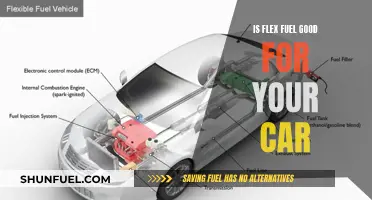

Converting a car to run on flex fuel, which is a blend of gasoline and ethanol, can be a cost-effective way to reduce emissions and save on fuel costs. This process involves modifying the engine and fuel system to accommodate the higher ethanol content. The first step is to choose the right flex-fuel sensor and engine control unit (ECU) that can accurately detect the fuel type and adjust the engine's performance accordingly. Next, you'll need to install an ethanol-compatible fuel pump and injectors, ensuring they can handle the increased pressure and flow rates. Proper fuel line and tank modifications may also be necessary to prevent ethanol-related corrosion. Finally, a thorough calibration of the ECU is essential to optimize engine performance and ensure reliable operation with the new fuel mixture.

What You'll Learn

- Engine Modifications: Alter fuel injectors, intake, and combustion chamber for flex-fuel compatibility

- Fuel System Upgrades: Install a flex-fuel sensor and compatible fuel pump and lines

- Software Updates: Modify engine control unit (ECU) to recognize and utilize alternative fuels

- Fuel Blend Management: Implement a system to precisely mix gasoline and ethanol for optimal performance

- Testing and Tuning: Calibrate the engine for optimal performance with varying ethanol percentages

Engine Modifications: Alter fuel injectors, intake, and combustion chamber for flex-fuel compatibility

When converting a vehicle to flex-fuel capability, engine modifications are crucial to ensure optimal performance and compatibility with different fuel types. One of the primary areas of focus is the engine's fuel injection system, which plays a vital role in delivering the correct amount of fuel to the engine's cylinders. Here's a detailed breakdown of the engine modifications required for flex-fuel compatibility:

Fuel Injector Alterations:

Flex-fuel vehicles require fuel injectors that can handle a wider range of fuel types, typically from gasoline to ethanol blends. Stock fuel injectors may not provide the necessary precision for ethanol-rich mixtures. Upgrading to high-flow or adjustable fuel injectors is essential. These injectors offer increased fuel capacity, allowing for more precise control over the fuel-air mixture, especially when using higher ethanol content. The process involves replacing the existing injectors with these modified ones, ensuring they can manage the expanded fuel range.

Intake System Modification:

The intake system, including the air filter and throttle body, needs to be optimized for flex-fuel operation. A performance air filter with a higher airflow capacity can improve power and efficiency across various fuel types. Additionally, some enthusiasts opt for a cold air intake system, which routes cooler air to the engine, enhancing performance and fuel efficiency. These modifications ensure that the engine receives an optimal air-fuel mixture, regardless of the fuel used.

Combustion Chamber Design:

The combustion chamber's design is critical for efficient combustion, especially with flex-fuel. The chamber's volume and shape can be adjusted to accommodate different fuel-air ratios. For flex-fuel vehicles, a slightly larger combustion chamber volume is often recommended to handle the higher ethanol content. This modification ensures complete combustion, reducing the risk of engine knock and improving overall performance.

These engine modifications are essential to ensure that the vehicle can run efficiently and reliably on various fuel types. It's important to note that professional installation and tuning are highly recommended to ensure the modifications are safe and effective. Additionally, regular maintenance and monitoring of the engine's performance are crucial to keep the flex-fuel system in optimal condition.

Methane as a Green Fuel: Powering Cars Sustainably

You may want to see also

Fuel System Upgrades: Install a flex-fuel sensor and compatible fuel pump and lines

Converting your car to run on both gasoline and alternative fuels like ethanol requires careful fuel system upgrades. One of the key components is installing a flex-fuel sensor, which is designed to detect the type of fuel in the tank and adjust the engine's performance accordingly. This sensor is crucial for ensuring your engine operates optimally with different fuel blends.

The first step is to source a flex-fuel sensor compatible with your vehicle's make and model. These sensors are available from specialty auto parts stores or online retailers. When purchasing, ensure you get a sensor designed for your specific engine type and fuel system configuration.

Once you have the sensor, the installation process begins. This typically involves replacing the existing fuel level sensor, as the flex-fuel sensor will take its place. Locate the sensor's mounting position, which is usually near the fuel tank. Carefully disconnect the old sensor's wiring and connect the new flex-fuel sensor in its place. Secure the sensor with the provided mounting hardware, ensuring it is firmly attached to avoid vibration-induced issues.

Next, you'll need to install a compatible fuel pump and lines. The fuel pump should be capable of handling the higher ethanol content, so choose one designed for flex-fuel applications. Install the pump in the fuel tank, ensuring it is properly secured and aligned. Then, replace the existing fuel lines with new ones that can accommodate the flex-fuel setup. This might require cutting and splicing the lines, so have the necessary tools and fuel-resistant tape ready.

After the sensor and pump installation, test the system to ensure proper functionality. Start the engine and monitor its performance with different fuel types. The flex-fuel sensor should now accurately detect the fuel type and adjust the engine's fuel-to-air mixture accordingly. Regularly check and maintain the sensor and pump to ensure long-term reliability and optimal performance with your flex-fuel vehicle.

E-Fuel: The Future of Sustainable Driving

You may want to see also

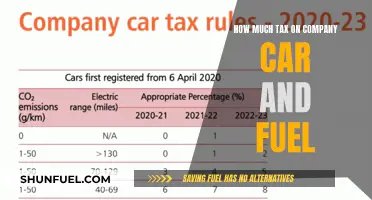

Software Updates: Modify engine control unit (ECU) to recognize and utilize alternative fuels

The process of converting a car to run on flex fuel involves a combination of hardware and software modifications, primarily focusing on the Engine Control Unit (ECU). This unit is the brain of the engine, responsible for managing fuel injection, timing, and overall performance. To make a vehicle flex-fuel capable, the ECU needs to be updated to recognize and process the new fuel types.

Software updates for the ECU are crucial as they enable the engine to adapt to different fuel types, such as ethanol blends (E10, E15, E85) or even pure ethanol (E100). The update involves programming the ECU to adjust the fuel injection, timing, and combustion parameters based on the type of fuel being used. For instance, ethanol-based fuels have a higher octane rating, which requires the ECU to modify the spark timing and fuel-air mixture to prevent engine knock.

The software update process typically includes calibrating the ECU to recognize the specific fuel's properties, such as its energy content, volatility, and combustion characteristics. This calibration ensures that the engine operates optimally with the new fuel, maintaining performance, fuel efficiency, and emissions standards. The ECU's programming can be modified to handle various fuel ratios, allowing the vehicle to run on a wide range of blends without requiring manual adjustments.

Additionally, the software update may involve enhancing the ECU's diagnostic capabilities to monitor fuel quality and system performance. This can include sensors and algorithms to detect issues like fuel contamination or system malfunctions, ensuring safe and efficient operation with alternative fuels. With the right software, the ECU can provide real-time feedback on fuel usage, helping drivers understand the impact of their fuel choices on the vehicle's performance.

Converting a car to flex fuel is a complex process that requires careful consideration of the vehicle's original design, engine specifications, and the chosen fuel types. Professional installation and calibration by experienced technicians are essential to ensure the modifications are safe and effective. The software updates play a critical role in making the conversion successful, allowing the engine to adapt and perform optimally with the alternative fuels.

The Evolution of NASCAR Engines: Carburetor or Fuel Injection?

You may want to see also

Fuel Blend Management: Implement a system to precisely mix gasoline and ethanol for optimal performance

Converting a vehicle to a flex-fuel system, which allows it to run on a blend of gasoline and ethanol, is an exciting modification that can offer both performance benefits and environmental advantages. To ensure optimal performance, implementing a precise fuel blend management system is crucial. This system will enable the engine to adapt to different fuel ratios, providing a seamless transition between gasoline and ethanol-rich mixtures.

The first step in creating this system is to understand the properties of both fuels. Gasoline, a widely available and refined fuel, is known for its high energy content and low volatility. Ethanol, on the other hand, is a renewable biofuel with a higher octane rating, making it ideal for enhancing engine performance. However, ethanol has a lower energy density, which means it requires careful management to maintain optimal power output.

To achieve precise fuel blending, a sophisticated fuel injection system should be employed. This system should be capable of handling the varying fuel properties and mixing ratios. One approach is to use a pump that can deliver both gasoline and ethanol with high precision. The pump should be calibrated to inject the correct volume of each fuel based on the engine's operating conditions, such as speed, load, and temperature. This ensures that the fuel mixture is always optimized for the current driving scenario.

Additionally, the fuel blend management system should include sensors to monitor the fuel levels and properties. These sensors will provide real-time data on the ethanol concentration, allowing the engine control unit (ECU) to make adjustments accordingly. For instance, if the sensor detects a higher ethanol content, the ECU can modify the fuel injection timing and spark plug timing to compensate for the different combustion characteristics. This dynamic adjustment ensures that the engine operates efficiently and smoothly across various fuel blends.

Furthermore, the system should have the capability to learn and adapt to the vehicle's specific requirements. By storing data on the vehicle's performance and fuel consumption patterns, the system can fine-tune the fuel blend over time. This adaptive learning feature ensures that the car's performance remains optimal as it ages or under different environmental conditions. Regular updates and calibration can further enhance the system's accuracy and reliability.

In summary, implementing a fuel blend management system for flex-fuel conversion requires a combination of advanced fuel injection technology, precise sensor integration, and adaptive learning capabilities. This system will enable vehicles to seamlessly transition between gasoline and ethanol, providing improved performance, reduced emissions, and the flexibility to utilize a wide range of fuel sources. With proper management, flex-fuel vehicles can offer a more sustainable and efficient driving experience.

Unleash Your Car's Fuel Efficiency: Qualities and Qualifications

You may want to see also

Testing and Tuning: Calibrate the engine for optimal performance with varying ethanol percentages

The process of converting a car to flex fuel opens up a world of possibilities for vehicle owners, allowing them to utilize a wider range of fuel types. However, to truly unlock the potential of this conversion, thorough testing and tuning are essential. This phase focuses on optimizing engine performance across different ethanol percentages, ensuring a smooth and efficient driving experience.

When calibrating the engine for varying ethanol blends, the primary goal is to maintain or even improve performance while ensuring the engine operates within safe limits. Ethanol, a renewable biofuel, can be blended with gasoline in different proportions, typically ranging from pure gasoline (0% ethanol) to E85 (85% ethanol). Each blend requires specific adjustments to the engine's calibration to function optimally.

Testing begins with a baseline performance evaluation using the lowest ethanol percentage, often starting with pure gasoline. This initial test provides a reference point for comparison as you gradually introduce higher ethanol blends. During this phase, it's crucial to monitor various parameters such as horsepower, torque, fuel consumption, and emissions. Advanced diagnostic tools and equipment can aid in this process, offering precise measurements and insights.

As you progress to higher ethanol percentages, such as E10 (10% ethanol) or E85, fine-tuning becomes essential. This involves adjusting the engine's calibration to accommodate the changing fuel-air mixture. For instance, with increased ethanol content, the air-fuel ratio may need to be slightly leaned out to maintain optimal combustion. Additionally, the engine control unit (ECU) might require reprogramming to handle the new fuel characteristics, ensuring proper fuel injection and timing.

Advanced testing techniques, such as dynamometer testing, can be employed to simulate real-world driving conditions and evaluate the engine's performance across different ethanol percentages. This method provides valuable data on power output, throttle response, and overall drivability. By analyzing this data, tuners can make informed decisions about the necessary adjustments to achieve the best performance and reliability.

In summary, testing and tuning for flex-fuel conversion is a meticulous process that requires a systematic approach. It involves a series of evaluations and adjustments to ensure the engine performs optimally across the entire ethanol range. With careful calibration, vehicle owners can enjoy the benefits of increased fuel flexibility while maintaining or even enhancing their vehicle's performance and efficiency.

Octane and Injectors: Fuel Cleaner's Role in Engine Performance

You may want to see also

Frequently asked questions

Converting a vehicle to flex-fuel capability involves modifying the engine and fuel system to accept both gasoline and an alternative fuel, typically ethanol. This process includes installing an additional fuel pump, injectors, and sensors to manage the blend of fuels. It's a complex task that requires specialized knowledge and equipment.

Flex-fuel conversion offers several advantages. It allows vehicle owners to take advantage of the potential cost savings of using ethanol blends, which can be cheaper than pure gasoline. Additionally, it promotes environmental benefits as ethanol is often derived from renewable sources, reducing the carbon footprint of the vehicle.

Yes, there are legal aspects to consider. In some regions, modifications to the vehicle's fuel system may require compliance with specific regulations to ensure safety and environmental standards. It's essential to check local laws and potentially obtain necessary permits before initiating the conversion process.

One of the main challenges is the potential for reduced engine performance and fuel economy. Ethanol-gasoline blends can have a lower energy content, leading to decreased power output. Additionally, the modified fuel system may require careful maintenance to prevent issues like fuel contamination or sensor malfunctions.