Hooking up an electric fuel pressure gauge is a straightforward process, but it's important to take the necessary precautions to ensure safety and accuracy. The first step is to identify the fuel line where you'll be installing the gauge. This can be done by locating the fuel rail or the fuel drain tube. You'll need to cut the fuel line and insert a T-fitting or use a banjo bolt to create a port for the gauge. Ensure you have the necessary fittings, hoses, clamps, and tools for a secure connection. It's crucial to release the fuel pressure before cutting the line and to plug the hoses to prevent fuel leakage. Once the gauge is installed, you'll need to prime the fuel system and check for any fuel leaks before starting the engine. The electric pressure gauge can be mounted remotely, and the output wire can be routed through the firewall to the gauge.

What You'll Learn

Where to place the gauge

When placing the gauge, it's important to remember that you should never place a fuel line inside the cockpit of your vehicle. Instead, you should use an isolator or an electrical gauge with a separate pressure sender.

For a mechanical fuel pressure gauge, you can install it on the fuel line. The source for your readings can be tapped at any point along the fuel rail, as long as it is on the feed side and not the return line. This will ensure that you get an accurate reading. You can also connect the gauge in-line on the upper rubber fuel hose.

If you are installing an electric pressure gauge, you can install the pressure sender in the same place as you would for a mechanical gauge and then route the output wire through the firewall to the gauge.

Another option for a temporary setup is to add a pressure gauge to the end of the fuel drain tube. Use a hose long enough that you can attach the gauge to the driver's side tow mirror support so you can see the pressure at wide-open throttle. Make sure to use hose clamps on either end of the hose to prevent leaks.

Adjustable Fuel Pressure Regulator: Installation Guide for Beginners

You may want to see also

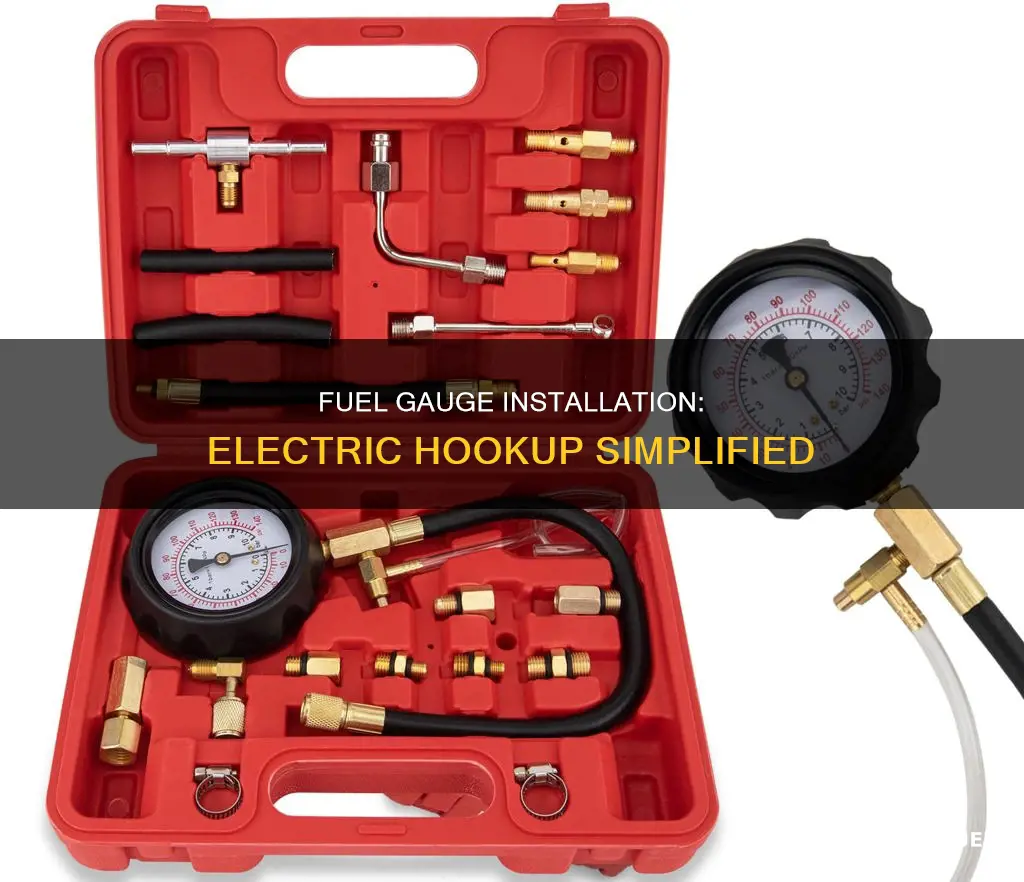

Choosing the right equipment

Fuel Pressure Gauge:

Select a suitable electric fuel pressure gauge that matches your vehicle's specifications. Ensure it has the correct pressure range and is designed for automotive use. The gauge should be easy to read and have clear markings.

Sending Unit:

The sending unit is a critical component that attaches to the fuel line. It collects data about the fuel pressure and transmits it to the pressure unit. Ensure you get a sending unit that is compatible with your fuel line and follow the manufacturer's instructions for proper installation.

Pressure Unit:

The pressure unit serves as the "brain" of the system. It receives information from the sending unit and processes it to provide meaningful data to the gauge. The pressure unit can be mounted in the passenger area of the car using screws or double-sided tape. Ensure it is securely attached and easily accessible.

Hoses and Clamps:

You will need appropriate hoses and clamps to connect the fuel pressure gauge to the fuel line. Select hoses that are compatible with your vehicle's fuel system and can withstand the pressure and temperature of the fuel. Ensure the clamps are of the correct size and made from durable materials.

Wiring and Connectors:

Electric fuel pressure gauges require proper wiring to function. You will need wires of different colours (black, white, red, green, and brown) and adequate length to reach between the sending unit, pressure unit, and gauge. Ensure you have the correct connectors and terminals to attach the wires securely.

Tools:

Assemble a set of tools required for the installation process. This may include wrenches, screwdrivers, wire strippers, and any other specialised tools mentioned in the manufacturer's instructions.

Compatibility and Safety:

Always refer to your vehicle's manual or seek advice from a qualified mechanic to ensure the equipment you choose is compatible with your specific vehicle model. Prioritise safety by selecting equipment that meets industry standards and is designed to handle flammable fuels.

By choosing high-quality, compatible equipment and carefully following installation instructions, you can ensure a successful hook-up of your electric fuel pressure gauge.

Malibu Maintenance: Locating Fuel Pressure Sensors

You may want to see also

Running the fuel line

Before you begin, ensure you have the necessary parts, including a suitable electric fuel pressure gauge kit, a fuel hose with the correct inside diameter, hose clamps, Teflon tape, and any other fittings or adapters required for your specific vehicle. It is also important to work with a near-empty fuel tank to minimize the risk of fuel spills.

Start by disconnecting the negative battery terminal for safety. Next, release the fuel pressure and vent the fuel system. Cut the fuel line at the desired point, making sure to catch any dribbling fuel with a rag. You may need to remove any insulation tubing from the fuel line to properly install the clamps.

Now, take the sending unit, which is part of the electric fuel pressure gauge kit, and fit it onto the fuel line. This will involve cutting the line and connecting the sending unit according to the manufacturer's instructions. The sending unit is responsible for sending information about the fuel pressure to the pressure unit.

At this stage, you can also install the gauge in your preferred location on the dashboard. It is common to place it on top of the dash for easy visibility. The gauge should have a white and a black wire. Connect the black wire to a good ground, and wire the white wire to the dash lighting to illuminate the gauge at night.

Finally, feed the wires from the sending unit through the engine compartment and into the passenger area of the car, where the pressure unit will be located. Strip the sheathing and wire tips as needed, and connect the wires to the corresponding terminals on the pressure unit, following the specific instructions provided with your kit.

Remember, always refer to your vehicle's manual or seek advice from a qualified mechanic if you are unsure about any steps or procedures.

Relieving Fuel Pressure in Your 2006 VW Passat

You may want to see also

Attaching the gauge

The electric fuel pressure gauge can be placed almost anywhere on the dashboard, but it is important to ensure that it is easily visible to the driver. Two wires, one white and one black, will be attached to the gauge. The black wire must be connected to a good ground, while the white wire should be wired to the dash lighting, allowing the gauge to be illuminated at night.

The pressure unit, which is the "brain" of the kit, should be located in the passenger area of the car, either screwed into place or attached with double-sided tape. If using tape, ensure the surface is thoroughly cleaned first.

The next step is to wire the sending unit. There will be four wires coming out of the sending unit, which need to be fed around the engine compartment and through a hole in the firewall to reach the pressure unit. Strip the sheathing and the wire tips, then attach the wires to the correct terminals on the pressure unit. The red wire goes to terminal 8, the black (or ground) wire to terminal 11, the white signal wire to terminal 12, and the remaining wire to terminal 9, which is the wire shield.

Finally, wire the gauge itself. Use a black wire from terminal 1 of the pressure unit to connect to a chassis ground. Terminal 2 should be connected to a 12-volt source, such as the terminal on the ignition switch. There will be one wire left, containing green, red, and brown wires. Attach these to the corresponding screws at the back of the fuel pressure gauge, with the green wire on the left, red in the middle, and brown on the right. Tighten the nuts with a wrench.

To complete the installation, attach the other ends of the wires to the correct terminals on the pressure unit: green to terminal 4, red to terminal 5, and brown to terminal 6. Reconnect the negative battery terminal and start the engine to test the setup.

Changing Fuel Pressure Regulator in Duramax LML: Step-by-Step Guide

You may want to see also

Checking for leaks

Before you begin, ensure that you have released the fuel pressure. This is a crucial step to avoid any accidents or complications. Now, carefully inspect the fuel system for any signs of leaks. Look closely for any wet spots or a strong smell of gasoline around the fuel lines, connections, and the fuel rail. Even a small leak can lead to a significant issue, so be thorough in your inspection.

If you have difficulty spotting leaks, there are a few other methods you can try. One way is to use your sense of smell. Start the engine and let it run for a while, then carefully sniff around the fuel injectors and the engine bay. A strong smell of gasoline near the injectors is a sign of a fuel leak. Be cautious not to lean too close to any hot or running engine parts during this process.

Another approach is to listen for unusual noises. Start the engine and let it run as usual, then move closer to the injectors and fuel rail to listen for any faint hissing sounds. Even subtle hisses may indicate small leaks, so stay vigilant. Additionally, you can perform a visual inspection of the fuel injectors. Look for any wet spots or a shiny substance that resembles gasoline, which could indicate potential leakage issues. Sometimes, you may notice an accumulation of dirt or grime around an injector, which could be a result of fuel leaking and attracting dust and debris.

If you suspect a leak in the fuel line, there is a way to pressurize the line to locate the exact source. You can use a small hand pump to pressurize the line from the engine back to the tank. Only a small amount of pressure, around 5-6 psi, is needed to identify the leak. This method will help you pinpoint the exact location of the leak so you can take the necessary steps to fix it. Remember to always prioritize your safety when working with fuel systems and follow standard safety protocols.

Replacing Fuel Pressure Regulator in 2001 Cavalier Z24: Step-by-Step Guide

You may want to see also

Frequently asked questions

An electric fuel pressure gauge is important for obtaining the best possible performance from your vehicle. It lets you see if the fuel is under-pressured as it flows through the fuel line so you can make adjustments if necessary.

The wiring is simple, so you don’t need much mechanical knowledge to fit a fuel pressure gauge. An electric fuel pressure gauge consists of 3 parts: the sending unit, the pressure unit, and the gauge itself. The sending unit fits on the fuel line and sends information to the pressure unit, which then sends signals to the gauge itself.

The gauge can be fitted almost anywhere on the dash; many people like to place it so it’s sitting on top and can easily be read. The pressure unit should be located in the passenger area of the car rather than in the engine.