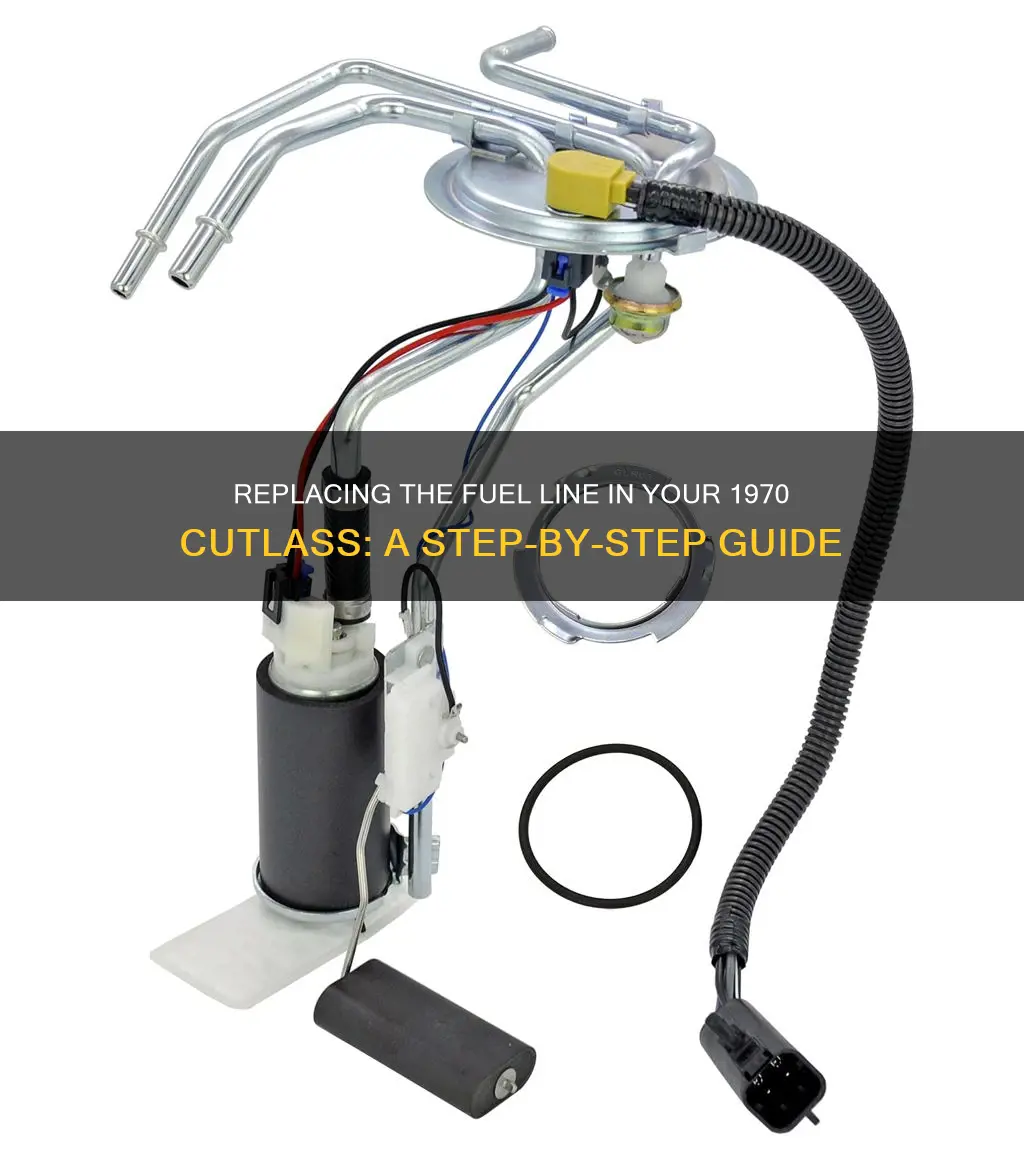

If you're looking to replace the fuel line in your 1970 Cutlass, you've come to the right place. This is a common issue for owners of this classic car, and there are a few options to consider. Firstly, it's important to inspect the fuel line and determine whether it needs to be replaced at all. If the car has been sitting idle for a long time, it might just need a good clean. However, if the fuel line is rusty or damaged, it's best to replace it. You can choose to replace the entire fuel line assembly or just the damaged sections. There are pre-made fuel line kits available for the 1970 Cutlass, which can make the job easier. When replacing the fuel line, it's crucial to use the correct size and type of fuel line, as well as ensuring a secure and leak-free connection.

What You'll Learn

Cleaning vs. replacing the fuel line

If your 1970 Cutlass has been sitting in a garage for 40 years, it's likely that the fuel line is rusty and clogged. While it is possible to clean a fuel line, it is often more advisable to simply replace it, especially if it is very old or damaged.

Cleaning a fuel line involves several steps and requires technical knowledge, as well as the handling of highly flammable substances. First, you will need to disconnect the car battery and the vehicle's fuel pump electrical connector. Then, you will need to attach a rubber hose to an external fuel pump to drain the old fuel from the tank. After that, you will need to rinse the tank with water and isopropyl alcohol to remove any remaining rust and debris. Finally, you will need to use compressed air and a fuel system cleaner to clean the fuel rail and pump, before reconnecting all the components and refilling the tank with fresh fuel.

On the other hand, replacing a fuel line is a more straightforward process. It involves disconnecting the fuel pump and fuel tank, removing the old fuel line, and installing a new one. This option may be more suitable if the fuel line is severely damaged or corroded.

The cost of replacing a fuel line can vary depending on the type of line and the extent of the damage. Rubber fuel lines typically cost between $7 to $35 to replace, while metal fuel lines can range from $25 to $350.

To ensure optimal fuel economy and engine performance, it is crucial to maintain clean fuel lines. This can be achieved through periodic checks and maintenance, such as using fresh gas, regularly replacing the fuel filter, and following the recommended maintenance schedule.

In summary, while cleaning a fuel line is possible, it is a more complex and time-consuming process that requires expertise and caution due to the flammable substances involved. Replacing a fuel line is generally a more feasible option, especially for older cars or those with significant damage.

Fuel Cap Replacement: When and Why to Do It

You may want to see also

Replacing the evap line

The evap line is part of the evaporative emissions control system (EVAP) in your 1970 Cutlass. This system is designed to capture harmful fuel vapors and direct them into the engine to be burned, reducing the release of these vapors into the atmosphere. It is a complicated network of hoses, valves, filters, the fuel tank, fuel filler neck, purge valve, charcoal canister, and lines.

To replace the evap line, follow these steps:

- Purchase a replacement evap line: You can find vehicle-specific evap lines at auto parts stores or online. Make sure to buy one that fits your 1970 Cutlass.

- Locate the evap line: The evap line runs alongside the gas line in your Cutlass. It connects the fuel tank to the vapor management valve (VMV) on the firewall.

- Disconnect the evap line: Start by disconnecting the evap line from the fuel tank and the VMV valve. You may need to remove other components, such as the fan/shroud, hoses, wiring, or shift linkage, for easier access.

- Inspect the system: Before installing the new evap line, inspect the EVAP system for any signs of damage or leaks. Look for rust, cracks, or holes in the lines, valves, and hoses. Also, check the fuel tank for any signs of corrosion or leakage.

- Clean or replace other components: If you find any issues during your inspection, clean or replace the affected components. This may include cleaning or replacing the fuel tank, hoses, valves, or other lines.

- Install the new evap line: Install the new evap line, ensuring it is securely connected to the fuel tank and the VMV valve. Use clamps or couplers as needed for a tight seal.

- Test the system: Once the new evap line is installed, test the EVAP system to ensure it is functioning properly. A professional mechanic can perform a diagnostic test and check for any trouble codes.

Remember, proper maintenance and inspection of the EVAP system are important to ensure it is working correctly and reducing harmful emissions. A faulty EVAP system can cause issues such as decreased fuel economy, hard starting, rough idle, and failed emissions tests.

Replacing the Fuel Filter in Your GLK250: When and Why

You may want to see also

Splicing the stainless steel gas line

Firstly, ensure you have the right tools for the job. You will need a proper-size pipe cutter, some adjustable wrenches, and fittings. It is also recommended to have screw clamps or tab clamps. You may also need a flaring tool if you want to create a bulge at the hose end for a better seal.

Before you begin any work on the gas line, it is imperative that you cut off the gas supply. Be aware that different gases have different properties; propane is heavier than air and will settle in the lowest part of your work area, while natural gas is lighter and will float to the highest point.

Now, you can start the splicing process. Cut the stainless steel gas line with your pipe cutter, ensuring a clean cut. You may want to create a bulge at the end of the line with your flaring tool if you are using hose and clamps for the connection. If you are using fittings, ensure you have the correct size and type for your specific gas line.

Once the new section of the gas line is fitted, use soapy water to check for leaks. Mix 2 cups of water with 1 tablespoon of dish soap and use a spray bottle or paintbrush to apply it to the new connections. If you notice any bubbles, tighten the fittings until the leak stops.

Finally, ensure your gas line is grounded, especially if it is on the outside.

Remember, when dealing with gas lines, it is always best to consult a professional.

Fuel Line Maintenance for LBZ Duramax: Parts Replacement Guide

You may want to see also

Lifting the body off the frame

Lifting the body of a car off its frame is a complex and stressful task, and it is recommended to have multiple people assisting with the process. The first step is to loosen the body mounts, and potentially other parts such as the front and rear bumper brackets, and the core support to the front crossmember bolts.

The next step is to carefully lift the body. This can be done in several ways. One method is to use a floor jack to lift the body, placing a piece of plywood under both seat pan areas, and using the jack to lift the body a few inches. This method may require someone to support the front end and maintain balance. Another method is to use an engine hoist, with the lift points being under the wheel wells and at the outer seat belt bolts. It is recommended to wrap the straps around the rails of the ladder frame, and to lift the body just enough to cause one corner to rise, then lower it and slide the straps toward the heavy end to find the correct balance. Yet another method is to use an engine hoist and cable to attach to the rear bumper bolt area, and a come-along attached to the rafters to lift the front of the car.

When lifting the body, it is important to be careful not to cause the body to tip or crack the glass. It is also important to keep the body balanced, as it can be difficult to recover if it starts to tip. It may be necessary to lift the body multiple times to find the centre of gravity.

Once the body is lifted, it can be placed on a support structure. This can be done using 4" x 4"s sitting on stacks of cinder blocks, or using floor jack stands. It is important to ensure that the body is secure and will not fall or tip over.

Lawnmower Fuel Line: Where to Buy Replacements

You may want to see also

Flushing the fuel line

- Disconnect the fuel line at the fuel pump and fuel tank: Before beginning the flushing process, it is important to disconnect the fuel line from both the fuel pump and the fuel tank. This will allow you to access the fuel line and ensure that the flushing solution can flow through it freely.

- Flush the fuel line with a suitable solvent: Obtain a suitable solvent for flushing the fuel line. Common options include fuel injector cleaner or rubbing alcohol. Pour the solvent into a clean bucket or container and ensure that it is large enough to catch the fluid coming out of the fuel line. Start by disconnecting the fuel line at the fuel pump and running the solvent through the line, allowing it to flow into the bucket. This will help remove any built-up debris, rust, or contaminants from the fuel line. It is important to discard the first batch of solvent as it will contain the majority of the impurities. Repeat this process until the solvent in the bucket appears clean, indicating that the fuel line is sufficiently flushed.

- Inspect the fuel: After flushing, carefully inspect the fuel in the bucket to determine if it is clean and free of any particles or debris. A clean fuel line should produce clear fuel with no signs of rust or impurities.

- Consider replacing the fuel filter: If the fuel appears clean after flushing, it is generally a good idea to replace the fuel filter. This will help ensure that any remaining contaminants are captured and prevent them from circulating back into the fuel system.

- Reattach the fuel line: Once you are satisfied with the condition of the fuel line and fuel, carefully reattach the fuel line to the fuel pump and fuel tank. Ensure that all connections are secure and tight to prevent any leaks.

- Test the vehicle: After completing the flushing process and reassembling the fuel line, start the vehicle and let it run for a few minutes. Keep an eye out for any unusual behaviour, leaks, or changes in engine performance. If the vehicle operates smoothly, the flushing process was successful.

Remember to exercise caution when working with fuel and solvents, and ensure proper ventilation in your work area. It is also recommended to wear protective gear, such as gloves and eye protection, during the flushing process.

Replacing the Fuel Supply Tube in a PT Cruiser

You may want to see also

Frequently asked questions

It is possible to clean the old fuel line, but after 40 years it is recommended to replace it.

Yes, it is recommended to replace the evap line as well, especially if it shows signs of rust or damage.

There should not be any flow issues if you splice the stainless steel gas line. However, it is generally recommended to replace the entire fuel line for better performance and to avoid potential leaks.

The size of the fuel line may vary depending on the specific model and year of your Cutlass. It's recommended to consult a mechanic or a parts specialist to ensure you get the correct size.

Replacement fuel lines for the 1970 Cutlass can be purchased from various online retailers and auto parts stores. Some popular options include eBay, CARiD, and LinesToGo.