Measuring fuel line hoses is an essential step in ensuring the proper functioning of your vehicle's fuel system. This process involves determining the correct length and diameter of the hose to ensure a secure and efficient connection. By following a few simple steps, you can accurately measure the hose, which is crucial for maintaining optimal fuel flow and preventing potential issues such as fuel leaks or reduced engine performance. Understanding how to measure fuel line hoses is a valuable skill for any vehicle owner or mechanic, as it contributes to the overall reliability and safety of the vehicle.

What You'll Learn

- Hose Length: Measure the total length of the fuel line hose from start to end

- Diameter: Use a caliper to measure the inner diameter of the hose

- Wall Thickness: Determine the wall thickness of the hose using a micrometer

- Flexibility: Test the hose's flexibility by bending it to various angles

- Pressure Rating: Check the hose's pressure rating to ensure it meets requirements

Hose Length: Measure the total length of the fuel line hose from start to end

To accurately measure the length of a fuel line hose, it's important to follow a systematic approach. Start by ensuring you have a straight and unobstructed path to measure along the hose. This is crucial to getting an accurate length measurement. Begin at the starting point of the hose and carefully trace its path to the end. Make sure you're measuring the hose itself, not any additional components like fittings or attachments.

Use a flexible measuring tape or a ruler to extend along the entire length of the hose. It's essential to maintain tension on the hose to ensure a precise measurement. You can use your hands or a helper to hold the hose taut while you measure. Take note of the point where the hose ends, and record the measurement in inches or centimeters, whichever your preference is.

For a more accurate measurement, consider using a measuring tape that can bend and conform to the hose's shape. This will allow you to get a more precise reading, especially if the hose has any curves or bends. If you're working alone, you might want to consider using a mirror to help you see the end of the hose while you measure.

Keep in mind that the measurement should include any bends or kinks in the hose, as these can affect the overall length. If the hose has any fittings or attachments, measure them separately and add their lengths to the total. This will give you a comprehensive understanding of the hose's length, including any potential issues or areas of concern.

By following these steps, you can ensure that you have a precise measurement of the fuel line hose's length, which is essential for various applications, including installations, replacements, or troubleshooting.

Ford Fuel Line Removal: Tips for a Tool-Free Process

You may want to see also

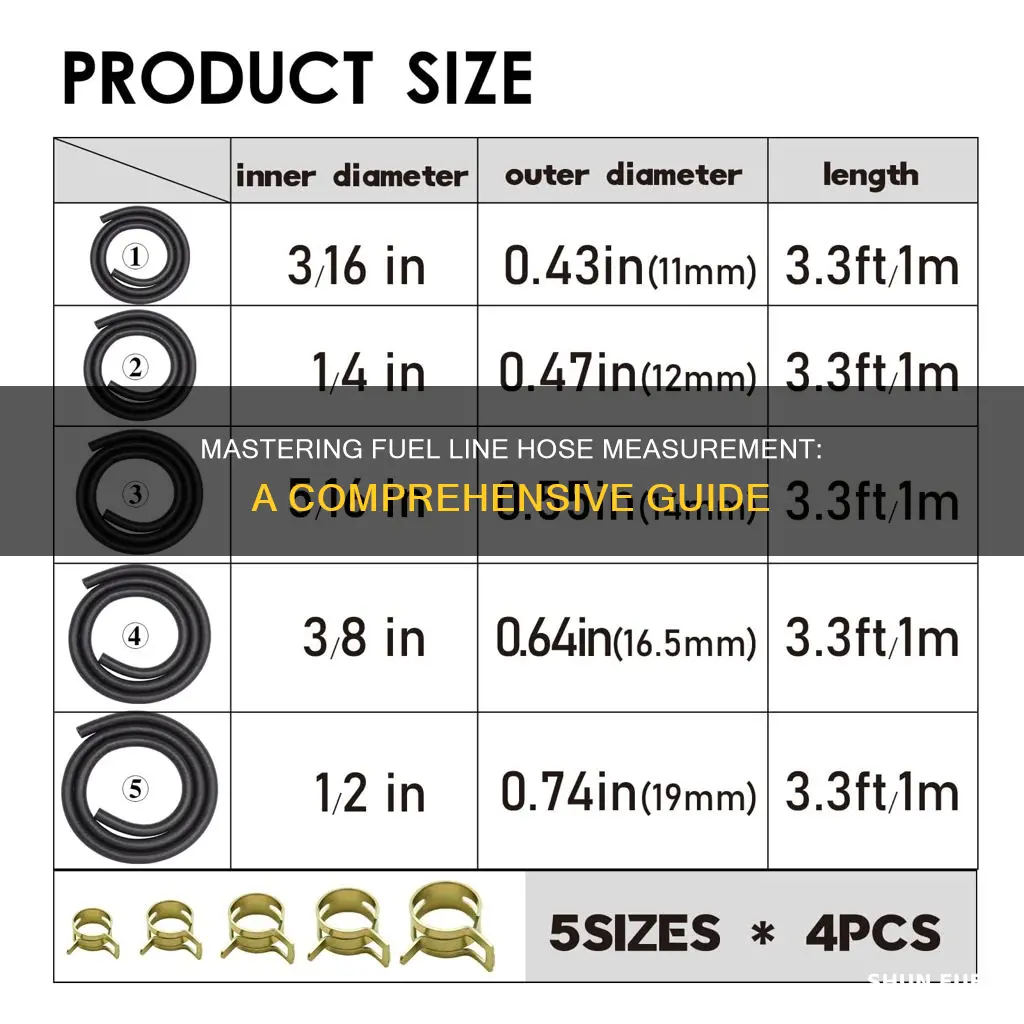

Diameter: Use a caliper to measure the inner diameter of the hose

When it comes to measuring the fuel line hose, one of the most critical aspects is determining its inner diameter. This measurement is essential to ensure compatibility with the fuel pump and other components in your vehicle's fuel system. Here's a step-by-step guide on how to measure the inner diameter of the hose using a caliper:

Step 1: Prepare the Tools

Before you begin, ensure you have a precise caliper, preferably one with a minimum resolution of 0.001 inches or 0.0254 mm. This level of accuracy is crucial for obtaining reliable measurements. Additionally, you'll need a clean, flat surface to work on and a straightedge or ruler to ensure the hose is aligned properly.

Step 2: Position the Hose

Place the hose on the flat surface so that it is straight and aligned with the caliper. Ensure that the hose is not twisted or bent, as this can affect the measurement. The goal is to measure the inner diameter, so position the hose accordingly.

Step 3: Caliper Placement

Position the caliper's anvil (the larger jaw) on one side of the hose, just above the point where you want to measure. The anvil should be firmly against the hose, but take care not to apply excessive force, as this can distort the measurement. The jaw of the caliper (the smaller jaw) should be placed on the opposite side of the hose, touching the hose's inner surface.

Step 4: Take the Measurement

With the caliper in place, gently squeeze the handles to close the jaws and measure the distance between the inner surfaces of the hose. Read the measurement on the caliper's scale. Ensure that you note the exact value, as even a small discrepancy can impact the hose's performance.

Step 5: Record and Compare

Record the measured diameter and compare it to the specifications provided by the manufacturer or your vehicle's manual. This comparison will help you determine if the hose is suitable for your fuel system or if you need to replace it. If the measurement deviates significantly from the recommended diameter, it may indicate wear and tear or damage to the hose.

By following these steps, you can accurately measure the inner diameter of a fuel line hose using a caliper. This measurement is vital for maintaining the efficiency and safety of your vehicle's fuel system.

E85 Compatibility: Running Ethanol on Stock Fuel Lines

You may want to see also

Wall Thickness: Determine the wall thickness of the hose using a micrometer

To accurately measure the wall thickness of a fuel line hose, you'll need to employ a precise tool: a micrometer. This device is specifically designed for measuring small dimensions with high accuracy. Here's a step-by-step guide on how to use it for this purpose:

Step 1: Prepare the Hose

Ensure the hose is clean and free of any debris or contaminants that might interfere with the measurement. You might want to wipe it down with a clean cloth to ensure a clear and accurate reading.

Step 2: Position the Micrometer

Place the micrometer's anvil (the flat, stationary part) against the hose, ensuring it is firmly in contact with the hose's inner wall. The anvil should be positioned at a point where you can get a clear and consistent reading.

Step 3: Take the Measurement

Rotate the thimble (the moving part of the micrometer) until the dial indicator shows zero. Then, slowly move the thimble along the hose's inner wall, taking care to maintain constant pressure. Read the value on the thimble when the dial indicator shows zero again. This reading will give you the wall thickness of the hose.

Step 4: Record the Data

Note down the measured wall thickness. It's essential to record this data accurately, as it will be crucial for comparison and analysis.

Step 5: Repeat and Compare

If you need to measure multiple points on the hose, repeat the process at different locations. This will provide a more comprehensive understanding of the hose's wall thickness. Compare the measurements to ensure consistency and identify any areas of concern.

Using a micrometer for wall thickness measurement is a precise and reliable method. It allows you to identify potential issues, such as wear and tear or manufacturing defects, in the fuel line hose. This information is vital for maintaining the performance and safety of the fuel system in vehicles or other applications.

Step-by-Step Guide: Installing Edelbrock Fuel Lines for Optimal Performance

You may want to see also

Flexibility: Test the hose's flexibility by bending it to various angles

To assess the flexibility of a fuel line hose, you can perform a simple yet effective test by bending it to various angles. This method helps identify any potential issues with the hose's pliability, which is crucial for its performance and longevity. Here's a step-by-step guide on how to conduct this test:

Start by laying the hose flat on a stable surface, ensuring it is straight and free from any obstructions. Then, begin to bend the hose at different angles, gradually increasing the curvature. For instance, you can start with a gentle curve, then progress to a more pronounced angle, mimicking the various bends and turns it might encounter in a vehicle's engine bay. The goal is to simulate the real-world conditions the hose will experience. Pay close attention to any signs of stress or strain on the hose during this process.

As you bend the hose, observe for any visible signs of damage, such as cracks, tears, or bulging. Also, listen for any unusual noises or sounds that might indicate the hose is not bending smoothly. The hose should yield to your bending actions without showing any permanent deformation or breaking. If you notice any issues, it could indicate a potential problem with the hose's flexibility, which may affect its ability to withstand the rigors of the vehicle's operation.

For a more comprehensive test, consider using a pair of hands or a tool to apply pressure and force while bending the hose. This will help you understand how the hose responds under different levels of stress. The hose should be able to absorb and distribute the force evenly without showing signs of excessive wear or damage. Remember, the primary goal is to ensure the hose can adapt to the various angles and positions it will encounter without compromising its integrity.

By systematically bending the fuel line hose and observing its behavior, you can gain valuable insights into its flexibility and overall quality. This simple test can help you identify potential issues early on, allowing for timely repairs or replacements, thus ensuring the optimal performance and safety of your vehicle's fuel system.

Dual Fuel Lines: Unraveling the Mystery Behind the Extra Line

You may want to see also

Pressure Rating: Check the hose's pressure rating to ensure it meets requirements

When it comes to measuring and ensuring the integrity of a fuel line hose, one critical aspect often overlooked is the pressure rating. This is a crucial factor that determines the hose's ability to withstand the fuel pressure it will encounter in the vehicle's system. Here's a detailed guide on how to check and verify the pressure rating of a fuel line hose:

Understanding Pressure Ratings: Before you begin, it's essential to understand what the pressure rating means. The pressure rating of a hose is the maximum pressure it can withstand without failing or leaking. Different vehicles and fuel systems operate at various pressure levels, so it's crucial to match the hose's pressure rating to the system's requirements. For instance, a high-performance engine might require a hose with a higher pressure rating to handle the increased fuel pressure.

Locate the Pressure Rating: Fuel line hoses typically have their pressure rating marked on them. This information is usually found on a label or sticker attached to the hose itself. Look for a series of numbers and/or a symbol indicating the pressure rating. For example, you might see "1000 psi" or a symbol resembling a pressure gauge. If the rating is not visible, you may need to consult the vehicle's service manual or the hose manufacturer's specifications.

Comparing with System Requirements: Once you've identified the pressure rating, compare it to the fuel system's requirements. Refer to your vehicle's manual or consult a professional mechanic to determine the recommended pressure range for your specific engine and fuel setup. Ensure that the hose's pressure rating exceeds this requirement to ensure a safe and reliable operation.

Testing and Verification: If you suspect that the hose's pressure rating might be an issue, you can perform a simple test. Use a pressure gauge to measure the actual pressure in the fuel system while it's operating. Compare this reading with the hose's pressure rating. If the measured pressure exceeds the rating, it indicates a potential issue and may require replacing the hose.

Regular Maintenance and Inspection: It's good practice to inspect the fuel line hoses regularly, especially if your vehicle is older or has been modified. Over time, hoses can degrade, and their pressure ratings may become compromised. By checking the pressure rating periodically, you can ensure that the hose is still capable of handling the fuel pressure, reducing the risk of fuel leaks or system failures.

Locate the JDX500 Fuel Line Shut-Off Valve: A Comprehensive Guide

You may want to see also

Frequently asked questions

To measure a fuel line hose, you will need a flexible measuring tape or a ruler, preferably with metric and imperial units. It's also helpful to have a helper to hold the hose steady while you measure.

For the most accurate measurements, ensure the hose is straight and not coiled or bent. If the hose is curved, measure along the longest straight section. Also, take your measurements at room temperature, as hoses can expand or contract with temperature changes.

It's common to measure fuel line hoses in inches or centimeters. Measure the length of the hose from one end to the other, and also note the diameter if required, which is usually measured in inches or millimeters.

When dealing with a curved or coiled hose, it's best to measure the straight-line distance between the two fixed points. You can also lay the hose flat and measure its length when straightened. This will give you an accurate length for your measurements.

To measure the diameter, you can use a caliper or a ruler. Place the hose on a flat surface, and then position the caliper or ruler across the center of the hose, ensuring it is perpendicular to the length. Measure the distance between the two points where the measuring tool touches the hose, and this will give you the diameter.