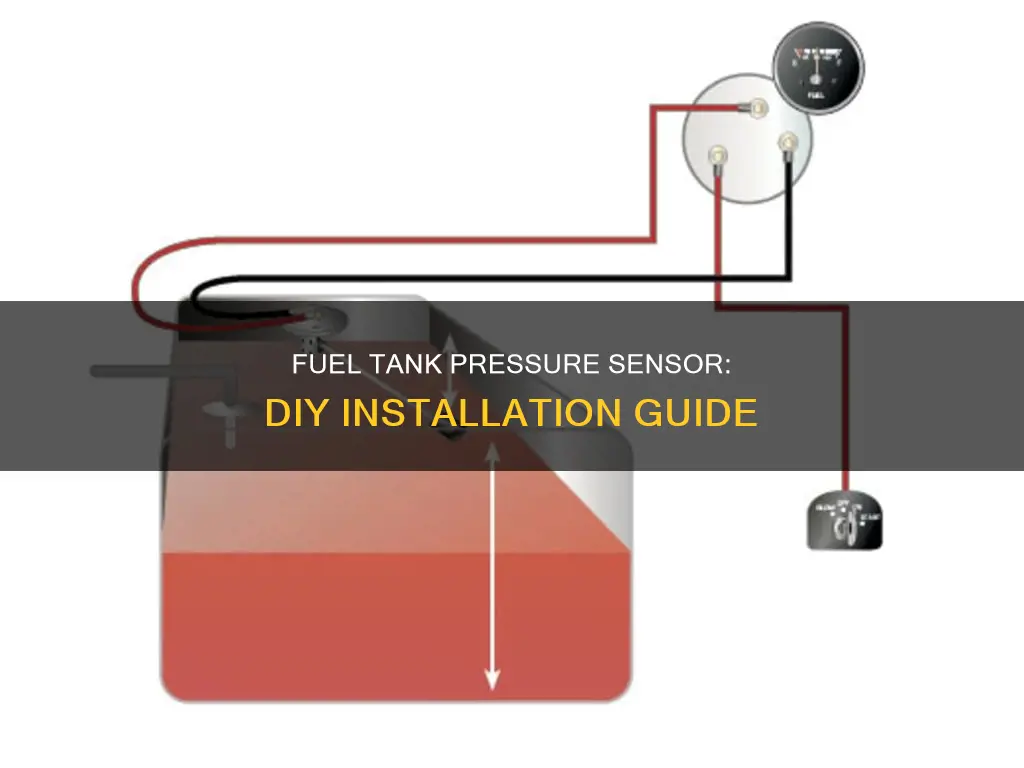

The fuel tank pressure sensor is an integral part of a car's evaporative emissions system (EVAP). It is placed atop or inside the fuel tank and monitors both positive and negative pressure to identify leaks in the fuel system, alert you to a defective gas cap, and signal the engine computer of the EVAP system's proper operation. While it is possible to replace the fuel tank pressure sensor yourself, especially if you have the tools and knowledge, it is recommended to leave it to professionals to avoid damage or malfunctions. The average cost for replacement ranges from $256 to $304, with labour fees between $139 and $176, and parts priced between $118 and $128.

| Characteristics | Values |

|---|---|

| Purpose | To identify leaks in the fuel system, alert you to a defective gas cap, signal the engine computer that the evaporative emissions system is operating properly, regulate the management of fuel consumption, and maintain compliance with state and federal emissions regulations |

| Location | On top of the fuel pump module, mounted on top or inside the fuel tank |

| Symptoms of a Faulty Sensor | Illuminated check engine light, engine stalling, loss of power, increased fuel consumption, loss of power and acceleration, black smoke coming out of the tailpipe, gasoline dripping from the tailpipe, rough engine |

| Replacement Cost | Between $256 and $304; labor costs between $139 and $176, while parts cost between $118 and $128 |

| Replacement Time | Approximately 2-3 hours |

What You'll Learn

Tools and knowledge needed

To install a fuel tank pressure sensor, you will need a good understanding of automotive repair and maintenance, as well as specific tools and safety precautions. Here is a detailed list of the tools and knowledge required:

Knowledge of Automotive Systems:

- Familiarity with the vehicle's emissions system: The fuel tank pressure sensor is an integral part of the evaporative emissions system (EVAP), which requires a certain level of knowledge for installation and maintenance.

- Understanding of pressure sensors: Knowledge about pressure sensors, their function, and their role in detecting fuel vapour leaks is essential.

- Diagnostic skills: The ability to diagnose issues with the EVAP system, such as leaks or faulty components, is crucial for effective installation and maintenance.

- Safety awareness: Working with automotive electronics and fuel systems can be dangerous. Understanding safety protocols and potential hazards is vital to ensure a safe working environment.

Tools and Equipment:

- Scan tool: A scan tool is essential for diagnosing fuel supply problems and verifying if the modules controlling the fuel pump are receiving correct data.

- Voltmeter: Used to check voltage levels and electrical supply to the sensor.

- Multimeter: A multimeter can be used to test the sensor for problems with voltage readings.

- Pressure gauge: A pressure gauge is useful for diagnosing fuel pump issues and verifying pressure levels.

- Basic hand tools: Screwdrivers, wrenches, and other basic hand tools may be needed to remove and replace components during installation.

- Safety equipment: Safety goggles, gloves, and fire prevention equipment are necessary to protect yourself from potential hazards.

Preventive Maintenance Tips:

- Fuel tank maintenance: Keeping the fuel tank at least half-full ensures proper pressure levels in the EVAP system, which is crucial for accurate sensor operation.

- Fuel cap care: Ensuring the fuel cap is tightly sealed prevents fuel vapour leaks that could affect sensor accuracy.

- High-quality fuel: Using high-quality fuel reduces the risk of contaminants that may impact the sensor's performance.

- Regular oil level checks: Monitoring engine oil levels helps prevent engine issues that could impact the fuel tank pressure sensor.

By having the necessary tools, knowledge, and maintenance tips, you can effectively install and maintain a fuel tank pressure sensor, ensuring the smooth operation of your vehicle's EVAP system.

Locating Fuel Pressure Check Points on a 2001 Tundra

You may want to see also

Disconnecting the battery

Locate the battery: The first step is to locate the battery in your vehicle. It is usually found in the engine bay, but it can also be located in the trunk or under a seat, depending on the make and model of your car. Once you have located the battery, proceed to the next step.

Gather the necessary tools: You will need a few tools to disconnect the battery safely. These include a pair of safety gloves to protect your hands from battery acid, a wrench or socket that fits the battery terminal bolts, and a non-conductive surface such as a piece of wood or rubber mat to place the disconnected battery on.

Loosen the negative terminal first: Before you begin, make sure that the engine is off and that you are wearing the necessary safety gear, including gloves and eye protection. Start by identifying the negative terminal of the battery, which should be marked with a "-" symbol or a black cover. Use the wrench or socket to loosen the nut that secures the negative battery cable. Do not allow the wrench to touch any other metal parts of the car, as this could cause a short circuit.

Disconnect the negative cable: Once the nut is loose, carefully remove the cable from the battery terminal. You may need to wiggle it gently to detach it completely. Place the cable to the side, ensuring it does not touch any metal surfaces.

Secure the battery: Place the disconnected battery on the non-conductive surface to prevent accidental contact with metal parts.

Repeat for the positive terminal: Following similar steps, loosen the nut on the positive terminal (marked with a "+" symbol or a red cover) and carefully remove the cable. Ensure that the positive cable does not touch any metal surfaces during this process.

Installation process: At this point, you can proceed with the installation of the fuel tank pressure sensor. Remember to follow the manufacturer's instructions and safety guidelines for the sensor installation.

Reconnecting the battery: After you have successfully installed the fuel tank pressure sensor, it is time to reconnect the battery. Start by reconnecting the positive cable first, tightening the nut securely. Then, reconnect the negative cable and ensure both connections are secure.

Dispose of the old sensor and battery materials properly: If you are replacing an old fuel tank pressure sensor, dispose of it properly according to your local regulations for electronic waste. Additionally, if your car battery is old or damaged, consider replacing it and disposing of the old one at a designated battery recycling center.

By following these steps for disconnecting and reconnecting the battery, you can ensure a safer and more efficient installation process for your fuel tank pressure sensor.

Fuel Pressure Maintenance for 2003 Mustang GTs

You may want to see also

Removing connectors

Locate the Sensor: Begin by identifying the location of the fuel tank pressure sensor. It is typically placed atop or inside the fuel tank, often on top of the fuel pump module. This understanding of its placement is essential for accessing the sensor and its connectors.

Access the Sensor: Before removing the connectors, you need to gain access to the fuel tank pressure sensor. This step may involve lowering the fuel tank or removing any obstructions that block your path to the sensor. Ensure you follow safety protocols and take the necessary precautions when working around automotive electronics and fuel systems.

Disconnect the Connectors: Once you have clear access to the fuel tank pressure sensor, it's time to disconnect the connectors. These connectors facilitate the sensor's communication with other vehicle systems. Gently pull or detach the connectors from the sensor, being mindful not to damage any surrounding components or wiring.

Clean the Surface: After removing the connectors, it is good practice to clean the surface around the faulty sensor. Use appropriate cleaning solutions or solvents to remove any dirt, grease, or debris that has accumulated over time. This step ensures that the area is prepared for the installation of the new sensor.

Inspect the Connectors: Before proceeding, take a moment to inspect the connectors for any signs of damage or corrosion. Ensure that the connectors are in good condition and properly seated within their housing. If any issues are identified, consider replacing the connectors or consulting a professional technician for advice.

Store the Connectors Safely: As you work, keep the removed connectors organized and stored safely. Place them in a secure location where they won't be misplaced or damaged. This ensures that you can easily access them when it's time to install the new fuel tank pressure sensor.

By following these steps, you can effectively remove the connectors associated with the fuel tank pressure sensor. Remember to work methodically and refer to vehicle-specific instructions or manuals for a more tailored guide. Always prioritize safety and, if in doubt, consult a qualified automotive technician.

Ford Fuel Pressure Regulator: Location and Maintenance Guide

You may want to see also

Cleaning the surface

When installing a fuel tank pressure sensor, cleaning the surface is an important step to ensure a proper installation and the optimal functioning of the sensor. Here is a detailed guide on how to effectively clean the surface before installing a fuel tank pressure sensor:

Locate the Sensor: The first step is to identify the location of the fuel tank pressure sensor. Refer to your vehicle's manual to determine whether it is situated on top of the fuel tank or along the EVAP line. This knowledge will help you access the sensor and its surrounding area for cleaning.

Prepare the Work Area: Before beginning any cleaning or installation work, ensure the engine is cool and the vehicle is in a safe working environment. This step is crucial for your safety and the protection of the vehicle's components. Disconnect the battery to prevent electrical issues or accidents during the cleaning and installation process.

Clean the Surface: Once you have located the sensor and ensured a safe working environment, it's time to clean the surface. Use a suitable cleaning agent or solvent that is compatible with automotive surfaces and will effectively remove any dirt, grease, or residue from the area. Carefully apply the cleaning agent and use a clean cloth or brush to wipe down the surface. Pay close attention to the area around the faulty part, as this is where the new sensor will be installed. Make sure the surface is completely free of any contaminants that could interfere with the installation or the sensor's performance.

Inspect the Surface: After cleaning, inspect the surface closely to ensure that it is thoroughly cleaned and free of any debris or residue. Use a bright light to check for any remaining dirt or grease in tight spaces or crevices. If necessary, repeat the cleaning process until you are satisfied that the surface is completely clean and prepared for the new sensor installation.

Prepare for Installation: Once the surface is clean and dry, you can prepare for the installation of the new fuel tank pressure sensor. Gather the necessary tools and the new sensor, ensuring it is the correct type and size for your vehicle. Refer to the vehicle's manual or seek guidance from a professional technician if you are unsure about the specific requirements for your car.

By following these steps, you can effectively clean the surface before installing a fuel tank pressure sensor, contributing to a successful installation and ensuring the optimal performance of this essential component in your vehicle's emissions system.

Fuel Line Pressure Optimization for Dodge 3500 Performance

You may want to see also

Running self-diagnostics

Understanding the Fuel Tank Pressure Sensor

The fuel tank pressure sensor is a component placed atop or inside your fuel tank, responsible for monitoring both positive and negative pressure within the tank. It is an integral part of your car's evaporative emissions system (EVAP), designed to contain all gasoline vapors within the fuel system after fuelling up. By detecting pressure changes, the sensor helps identify leaks in the fuel system, defective gas caps, and ensures the EVAP system operates properly.

Signs of a Faulty Fuel Tank Pressure Sensor

The primary indication of a faulty fuel tank pressure sensor is the illumination of the "Check Engine" light on your dashboard. While this light can signify various issues, a faulty sensor is one potential cause. Other symptoms of a faulty sensor may include increased fuel consumption, loss of power and acceleration, black smoke from the tailpipe, gasoline dripping from the tailpipe, and a rough-running engine.

To run self-diagnostics on the fuel tank pressure sensor, you can follow these steps:

- Purchase an OBD2 scanner: You can buy an OBD2 scanner from online sites like Amazon.com for around $30 to $40. This tool will help you read error codes and diagnose issues with the fuel tank pressure sensor.

- Connect the OBD2 scanner: Once you have the scanner, connect it to the OBD2 port in your vehicle. The port is usually located under the dashboard on the driver's side.

- Read the error codes: With the scanner connected, it will communicate with your vehicle's computer and display any error codes related to the fuel tank pressure sensor. Common error codes related to the sensor include P0440, P0441, and P0442.

- Interpret the error codes: Each error code will provide specific information about the issue. For example, the code P0442 indicates a small leak detected in the evaporative emission system.

- Refer to a mechanic: If you are unsure about interpreting the error codes or performing repairs, it is best to consult a professional mechanic. They will have the expertise and equipment to accurately diagnose and resolve the issue.

Preventative Measures

To help prevent issues with the fuel tank pressure sensor and the EVAP system, it is recommended to avoid overfilling or topping off the fuel tank. Additionally, always take proper precautions and disconnect the battery when working with fuel to mitigate fire hazards.

Finding Fuel Pressure Fitting in 2007 Chevy Trailblazer

You may want to see also

Frequently asked questions

The fuel tank pressure sensor is often located on top of, or inside, the fuel tank. It is usually placed on top of the fuel pump module.

The fuel tank pressure sensor is part of the evaporative emissions or EVAP system. It monitors pressure to detect evaporative leaks and loose or faulty gas caps that may be preventing fuel vapors from being contained in the EVAP system.

The common symptoms associated with a faulty FTP sensor include an illuminated check engine light, engine stalling, and loss of power.

While it is possible to replace the FTP sensor yourself, especially if you have the tools and knowledge, it is advised to leave it to professionals to lessen the chances of damage or malfunctions.