A fuel pressure gauge is a device that measures the pressure of the gasoline delivered to the engine, usually in pounds per square inch (psi). It can be easily fitted along the fuel line. The pressure reading will help determine if the pressure is sufficient to deliver the right amount of fuel to the engine. If the pressure is too low, the engine won't run efficiently. This article will provide a step-by-step guide on how to fit a fuel pressure gauge, covering topics such as the types of fuel pressure gauges, the placement of the gauge, and the tools and parts required for installation.

What You'll Learn

Choosing the right fuel pressure gauge

Type of Gauge:

You can choose between a mechanical or digital fuel pressure gauge. Mechanical gauges are typically more affordable and widely used, while digital gauges offer greater accuracy and precision, making them suitable for calibration.

Vehicle Type:

Consider the type of vehicle and its specific requirements. Different vehicles may have varying fuel pressure needs, so it's essential to refer to your vehicle's specifications when choosing a fuel pressure gauge.

Fuel Type:

The fuel type of your vehicle is another important consideration. For carbureted engines, a fuel pressure gauge with a reading of 0 to 15 psi is suitable. In contrast, fuel-injected engines require higher pressures, typically ranging from 0 to 100 psi.

Gauge Size:

Mechanical pressure gauges come in various nominal sizes. Choose a size that offers the best readability, space optimisation, and precision for your needs. A larger dial face provides more precise readings and is easier to see from a distance, but may not fit in all applications.

Temperature Considerations:

The ambient and media temperatures will influence the choice of gauge material. For extremely cold environments, consider a liquid-filled gauge to prevent internal parts from icing. If the media temperature exceeds 140°F (60°C), opt for a stainless steel gauge as brass gauges can fail at this temperature.

Media/Pipeline Contents:

The media or contents of the pipeline will determine the gauge material, especially for the wetted parts that come into direct contact. Brass or copper alloy gauges are suitable for non-aggressive liquids or gases like water and air. However, harsh chemicals like sour gas or ammonia require corrosion-resistant materials such as stainless steel or nickel-copper alloys.

Pressure Type and Range:

Determine the type of pressure you need to measure, such as gauge pressure, absolute pressure, or differential pressure. Additionally, consider the operating range of your application and select a gauge with a range that is twice the optimal operating pressure for optimal performance.

Process Connections:

Consider the type and size of process connections ("Ends") you need. The most common type in the U.S. and Canada is NPT, while other countries often use G (metric) connections. Choose the appropriate connection size and location, such as lower (bottom) mount or back (rear) mount.

Delivery Time:

While this may not be a primary factor, it's worth noting that standard gauges in popular nominal sizes are readily available for immediate delivery. Customised gauges with specific options may require a longer waiting period.

Fuel Pressure Fundamentals for Nitrous Users

You may want to see also

Where to place the gauge

When installing a fuel pressure gauge, it is important to consider the type of gauge and the fuel system of your vehicle.

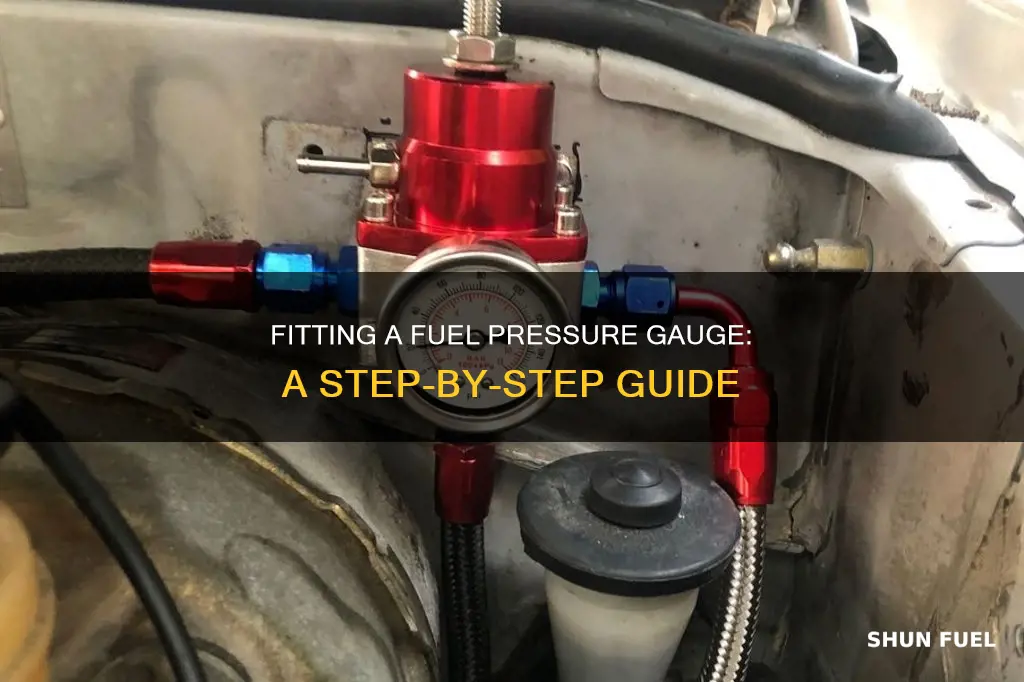

A fuel pressure gauge is typically installed near a fuel line in the engine bay. The specific location will depend on the type of gauge you are using: mechanical or electronic.

Mechanical Gauge

A mechanical gauge is plumbed into the fuel line, often directly before the carburetor. This type of gauge uses a valve to detect the pressure of the fuel as it is pumped into the engine. Due to its location along the fuel line, a mechanical gauge can be difficult to see while driving. If you want to monitor the fuel pressure while the vehicle is in motion, you can consider placing the gauge near the cowl, depending on your hood design.

It is important to note that plumbing a mechanical gauge into the passenger compartment is not recommended as it is unsafe to have a fuel line inside the vehicle.

Electronic Gauge

An electronic gauge uses a sensor in the fuel line to measure pressure and transmits the data via wires to the gauge. This allows for greater flexibility in placement, even on the dashboard.

Fuel System

The fuel system of your vehicle will also determine the ideal location for the fuel pressure gauge. For carbureted engines, the fuel pressure gauge is typically installed along the fuel line before the carburetor. For fuel-injected engines, you can tap into either fuel rail as long as the source for your readings is at the same pressure as the fuel injectors.

General Guidelines

When installing a fuel pressure gauge, it is crucial to follow safety precautions. Do not route a fuel line into the cockpit or passenger compartment. If you wish to place the gauge inside the vehicle, you must use an isolator or an electrical gauge with a separate pressure sender to avoid the risk of fire or explosion. Additionally, ensure that the gauge tubing is free from hazards of moving parts or hot engine components.

Fuel Pressure Regulator: LS1Tech Mounting Location Guide

You may want to see also

Preparing the fuel line

Before you start, ensure your engine is cold. Locate the fuel line you want to tap into. This is usually the fuel line closest to the oil dipstick. It is a rubber hose that connects to a metal pipe near the engine.

Release the fuel pressure using a release fuel pressure how-to guide. Now, cut the fuel line. Use a rag to prevent fuel from spraying and have two 5/16 inch plugs ready to stop the fuel flow. Two Bic pen-type caps will work. The fuel will continue to dribble out unless you plug the hoses.

The fuel lines are wrapped in an insulation tube, which makes them look larger than they are. Remove the insulation tube from the fuel line so you can get the clamps on the hose. The insulation tube will come right off after you cut the fuel line.

Now you can install the gauge and tighten the clamps. Prime the fuel system. Make sure there is no pooled fuel anywhere before you start the engine. Check carefully for any fuel leaks.

Try to do this with as little fuel in the tank as possible to minimise fuel spill.

Normal idle fuel pressure is 28-32 psi. Pressure with the F/P (fuel pump) and GND (ground) diagnosis terminals jumpered should be 36-38 psi. You can check the maximum fuel pressure (71-107 psi) by pinching the fuel line on the engine side of the fuel gauge.

Do not route a fuel line into the cockpit. To place a fuel gauge in the cockpit, you must use an isolator or an electrical gauge with a separate pressure sender.

Finding the Fuel Pressure Sensor in a Range Rover Evoque

You may want to see also

Attaching the gauge

Next, wrap the gauge's threads with Teflon tape, ensuring it doesn't extend below the threads to prevent any tape from getting into the fuel lines. Screw the gauge into the fitting, using a wrench to tighten it securely.

Now, you can attach the gauge to the fuel line. Try to do this with as little fuel in the tank as possible to minimise spillage. Locate the correct fuel line, which is usually the one closest to the oil dipstick. It is a rubber hose that connects to a metal pipe near the engine. Remember to release the fuel pressure before cutting the fuel line. Use a rag to prevent fuel from spraying and have two 5/16 inch plugs ready to stop the fuel flow.

After installing the gauge and tightening the clamps, you will need to prime the fuel system. Check for any pooled fuel before starting the engine and carefully inspect for any fuel leaks.

Finally, you can check the fuel pressure readings. A normal idle fuel pressure is typically around 28-32 psi. You can check the maximum fuel pressure by plugging or pinching the fuel line on the engine side of the fuel gauge, which should be around 71-107 psi.

It is important to note that routing a fuel line into the cockpit is not recommended. If you wish to place the gauge in the cockpit, you must use an isolator or an electrical gauge with a separate pressure sender to ensure safety.

Fuel Pressure Maintenance for 2005 Polaris Ranger 700 XP

You may want to see also

Testing the gauge

Testing the fuel pressure gauge is a straightforward process, but it requires careful attention to ensure safety and accurate readings. Here is a detailed guide on how to test the fuel pressure gauge:

Prepare the Vehicle:

Park your vehicle on flat ground and ensure it is in park with the emergency brake set. Turn off the engine, and ensure there is no smoking or open flame nearby. This step is crucial for safety.

Locate the Fuel Pressure Port:

Identify the fuel pressure port, which is usually on the engine fuel rail. Some vehicles have a convenient pressure port with a cap that can be removed. If your vehicle doesn't have one, you may need an adapter from a test kit. The adapter can be attached at the fuel filter or the fuel pressure feed line leading to the engine's fuel rail.

Connect the Fuel Pressure Gauge:

Remove the fuel pressure gauge from the kit and attach it to the pressure port. A small amount of fuel may be present, so be prepared with a shop towel. Ensure that the gauge is securely connected to prevent any fuel leakage.

Test Fuel Pressure with Engine Off:

Without starting the engine, turn the ignition key to the "on" position. The fuel pump should pressurize the fuel system, and the gauge should display a reading. For direct port injection systems, the reading should be between 45 psi and 58 psi. For throttle-body injection, the reading should typically be between 13 and 17 psi as the system primes. If there is no pressure, recheck the hose or adapter connection and recycle the ignition switch.

Test Fuel Pressure with Engine Running:

Now, start the engine and observe the fuel pressure gauge. The fuel pressure should drop slightly, and then, when you snap the throttle, the pressure should increase by approximately 5 psi. This indicates that the fuel pump and pressure regulator are functioning correctly. If the fuel pressure does not respond as expected, inspect the regulator vacuum feed line, as there may be an issue with the fuel pressure regulator.

Perform a Load Test:

Conduct a load test to determine how the fuel pump performs under the load of use. There are two ways to do this: first, you can load the engine by putting the transmission in reverse (for automatic vehicles) and holding the brake while gently applying throttle. Alternatively, you can close the hood to the first safety catch and drive the car at a slow speed while keeping the gauge visible. The pressure should remain steady throughout the test. If the fuel pressure drops under load or while idling, it could be due to a clogged fuel filter or a failing fuel pump.

Final Checks:

Remove the fuel pressure gauge and reinstall the dust cap or remove the fuel line adapter. Clean up any excess fuel, and ensure that all components are securely reconnected.

Safety Precautions:

Fuel vapors are highly flammable, so ensure that you perform these tests in a well-ventilated area and take necessary safety precautions, such as wearing safety glasses and gloves. Keep a fire extinguisher nearby in case of any accidents.

Finding Fuel Pressure Checkpoints in 2002 Cavaliers

You may want to see also

Frequently asked questions

A fuel pressure gauge is normally installed near a fuel line in the engine bay. A mechanical gauge is usually located near the carburetor, but if you want to know the fuel pressure while driving, you could put it near the cowl, depending on your hood design. An electronic gauge can be placed anywhere, even on the dashboard.

First, ensure your engine is entirely cold. Then, pop the hood and find a Schrader valve fitting on the fuel rail. Remove the Schrader valve cap and attach the appropriate fuel pressure tester fitting. Make sure it threads on properly for a leakproof fit. Turn the ignition to "on", not start, and check the psi reading.

A good fuel pressure reading depends on the engine. Some older throttle-body injected systems need as little as 10 psi, while multi-port injection can see as high as 60. If you don't know what your engine needs, grab a repair manual and check the specifications section.

A fuel pressure gauge measures the pressure of the gasoline delivered to the engine, usually in pounds per square inch (psi). It lets you see if the pressure is sufficient to deliver the right amount of fuel to your engine. If the fuel pressure is too low, your engine won't run efficiently.