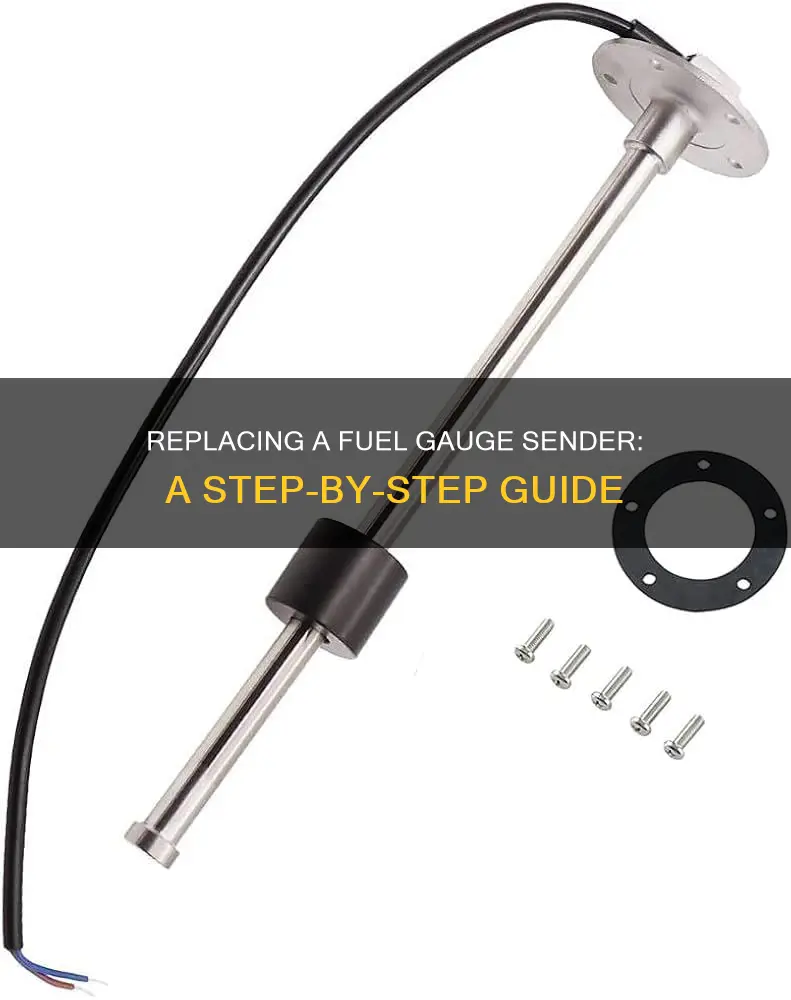

Replacing a fuel gauge sender is a common fix for older vehicles, including cars and boats, with faulty fuel gauges. The fuel gauge sender is a device that transmits data from the fuel tank to the fuel gauge, telling the driver how much fuel is left. A faulty sender unit may cause the gauge to read empty when there is fuel in the tank, or constantly read as full. Before attempting to replace the fuel gauge sender, it is important to check that the gauge itself is not faulty. This can be done by testing the power the gauge is receiving and checking the wiring. If the fuel gauge sender does need to be replaced, safety precautions must be taken, as you will be dealing with fuel, which is highly flammable. It is also important to note that, in most cases, the whole sender unit must be purchased, as it is not possible to buy a replacement float.

| Characteristics | Values |

|---|---|

| What is a fuel gauge sender? | A device that transmits data from the fuel tank to the fuel gauge. |

| Where is it located? | Inside the fuel tank, attached to the fuel pump. |

| What does it look like? | A base with a rod and float attached to it. |

| What is the function of the float? | The float is light and hollow, allowing it to lay on top of the fuel without sinking. |

| How does the fuel gauge sender work? | The rod attached to the float moves across a coil, connecting a different resistance pattern as the fuel tank fills up. |

| What are the signs of failure? | The fuel gauge will register overfull when the tank is full and show more fuel than there is when the tank is empty. |

| How to verify the fuel gauge sender condition? | Check the fuel gauge reading when the vehicle is fuelled up and when the fuel low light comes on. |

| How to replace the fuel gauge sender? | A series of steps involving disconnecting the battery, raising the vehicle, removing the fuel tank, and replacing the fuel pump and sender. |

| What tools are needed for replacement? | Flathead screwdriver, ratchet with metric and standard sockets, fuel-resistant gloves, and a nine-volt battery saver. |

| Precautions | Ensure the vehicle is parked on a flat, hard surface and use wheel chocks. Disconnect the negative battery cable to prevent electrical sparks. Work in a well-ventilated area to avoid inhaling fumes. |

What You'll Learn

How to identify a faulty fuel gauge sender

A faulty fuel gauge sender can cause a lot of inconveniences, such as the gauge reading empty when there is fuel in the tank or the gauge reading full when the car has travelled a distance and used some fuel. Here are some ways to identify a faulty fuel gauge sender:

Check the Fuel Gauge

Fuel up your vehicle until the fuel pump at the gas station stops. Note the level on the fuel gauge. Then, drive your vehicle until the fuel low light comes on. Check the fuel gauge again. If the light comes on before the gauge hits "E", then the fuel gauge sender has too much resistance.

Check the Voltage

Turn on the engine's ignition and use a multimeter to check for 12 volts of power between the ground and the positive terminal on the back of the gauge. If there is no voltage, the fault is in the ignition circuit, and the gauge is likely fine. If there are 12 volts, either the sender, the gauge, or its wiring is the issue.

Disconnect the Sending Wire

With power still running to the gauge, disconnect the sending wire, which will be marked with an "S" at the back of the gauge. Once the wire is disconnected, the gauge should jump to its highest possible reading. If it does not, the gauge is faulty.

Jump a Wire or Screwdriver

Jump a wire or a screwdriver across the sending pin to the ground pin on the back of the gauge. If there is no ground pin, use a longer wire and jump the sending pin to the engine block. The gauge should go to its lowest reading if it is working properly.

Check the Wiring

If the gauge is fine, the next step is to check the wire running to the sender. Disconnect it from both the sender and the "S" pin on the back of the gauge. Set your multimeter to the Ohms scale and check the resistance within the wire. If there is no resistance, the circuit is good and the sender is faulty.

Check for Other Issues

In addition to a faulty fuel gauge sender, there are other potential issues that can cause problems with your fuel gauge. These include circuit problems, fuel gauge failure, and instrument cluster failure. Perform tests on the instrument cluster, fuel sender, and fuel gauge to diagnose the issue accurately.

Replacing the Fuel Pump in Your 2001 Chevy Tahoe

You may want to see also

How to check the fuel gauge

To check your fuel gauge, you must first determine whether the problem is with the gauge or the sending unit. The test for this is straightforward. First, check that the gauge is receiving 12 volts of power. Turn on the engine's ignition and probe with a multimeter between the ground and the positive terminal on the back of the gauge; it should be marked with a “+” or an “I”. If there is no voltage, the fault is in the ignition circuit, and the gauge is probably good. If there are 12 volts at the gauge, either the sender, the gauge or its wiring is the culprit, so you need to proceed to the next step.

With power running to the gauge, disconnect the sending wire; it will be marked with an “S” at the back of the gauge. Once the wire is disconnected, the gauge should jump to its highest possible reading. If this is the case, the gauge is good and you can proceed to the next step. If the gauge does not reach its maximum reading, it is faulty and must be replaced.

Another test is to jump a wire or a screwdriver across the sending pin to the ground pin on the back of the gauge. If there is no ground pin, use a longer wire and jump the sending pin to the engine block. When you do this, the gauge should go to its lowest reading. If it does, it is working properly.

If the gauge is good, the next step is to check the other system components, as either the wire running to the sender or the sender itself must be faulty. To check the wire, disconnect it from both the sender and the “S” pin on the back of the gauge. Set your multimeter to the Ohms scale and check the resistance within the wire. If there is no resistance (as close to zero Ohms as possible), the circuit is good and the sender is faulty.

You can also check the tank's sending unit with an Ohm meter. Ground the multimeter probe somewhere on the vehicle chassis/body/tank and probe the sender wire with the other end of the multimeter. This will display a number in Ohms. If the sender is out of the tank, move the float up and down while measuring the resistance. That will tell you the whole story of which sender you have. If the sender is in the tank and installed in the vehicle, approximate the amount of fuel in the tank to tell you which sender you have.

If the gauge is receiving power and ground and still does not move, that means the gauge is faulty.

Replacing the 350Z Fuel Damper: A Step-by-Step Guide

You may want to see also

How to remove the fuel tank

Before removing the fuel tank, you must first check if your fuel gauge is faulty. If your fuel gauge is stuck on empty, this could be due to a faulty sender unit, a faulty gauge, or a break in the wiring between the gauge and the sender.

To check if the sender unit is faulty, ask a helper to watch the fuel gauge, then switch on the ignition. Disconnect the fuel-gauge wire from the sender unit and scratch its bare end against the tank, or any other bare metal on the chassis or bodywork, to earth it. If the gauge needle swings to 'full' when the tank is half-full, there is no electrical fault, but there may be a mechanical fault in the sender unit, such as a detached float.

If you have determined that your fuel gauge is faulty, you will need to replace the sender unit. To do this, you must first remove the fuel tank.

Safety Precautions

Before doing any repair or replacement work on the tank, take off the battery leads, as a precaution against accidental sparks. As you are dealing with fuel, which is highly flammable, you should also work in a well-ventilated area to prevent breathing in fumes. You could also use a professional respirator.

Locating the Fuel Tank

The fuel tank is located at the top of the fuel tank and is accessible under the back seat or under the carpet in the trunk. The sending unit will be protected by an access cover, usually held on with a couple of screws.

Lift your back seat or trunk carpet and locate the access cover for your fuel tank sending unit. Remove the screws holding the cover in place and remove the access cover to reveal the fuel tank sending unit.

Removing the Fuel Tank

Another safety note: by removing the fuel tank sending unit, you are opening the gas tank. Be sure there are no sources of sparks or flames nearby. Always do this repair outside with the windows of your vehicle rolled down. Never open your tank in a garage that could have a source of ignition, such as a furnace or water heater.

With the access cover removed, you will see the fuel tank sending unit. It will have a wiring harness plugged into the top, which tells the gas gauge how much fuel is in the tank.

Unplug the wiring harness and move it safely to the side. If your fuel tank sending unit is screwed or bolted in place, remove the screws or bolts.

Some sending units are a "twist-lock" type and work like the old twist-lock gas caps. You'll see a few notches along the outer ring of the sending unit. Place the tip of a sturdy, flat-head screwdriver in the notch and gently tap it counter-clockwise. The sending unit will rotate until it's loose. Now you can remove the fuel tank sending unit in one piece.

Attached to the sending unit is a long rod with a float at the end, so you might have to try a couple of different angles to get it out.

Replacing Weed Wacker Fuel Lines: A Step-by-Step Guide

You may want to see also

How to remove the fuel gauge sender

Before removing the fuel gauge sender, it is important to note that this process involves dealing with fuel and electricity, which can be dangerous if not handled properly. Therefore, it is recommended to work in a well-ventilated area and take the necessary precautions to avoid any sparks or flames that could cause an explosion or fire.

The fuel gauge sender is typically located at the top of the fuel tank and can usually be accessed by lifting the back seat or the trunk carpet. The sender is protected by an access cover, which needs to be removed by unscrewing it. This will reveal the fuel tank sending unit.

To ensure that no fuel escapes during the removal process, it is advisable to cover the work area inside the car with plastic and an old towel. This area can be used to stage the parts that will come into contact with fuel.

The next step is to unplug the wiring harness from the top of the fuel tank sending unit and move it safely to the side. The sending unit is typically screwed or bolted in place, so the next step is to remove these screws or bolts. In some cases, the sending unit may be a "twist-lock" type, similar to the old twist-lock gas caps. To remove this type of sending unit, place the tip of a sturdy, flat-head screwdriver in the notch and gently tap it counter-clockwise to loosen it.

Now, the fuel tank sending unit can be removed as one piece. Attached to it is a long rod with a float at the end, so it might be necessary to try different angles to get it out without damaging the float.

It is important to note that by removing the fuel tank sending unit, the gas tank is now open, and extra care should be taken to avoid any sources of spark or flame nearby. Always perform this repair outside, with the windows of the vehicle rolled down.

Safety Precautions

Before doing any repair or replacement work on the fuel tank, it is crucial to take the following safety precautions:

- Disconnect the negative battery cable to ensure that no electrical sparks are possible.

- Work in a well-ventilated area to prevent breathing in harmful fumes. Alternatively, use a professional respirator.

- Be aware that gasoline is highly flammable, and there should be no sources of spark or flame nearby during the removal process.

- Do not perform this repair in a garage that has potential sources of ignition, such as a furnace or water heater.

Audi S5 Fuel Injector: DIY Replacement Guide

You may want to see also

How to install the new fuel gauge sender

Now that you have determined that your fuel gauge sender is faulty and have removed the old one, it is time to install the new one. Here is a step-by-step guide on how to do this:

- Prepare the new fuel gauge sender: Before you begin, ensure that you have purchased a new fuel gauge sender that is compatible with your vehicle's fuel tank and fuel gauge. Carefully read the instructions provided with the new unit, as the installation process may vary slightly depending on the make and model of your vehicle.

- Measure the tank depth: Measure the depth of your fuel tank from the top of the tank, near the sending unit, to the bottom. This measurement will determine the length of the sending unit's float arm.

- Trim the float arm: Using a strong pair of wire cutters or a hacksaw, trim the float arm of the new sending unit to match the depth of your fuel tank. This step ensures that the float arm can move freely within the tank and provide accurate fuel level readings.

- Secure the float arm: Once you have trimmed the float arm to the correct length, use setscrews to securely fasten it to the flange of the new sending unit. This flange will be screwed into the top of your fuel tank during installation.

- Disconnect the old sending unit wires: Turn off the power to your vehicle's electrical systems. Then, disconnect the sending wire and the ground wire from the old sending unit. The sending wire typically comes off a post in the centre of the flange, while the ground wire may come off a second post at the edge.

- Remove the old fuel gauge wires: Remove the three wires connected to the back of the old fuel gauge. One wire connects to the centre pin on the tank sending unit, one goes to ground, and the third connects to a 12-volt source, usually the ignition switch.

- Install the new sending unit: Lower the float and float arm into the fuel tank. Ensure that the float arm is oriented in such a way that its movement will not be hindered by the walls of the tank. Slide a new gasket into place under the flange, and align the gasket with the holes in the sender and the tank. Mark the gasket and the screw holes to ensure proper alignment during installation.

- Secure the new sending unit: Put in the new screws and tighten them down. Check the wiring diagram provided with your new sending unit to ensure proper wiring connections. Mark the back of the new fuel gauge with symbols for each post: "S" for the sender, "G" or "-" for ground, and "I" for the ignition.

- Reconnect the wires: Reconnect the sending wire and the ground wire to the new sending unit. Then, reconnect the wires to the new fuel gauge, ensuring that the wiring matches the diagram provided.

- Turn on the power: With the new sending unit and fuel gauge installed, turn on the power to your vehicle's electrical systems. The fuel gauge should now show the correct fuel level in the tank. To ensure accurate readings, top off the tank and observe the gauge.

- Check for proper grounding and power: If the gauge does not read at all, check the power with a multimeter at the gauge terminal. Test between the positive terminal on the fuel gauge and a good ground; the reading should be 12 volts. If there is no power, check the ignition circuit.

- Test the vehicle: Start the vehicle and allow it to run for a few minutes. Monitor the fuel gauge to ensure that it is providing accurate readings. Take the vehicle for a test drive and go over bumps to allow the fuel to slosh around inside the tank. Observe the fuel gauge and dashboard for any engine lights or unusual behaviour.

By following these steps, you can ensure that your new fuel gauge sender is installed correctly and functioning properly.

Replacing the Fuel Damper in a Jeep Grand Cherokee (2002 model)

You may want to see also

Frequently asked questions

If your gas gauge is stuck on empty, this could be due to a faulty sender unit, a faulty gauge, or a break in the wiring between the gauge and sender. If the gauge reads empty when you know there is fuel in the tank, there may be a fault in the insulation of the wiring, resulting in a short circuit.

Before beginning, disconnect the negative battery cable to ensure no electrical sparks are possible. You should also work in a well-ventilated area to prevent breathing in fumes. The fuel tank sending unit is located at the top of the fuel tank and is accessible under the back seat or in the trunk. You will need to remove the access cover, which is usually held on with a couple of screws. With the access cover removed, you will see the fuel tank sending unit, which will have a wiring harness plugged into the top. Unplug the wiring harness and remove the unit by unscrewing or unbolting it.

Gasoline is highly flammable, so it is important to take precautions to avoid any sources of sparks or flames when replacing the fuel gauge sender. Always do this repair outside with the windows of your vehicle rolled down and ensure there are no sources of ignition nearby, such as a furnace or water heater. It is also a good idea to cover part of the work area inside the car with plastic and an old towel to catch any escaping fuel.