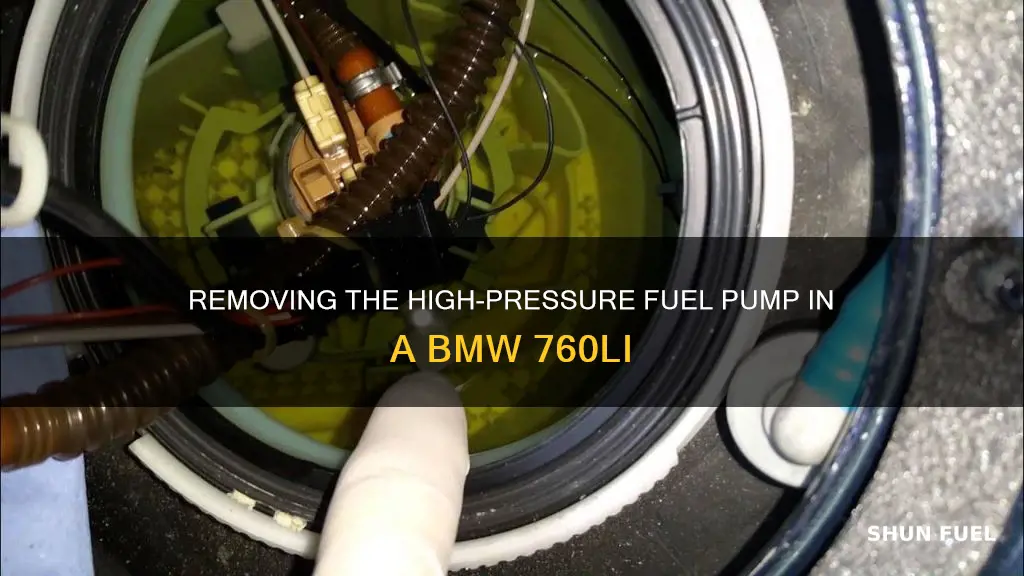

If you're looking to remove the high-pressure fuel pump from your 2004 BMW 760Li, this step-by-step guide will help you get the job done. Before you begin, it's important to make sure that your pump is the culprit by checking for any fuel leaks from the vent lines. You'll also need to gather the necessary tools and parts, including a new diaphragm, needle-nose vice grips, a sharp razor, paper towels, and a flat-head screwdriver. Start by removing the black vent hose and placing towels under the pump to catch any dripping fuel. Loosen the screw connecting the vent pipe to the pump and remove the four screws on the outside of the pump. Now, carefully remove the cap, spring, metal ring, blue O-ring, and circular black cap. Use your fingers to pull out the ring that holds the diaphragm in place, being careful not to angle it. Remove the old diaphragm and cut the new one to size, placing it inside the pump with the metal ring. Reassemble the pump, reattach the vent hose, and turn the ignition to position 2 to get fuel back into the lines. Start the car and you're done!

What You'll Learn

Removing the high-pressure fuel pump diaphragm

To remove the high-pressure fuel pump diaphragm of a 2004 BMW 760Li, follow these steps:

Tools and Parts Required:

- 2 Magnafuel diaphragms, part number MP-9400-03 (one for each side)

- Needle-nose vice grips

- Sharp razor

- Paper towels

- Flathead screwdriver

Removal Process:

- Remove the black vent hose by pushing in on the black piece.

- Place towels under the pump to collect any fuel that may drip out of the vent lines.

- Loosen the screw connecting the vent pipe on the top of the HPFP, or remove it from the pump. Pull it off once the clamp is loose enough.

- Remove all four screws on the outside of the pump with your vice grips and ensure that the pump can move freely and is loose from the engine. This step is crucial and must not be skipped.

- Loosen each bolt on the cap of the HPFP a little bit at a time until they are all out.

- Carefully remove the spring, metal ring, blue O-ring, and circular black cap from inside the cap.

- Use your fingers to pull out the ring that holds the diaphragm in place. Apply light pressure upwards on the pump to ensure the ring doesn't get stuck inside. Alternatively, use a socket that fits snugly inside the hole to pull it out.

- Remove the diaphragm. It might be stuck to the metal ring or inside the pump. If it is loose, use your nails to get the edge up and pull it out. If it is stuck, poke a hole in the middle and use a small screwdriver to get it out, being careful not to scratch the inner surfaces of the pump.

- Place the larger, thicker metal ring inside the new Magnafuel diaphragm and carefully trim the excess material off the outside.

- Compare the new diaphragm to the old one to ensure they are the same size.

- Place the new diaphragm inside the pump, ensuring a snug fit with no gaps that could let fuel through.

- Put the metal ring back inside the pump evenly, being careful not to angle it so it doesn't get stuck.

- Replace the black circular plastic piece and the blue O-ring. The O-ring can be tricky to place, but it has a groove that it fits into and will stay in place once installed.

- Replace the thinner metal circle with the high part facing up, and put the spring and cap back on the pump. Compress the cap and hand-tighten the screws. Torque the bolts to 69 inch-pounds with an inch-pound torque wrench.

- Reinsert the four long bolts that secure the pump to the engine. You may need to push the pump down to start the bolts. Tighten them snugly, then a little more.

- Reattach the vent hose to the nipple on the top of the pump.

- Attach the second vent line by pushing the two lines together until you hear or feel a click. Tug lightly to ensure it is connected.

- Turn the ignition to position 2, foot off the brake, and push the start button about five times. Then, start the car and let it run. The engine may not start immediately, and there may be a 2-3 second delay as the fuel system was open.

Additional Notes:

- Before beginning this procedure, ensure that your HPFP is the culprit by checking that there are no other parts in your fuel system causing similar problems.

- This repair should take no more than 30-45 minutes per side. The driver's side is the hardest due to the presence of tubes, wires, tanks, and engine components.

- When removing and replacing the cap, be extra careful, as this is when parts may fall underneath the car.

- It is recommended to replace the fuel filter and the tank recirculation (carbon canister) filter as well.

- Only one diaphragm is needed per side, not two.

- The bolts need to be torqued accordingly; otherwise, you will damage the diaphragm.

Testing Fuel Pressure: Locating the Right Spot for Your 454 Mag MPI

You may want to see also

Tools and parts required for the job

To remove the high-pressure fuel pump from a 2004 BMW 760Li, you will need the following tools and parts:

Tools:

- Needle-nose vice grips

- Sharp razor

- Paper towels

- Flat-head screwdriver

Parts:

- 2 Magnafuel diaphragm's, part number MP-9400-03 (one for each side)

- New high-pressure fuel pump o-ring, part number 11128636401

- New high-pressure fuel pump, part number 13517529068 or 13517560364

It is also recommended to replace the fuel filter and the fuel return filter.

DIY Fuel Pressure Tester: Crafting Your Own Solution

You may want to see also

Removing the black vent hose

To remove the black vent hose of a 2004 BMW 760Li high-pressure fuel pump, follow these steps:

Firstly, put some towels down to collect any fuel that might drip out of the vent lines. Next, locate the black vent hose and push in on the black piece to remove it. Now, loosen the screw connecting the vent pipe on the top of the high-pressure fuel pump (HPFP) and remove it. It might be on tightly, so ensure the clamp is loose enough for it to move freely. Give it a good pull, and the vent hose should come off without too much effort.

At this point, you will need to remove the HPFP itself. To do this, remove all four screws on the outside of the pump with a suitable tool, such as needle-nose vice grips. Ensure that the pump can move around and is loose from the engine. This step is crucial and should not be skipped.

Now, you can begin to disassemble the HPFP. First, remove the cap by loosening each bolt a little bit at a time until they can be removed. Under the cap, there is a spring, metal ring, blue O-ring, and a circular black cap. Remove these carefully and set them aside. Next, use your fingers to pull out the metal ring that holds the diaphragm in place. Use light pressure upwards on the pump, ensuring that the ring does not get cocked inside and get stuck. Alternatively, you can use a socket that fits snugly inside the hole to pull it out.

With the ring removed, it is now time to remove the diaphragm. It might be stuck to the metal ring or inside the pump. If it is loose, use your fingernails to get the edge up and pull it out. If it is stuck, poke a hole in the middle and use a small tool, such as an electronics screwdriver, to remove it carefully. Take care not to scratch the inner surfaces of the pump.

Now, you can prepare the new diaphragm. Place the larger, thicker metal ring inside and carefully trim the excess material from the outside. Compare it to the old diaphragm to ensure they are the same size. Place the new diaphragm inside the pump, ensuring a snug fit with no gaps.

To reassemble the HPFP, first, place the metal ring back inside the pump evenly, ensuring it does not angle and get stuck. Then, replace the black circular plastic piece and the blue O-ring. The O-ring has a groove that it fits into and will stay in place once installed. Next, replace the thinner metal circle with the high part facing up, followed by the spring and the cap. Compress the cap and hand-tighten the screws. Finally, torque the bolts to 69 inch-pounds with a torque wrench.

With the HPFP reassembled, you can now reattach it to the engine. Insert the four long bolts that secure the pump and tighten them. Reattach the vent hose to the nipple on the top of the pump, and then attach the second vent line by pushing the two lines together until you hear or feel a click.

To finish, turn the ignition to position 2 and push the start button about five times to get fuel back into the lines and pump. The engine may not start immediately, so expect a 2-3 second delay.

Best Duramax Tuners for Boost and Fuel Rail Pressure Adjustments

You may want to see also

Loosening the screw connecting the vent pipe

To loosen the screw connecting the vent pipe on the top of the high-pressure fuel pump (HPFP) of your 2004 BMW 760Li, follow these steps:

- Remove the black vent hose by pushing in on the black piece.

- Place some towels under the pump to collect any fuel that might drip out of the vent lines.

- Loosen the screw connecting the vent pipe on the top of the HPFP. It might be on there tightly, so make sure the clamp is loose enough for it to move freely around the tube. Then, give it a good pull—it should come off without too much effort.

Now you can proceed to the next steps to remove the 2004 BMW 760Li high-pressure fuel pump.

Fuel Line Pressure: How Much Can It Take?

You may want to see also

Reattaching the vent hose

Step 1:

Place some towels or rags underneath the pump to catch any fuel that may drip during the reattachment process. It is important to be cautious and prepared for any potential fuel leakage.

Step 2:

Loosen the screw that connects the vent pipe to the top of the high-pressure fuel pump (HPFP). This will allow you to freely move the vent pipe and ensure a proper connection. Make sure the clamp is loose enough so that the vent pipe can be easily adjusted.

Step 3:

Before reattaching the vent hose, ensure that the four screws on the outside of the HPFP are tightened securely. This step is crucial, as it ensures that the pump is firmly attached to the engine. You should be able to move the pump around slightly, but it should still feel securely attached.

Step 4:

Now, carefully reattach the vent hose to the nipple on the top of the HPFP. Push the vent hose firmly onto the nipple until you hear or feel a satisfying click, indicating that it is securely attached.

Step 5:

Next, attach the second vent line by carefully pushing the two lines together. Again, listen for a clicking sound or feel for a slight resistance, indicating that the lines are properly connected.

Step 6:

After reattaching the vent hose and vent line, it is important to refill the fuel lines and the pump with fuel. To do this, turn the ignition to position 2, without pressing the brake pedal, and push the start button. Repeat this process about 5 times, and then try to start the car. Due to the open fuel system, there may be a slight delay of 2-3 seconds before the engine starts.

By carefully following these steps, you can ensure that the vent hose and vent line are securely reattached, preventing any fuel leaks and ensuring the proper functioning of your 2004 BMW 760Li's high-pressure fuel pump.

How Scangauge 2 Reads Fuel Pressure in 99 Tahoe

You may want to see also