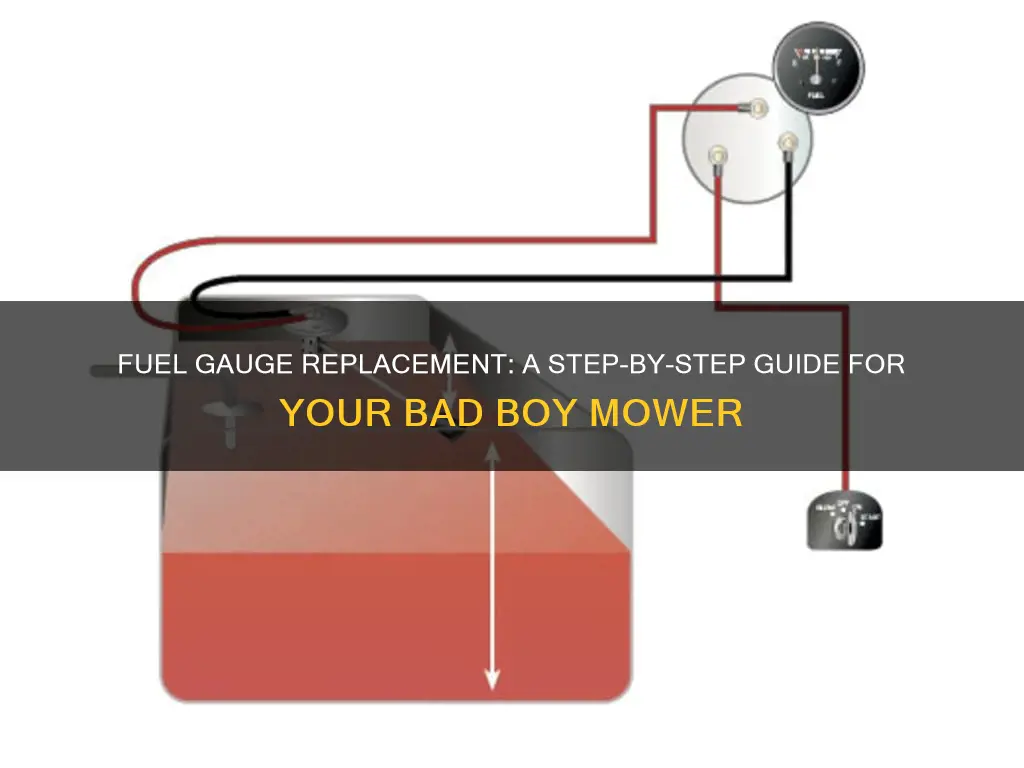

Replacing the fuel gauge on a Bad Boy mower can be a straightforward process if you follow the right steps. This guide will provide a step-by-step tutorial on how to replace the fuel gauge, ensuring your mower is back in working order. It's important to have the necessary tools and safety equipment before you begin, and the process involves removing the old gauge, installing the new one, and testing to ensure it's functioning correctly. With the right approach, you can easily fix this issue and get your mower running smoothly again.

| Characteristics | Values |

|---|---|

| Tools Required | Screwdriver, pliers, fuel gauge replacement kit, safety gloves, safety goggles |

| Fuel Gauge Location | Usually found on the dashboard or near the steering column |

| Fuel Gauge Type | Mechanical or electronic |

| Fuel Gauge Replacement Steps | 1. Disconnect the negative battery terminal. 2. Remove the old fuel gauge by prying it out with a screwdriver. 3. Install the new fuel gauge, ensuring it is aligned correctly. 4. Secure the gauge with screws. 5. Reconnect the battery and test the gauge. |

| Common Issues | Malfunctioning due to fuel contamination, sensor failure, or wiring problems |

| Safety Precautions | Wear safety gear to protect against fuel spills. Ensure the engine is off and cooled before working on it. |

| Maintenance Tips | Regularly check fuel levels and inspect the gauge for any signs of damage or wear. |

| Professional Help | Consider consulting a professional mechanic if you're unsure or encounter complex issues. |

What You'll Learn

- Accessing the Gauge: Locate the fuel gauge housing and remove any screws or fasteners

- Removing the Old Gauge: Disconnect the wiring harness and carefully pull out the old gauge

- Preparing the New Gauge: Ensure compatibility and attach the new gauge securely

- Wiring Connections: Match and connect the new gauge's wires to the existing harness

- Testing and Calibration: Verify functionality and calibrate the gauge for accurate fuel level readings

Accessing the Gauge: Locate the fuel gauge housing and remove any screws or fasteners

To begin the process of replacing the fuel gauge on your Bad Boy mower, you'll need to access the gauge itself. Start by locating the fuel gauge housing, which is typically found on the driver's side of the mower, near the steering column. This housing is usually a plastic or metal component that houses the fuel gauge and related wiring. Once you've identified the housing, carefully inspect the area to locate any screws or fasteners that secure it in place. These screws are often small and may be hidden by trim panels or other components.

Using a screwdriver or appropriate tool, remove these screws to release the housing from its mounted position. Be gentle when doing so to avoid damaging any surrounding parts. As you remove the screws, set them aside in a secure place to ensure you can replace them later. With the screws removed, you should now have access to the fuel gauge and its associated wiring. Carefully lift the gauge housing away from the mower, exposing the gauge and the wiring harness.

Take note of the wiring connections and their respective positions. It's important to understand which wires are connected to the gauge and how they are routed. This information will be crucial when you start the replacement process. Once the gauge housing is removed, you can proceed to the next steps of replacing the fuel gauge, which may involve disconnecting the old gauge and installing the new one according to the manufacturer's instructions.

Remember, when working with electrical components, it's essential to exercise caution and ensure you are not touching any live wires. If you are unsure about any step, consult the mower's manual or seek guidance from a professional to avoid any potential hazards. By carefully accessing the fuel gauge housing and removing the necessary fasteners, you'll be one step closer to successfully replacing the fuel gauge on your Bad Boy mower.

Replacing Toyota Previa Fuel Pump: Step-by-Step Guide

You may want to see also

Removing the Old Gauge: Disconnect the wiring harness and carefully pull out the old gauge

To replace the fuel gauge on your Bad Boy mower, you'll need to carefully remove the old gauge to ensure a smooth installation of the new one. Here's a step-by-step guide to help you through the process:

Start by locating the wiring harness that connects to the fuel gauge. This harness is typically a bundle of wires that runs along the side of the mower's frame. Carefully disconnect the wiring harness by unscrewing or unclipping the connections. Take note of the wiring colors and their respective connections to avoid any confusion during the reinstallation process.

Once the wiring harness is disconnected, you'll need to access the fuel gauge itself. This may involve removing a small panel or cover on the mower's dashboard or console. Use a screwdriver or a suitable tool to carefully pry open the panel, being mindful of any screws or clips that hold it in place. Set the panel aside in a safe place.

With the panel removed, you should now be able to see the old fuel gauge. Carefully reach behind the gauge and pull it straight out of its mounting position. You might need to wiggle it slightly to free it from any remaining connections or obstructions. Ensure you handle the gauge with care to avoid any damage to the gauge or the surrounding components.

After successfully removing the old fuel gauge, you can now proceed with installing the new one, following the appropriate steps and instructions for your specific mower model. Remember to reconnect the wiring harness securely and reattach any panels or covers you removed earlier.

The Fossil Fuel Conundrum: Easy Alternatives?

You may want to see also

Preparing the New Gauge: Ensure compatibility and attach the new gauge securely

Before you begin the replacement process, it's crucial to ensure that the new fuel gauge is compatible with your Bad Boy mower. Check the model number and specifications of your mower to find the correct gauge. You can often find this information in the owner's manual or on the mower itself. Compatibility is key to a successful installation, as an incompatible gauge may not function properly or even damage other components.

Once you've acquired the correct replacement gauge, it's time to prepare it for installation. Inspect the gauge for any signs of damage or defects. Ensure that all the necessary components, such as wiring harnesses and mounting brackets, are included with the gauge. If any parts are missing, contact the manufacturer or supplier to obtain the required items.

Now, let's focus on the installation process. Start by disconnecting the power to the fuel gauge. This is an essential safety step to prevent any accidental activation or short circuits. Locate the mounting holes on your mower's dashboard or console where the old gauge was installed. Ensure that these holes align with the new gauge's mounting points.

With the mounting holes aligned, secure the new fuel gauge in place using the appropriate screws or fasteners. Make sure the gauge is firmly attached and won't come loose during operation. Check that all connections are tight and secure, especially the wiring harness. Connect the gauge's wiring to the corresponding terminals on the mower's dashboard, ensuring a proper match between the gauge's pins and the mower's wiring.

Finally, test the new fuel gauge to ensure it's functioning correctly. Turn on the mower's ignition and observe the gauge's behavior. It should provide accurate fuel level readings and respond to changes in fuel consumption. If everything is working as expected, you've successfully replaced the fuel gauge on your Bad Boy mower.

Kia Spectra Fuel Filter Replacement: A Step-by-Step Guide

You may want to see also

Wiring Connections: Match and connect the new gauge's wires to the existing harness

When replacing the fuel gauge on your Bad Boy mower, proper wiring connections are crucial to ensure accurate fuel level readings. Here's a step-by-step guide to help you with this process:

Identify the Wiring Diagram: Begin by locating the existing wiring diagram for your Bad Boy mower. This diagram will provide a visual representation of the electrical system, including the connections for the fuel gauge. You can often find this diagram in the mower's manual or online resources specific to your mower model. Understanding the wiring layout is essential to make accurate connections.

Locate the Existing Wires: Inspect the mower's dashboard or the area where the fuel gauge is mounted. Carefully identify the wires connected to the old fuel gauge. Typically, you will find two or three wires: a power wire, a ground wire, and a signal wire. Take note of the color-coding or any distinct markings on the wires to ensure correct identification.

Prepare the New Fuel Gauge: Before connecting the wires, ensure that the new fuel gauge is properly installed and functioning. Check if it has any specific mounting requirements or if there are any initial setup procedures mentioned in the gauge's instructions. This step is crucial to ensure the gauge works correctly once the wiring is completed.

Match and Connect the Wires: Compare the identified wires from the old gauge with the corresponding wires on the new fuel gauge. Match the power wire (often a black or brown wire) to the power input on the new gauge. Similarly, connect the ground wire (usually a green or yellow wire) to the ground terminal. The signal wire (often a white or orange wire) will be connected to the sensor or sender unit, which sends the fuel level data to the gauge. Ensure that the connections are secure and tightly fastened.

Test the Wiring: After completing the connections, double-check the wiring to ensure there are no loose ends or incorrect pairings. Then, start the mower's engine and test the fuel gauge. Check if the gauge reads the fuel level accurately and responds to engine operation. If everything is connected correctly, you should see the fuel level update as you drive the mower.

Remember, proper wiring is essential for the correct functioning of the fuel gauge. Take your time to identify the correct wires and make secure connections to avoid any issues with the mower's electrical system.

Replacing Fuel Filter in ML320: Step-by-Step Guide for 2000 Models

You may want to see also

Testing and Calibration: Verify functionality and calibrate the gauge for accurate fuel level readings

When replacing the fuel gauge on your Bad Boy mower, it's crucial to ensure its proper functioning and accuracy. Here's a step-by-step guide to testing and calibrating the new fuel gauge:

Initial Testing: After installing the new fuel gauge, start by checking its basic functionality. Turn on the mower's ignition and observe the gauge's behavior. It should display a full tank initially. Then, manually add a small amount of fuel to the tank and watch how the gauge responds. It should reflect the increase in fuel level accurately. This initial test will give you a baseline understanding of the gauge's performance.

Verifying Fuel Level Accuracy: The next step is to verify that the fuel gauge provides accurate fuel level readings. Park the mower on a level surface and ensure the engine is off. Locate the fuel tank's dipstick and remove it to check the fuel level. Compare this reading with the gauge's display. If there's a significant discrepancy, you may need to calibrate the gauge.

Calibration Process: Calibration is essential to ensure precise fuel level measurements. Here's how you can calibrate the gauge:

- Start by draining a known amount of fuel from the tank, ensuring you have a reference point.

- Reinstall the dipstick and allow the engine to run until it reaches a steady state.

- Observe the fuel gauge's reading and make a note of it.

- Now, carefully adjust the fuel gauge's calibration screw (usually located behind the gauge or in the dashboard) using a small screwdriver. Turn it clockwise to increase the reading or counterclockwise to decrease it. Adjust the screw until the gauge's reading matches the actual fuel level you measured with the dipstick.

Final Checks: After calibration, perform a few more tests to ensure everything is functioning correctly. Run the mower for an extended period, checking the fuel gauge's accuracy at various fuel levels. Also, simulate different driving conditions and observe if the gauge responds accordingly.

Remember, proper calibration is key to accurate fuel level monitoring, ensuring you don't run out of fuel unexpectedly during your lawn care tasks. If you encounter any issues or inconsistencies, double-check your connections and consider consulting the mower's manual or seeking professional assistance.

Replacing Fuel Pump in 2006 Dodge Dakota: Step-by-Step Guide

You may want to see also

Frequently asked questions

To access the fuel gauge, you'll need to remove the dashboard or control panel of your mower. Start by identifying the screws or fasteners that secure the panel. These are often located around the edges and can be removed with a screwdriver. Carefully pry open the panel, being mindful of any cables or wires connected to it. Once the panel is open, locate the fuel gauge and inspect it for any signs of damage or malfunction.

Replacing the fuel gauge typically requires a few basic tools. You'll need a screwdriver (flat or Phillips head, depending on the screws) to remove the existing gauge and its mounting screws. It's also a good idea to have a small pry bar or a thin, flat tool to gently pry open the dashboard if needed. Additionally, ensure you have the correct replacement gauge for your specific Bad Boy mower model.

While replacing a fuel gauge is a task that can be tackled by a DIY enthusiast, it's important to have some mechanical knowledge and experience. If you're unsure or uncomfortable with the process, it's recommended to seek assistance from a professional lawn and garden equipment repair technician. They can ensure the job is done safely and effectively, especially if the gauge is located in a hard-to-reach area or requires specialized tools.