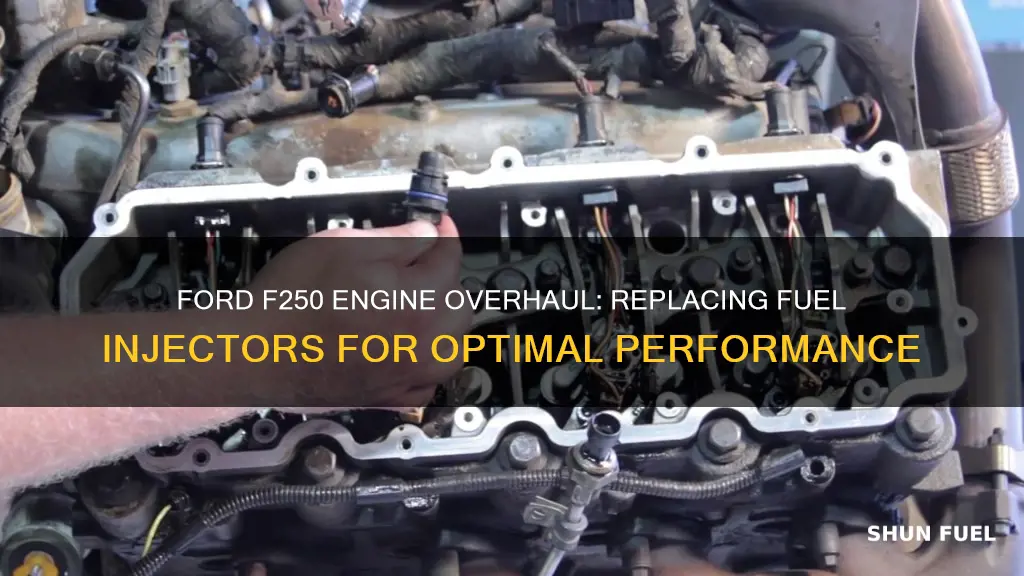

Replacing the fuel injectors in a 1991 Ford F250 4x4 engine is a crucial task for maintaining optimal performance and fuel efficiency. This process involves carefully removing the old injectors, ensuring a precise fit for the new ones, and reconnecting the wiring harnesses. Understanding the specific steps and tools required for this task is essential to ensure a successful and safe replacement. By following a detailed guide, you can effectively address any issues related to fuel delivery, potentially improving engine performance and longevity.

| Characteristics | Values |

|---|---|

| Vehicle Model | 1991 Ford F250 4x4 |

| Engine Type | V8 |

| Fuel Injector Location | Engine Block (Inlet Manifold) |

| Number of Fuel Injectors | 8 |

| Fuel Injector Type | Electronic Fuel Injection (EFI) |

| Symptoms of Faulty Fuel Injectors | Poor engine performance, hard starting, stalling, reduced power, rough idling, and increased fuel consumption. |

| Tools Required | Wrenches, socket set, fuel pressure gauge, new fuel injectors, and a fuel pressure regulator. |

| Steps to Replace Fuel Injectors | 1. Drain the fuel tank and disconnect the fuel lines. 2. Remove the intake manifold and access the fuel injectors. 3. Unclip or unscrew the old fuel injectors. 4. Install the new fuel injectors, ensuring correct orientation. 5. Reattach the fuel lines and refill the tank. 6. Test the engine to ensure proper operation. |

| Common Issues | Clogged fuel injectors, worn-out o-rings, and faulty wiring harnesses. |

| Maintenance Tips | Regularly check for fuel contamination and replace the fuel filter. Keep the engine properly lubricated to prevent internal damage. |

What You'll Learn

- Prepare the Engine: Disconnect the battery, drain the fuel, and disconnect the negative battery cable

- Remove the Old Injectors: Carefully take out the old fuel injectors using the appropriate tools

- Install New Injectors: Align and secure the new injectors, ensuring proper wiring and connections

- Test and Adjust: Verify proper function and adjust the timing and fuel pressure as needed

- Reassemble and Test: Reinstall the engine components and start the vehicle to ensure proper operation

Prepare the Engine: Disconnect the battery, drain the fuel, and disconnect the negative battery cable

Before you begin the process of replacing the fuel injectors in your 1991 Ford F250 4x4 engine, it's crucial to ensure that you have a safe and controlled environment. Here's a step-by-step guide to preparing the engine for the replacement:

Disconnect the Battery: Start by locating the battery in your vehicle. It is typically found in the engine compartment or sometimes under a cover. Carefully disconnect the negative battery cable, which is usually a black cable. This step is essential as it will prevent any accidental electrical discharges that could damage the new injectors or the engine's electronics. Remember to label the cables or take a picture for future reference to avoid confusion when reconnecting.

Drain the Fuel: Fuel drainage is a critical safety measure. Locate the fuel drain valve, which is usually a small valve on the fuel tank. Open this valve to release the fuel from the system. You might need to locate a small screw or a dedicated fuel drain port. If you're unsure, consult your vehicle's manual. Once the valve is open, allow the fuel to drain completely. This process ensures that you don't have any fuel pressure or spills during the replacement.

Disconnect the Negative Battery Cable (Again): After confirming that the fuel has been drained, it's time to disconnect the negative battery cable again, but this time from the engine side. Locate the cable connected to the engine block and carefully remove it. This step ensures that the engine is completely disconnected from the power source, providing a safe working environment.

By following these steps, you are creating a safe and controlled environment for the fuel injector replacement. It's important to take these precautions to avoid any potential hazards and ensure a successful repair. Remember to double-check all connections and labels to make the reassembly process straightforward.

Fuel Filter Replacement: Where to Start?

You may want to see also

Remove the Old Injectors: Carefully take out the old fuel injectors using the appropriate tools

To replace the fuel injectors in your 1991 Ford F250 4x4 engine, you'll need to carefully remove the old injectors. Here's a step-by-step guide to ensure a smooth process:

Step 1: Gather the Right Tools

Before you begin, make sure you have the necessary tools for the job. You'll typically need a fuel rail removal tool, which is designed to safely take out the fuel injectors without causing damage. Additionally, have a set of socket wrenches or a fuel rail socket that fits your injector's mounting bolts. It's also a good idea to have a new set of fuel injectors ready for installation.

Step 2: Locate the Injectors

Identify the fuel injectors you want to replace. These are usually located along the top of the engine, positioned near the intake manifold. There may be multiple injectors, so take note of their positions to ensure proper reinstallation.

Step 3: Disconnect Fuel Lines (Optional)

For easier access, you might want to disconnect the fuel lines connected to the old injectors. This step is optional but can make the removal process less cumbersome. Use the appropriate tools to carefully disconnect the lines, ensuring you don't damage any surrounding components.

Step 4: Remove the Old Injectors

Now, carefully take out the old fuel injectors. Insert the fuel rail removal tool into the mounting holes of the injector and apply gentle, steady pressure. The tool should help you pry the injector out of its socket. Be cautious not to force it, as the injector can be delicate. Once removed, set the old injectors aside, preferably in a secure place to avoid losing small parts.

Step 5: Clean and Inspect (Optional)

If you plan to reuse the old injectors or want to ensure a thorough replacement, consider cleaning them. This can involve removing any deposits or debris using a suitable cleaner. Additionally, inspect the injectors for any signs of damage or wear that might have contributed to the failure.

Remember, when working with fuel systems, safety is paramount. Ensure the engine is cool before starting the removal process, and always follow manufacturer guidelines for your specific vehicle.

Replacing Fuel Injectors: 2002 Sentra Spec V Guide

You may want to see also

Install New Injectors: Align and secure the new injectors, ensuring proper wiring and connections

When replacing the fuel injectors in your 1991 Ford F250 4x4 engine, it's crucial to follow a systematic approach to ensure a successful installation. Here's a step-by-step guide to help you through the process:

Preparation and Alignment: Begin by laying out the new fuel injectors on a clean, well-lit work area. Compare them with the old ones to familiarize yourself with their design. Take note of the wiring harness and any unique features or markings on the injectors. This visual inspection will help you understand the correct orientation and positioning. Ensure that you have the necessary tools, including socket wrenches, screwdrivers, and possibly a torque wrench, depending on your specific vehicle model.

Removing the Old Injectors: Locate the old fuel injectors, which are typically mounted on the engine block or near the intake manifold. Carefully disconnect the wiring harness from the old injectors, taking note of the color-coded wires and their respective connections. Remove the screws or fasteners securing the injectors and carefully pull them away from the engine. Keep the old injectors aside for reference or disposal.

Installing the New Injectors: Now, it's time to install the new fuel injectors. Start by aligning the new injectors with the mounting positions of the old ones. Ensure that the wiring harness is routed correctly, matching the color-coded wires to their respective connections. Secure the new injectors using the appropriate screws or fasteners, tightening them by hand first to avoid over-tightening. Double-check the wiring connections to ensure they are secure and properly aligned.

Final Adjustments and Testing: After securing the injectors, carefully route the wiring harness through the engine compartment, ensuring it is neat and free from any obstructions. Double-check all connections and wiring to prevent any issues during operation. Start the engine and listen for any unusual noises. Check for proper fuel flow and engine performance. If everything is functioning correctly, you've successfully installed the new fuel injectors.

Remember, each vehicle model may have slight variations in the installation process, so it's essential to consult the manufacturer's guidelines or seek professional assistance if needed. Proper alignment and secure wiring are critical to ensuring optimal engine performance and longevity.

Replacing the Fuel Pump in Your 99 GMC: Step-by-Step Guide

You may want to see also

Test and Adjust: Verify proper function and adjust the timing and fuel pressure as needed

Once you've replaced the fuel injectors in your 1991 Ford F250 4x4, it's crucial to test and adjust the system to ensure optimal performance. This process involves verifying the proper function of the injectors and making any necessary adjustments to the timing and fuel pressure. Here's a step-by-step guide to help you through this critical phase:

Testing the Fuel Injectors:

- Start the engine and listen for any unusual noises. Properly functioning injectors should deliver a steady, consistent fuel spray without any clattering or sputtering.

- Use a fuel pressure gauge to check the pressure. The ideal pressure varies depending on the engine's operating temperature and speed, but a typical range is 35-65 psi. If the pressure is too low, it may indicate a clogged or faulty injector.

- Inspect the engine for any fuel leaks. Even a small leak can cause performance issues and potential safety hazards.

- Check the engine's idle quality. A well-adjusted system should provide a smooth, steady idle without excessive vibrations or fluctuations.

Adjusting Timing and Fuel Pressure:

- Timing is critical for proper engine operation. Use a timing light or similar tool to ensure the engine's timing is accurate. The timing should be set according to the vehicle's specifications, typically with the camshaft and crankshaft synchronized.

- Adjust the fuel pressure regulator if necessary. This component controls the overall fuel pressure in the system. If the pressure is too high, it can cause engine misfires and performance issues. If it's too low, the engine may run rich, leading to reduced efficiency and potential damage.

- Fine-tune the fuel pressure by making small adjustments to the regulator and testing the engine's response. You may need to consult a service manual or seek professional advice for precise adjustment values.

- After making adjustments, retest the fuel injectors and overall system performance. Ensure that the engine runs smoothly, idles steadily, and accelerates responsively.

Remember, proper testing and adjustment are essential to guarantee the longevity and reliability of your engine. It's a delicate process that requires attention to detail and a methodical approach. If you're unsure about any step, consider seeking assistance from a qualified mechanic who can provide guidance tailored to your specific vehicle.

Replacing the Fuel Pump in a 2003 Hyundai Santa Fe

You may want to see also

Reassemble and Test: Reinstall the engine components and start the vehicle to ensure proper operation

After replacing the fuel injectors in your 1991 Ford F250 4x4 engine, it's crucial to reassemble the engine and test its operation to ensure everything is functioning correctly. Here's a step-by-step guide to help you through this process:

Reinstalling Engine Components:

- Engine Disassembly: Begin by carefully reassembling the engine components that were removed during the injector replacement. This includes installing the new injectors, ensuring they are securely attached to the engine block and aligned with the intake valves. Reattach the fuel lines, making sure they are properly connected and free of any kinks or obstructions.

- Timing and Sensors: Double-check the timing belt or chain and ensure it is correctly positioned and tensioned. Reinstall any sensors that were removed, such as the crankshaft position sensor and camshaft sensor, as these are essential for engine management.

- Air Intake and Exhaust: Reattach the air intake system, including the air filter and any associated hoses. Similarly, reconnect the exhaust system, ensuring a tight seal to prevent any leaks.

Starting and Testing the Engine:

- Fuel System Check: Before starting the engine, verify that the fuel system is operational. Check for any fuel leaks around the injectors and lines. Ensure that the fuel pump is functioning correctly by listening for its operation and checking the fuel pressure.

- Engine Start-Up: With the engine reassembled, start the vehicle. Listen for any unusual noises and observe the engine's behavior. It should start smoothly and run without any erratic behavior.

- Performance Testing: Allow the engine to idle and monitor its performance. Check for any signs of misfires, rough idling, or excessive smoke from the exhaust. Ensure that all warning lights on the dashboard are functioning and that there are no error codes displayed.

- Drive Test: Take the vehicle for a short drive to assess its overall performance. Pay attention to acceleration, power delivery, and handling. Ensure that the engine responds promptly to throttle inputs and that there are no unusual vibrations or noises.

- Post-Drive Inspection: After the test drive, inspect the engine for any signs of abnormal wear or damage. Check the fluid levels, including engine oil and coolant, and ensure they are at the recommended levels. Look for any leaks or unusual stains on the ground beneath the vehicle.

Remember, proper reassembly and testing are critical to ensuring the longevity and reliability of your engine. If any issues arise during this process, it's essential to address them promptly to avoid further complications.

Replacing Husqvarna 125B Fuel Line: Step-by-Step Guide

You may want to see also

Frequently asked questions

Common signs that your fuel injectors may need replacement include rough idling, reduced power, poor fuel economy, and the engine may even stall. If you notice any of these symptoms, it's best to have the injectors inspected by a professional mechanic.

While it is technically possible to replace fuel injectors yourself, it is a complex process that requires specialized tools and knowledge. It's highly recommended to have this task performed by an experienced mechanic to ensure proper installation and avoid any potential issues.

You will need a set of specialized tools, including a fuel pressure gauge, a fuel pump primer, and possibly a fuel injection tester. Additionally, have a new set of fuel injectors ready that are compatible with your specific engine model and year.

Yes, the process involves draining the fuel tank, disconnecting the fuel lines and injectors, removing the old injectors, and then installing the new ones. It's crucial to follow the manufacturer's instructions and ensure proper alignment and torque specifications during installation.

The time required can vary depending on your mechanical skills and access to the necessary tools. On average, it may take several hours to complete the task, but seeking professional assistance can ensure a faster and more reliable solution.