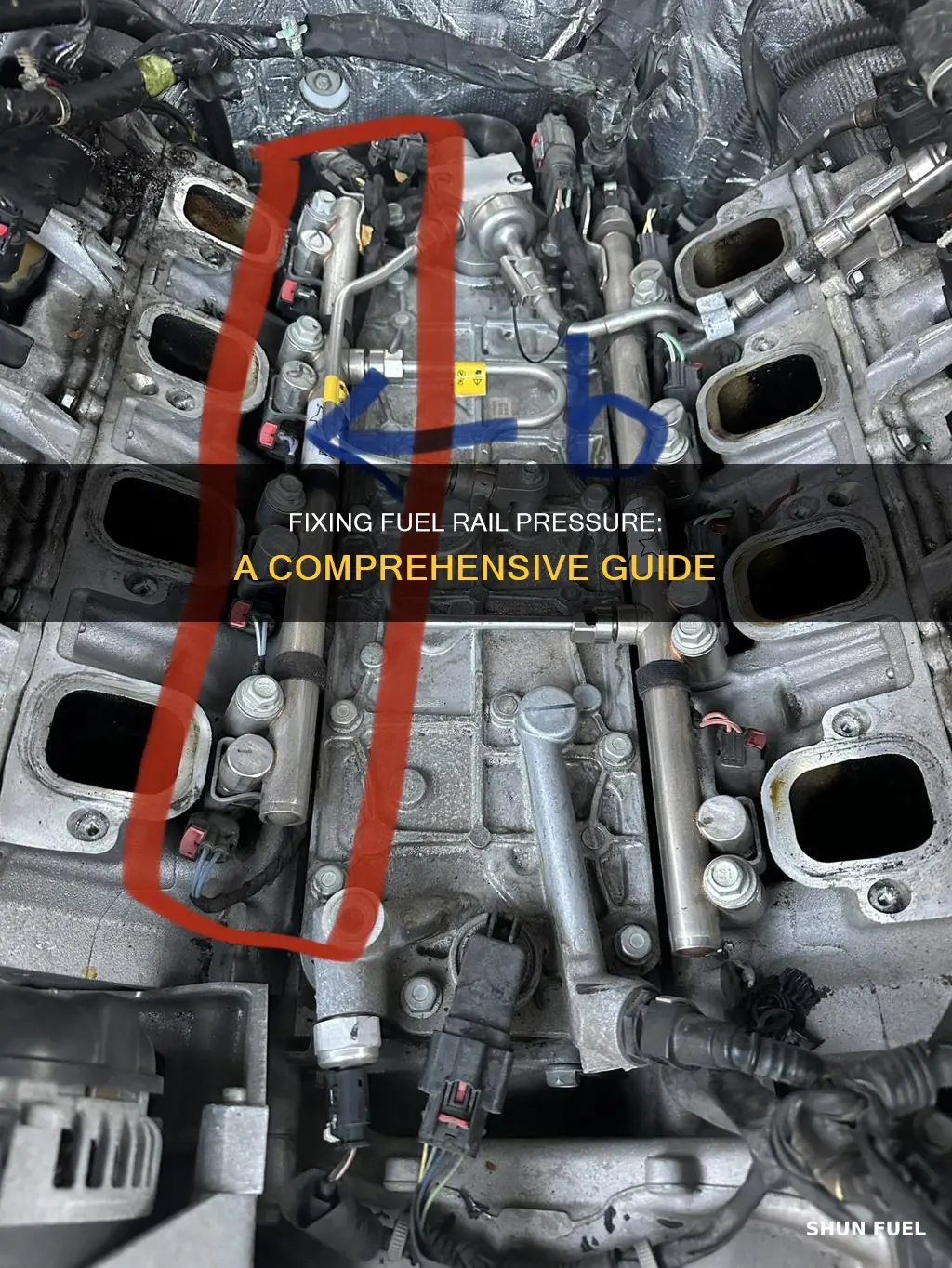

A car's fuel system is made up of several components, including the fuel pump, fuel pressure sensor, fuel rail, and the ECU, which monitors everything. If the fuel rail pressure is too high or too low, it can cause a variety of issues, such as an unresponsive throttle, a stalling engine, difficulty starting the car, a check engine light, misfires, or low performance.

There are several potential causes for high or low fuel rail pressure, including a faulty fuel pump, clogged fuel filter, or a faulty fuel pressure regulator. If left unchecked, this issue can lead to engine damage.

To fix fuel rail pressure, it is recommended to seek professional help. A mechanic will be able to diagnose the exact cause of the issue and replace any necessary components, such as the fuel pump, fuel pressure sensor, fuel filter, or fuel injectors. In some cases, the issue may be caused by outdated or faulty ECU software, which a mechanic can update or reprogram.

| Characteristics | Values |

|---|---|

| Signs of low fuel pressure | Unresponsive throttle, stalling engine, difficulty starting the car, check engine light on, misfires, low performance |

| Causes of low fuel pressure | Clogged fuel filter, faulty fuel pump, faulty fuel pressure regulator, stuck fuel injector, faulty fuel pipe line, faulty fuel pressure sensor |

| Fuel rail pressure sensor fixes | Locate the sensor, disconnect electrical connector, set multimeter, measure resistance, check resistance, inspect wiring and connector, reconnect, clear error codes, test drive |

| Fuel rail pressure sensor replacement cost | Parts: $50-$150; Labor: $100-$200; Total: $150-$350 |

What You'll Learn

Check for a faulty fuel pump

A faulty fuel pump can cause a vehicle's engine to experience major performance issues. Here are some detailed checks to help identify a faulty fuel pump:

Engine Behaviour

An engine that is receiving insufficient fuel will often stutter, stumble, and stall. If the fuel pump is unable to deliver the required amount of fuel, the engine will struggle to start and run. This can manifest as an engine that takes longer to start, requires multiple attempts to ignite, or exhibits spluttering during ignition attempts. Additionally, a faulty fuel pump may cause the engine to shut off suddenly while driving, or immediately after starting.

Unusual Noises

A failing fuel pump may emit a loud, whining sound, which can be heard from the gas tank. This noise may indicate that the pump is damaged or that the fuel is contaminated. In contrast, a normally functioning fuel pump will produce a low hum.

Engine Response

If the fuel pump cannot maintain a constant stream of fuel at higher speeds, the engine may sputter and threaten to stall. This can be indicative of a worn pump that has lost pressure and is unable to meet the engine's fuel demands.

Fuel Efficiency

A faulty fuel pump can lead to lower fuel efficiency. If the pump is pushing too much fuel into the engine, you may experience power surges while driving, resulting in speed spikes and drops.

Diagnostic Tools

To confirm a faulty fuel pump, you can use a fuel pressure test kit or a diagnostic scanner to check for specific trouble codes, such as P0087 or P0190, which indicate issues with fuel rail pressure or fuel pressure sensors, respectively.

It is important to note that a qualified technician should be consulted for a comprehensive inspection and diagnosis, as the specific repair steps may vary depending on the vehicle's make and model.

Fuel Pressure Regulator: Can It Stop Your Car?

You may want to see also

Inspect fuel filters for debris

Inspecting your fuel filters for debris is an essential aspect of maintaining optimal fuel rail pressure and ensuring your engine's performance, efficiency, and reliability. Here's a detailed guide on how to inspect your fuel filters for debris:

Understanding the Fuel System

Before inspecting your fuel filters, it's crucial to understand the basics of the fuel system. The fuel rail pressure is the pressure at which fuel is delivered to the engine's fuel injectors, and it plays a critical role in determining the flow rate and atomization of the fuel. This pressure is typically measured in pounds per square inch (PSI) or kilopascals (kPa). In modern fuel-injected engines, high fuel rail pressures are required for efficient combustion and optimal engine performance.

Safety First

When working on your vehicle's fuel system, always put safety first. Park your vehicle in a well-ventilated area away from any open flames or sparks. Disconnect the negative terminal of the vehicle's battery to prevent any electrical issues. It is also recommended to wear safety gear, such as gloves and eye protection, when working on your car.

Locate the Fuel Filters

Fuel filters are typically located along the fuel lines, which run from the fuel tank to the engine. Consult your vehicle's service manual or repair guides specific to your car's make and model to pinpoint the exact location of the fuel filters. Different vehicles may have multiple fuel filters, so ensure you identify all of them.

Inspect for Debris and Clogs

Once you have located the fuel filters, it's time to inspect them for debris and clogs. Carefully remove the fuel filters from their housing or mounting. Some filters may have quick-release connectors, while others may require unscrewing. Visually inspect the fuel filters for any signs of debris, such as dirt, rust, or contaminants. Look for any blockages or restrictions within the filter media. If the filter appears dirty or clogged, it's likely time to replace it.

Clean or Replace the Fuel Filters

If you find debris or clogs in your fuel filters, you have two options: cleaning or replacement. Some fuel filters can be cleaned and reused, while others are designed to be replaced. Refer to your vehicle's maintenance guidelines or seek advice from a qualified mechanic to determine the best course of action. If you decide to clean the fuel filters, use a suitable cleaning solution and follow the manufacturer's instructions. Ensure the filters are thoroughly dried before reinstalling them.

Reinstall the Fuel Filters

After cleaning or replacing the fuel filters, carefully reinstall them in their original positions. Ensure all connections are secure and tight to prevent any leaks. Refer to your vehicle's service manual or repair guides for specific instructions on reassembling the fuel filters.

Regular Maintenance

Regular inspection and maintenance of your fuel filters are crucial to maintaining optimal fuel rail pressure. Fuel filters should be inspected and replaced at recommended intervals, as specified in your vehicle's maintenance schedule. This proactive approach will help prevent fuel system issues and ensure your engine's performance and longevity.

By following these steps and maintaining your fuel filters, you can help ensure your vehicle's fuel rail pressure is within the optimal range, promoting efficient fuel delivery, combustion, and engine performance. Remember to consult reliable sources and seek professional assistance if needed, as working on your vehicle's fuel system requires caution and precision.

Understanding Stock Fuel Pressure in the Challenger RT

You may want to see also

Test fuel pressure

Testing fuel pressure is a simple process that can help you identify issues with your car's fuel delivery system. Here's a step-by-step guide on how to test fuel pressure:

Step 1: Understand the Basics

Before you begin, it's important to know that an engine needs just four things to run: air, fuel, spark, and compression. Checking fuel pressure will help you determine if there's an issue with the fuel delivery to the engine.

Step 2: Prepare the Necessary Tools

To test fuel pressure, you will need a fuel pressure tester. This tool typically consists of a gauge attached to a fuel hose with multiple fittings that can connect to the fuel system of almost any vehicle. You can purchase or rent one from an auto parts store.

Step 3: Locate the Fuel Rail

Pop the hood of your car and locate the fuel rail. It is usually found on the engine, often hidden under a fuel rail cover or another plastic engine cover.

Step 4: Connect the Fuel Pressure Tester

With the engine completely cold, remove the Schrader valve cap from the fuel rail. Attach the appropriate fuel pressure tester fitting securely, ensuring a leakproof fit.

Step 5: Turn on the Ignition

Turn the ignition to "on" but do not start the engine. Observe the psi reading on the fuel pressure tester gauge. A drop in psi over time indicates a leak in the system, while a steady reading means the system is holding pressure well.

Step 6: Interpret the Results

The desired fuel pressure varies depending on the engine. Older throttle-body injected systems may need as little as 10 psi, while multi-port injection systems can require up to 60 psi. Consult your vehicle's repair manual to determine the specific fuel pressure requirements for your engine.

If the fuel pressure is significantly lower than the recommended level, it could be due to a clogged fuel filter, a failing fuel pump, or a faulty fuel pressure regulator. On the other hand, if the pressure is higher than expected, it could be caused by a clogged or kinked fuel return line or a faulty fuel pressure regulator.

Step 7: Start the Engine

Start the engine and let it idle. Observe the fuel pressure gauge. You should see steady fuel pressure, within a few psi of the recommended pressure.

Step 8: Rev the Engine

Slowly rev the engine and observe the fuel pressure. The pressure should rise with the increase in RPMs. If the fuel pressure holds steady, rises with engine speed, and is within the recommended range, your engine problem is likely not fuel-related.

Safety Precautions

When performing fuel pressure tests, always work in a well-ventilated area and keep a fire extinguisher nearby. Fuel vapors are highly flammable, so take extra caution to avoid any potential ignition sources.

Understanding the Role of Fuel Injector Pressure Sensors

You may want to see also

Check for fuel injector issues

To check for fuel injector issues, you can start by looking for common symptoms of low fuel pressure. These symptoms include an unresponsive throttle or a stalling engine, difficulty starting the car, a check engine light on the dashboard, misfires, and low performance.

If you suspect that your fuel injectors may be the cause of low fuel pressure, there are a few things you can do to check for issues. One of the most common issues with fuel injectors is when they become stuck open, which can cause low fuel pressure in the rail. This is often indicated by misfire codes on a specific cylinder.

Another issue to look out for is back leakage, which occurs when fuel takes the path of least resistance back to the fuel tank via the back channel at the top of the injector. This can be caused by worn seals or control/pilot valves, or blocked or sticking nozzles/injector tips.

Additionally, you can check for blow-by, which happens when seating seals between the injector and the cylinder head become worn, resulting in a loss of pressure in the cylinder. If this problem persists, it can lead to diesel wash, where escaped diesel fuel removes the oil lubricating the piston head.

If you suspect that your fuel injectors may be faulty, it is important to replace them as soon as possible. Faulty fuel injectors can cause a range of problems, including low fuel pressure, engine performance issues, and increased fuel consumption.

Connecting a Fuel Pressure Gauge to Your Ford: Easy Steps

You may want to see also

Look for fuel line damage

To identify damage to your fuel line, there are several signs you can look out for. One of the earliest signs of a damaged fuel line is the smell of gasoline inside your car while driving. This strong and distinct smell means that the fuel is escaping from where it should be within the fuel line. Gaseous fumes within the car can cause headaches and nausea for passengers, so if you smell gasoline, it should be treated as urgent.

Another sign of a damaged fuel line is a reduction in engine performance. If your vehicle struggles to start, idles roughly, or experiences unexpected power loss, these could be symptoms of fuel line problems. A compromised fuel line means there is too much air and not enough fuel in the engine's combustion chamber, which can overheat the car and damage the engine.

You may also notice a hissing sound coming from your vehicle if the fuel line is damaged. This is due to escaping fuel, and the sound is similar to when a tire is releasing air. The hissing is most noticeable when the engine is idle or immediately after turning the engine off, and it may be accompanied by a drop in fuel efficiency.

If you suspect a damaged fuel line, you can also look for visible leaks. If your gas is burning faster than usual, check for fuel on the ground where your car was last parked. Leaks can often be seen after long drives or when the vehicle has been sitting for extended periods. Visible leaks can absorb dust and debris, which will eventually seep into the fuel line and cause further deterioration and potential engine problems.

Finally, if something is wrong with the fuel line, sensors can trigger the check engine light. The check engine light can be due to various issues, but if it coincides with other problems like fuel odours or performance issues, it's worth taking a look at the fuel line.

Installing a Fuel Pressure Regulator: Carburetor Setup

You may want to see also

Frequently asked questions

The most common symptom of low fuel rail pressure is an unresponsive throttle or a stalling engine. You may also notice difficulty starting the car, a check engine light on the dashboard, misfires, or low performance.

The most common causes of low fuel rail pressure are a clogged fuel filter or a bad fuel pump. It can also be caused by a bad fuel pressure regulator, a stuck fuel injector, a fuel pressure sensor, or a damaged fuel pressure line.

Engine power is derated and the engine may stop.

Possible causes for high fuel pressure include the fuel pressure regulator, obstructed return lines, the fuel rail pressure sensor, the fuel rail relief valve, and the high-pressure fuel pump.

You can fix low fuel rail pressure by replacing the faulty fuel system components, such as the fuel pump, fuel pressure sensor, fuel filter, or fuel injectors.