft-deterrent and engine priming mechanism. This modification involves carefully routing wires, mounting a switch, and connecting the fuel pump wires to the switch.

| Characteristics | Values |

|---|---|

| Safety precautions | Wear safety glasses and gloves. Keep a fire extinguisher close by. |

| First step | Disconnect the negative battery terminal. |

| Second step | Disconnect the fuel pump harness from the tank. Remove tape and black plastic conduit from the harness. |

| Third step | Match old wiring to new. If they are not identical, refer to the diagram that comes with the new wiring. |

| Fourth step | Cut the wires, stagger the cuts, and strip the wires. |

| Fifth step | Crimp the vehicle wiring to the new wiring harness. |

| Sixth step | Shrink the insulation with a heat gun. |

| Seventh step | Install the black plastic conduit and re-tape the wires. |

What You'll Learn

Disconnect the negative battery terminal

Disconnecting the negative battery terminal is the first step in replacing a fuel pump wiring harness. It is important to take safety precautions when performing this task, such as wearing safety glasses and gloves to protect against acid and electrical hazards. Additionally, removing any metal jewellery can prevent accidental short circuits.

To begin, locate the battery, which is typically found under the hood on either side of the engine bay. You can refer to the owner's manual if you are unsure of its location. Once you have located the battery, identify the terminals. The negative terminal will be marked with a minus (-) sign and often has a black cover.

Now, use a wrench to loosen the nut or bolt connecting the cable to the negative terminal. Turn it counter-clockwise until it is loose enough to remove by hand. You may need to wiggle the terminal to detach it. It is important to only loosen the connection enough to remove it; there is no need to completely undo the nut or bolt. Once removed, tuck the terminal in a safe place away from the battery to prevent accidental contact.

After the negative terminal is disconnected, you can move on to disconnecting the positive terminal. It is important to always disconnect the negative terminal first to minimise the risk of a short circuit.

By following these steps, you will successfully and safely disconnect the negative battery terminal, allowing you to proceed with replacing the fuel pump wiring harness.

Replacing the Fuel Pump in a Chrysler Pacifica: Step-by-Step Guide

You may want to see also

Disconnect the fuel pump harness from the tank

To disconnect the fuel pump harness from the tank, you must first disconnect the negative battery terminal. This is an essential safety precaution. It is also important to wear safety glasses and gloves and keep a fire extinguisher close by.

Once you have disconnected the negative battery terminal, you can begin to disconnect the fuel pump harness from the tank. To do this, you will need to remove about a foot of tape and black plastic conduit from the harness. Be careful not to confuse the fuel pump harness with the fuel pressure sensor connector.

If you are having trouble unclipping the wiring harness, you may need to drop the tank slightly to access the clip. The harness may also be mounted to the body near the fuel pump. In some cases, you may need to twist a red ring, push the fuel line into the fuel pump, and pull a blue ring away from the fuel pump to remove the fuel line.

Always refer to the specific instructions and diagrams for your vehicle when performing any fuel pump-related repairs or replacements.

Replacing the Fuel Pump in Your 1988 Ford Ranger

You may want to see also

Match old wiring to new

When replacing the wiring harness for your fuel pump, it is essential to match the old wiring to the new wiring. This is because your new fuel pump may not work properly if you don't.

Firstly, disconnect the negative battery terminal and the fuel pump harness from the tank. Remove about a foot of tape and black plastic conduit from the harness, ensuring you are not dealing with the fuel pressure sensor connector.

Now, you need to compare the old wiring with the new wiring. If they are identical, you can proceed to the cutting step. If not, refer to the diagram that comes with the new wiring to help you match the old to the new.

Once you have matched the wires, you are ready to start cutting. Cut the first pair of wires about two inches away from the electrical connectors. Then, stagger the rest of your cuts by about an inch and a half and strip the wires. Crimp the vehicle wiring to the new wiring harness with the supplied connectors on all wires, ensuring you don't trap any insulation between the electrical connector crimp.

Finally, shrink the insulation with a heat gun to secure the connections, keeping this process away from any fuel. You'll know the connections are weather-tight when the glue begins to come out of the connector.

Replacing Fuel Pump in 2006 Toyota Tacoma: Step-by-Step Guide

You may want to see also

Cut and strip wires

To cut and strip wires when replacing a fuel pump wiring harness, you will need to follow a few important steps. Firstly, make sure you have the necessary tools, such as wire strippers, and safety equipment, including safety glasses and gloves. It is also recommended to have a fire extinguisher nearby.

Begin by cutting the first pair of wires about two inches away from the electrical connectors. This will give you enough space to work with. Then, stagger the rest of your cuts by about an inch and a half. This means that you should cut the wires at different lengths to avoid confusion when stripping and reconnecting them.

After making the cuts, it's time to strip the wires. Carefully remove the insulation from the ends of the wires, exposing the metal conductor inside. Be cautious not to damage the wires or the conductor during this process. The length of insulation to be removed will depend on the specific connector being used, so refer to the manufacturer's instructions or a professional for advice.

Once the wires are stripped, it's important to prepare them for the new connections. Use a crimping tool to crimp the vehicle's wiring to the new wiring harness with the supplied connectors on all wires. Ensure that no insulation is trapped between the electrical connector crimps.

Replacing the Fuel Pump in a 2004 Tahoe: Step-by-Step Guide

You may want to see also

Finish up by installing the black plastic conduit

Now that you've cut and connected the wires, it's time to finish up by installing the black plastic conduit and securing the wires in place. This is an important step to protect the wires and ensure they don't move around, causing potential damage.

First, locate the black plastic conduit that you removed earlier. You should have set it aside with the tape after removing about a foot of it from the harness. If you're reusing the old conduit, check that it's in good condition and free from any cracks or damage. If it looks worn out, it's best to replace it with a new one to ensure maximum protection for the wires.

Next, carefully feed the wires back into the conduit. Take your time with this step to avoid any tangles or kinks in the wires. Make sure the wires are sitting securely inside the conduit and aren't bunching up or protruding out of either end. Once you're satisfied with the positioning, use electrical tape to secure the conduit in place. Wrap the tape tightly and neatly around the conduit, covering any gaps or openings to ensure the wires are fully protected.

After the conduit is taped up, it's time to reinstall it onto the harness. Line up the conduit with the harness and gently push it back into place. Make sure it's secure and not loose or wobbly. You might need to apply some gentle force, but be careful not to push too hard and damage the wires or the harness.

Finally, take a step back and inspect your work. Make sure the conduit is firmly attached, and the wires are not exposed at any point. Give the conduit a gentle tug to ensure it's secure and won't come loose with regular vehicle movement. Now you can be confident that your new fuel pump will have a secure connection for the life of your vehicle.

Replacing Fuel Pump in Chevy Colorado: Step-by-Step Guide

You may want to see also

Frequently asked questions

You will need to disconnect the negative battery terminal first. Then, remove about a foot of the tape and black plastic conduit from the harness. Be careful not to confuse it with the fuel pressure sensor connector.

You can refer to the diagram that comes with the new wiring to help you match the old wiring to the new.

Cut the first pair of wires about two inches away from the electrical connectors. Then, stagger the rest of the cuts by about an inch and a half and strip the wires. Crimp the vehicle wiring to the new wiring harness with the supplied connectors on all wires.

Always put safety first. Be sure to wear safety glasses and gloves, and have a fire extinguisher close by.