Testing the fuel rail pressure is an important aspect of car maintenance, as it helps identify issues with the fuel system and ensures the engine receives the required amount of fuel for optimal performance. Before initiating any diagnostic tests, it is crucial to prioritise safety by wearing protective gear and working in a well-ventilated area due to the risk of fire and injury associated with releasing fuel under pressure. This article will provide a comprehensive guide on how to pressure test a fuel rail, covering various steps, tools, and parameters to consider for a safe and effective testing process.

| Characteristics | Values |

|---|---|

| Safety precautions | Wear safety glasses and gloves, work in a well-ventilated area, and don’t smoke or have anything around that can cause a spark |

| Fuel pressure test | Start the car and let it idle. Install a fuel pressure gauge, run the pump, and note the pressure reading. Then compare it to the manufacturer specification |

| Fuel volume test | Collect a fuel sample for five seconds with the pump running. Check your manufacturer specification to see if your pump is delivering the right amount |

| Testing fuel delivery | Use a flowmeter or a glass measuring container |

| Fuel pressure tester | A gauge attached to a fuel hose and multiple fittings. The various fittings connect to the fuel system of nearly any vehicle |

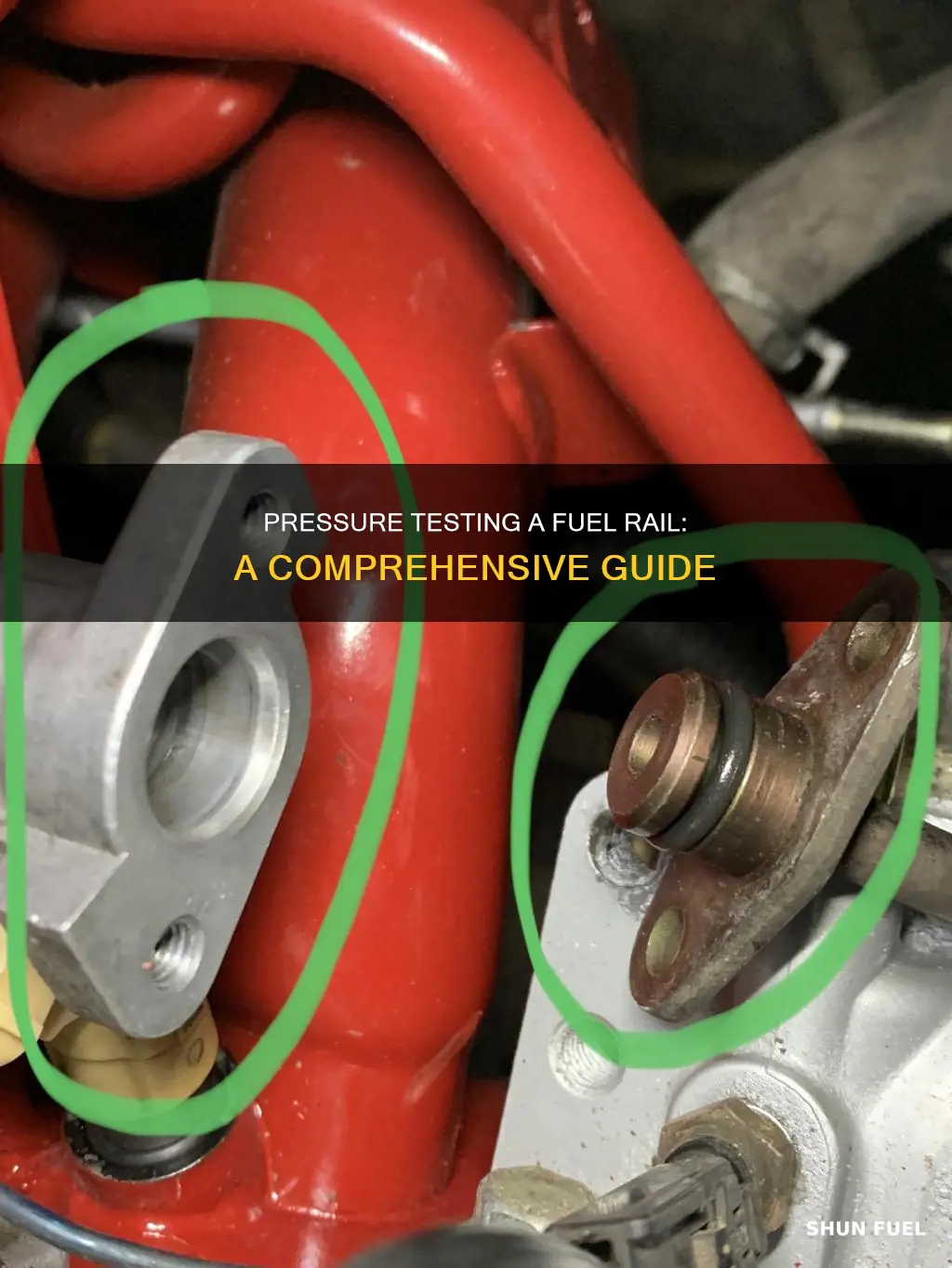

| Fuel pressure tester connection | Find a Schrader valve fitting on the fuel rail. Remove the Schrader valve cap. Attach the appropriate fuel pressure tester fitting |

| Fuel pressure tester reading | Turn the ignition to "on," not start. Check the psi reading. Wait and watch for a psi drop indicating a leak in the system |

| Fuel pressure tester reading interpretation | If the fuel pressure drops over 10 minutes, that means there is a leak in the fuel system |

| Fuel pressure with engine idling | You should see steady fuel pressure, within a few psi of recommended pressure |

| Fuel pressure with engine revving | Once warmed up, give the engine a slow rev, making sure pressure rises with RPMs |

| Zero fuel pressure | The pump is dead or not getting power. First, check the fuel pump fuse. Then verify power to the pump with a multimeter, and if it's good, swap out the fuel pump |

| Low fuel pressure | The fuel filter could be clogged, or the pump could be failing. If it is a serviceable type filter, change the fuel filter. This could also be improper tank venting, an emissions issue caused by a loose gas cap |

| High fuel pressure | Look for a clogged or kinked fuel return line. This could also be a bad fuel pump driver module or powertrain control module. High fuel pressure can also be caused by a faulty fuel pressure regulator |

What You'll Learn

Safety precautions

Pressure testing a fuel rail can be a dangerous task if not done correctly. Here are some safety precautions to follow when pressure testing a fuel rail:

Wear Protective Gear

Before starting, put on safety glasses and gloves to protect your eyes and hands from any fuel or debris that may be released during the test. It is also recommended to wear long sleeves and pants to protect your skin.

Work in a Well-Ventilated Area

Fuel vapours are highly flammable, so it is crucial to perform the test in an open, well-ventilated area to avoid the risk of fire or explosion. Ensure there are no sources of ignition nearby, such as lit cigarettes or open flames.

Check for Leaks

Before beginning the test, carefully inspect the fuel rail and all connected components for any signs of leaks or damage. If there is any leakage, do not proceed with the test and repair the issue first.

Disconnect the Battery

Before performing any work on the fuel rail, disconnect the negative cable from the vehicle's battery. This is an important safety precaution to prevent electrical shocks and reduce the risk of sparks that could ignite fuel vapours.

Use Proper Tools

Ensure you have the correct tools and equipment for the job. Use only approved fuel pressure testers and gauges designed for automotive use. Do not attempt to modify or adapt household tools for this task.

Be Mindful of Pressure

Fuel under pressure can be dangerous if released unexpectedly. Always be cautious when connecting or disconnecting hoses and fittings. Release pressure slowly and never point a hose or fitting towards yourself or others.

Follow Manufacturer's Instructions

Refer to the vehicle's repair manual or seek guidance from a qualified mechanic if you are unsure about any steps in the testing process. Each vehicle may have specific requirements or variations in the testing procedure.

Dispose of Fuel Properly

If you need to drain or collect fuel during the test, use appropriate containers and dispose of the fuel safely and responsibly. Do not leave open containers of fuel unattended.

Be Aware of Warning Signs

If you notice any unusual smells, sounds, or behaviour during the test, stop immediately and re-evaluate the situation. Do not ignore warning signs, as they could indicate a potential hazard.

Have a Fire Extinguisher Nearby

Keep a fire extinguisher close at hand in case of any accidents or fires. Ensure that you know how to use the fire extinguisher properly before starting the test.

Do Not Smoke

Do not smoke while performing the test or working on the vehicle. Smoking near fuel vapours is extremely dangerous and can lead to serious accidents.

Troubleshooting No Fuel Pressure: Common Causes and Solutions

You may want to see also

Checking fuel pressure

Prepare for the Test:

Before initiating the test, it's important to prioritize safety. Fuel pressure testing involves handling flammable substances, so take necessary precautions. Wear safety gear, such as gloves and goggles, and ensure the work area is well-ventilated. Do not smoke or have any ignition sources nearby. Additionally, keep a fire extinguisher close at hand.

Understanding the Fuel System:

Your car's fuel system provides fuel to the engine's injectors. It may include one or more styles of pumps, either mechanical or electric, depending on the design. Direct injection fuel systems, for instance, have a primary pump in the fuel tank and a secondary high-pressure pump mounted on the engine. Understanding your car's fuel system is essential for effective testing.

Locate the Fuel Pressure Port:

Most modern vehicles are designed with a convenient pressure port on the engine's fuel rail. Simply remove the cap to access the port. However, if your car doesn't have this feature, you may need an adapter from a test kit. This adapter can be attached at the fuel filter or the fuel pressure feed line leading to the fuel rail.

Connect the Fuel Pressure Gauge:

With the engine off, connect the fuel pressure gauge from the test kit to the pressure port. Be prepared to handle a small amount of fuel that may be released during this process. Use a shop towel to absorb any excess fuel. Ensure the gauge is securely connected to prevent leaks.

Test Static Fuel Pressure:

Turn the ignition key to the "on" position without starting the engine. Observe the gauge reading, which should be within the specified range for your car. For direct port injection systems, the pressure should be between 45 psi and 58 psi. For throttle body injection (TBI), the typical range is between 13 and 17 psi. If there is no pressure, recheck your connections and recycle the ignition switch. Persistent lack of pressure may indicate a faulty fuel pump, relay, or fuse.

Test Fuel Pressure with Engine Running:

Start the engine and observe the fuel pressure gauge. The pressure should drop by approximately 5 psi from the static prime pressure. Then, gently rev the engine, and the pressure should increase by about 5 psi. This indicates that your fuel pump and pressure regulator are functioning correctly. If the pressure doesn't respond as expected, inspect the regulator vacuum feed line, as there may be an issue with the fuel pressure regulator.

Perform a Load Test:

To assess the fuel pump's performance under load, you can conduct a load test. There are two ways to do this: first, with the transmission in reverse (for automatic cars) and the brake engaged, gently apply throttle to load the engine without moving the car. Alternatively, you can drive the car at moderate speeds with the hood slightly open, keeping the gauge visible. The pressure should remain steady throughout the test. If the fuel pressure drops under load or during idle, it could be due to a clogged fuel filter or a failing fuel pump.

Analyze Fuel Pressure Readings:

Now that you have obtained fuel pressure readings, it's time to interpret them. Zero fuel pressure indicates a dead pump or a lack of power supply to the pump. Low fuel pressure may be caused by a clogged fuel filter or a failing pump. On the other hand, high fuel pressure could be due to a clogged or kinked fuel return line, a faulty fuel pump driver module, or a powertrain control module issue. Refer to your car's repair manual to understand the specific pressure requirements for your engine.

Address Any Issues:

If you identify any issues with your fuel pressure, take appropriate action. For example, if the fuel filter is clogged, simply replace it. If the fuel pump is faulty, you may need to replace it. Always refer to a qualified mechanic if you're unsure about any aspect of the testing or repair process.

Testing Fuel Pressure: 1996 GMC Truck Guide

You may want to see also

Using a flowmeter

To test your fuel rail using a flowmeter, start by ensuring your car is on flat ground, in park, with the emergency brake set and the engine off. It's important to take safety precautions, such as wearing safety glasses and gloves, working in a well-ventilated area, and avoiding any smoking or open flames.

Next, locate the pressure port on the engine fuel rail and remove the cap. If your car doesn't have a pressure port, you'll need an adapter from a test kit, which can be attached at the fuel filter or fuel pressure feed line. Attach the flowmeter to the pressure port or adapter, making sure it's securely connected to prevent leaks.

Turn the ignition key to the "on" position without starting the engine. The flowmeter should indicate a specific fuel pressure reading, which you can compare to the manufacturer's specifications. If there is no pressure, check your connections and recycle the ignition switch to recheck. If there is still no pressure, it may indicate a faulty fuel pump, fuel pump relay, or fuse.

Now, start the engine and observe the flowmeter. The fuel pressure should drop slightly, and then increase when you snap the throttle. If the fuel pressure responds as expected, it means your fuel pump and pressure regulator are functioning correctly.

Finally, perform a load test to evaluate the pump's performance under load or while idling. You can do this by loading the engine in reverse (for automatic transmissions) or closing the hood to the first safety catch and driving at a slow speed while monitoring the flowmeter. If the fuel pressure drops under load or while idling, it could indicate a clogged fuel filter or a failing fuel pump that needs replacement.

Remember to always refer to your vehicle's repair manual for specific instructions and specifications related to your particular make and model.

Best Places to Buy 855 Cummins Fuel Pressure Spring

You may want to see also

Interpreting fuel pressure readings

Zero fuel pressure means the engine won't run. Check the fuel pump fuse and verify power to the pump with a multimeter. If it's working as it should, swap out the fuel pump.

Low fuel pressure can cause a slow start-up, low performance, misfires, and stalling. This could be due to a clogged fuel filter, a failing pump, or improper tank venting. Check the fuel filter first, and if that's not the issue, try changing the fuel filter. It could also be caused by an emissions issue due to a loose gas cap. Check that the cap gasket isn't damaged, and tighten it until it clicks.

High fuel pressure will cause excessive fuel consumption, black smoke from unburned gas, an overheating catalytic converter, and rough idle. Suspect a clogged or kinked fuel return line, a bad fuel pump driver module, or a faulty fuel pressure regulator. These issues are likely to store a code and show a "check engine" light.

If your fuel pressure readings are not within the manufacturer's specifications, refer to a vehicle service manual for step-by-step diagnostic procedures to pinpoint the faulty component.

It's important to note that fuel pressure readings depend on the engine. Older throttle-body injected systems may need as little as 10 psi, while multi-port injection can reach as high as 60 psi. Always check your vehicle's repair manual to determine the specifications for your particular engine.

Fuel Pressure Regulator: Evo X Maintenance Must-Know

You may want to see also

Troubleshooting fuel pressure issues

Safety First:

Before performing any troubleshooting or maintenance on your vehicle, it is crucial to prioritize your safety and the protection of those around you. Ensure you are wearing appropriate safety gear, including gloves and safety glasses. Conduct your work in a well-ventilated area, and refrain from smoking or creating any sparks that could cause an explosion or fire.

Understanding Fuel Pressure Sensors:

Fuel rail pressure sensors are essential for monitoring the pressure of the fuel in the fuel rail. They send this information to the engine control module (ECM), which adjusts the fuel injection system to ensure the engine runs smoothly and efficiently. A faulty fuel rail pressure sensor can cause various issues, including hard starting, decreased fuel efficiency, and the check engine light turning on.

Common Symptoms of Low Fuel Pressure:

- Unresponsive throttle or stalling engine

- Difficulty starting the car

- Check engine light on

- Misfires or low performance

- Poor acceleration

- Slow start-up

- Engine stalling

Causes of Low Fuel Pressure:

- Clogged fuel filter: Replace the fuel filter if it has not been changed for a long time.

- Bad fuel pump: The fuel pump may be damaged or slowed down, preventing it from pushing enough fuel to the engine.

- Bad fuel pressure regulator: The regulator controls fuel pressure and can create too low or too high pressure in the rail.

- Stuck fuel injector: A damaged injector stuck open can cause low fuel pressure, often indicated by misfire codes on a specific cylinder.

- Damaged fuel pipe line: Driving on bumpy roads or off-road may cause damage to the fuel pipes, resulting in low fuel pressure.

- Faulty fuel pressure sensor: The sensor may read the wrong pressure, tricking the fuel pressure regulator.

Troubleshooting Fuel Rail Pressure Sensor Issues:

- Conduct a visual inspection of the sensor and its wiring for any signs of damage or wear.

- Use a multimeter to test the resistance of the sensor and compare the readings to the manufacturer's specifications.

- Perform pressure testing on the fuel rail using a fuel pressure gauge and compare the readings to the manufacturer's recommended pressure.

Preventive Measures and Maintenance Tips:

- Use high-quality fuel to prevent contamination and clogging in the fuel system.

- Regularly replace fuel filters to prevent contaminants from entering the system and damaging the sensor.

- Check for fuel leaks in the fuel system as leaks can cause a drop in fuel pressure.

- Clean the fuel system regularly to prevent clogs and contamination.

- Perform regular diagnostics to detect any issues early on and prevent further damage.

Finding the Right Spot for Vacuum Line Fuel Regulation

You may want to see also

Frequently asked questions

If your car is having trouble starting, stalling, or running rough, it may be time to check your fuel sensor. A bad fuel sensor can cause all sorts of engine performance issues, so it's important to know how to spot one.

If the fuel rail pressure sensor is unplugged, the pump will run at a set speed and may cause the engine to run at reduced power and throttle. This can lead to decreased fuel economy and increased emissions.

A faulty fuel rail pressure sensor can cause your car to run lean, or use too much fuel. Additionally, it can cause your car to hesitate or stall when accelerating.