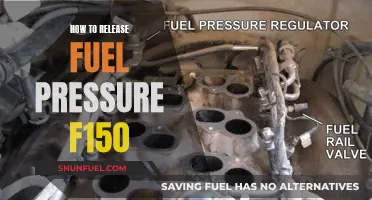

A fuel pressure regulator is a device that maintains constant fuel pressure for proper fuel atomization. Inside the regulator housing, a spring pushes against a diaphragm, with the spring pressure pre-set by the manufacturer for the desired fuel pressure. This allows the fuel pump to pump enough fuel and maintain the necessary pressure to overcome the spring pressure. When the vehicle engine is at idle, there is less pressure against the incoming fuel, and the vacuum drops when the throttle is open, allowing the spring to push the diaphragm out and increase the fuel pressure in the rail. To disassemble an Aeromotive fuel pressure regulator, you will need to remove the mounting hardware and vacuum line from the regulator, before taking it off the fuel rail.

What You'll Learn

Check for engine light codes and engine operation

When something goes wrong with a vehicle, there are many alert signals that might be sent to a driver, such as messages on the electronic display about low tyre pressure, or dashboard warning lights related to high engine temperature or low oil pressure. But the signal that causes the most concern for many folks is usually the check engine light.

When the Engine Control Module (ECM) detects a problem with a vehicle system, it will store information that can later be accessed by a repair technician. It will also turn on the check engine light to let you know that something is wrong. The issue could be something as simple as a loose gas cap, or it could be something as serious as an engine misfire. When you see the check engine light come on, you should know that it is time to take your vehicle to a technician for an accurate diagnosis.

The presence of a check engine light is often misunderstood because it bears many meanings. When it lights up, there is no knowing if the cause is a simple fix or a more grave problem that could damage your engine. In some cases, the check engine light might come on when there is nothing wrong with your vehicle at all. In those cases, the light should go off by itself after a short amount of time. But if it stays on, the check engine light should not be ignored. And if it is blinking on and off, do not continue to drive your vehicle.

There are many causes of a check engine light, some simple and others more severe. Examples of problems that might lead to a check engine light include:

- A bad oxygen sensor in the exhaust system

- Faulty spark plugs, ignition coil, or wiring

- A malfunctioning mass air flow sensor

- A plugged catalytic converter

- Problems with the EVAP system

- Failing engine thermostat

- An intake manifold gasket that leaks coolant into a combustion chamber

A faulty fuel pressure regulator can lead to a wide range of engine performance problems. Some of the symptoms include:

- An illuminated check engine light

- Black smoke from the exhaust

- Poor engine performance

- A vehicle that won’t start or stalls

- Leaks if the fuel pressure regulator fails

Diagnostic Trouble Codes (DTCs) are five-digit alphanumeric codes that fall into four different categories, depending on where a particular malfunction might be found. Each category is represented by a letter:

- Network Communications (U)

- Powertrain (P)

- Body (B)

- Chassis (C)

DTCs are further divided into two groups:

- Generic codes – These codes are common to all vehicles no matter the manufacturer. Generic codes are indicated with a “0” as the second digit (i.e. P0000).

- Enhanced codes – Enhanced codes are those that are manufacturer-specific and related to a specific (often outside the engine control system) vehicle application. Enhanced codes are represented with a “1” as the second digit (i.e. P1000).

Code P0089 stands for “Fuel Pressure Regulator Performance”. This code is set when the PCM determines that the fuel pressure doesn’t match the desired levels. It is commonly caused by fuel pressure regulator failure, fuel pump failure, and fuel injector leaks. Common symptoms include a lit check engine light, poor fuel economy, and poor acceleration.

How Diesel Fuel Pressure Testers Keep Trucks Running

You may want to see also

Inspect vacuum hoses for damage

Inspecting your vacuum hoses for damage is an important step in maintaining your fuel pressure regulator and overall engine health. A fuel pressure regulator vacuum hose helps maintain the correct fuel pressure level in the fuel system, ensuring optimal engine performance. Over time, this hose can become damaged or disconnected, leading to various issues.

- Locate the Fuel Pressure Regulator Vacuum Hose: The vacuum hose is connected to the negative side of the regulator and runs up to the intake manifold or carburetor. Consult your vehicle's repair manual to identify its exact location, as it may vary depending on the make and model.

- Inspect for Damage: Once you have located the vacuum hose, carefully examine it for any signs of damage or wear and tear. Look for cracks, leaks, deterioration, or any other visible issues. Pay close attention to the rubber hose, as it can become brittle or cracked over time due to exposure to high temperatures and harsh environmental conditions.

- Check for Disconnection: Ensure that the vacuum hose is securely connected at both ends. Improper installation or loose connections can lead to disconnection, causing a decrease in engine performance and potential damage to other components.

- Inspect for Vacuum Leaks: Vacuum leaks can cause a variety of issues, including poor engine performance and idling problems. Check the vacuum hose for any signs of leaks, such as cracks or splits. A leaking vacuum hose can affect the performance of the fuel pressure regulator, leading to fluctuating fuel pressure and inconsistent engine performance.

- Replace if Necessary: If you notice any damage, cracks, leaks, or deterioration on the vacuum hose, it is important to replace it with a new one. Replacing the hose is generally cheaper and easier than attempting to repair it. This will ensure proper fuel pressure regulation and prevent further issues.

- Regular Maintenance: Regular maintenance of the vacuum hose is crucial to keep it in good working condition. Clean the hose regularly and include it in your vehicle's maintenance routine. This will help extend its lifespan and reduce the risk of unexpected failures.

By following these steps and guidelines, you can effectively inspect your vacuum hoses for damage and take appropriate action if necessary. Remember that a properly functioning fuel pressure regulator vacuum hose is essential for optimal engine performance and fuel efficiency.

Understanding Fuel Pressure in the 89 Celica

You may want to see also

Disconnect the battery

Disconnecting the battery is an important step when disassembling an aeromotive fuel pressure regulator. This is because it disables the power going to the fuel pump, which is crucial for safety reasons. Here is a detailed, step-by-step guide on how to do this:

Park your vehicle on a flat, hard surface and ensure that the transmission is in park for automatics or in first gear for manual vehicles. This is important for stability and to prevent the vehicle from moving during the process.

Secure the front tires by placing wheel chocks around them. Engage the parking brake to lock the rear tires from moving as well. This ensures that your vehicle remains stationary while you work.

Open the vehicle's hood to access the battery. Before proceeding, it is crucial to put on protective gloves to shield your hands from any potential hazards. Battery terminals can be dangerous, so this safety precaution is essential.

Locate the ground cable connected to the battery's negative post. This cable supplies power to the fuel pump, and by disconnecting it, you will cut off the power source. It is recommended to follow the vehicle's owner's manual for proper battery cable removal instructions.

Carefully remove the ground cable from the battery's negative post. Pay close attention to the cable's routing and ensure that you do not damage any nearby components. Take your time with this step to avoid any accidental short circuits or damage to the battery.

Once the ground cable is disconnected, verify that the power to the fuel pump has been successfully cut off. You can use a voltage tester to check for any remaining electrical current. Safety should always be a priority when working with electrical systems.

By following these steps, you will have safely disconnected the battery, ensuring that there is no power supplied to the fuel pump during the disassembly process. Remember to handle the battery and its components with care to avoid any potential hazards.

Fuel Pressure Requirements for Toyota 22RE Engines

You may want to see also

Remove the fuel pressure sensor

To remove the fuel pressure sensor, first remove the engine cover. Take off any brackets that may be in the way of the fuel pressure regulator. If your engine has an intake that is transverse-mounted or overlaps the fuel pressure regulator, you must remove the intake before removing the fuel pressure regulator.

Next, find the Schrader valve, or test port, on the fuel rail. Put on safety glasses and protective clothing. Place a drip pan under the rail and cover the port with a towel. Using a small flat screwdriver, open the valve by pushing on the Schrader valve. This will release the pressure in the fuel rail. Note that if you do have a test port or a Schrader valve, you will need to remove the supply fuel hose to the fuel rail. When doing so, you will need a drip pan and a fuel hose quick disconnect tool kit. Use the correct tool to remove the fuel hose from the fuel rail, releasing the pressure.

Now, remove the vacuum line from the fuel pressure regulator. Take off the mounting hardware and remove the fuel pressure regulator from the fuel rail.

Fuel Rail Pressure: Sensor Troubleshooting Guide

You may want to see also

Install a new fuel pressure regulator

Installing a new fuel pressure regulator is a simple process, but it is important to take the necessary precautions and follow the correct steps to ensure a safe and proper installation. Here is a detailed guide on how to install a new fuel pressure regulator:

First, it is important to understand the type of fuel pressure regulator you need. There are two common types: deadhead-style and bypass. Deadhead-style regulators are the simplest and most popular, using a restriction to lower fuel pressure by decreasing fuel flow. These regulators do not use a return line, which can limit performance capabilities. On the other hand, bypass regulators bleed off excess fuel pressure and return it to the fuel tank, helping to eliminate pressure creep and lower fuel temperatures.

Next, make sure you have the correct tools and materials. You will need a new fuel pressure regulator, thread sealant, a screwdriver or ratchet, a wrench, new O-rings, and any other fittings or adapters required for your specific vehicle. It is also recommended to have rags or paper towels handy to catch any fuel that may spill during the process.

Now, you can begin the installation process:

- Depressurize the fuel lines by removing the fuel pressure from your fuel lines. This can be done by unplugging the fuel cap and removing the fuel pump fuse, then cranking the car until it stalls and turns off.

- Remove your old fuel pressure regulator. Be careful when removing any screws or bolts, as stripping them can cause damage.

- Once the old regulator is removed, you may notice a rubber O-ring. Replace this with a new one to ensure a proper seal and prevent leakage.

- Test fit the new fuel pressure regulator to ensure it fits properly and doesn't interfere with any other components. You may need to create a bracket or adapter to secure it in place.

- Finalize the fuel lines plumbing. Refer to your new fuel pressure regulator's manual to identify the fuel inlet and outlet ports, and adjust your fuel lines accordingly.

- Secure the new fuel pressure regulator in place, using the provided mounting bracket and any necessary hardware.

- Connect the vacuum hose from the manifold to the fuel pressure regulator.

- Adjust the fuel pressure to the recommended setting for your vehicle. This can be done by loosening the lock nut and turning the hex key to raise or lower the pressure.

- Clean up any spills or leaks, and take your vehicle for a test drive to ensure the new fuel pressure regulator is functioning properly.

By following these steps, you can safely and effectively install a new fuel pressure regulator, improving your vehicle's performance and reliability.

Fuel Rail Pressure: Common Causes of Abnormal Readings

You may want to see also