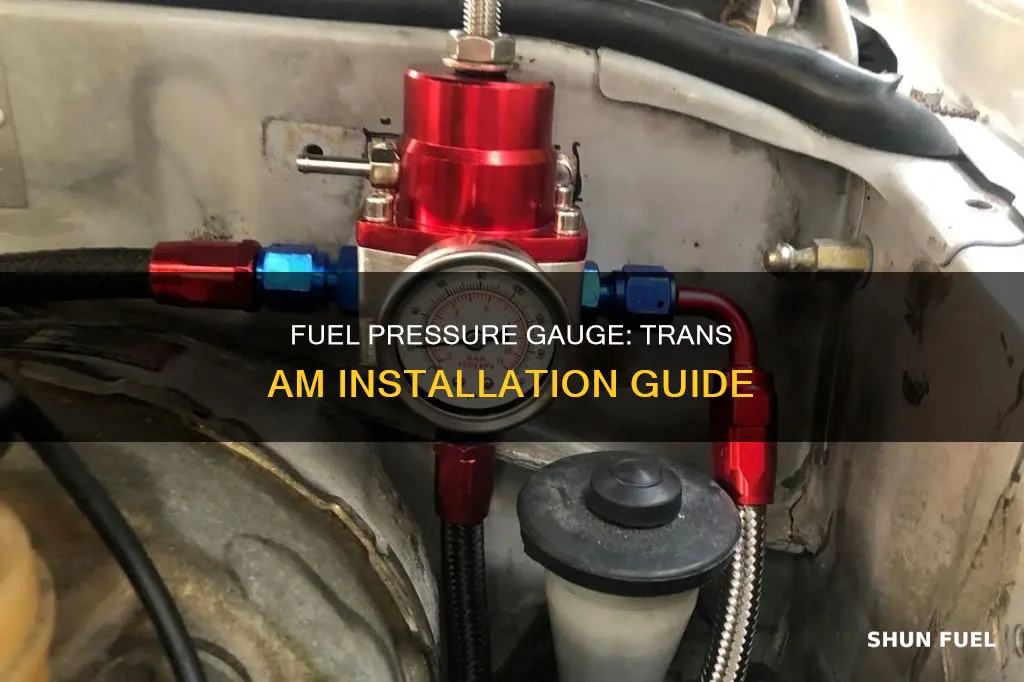

Hooking up a fuel pressure gauge to a Trans Am can be done in several ways. One method is to tap into the fuel system by drilling out the end of a banjo bolt and tapping it for a fitting to attach the gauge. Another way is to cut the fuel line and insert a T-fitting that provides a port for the gauge, but this may restrict the fuel line. A more complex method involves making a new stainless steel braided Teflon line with compression fittings to attach to the stock hard lines. Additionally, some vehicles may have a Schrader valve on the fuel rail, which can be used to connect the gauge. It is important to ensure that the gauge is mounted securely and that all fuel lines are properly clamped to prevent leaks.

What You'll Learn

Finding the right fuel line

To find the right fuel line, you must first identify the fuel line size. This can be done by measuring the outer diameter of the tube, as fuel lines are typically sized based on this dimension. One way to do this is by using an open-end wrench; simply slide the open end of the wrench over the tube, and whichever wrench fits snugly over the tube corresponds to the size of the fuel line. For example, if a 5/16" wrench fits, then your fuel line is 5/16".

It is important to note that fuel lines are typically sized based on their outer diameter, while pipes are sized based on their inner diameter. Therefore, when measuring fuel lines, you should always measure the outer diameter.

Another way to identify the fuel line size is by visually inspecting the fuel line and comparing it to known sizes. This method may be more challenging, especially for those unfamiliar with fuel lines, as the differences between sizes can be subtle. However, with a keen eye and a good sense of measurement, it is possible to estimate the fuel line size this way.

Once you have identified the size of your fuel line, you can proceed with the next steps in hooking up your fuel pressure gauge. It is important to ensure that you are using the correct fuel line to avoid any potential issues or complications.

In some cases, you may need to tap into the fuel system to install a sending unit for your fuel pressure gauge. This can be done by drilling out a banjo bolt and tapping it for a fitting, or by cutting the fuel line and inserting a T-fitting. Alternatively, you can create a new stainless steel braided Teflon line with compression fittings, as mentioned by a user on the "Toyota Tundra Forums".

Additionally, some vehicles may have a Schrader valve or a test port plug on the fuel filter housing, which can be used to connect your fuel pressure gauge. This is a convenient option if your vehicle has this feature.

By following these steps and identifying the correct fuel line, you can ensure a proper connection for your fuel pressure gauge installation.

Fuel Pressure Requirements for a 5-3 Engine

You may want to see also

Using a pressure gauge on the fuel drain tube

To hook up a fuel pressure gauge to your Trans Am, you can add a pressure gauge to the end of the fuel drain tube. This is where you would usually attach a hose when draining the fuel bowl.

To do this, you will need a hose that is long enough to reach from the drain tube to the driver's side mirror support, so you can see the pressure at WOT. Attach the pressure gauge to the hose and then attach the other end of the hose to the drain tube. Make sure you put hose clamps on both ends of the hose to prevent any leaks.

Once you have attached the hose and gauge, start the car and open the drain valve to check for leaks before taking it for a test drive.

This method is quick and temporary, but it is a useful way to check the fuel pressure in your Trans Am.

Understanding Fuel Pressure in the 1992 Ducati 907 IE

You may want to see also

Using a test port plug

To hook up a fuel pressure gauge using a test port plug, you will need a 3/16" Allen wrench to remove the test port plug. This is located on the back of the filter housing. You can then attach a fuel pressure gauge to this test port.

You can make up a test gauge and keep it in your toolbox. The fitting that plugs into the filter housing is the hardest part to find. You can find test port fittings on the Guzzle's website.

You can leave the fuel pressure gauge in the test port all the time, but the gauge and hoses will need to withstand the heat. You don't want to keep a fluid-type gauge inside the cab, as the smell of diesel will be hard to get out if it leaks.

You can also mount the gauge on the passenger wheel well, by the vacuum pump, or in the plastic filter cover.

Fuel Pump Pressure: 340lph Pumps and Performance

You may want to see also

Running a fuel line to the gauge

To run a fuel line to the gauge, you will need to tap into the fuel system. There are a few different ways to do this. One method is to drill out the end of a banjo bolt, tapping it for a fitting that can be attached to the gauge. Another option is to cut the fuel line and insert a T-fitting, providing a port for the gauge, but this will induce a restriction in the fuel line. A more involved method is to create a new stainless steel braided Teflon line with compression fittings that attach to the stock hard lines. This can be done by following online guides or resources.

When running the fuel line, it is important to use a diesel-rated fuel line and ensure that all connections are secure to prevent leaks. The gauge should be mounted securely, and the hoses should be able to withstand the heat and pressure of the fuel system. It is also crucial to consider the location of the gauge and ensure that it is easily accessible and visible.

In some cases, you may need to use a special kit to tie into the fuel system, especially if there is no Schrader valve present. This kit will allow you to unhook the fuel pressure line from the rail and use a special T-fitting to tie in and read the pressure. It is important to follow the vehicle-specific instructions and take the necessary precautions when working with the fuel system.

Additionally, when choosing the location to tap into the fuel system, it is important to ensure that you are tapping into the feed side and not the return line. This will ensure that you are getting an accurate reading of the fuel pressure that the fuel injectors are receiving.

Finding the Right Spot for Vacuum Line Fuel Regulation

You may want to see also

Tapping into the fuel system

Step 1: Determine the Location

Before you begin, you need to decide where you want to mount the fuel pressure gauge. This will determine where you will tap into the fuel system. Common locations include the fuel rail, the fuel drain tube, or the fuel filter housing.

Step 2: Gather the Necessary Tools and Materials

You will need a fuel pressure gauge kit, which typically includes a gauge, fittings, hoses, and clamps. Make sure the kit you choose is compatible with your vehicle's fuel system. You will also need basic tools like wrenches and clamps.

Step 3: Access the Fuel System

Turn off the engine and ensure it is cool before beginning any work. Refer to your vehicle's manual to locate the specific components of the fuel system, such as the fuel rail, fuel lines, and fuel pressure regulator.

Step 4: Tap into the Fuel System

There are several methods to tap into the fuel system:

- Drill and Tap Method: This method involves drilling and tapping into an existing banjo bolt on the fuel rail. First, remove the banjo bolt and drill out the centre to accommodate a fitting for your gauge. This method requires careful drilling to avoid damaging the thread.

- Fuel Line Cut and Insertion: In this method, you cut the fuel line and insert a T-fitting. This provides a port for the gauge but may induce a restriction in the fuel line. Ensure you clamp the fittings securely to prevent leaks.

- New Braided Teflon Line: Instead of cutting the existing fuel line, you can create a new stainless steel braided Teflon line with compression fittings that attach to the stock hard lines. This method avoids restrictions in the fuel line.

- Fuel Rail Schrader Valve: Some fuel rails have a Schrader valve, which can be used to connect the fuel pressure gauge. You may need an adapter to ensure a secure connection.

Step 5: Mount the Gauge

Run the fuel line to the desired location of the gauge, ensuring it is securely clamped and routed away from any moving or high-temperature components. Mount the gauge in a location that is easily visible and accessible.

Step 6: Test for Leaks

Before starting the engine, turn the key to the "on" position to pressurize the fuel system. Check all connections and fittings for any signs of leaks. If leaks are detected, tighten the clamps and fittings, and re-test until no leaks are present.

Step 7: Start the Engine and Test

Start the engine and observe the fuel pressure gauge. You may need to adjust the gauge or the fuel pressure regulator to ensure accurate readings. Refer to your vehicle's manual or a mechanic for specific fuel pressure values.

Remember to always exercise caution when working with fuel systems, as they are under high pressure and involve flammable liquids. If you are unsure about any steps, consult a professional mechanic.

Resealing Fuel Pressure Regulators: DIY Guide for Car Owners

You may want to see also

Frequently asked questions

The best place to hook up a fuel pressure gauge is somewhere along the fuel rail. The gauge can be installed before or after the FPR, as long as it is on the feed side and not the return line.

You will need a fitting that matches the thread size of the banjo bolts on your fuel rail. For example, M12 x 1.5 or M12 x 1.25. You may also need an adapter to connect the fitting to the gauge.

Yes, but make sure that the gauge and hoses can withstand the heat and that there are no leaks. It is also recommended to keep the gauge outside of the cabin to avoid the smell of diesel in case of a leak.

You will likely need a 3/16" Allen wrench to remove the test port plug and a drill to drill out the end of a banjo bolt if you need to tap into the fuel system.