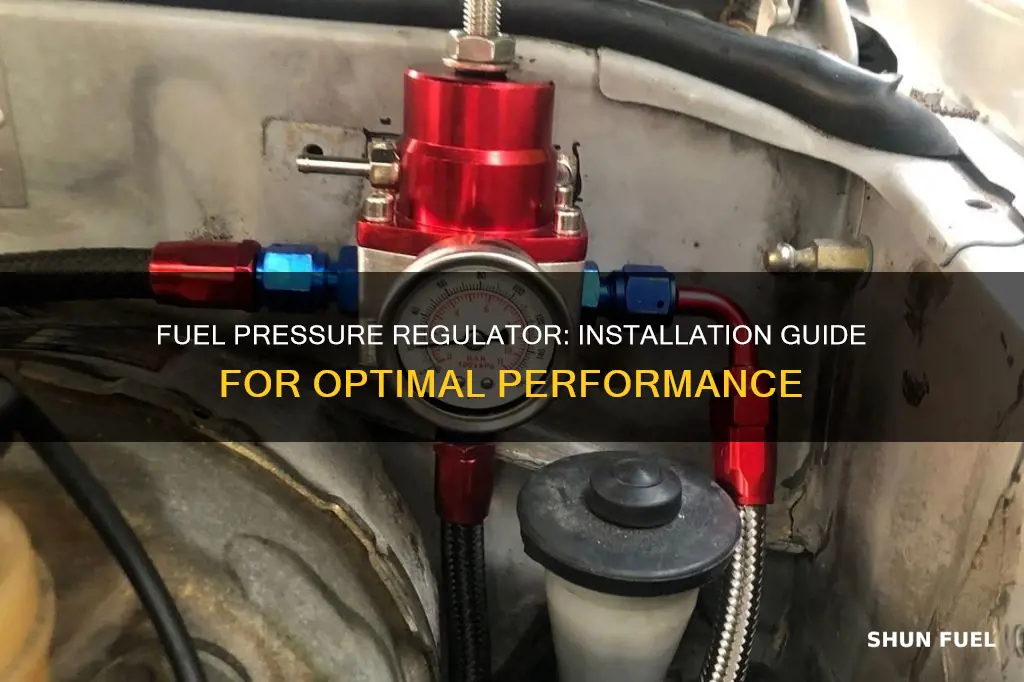

Installing a fuel pressure regulator (FPR) is a simple process that can be done at home. The FPR is a critical component of a vehicle's fuel delivery system, working alongside the fuel pump to maintain steady pressure. When choosing an FPR, it's important to match it to your fuel delivery system and pump. This ensures a safe and reliable fuel system performance for your engine. The process of installation involves removing the old FPR, test-fitting the new one, and finalizing the fuel lines. It's important to refer to the FPR manual to identify the fuel in/out ports and take safety precautions when working with fuel.

What You'll Learn

Choosing the correct fuel pressure regulator

Understand Your Fuel System

Firstly, you need to determine what type of fuel system your vehicle has. It will either have a carburetor or an Electronic Fuel Injection (EFI) system. Carburetors are typically found in older vehicles and operate at lower fuel pressures, around 4 to 7 psi. EFI systems, on the other hand, deliver fuel more accurately and run at higher pressures, usually between 30 and 60 psi.

Know the Different Types of Regulators

There are two main types of fuel pressure regulators: return-style (or bypass) and deadhead (or blocking) regulators. Return-style regulators stabilize fuel pressure by directing excess fuel back to the tank, ensuring a consistent fuel supply. These regulators are adjustable and are commonly used in EFI systems and carburetor setups with high-pressure fuel pumps. Deadhead regulators, on the other hand, do not have a return line. They regulate fuel pressure by restricting fuel flow once it reaches a predetermined level, which can lead to an increase in fuel temperature. Deadhead regulators are simpler in design and are often used in less demanding applications, such as classic cars with carbureted engines.

Consider Your Vehicle's Performance

If you have a high-performance engine, you will need a fuel pressure regulator that can manage the increased fuel volume and pressure. Return-style regulators are ideal in this case, as they ensure a consistent fuel pressure, optimizing engine performance. Deadhead regulators, due to their design, can place additional load on the fuel pump and may not be suitable for high-performance applications.

Match the Regulator to Your Fuel System

When choosing a fuel pressure regulator, make sure it is compatible with your fuel system. Return-style regulators are typically recommended for EFI installations and carburetor installations with high-pressure pumps. Deadhead regulators, on the other hand, are usually suitable for carburetor systems with single pumps but multiple regulators.

Weigh the Advantages and Disadvantages

Both return-style and deadhead regulators have their advantages and disadvantages. Return-style regulators keep fuel temperature stable and allow high-pressure pumps to operate efficiently. However, they increase system complexity due to the requirement of a return line. Deadhead regulators offer simple, one-line installation and can be used in systems with multiple regulators. However, they may lead to increased fuel temperature and are not suitable for most EFI systems.

Consult Manufacturer Recommendations

When in doubt, always refer to the manufacturer's recommendations for choosing the right fuel pressure regulator. They will provide specific guidance on the type of regulator, its installation, and any other considerations for your particular vehicle and fuel system.

Removing Fuel Pressure Sensor: A Step-by-Step Guide

You may want to see also

Removing the old regulator

Next, locate the old regulator. In most cases, it will be located near the fuel rail. Once you've found it, carefully remove the screws holding it in place. Be very careful not to strip the screws, as this can cause damage and make the process more difficult.

After removing the screws, loosen the fuel hose clamps. You may need to completely remove the hose, depending on your vehicle. Pull out the old regulator, being mindful of any fuel that may spill. Once the regulator is out, you will notice a rubber O-ring. Normally, this should be replaced when installing a new regulator to ensure a proper seal and prevent leakage.

Finally, you will need to remove the regulator from the fuel return line. This step can be a little messy, as some fuel may spill out. Simply remove the hose, and the old regulator will be completely detached from the system.

Renting Fuel Pressure Testers: How Much Does It Cost?

You may want to see also

Installing the new regulator

Firstly, ensure you have chosen the correct fuel pressure regulator for your vehicle. The regulator should match your fuel delivery system and fuel pump. You will also need to decide whether you require an adjustable FPR. If you are unsure, it is best to consult a mechanic or a forum for car modifications.

Once you have the correct regulator, you will need to remove the old one. This process will vary depending on your vehicle, so it is important to consult your repair manual or seek advice from a mechanic. In general, you will need to remove the fuel pressure from your fuel lines, then remove the old FPR, being careful not to strip any screws. You will also need to remove the fuel hose and loosen the clamps.

Now you are ready to install the new FPR. Again, the exact process will depend on your vehicle, but you will typically need to test fit the new regulator to ensure it sits correctly and that the bonnet can close properly. You may need to make adjustments or create a bracket to hold the FPR in place. Once you are happy with the fit, you can secure the FPR in place using the appropriate fittings and seals. Be sure to refer to your FPR manual to identify the fuel IN/OUT ports and ensure they are correctly connected.

Finally, you will need to reconnect the vacuum hose from the manifold to the FPR. Start the car and check for any leaks. If there are no leaks, you can then adjust the fuel pressure to the desired level.

Fuel Pump: Understanding Pressure-Induced Auto-Shutoff

You may want to see also

Finalising fuel lines plumbing

Finalising the fuel lines plumbing is a crucial step in installing a fuel pressure regulator. Here is a detailed guide to help you through the process:

Firstly, it is important to determine the type of fitting required for your fuel system. Most production cars use push-on hoses, with 8mm bore being the most common size. However, older cars with smaller engines may have 6mm hoses, while larger engines can use 10mm hoses. You should also consider the type of hose you will be using. Push-on hoses are cost-effective and easy to install, but they may not be suitable for use inside the car as they allow fumes to escape. Reusable or cutter hoses, on the other hand, offer a more secure connection and can be used with low or high-pressure systems.

When finalising the fuel lines, it is important to ensure that all connections are secure and that the hoses are properly clamped to prevent leaks. You should also consider the routing of the hoses to avoid any sharp bends or kinks that could restrict fuel flow. Use hose clips or, in some cases, factory swaging to secure the hoses in place. Additionally, consider using a threaded bulkhead fitting to pass through a bulkhead, as this will provide a more secure connection than a grommet.

Another important consideration is the location of the fuel pressure regulator. Some people prefer to mount the regulator before the engine or even at the rear of the car to avoid heating the fuel. Others argue that mounting the regulator after the fuel rails provides more consistent fuel pressure to each injector. If you decide to mount the regulator near the engine, consider adding a cooler to the return line to help manage the temperature of the fuel.

Finally, don't forget to include any necessary adapters or fittings to connect the fuel lines to the regulator and other components, such as the fuel rail and the fuel pump. Ensure that all connections are tight and secure before starting the engine.

By following these steps and paying attention to the specific requirements of your vehicle, you can successfully finalise the fuel lines plumbing when installing a fuel pressure regulator.

Finding the Fuel Pressure Regulator in a 1998 Chevy Silverado

You may want to see also

Testing for leaks

Before starting, ensure you have depressurized the fuel lines and removed the old FPR, following the necessary safety precautions when working with fuel. Refer to your car's repair manual for specific instructions on depressurizing the fuel lines.

Testing the New Fuel Pressure Regulator:

- Visual Inspection: Before installing the new FPR, carefully inspect it for any defects or damage. Look for any signs of deformation or cracks on the regulator body and the vacuum port.

- O-Ring Check: The O-ring seal plays a vital role in preventing leaks. Ensure that the O-ring is in good condition, properly seated, and creates a tight seal between the FPR and the fuel rail. Replace the O-ring if necessary.

- Dry Fit: Perform a dry fit of the new FPR without tightening any screws or connections. Ensure that it fits securely and aligns properly with the fuel rail and vacuum hose connections.

- Vacuum Hose Inspection: Inspect the vacuum hose for any cracks, perforations, or signs of deterioration. If the hose is damaged, replace it with a new one of the same specifications.

- Thread Sealant: If your FPR requires thread sealant, apply a high-quality sealant to the fittings. Follow the sealant manufacturer's instructions for curing time, typically overnight for liquid sealants.

- Initial Start-Up: After installing the new FPR, start the car and let it idle. Check for any unusual noises, such as popping sounds, which could indicate a problem with the FPR or the fuel system.

- Fuel Pressure Check: Using a fuel pressure gauge, monitor the fuel pressure at the fuel rail. With the vacuum hose disconnected, the base fuel pressure should be at the specified level (e.g., 43 psi for a Nissan RB25). If the pressure is low or non-existent, it could indicate a leaking or stuck-open FPR.

- Vacuum Port Leak Test: One common area for leaks is the vacuum port of the FPR. To test for leaks in this area:

- Replace the vacuum line going into the FPR with a length of clear tubing of the same diameter. Standard small-diameter airline tubing from an aquarium supply store can be used.

- With the clear tubing in place, have an assistant rev the engine up and down repeatedly.

- If fuel is visible in the clear tubing, it indicates a leak at the vacuum port. The regulator will need to be replaced.

Fuel Return Line Test: If you suspect the FPR is not allowing sufficient pressure to build in the system, perform the following test:

- Close or pinch-block the fuel return line.

- Cycle the key a few times.

- Observe the maximum pump pressure on your fuel pressure gauge. If the pressure does not increase, it suggests a faulty FPR.

Engine Performance: Pay attention to how your engine performs after installing the new FPR. Black smoke coming from the engine could indicate that the engine is running rich due to a leaking diaphragm inside the FPR. Additionally, issues such as hard starting, spark plug fouling, or engine misfiring may also be signs of a faulty FPR.

Remember to consult a qualified mechanic if you are unsure about any aspects of the installation or testing process. Safety should always be the top priority when working with fuel systems.

Fuel Pressure Check: 1998 Oldsmobile Bravada Guide

You may want to see also

Frequently asked questions

A fuel pressure regulator works with the fuel pump to maintain a steady pressure relationship between the fuel line side of the injectors and the intake manifold. It is necessary to regulate and flow increased volumes of fuel pumped by high-flow aftermarket fuel pumps.

The regulator should be matched to the type of fuel delivery system and the fuel pump you are using. Some fuel pumps have a regulator built into them, so check before purchasing an external unit.

A deadhead-style regulator is one of the simplest regulator setups and is placed between the fuel pump and the carburetor. It uses a restriction to lower the fuel pressure by decreasing the fuel flow.

A bypass-style regulator helps to alleviate issues with over-working a dead-head regulator by bleeding off excess fuel pressure and returning it to the fuel tank. This helps to eliminate pressure creep, lower fuel temperatures, and provide a more stable pressure curve.

You will be working with fuel, so make sure to take the necessary precautions. Refer to your car's manual to identify the location of your FPR and which ports are fuel in/fuel out.