Gator fuel lines are an essential component for any off-road enthusiast, and knowing how to put them together is a valuable skill. This guide will provide a step-by-step process to ensure a secure and efficient installation, covering the necessary tools, materials, and techniques to create a reliable fuel line system for your vehicle's engine.

What You'll Learn

- Prepare Tools: Gather necessary tools like fuel line, crimping tool, and fuel filter

- Inspect Lines: Check for damage, bends, and leaks before installation

- Cut and Prepare: Measure and cut fuel line to correct length, ensuring a clean cut

- Crimp Connections: Use a crimping tool to secure fuel line to fittings tightly

- Test for Leaks: After installation, check for any fuel leaks at connections

Prepare Tools: Gather necessary tools like fuel line, crimping tool, and fuel filter

Before you begin the process of assembling the Gator fuel line, it's crucial to gather all the necessary tools and components. This ensures a smooth and efficient repair or installation process. Here's a detailed guide on preparing the tools required for the task:

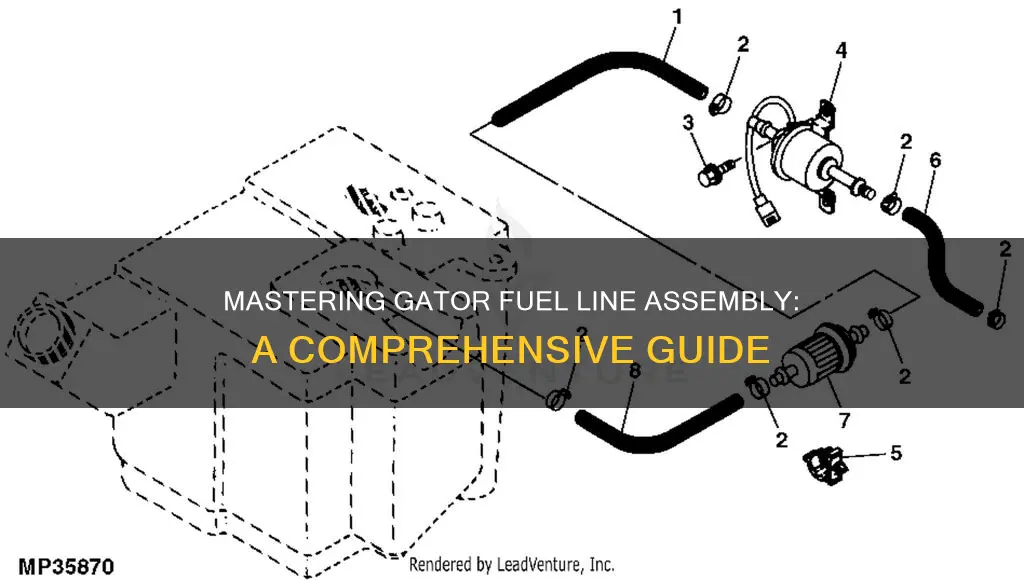

Fuel Line and Crimping Tool: Start by acquiring the appropriate fuel line, which is specifically designed for the Gator model you are working on. Measure the required length to ensure a proper fit. Along with the fuel line, you'll need a crimping tool, which is essential for securing the connections. Crimping tools come in various types, but for this task, a manual or power crimper with the appropriate die set for fuel line connections will be sufficient. Make sure to choose a tool that matches the size and type of fuel line you are using.

Fuel Filter: Another critical component is the fuel filter, which helps prevent contaminants from entering the fuel system. Select a filter that is compatible with your Gator model and the fuel line size. The filter should have a suitable flow rate and capacity to handle the fuel requirements of your machine. It's essential to inspect the filter's condition before installation to ensure it is free from any damage or blockages.

Additional Tools: Besides the primary tools, you might also need some basic hand tools like pliers, screwdrivers, and a wrench. These can be handy for adjusting fittings, tightening connections, and making any necessary adjustments during the assembly process. Additionally, consider having a fuel line cutter or a utility knife for precise fuel line trimming.

By gathering these tools and components in advance, you'll be well-prepared to tackle the task of assembling the Gator fuel line. This organized approach ensures that you have everything readily available, making the repair or installation process more efficient and less stressful. Remember to double-check the compatibility of the tools and parts with your specific Gator model to ensure a successful outcome.

Dorman Fuel Line Sizes: A Comprehensive Guide for 55240

You may want to see also

Inspect Lines: Check for damage, bends, and leaks before installation

Before you begin the installation process of your Gator fuel line, it is crucial to conduct a thorough inspection to ensure the system is in optimal condition. This step is often overlooked but is essential for the safety and efficiency of your equipment. Here's a detailed guide on how to inspect the fuel lines:

Damage Assessment: Start by visually examining the fuel lines for any signs of damage. Look for cuts, punctures, or tears along the length of the line. Even small tears can lead to fuel leaks, which can be dangerous and cause environmental hazards. Check for any signs of wear and tear, especially in areas where the line might have come into contact with sharp objects or rough terrain. Inspect the fittings and connections as well; ensure they are intact and secure. If you notice any damage, it is best to replace the affected section to prevent potential issues during operation.

Bending and Flexibility: Fuel lines should be flexible to accommodate the movement of the Gator machine. Inspect the lines to ensure they can bend without kinking or cracking. Kinking can restrict fuel flow and potentially damage the engine. If you find any sections that are excessively bent or show signs of permanent deformation, it's advisable to replace those parts. Remember, the goal is to maintain a smooth and flexible fuel line throughout its length.

Leak Testing: One of the most critical aspects of inspection is checking for leaks. Start by removing the fuel tank cap and using a fuel line tester or a simple bubble solution. Hold the fuel line under the tester or submerge it in the solution and observe for any bubbles. Bubbles indicate the presence of air, which can lead to engine misfires and performance issues. If you detect air bubbles, you'll need to bleed the fuel line to remove the air. Additionally, inspect the connections for any signs of leakage. Apply a small amount of diesel fuel or soapy water around the fittings to ensure there are no leaks. Any leaks should be addressed by tightening connections or replacing damaged sections.

During this inspection process, it's important to take notes and document any issues found. This documentation will help you make informed decisions when replacing or repairing the fuel lines. Remember, a well-maintained fuel line system is vital for the reliable operation of your Gator vehicle.

Fuel Line Conversion: 5 mm to Inches Explained

You may want to see also

Cut and Prepare: Measure and cut fuel line to correct length, ensuring a clean cut

When preparing to assemble the Gator fuel line, the first crucial step is to measure and cut the fuel line to the correct length. This process requires precision to ensure a proper fit during assembly. Start by referring to the manufacturer's instructions or the diagram provided with your Gator model to determine the exact length needed for the fuel line. It's essential to measure twice to avoid any mistakes, as cutting the fuel line too short can lead to issues with fuel flow and potential engine problems.

Using a sharp utility knife or a fuel line cutter, carefully measure and mark the desired length on the fuel line. Ensure that the cut is straight and clean to prevent any burrs or sharp edges that could damage the fuel line or the fuel tank during installation. A clean cut will also make it easier to insert the fuel line into the appropriate ports.

Hold the fuel line at the marked length and make a precise cut, being mindful of your fingers and any nearby objects. Consider using a cutting guide or a straight edge to assist with the cutting process and maintain accuracy. Once cut, inspect the ends of the fuel line to ensure they are free of any debris or damage.

With the fuel line now measured and cut to size, you're ready for the next step in the assembly process. Properly preparing the fuel line by cutting it to the correct length is fundamental to ensuring a successful and safe installation.

Fuel Line Disconnect: Tools and Tips for a Smooth Process

You may want to see also

Crimp Connections: Use a crimping tool to secure fuel line to fittings tightly

When it comes to connecting the Gator fuel line to your engine, ensuring a secure and tight crimp connection is crucial for optimal performance and safety. This process involves using a crimping tool to create a reliable bond between the fuel line and the fittings. Here's a step-by-step guide to mastering crimp connections:

Start by gathering the necessary tools and materials. You'll need a crimping tool specifically designed for fuel line connections, a variety of crimp dies that match the sizes of your fittings, and of course, the Gator fuel line itself. Ensure you have the correct size crimp die for the fitting you are using; this is essential for a proper connection.

Prepare the fuel line by cleaning the fittings. Remove any dirt or debris from the threads of the fitting and the fuel line. This ensures a clean and secure connection. Take your crimping tool and position it over the fitting, ensuring it is aligned correctly. Insert the fuel line into the fitting, pushing it until it reaches the desired depth. The key to a successful crimp is applying the right amount of force. Use the crimping tool to apply pressure to the fuel line, squeezing it onto the fitting. The amount of force required varies depending on the size of the fitting and the crimp die used. As a general rule, apply firm pressure and hold it for a few seconds, ensuring the crimp is secure.

After crimping, inspect the connection. Check for any signs of slippage or uneven pressure. A well-crimped connection should have a smooth, uniform appearance around the fitting. If any adjustments are needed, carefully remove the fuel line and re-crimp, ensuring you follow the same steps.

Practice and patience are key when mastering crimp connections. It may take a few attempts to get the technique perfect, but with time, you'll be able to create tight, reliable connections that ensure your engine receives the fuel it needs. Remember, a secure crimp connection is vital for the longevity of your fuel system and the overall performance of your vehicle.

Duramax Fuel Line Removal: A Step-by-Step Guide for DIY Mechanics

You may want to see also

Test for Leaks: After installation, check for any fuel leaks at connections

After successfully assembling the Gator fuel line, it is crucial to conduct a thorough leak test to ensure the system's integrity and prevent any potential fuel loss. This step is essential to guarantee that the fuel line is securely connected and free from any defects that could lead to fuel leakage. Here's a detailed guide on how to perform this test:

Preparation: Before starting, ensure you have the necessary tools and materials, including a fuel leak detector or a soapy water solution. It is recommended to wear protective gear, such as gloves and goggles, to safeguard yourself during the process. Gather all the components of the fuel line, including the connections, fittings, and any additional parts used during the assembly.

Leak Detection Process: Begin by inspecting each connection point thoroughly. Look for any visible signs of damage, such as cracks or bends in the fuel line. Check the fittings and connectors for any debris or dirt that might have accumulated during the installation process. Use the leak detector or soapy water to carefully examine the connections. Apply a small amount of the leak detector or soapy water to each connection and observe for any bubbles or foam. If you notice any, it indicates a potential leak. If using soapy water, any bubbles forming around the connection points signify a leak.

Troubleshooting and Repairs: If a leak is detected, it is crucial to address it promptly. Start by identifying the source of the leak, which could be a faulty connection, a damaged fuel line, or a poorly tightened fitting. Carefully inspect the affected area and consider the following steps: Re-tighten the connection if it was not secured properly. Replace any damaged fuel line sections or fittings. Ensure that all connections are clean and free from any debris. If the leak persists, it may be necessary to seek professional assistance or disassemble the fuel line again for further inspection and repair.

Safety Precautions: When testing for leaks, always prioritize safety. Fuel is highly flammable, so ensure the engine is off and the fuel source is disconnected. Work in a well-ventilated area, and be cautious of any potential hazards. If you suspect a significant leak, it is advisable to seek professional help to avoid any accidents or health risks associated with fuel exposure.

By following these steps, you can effectively test for leaks after installing the Gator fuel line, ensuring a reliable and safe fuel system. Regular maintenance and leak checks are vital to the longevity and performance of any fuel-related equipment.

Duramax Fuel Line Pressure: What Your 05 Needs

You may want to see also

Frequently asked questions

Before you begin, ensure you have the necessary tools and materials. This includes the fuel line itself, a fuel filter, fuel pump, and any required fittings or adapters. It's also advisable to have a wrench or pliers for tightening connections, a fuel line cutter or a sharp knife for precise cuts, and a fuel line cleaner or solvent to ensure a clean and secure installation.

Measuring and cutting the fuel line accurately is crucial. Use a fuel line cutter or a sharp knife to make a clean cut. Measure the length required, typically from the fuel pump to the engine's fuel injection system or the desired point of connection. Ensure the cut is straight and smooth to prevent any leaks or damage.

When connecting the fuel line, start by attaching the fuel pump side of the line to the pump's outlet port using the appropriate fittings. Tighten the connections securely but be careful not to overtighten. Then, connect the engine side of the line to the fuel injection system or the desired port. Again, ensure a tight and secure fit. Use fuel line cleaner or solvent to remove any debris and ensure a leak-free connection.

Regular maintenance is essential to ensure the longevity of your fuel line. Check for any signs of damage, cracks, or leaks periodically. Keep the fuel line free from debris and contaminants by using a fuel line cleaner or solvent when necessary. Avoid excessive bending or kinking of the line, as this can lead to reduced performance and potential leaks. Additionally, consider using a fuel stabilizer in the fuel tank to prevent gumming and maintain the overall health of the fuel system.