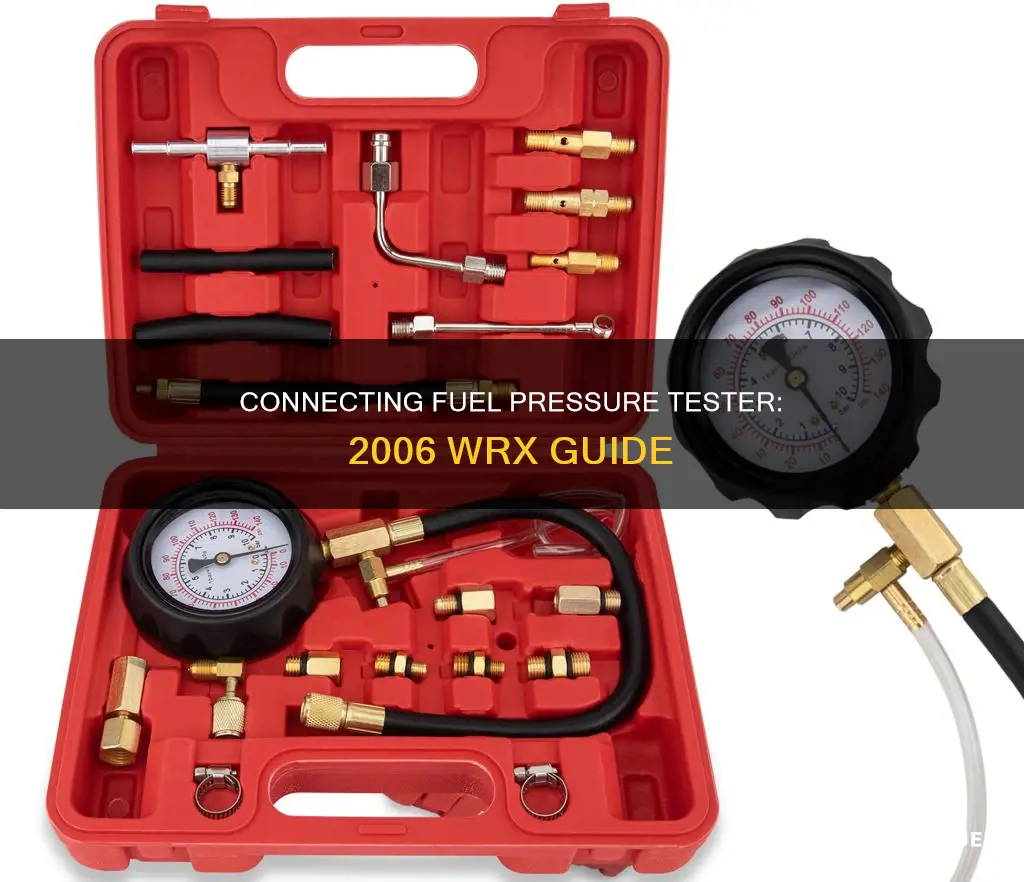

To connect a fuel pressure tester to a 2006 WRX, you will first need to identify the correct fuel line. The top line is the feed, the bottom is the return, and the middle is the evap line. You can then install the gauge on the top line and check the pressure. If you are using a kit, it will likely come with a T-shaped adapter that you can use to connect the tester to the fuel rail line connection.

What You'll Learn

Locating the fuel pressure regulator

Firstly, it's important to understand the purpose of the fuel pressure regulator. This component is responsible for maintaining the correct fuel pressure in the engine's fuel injection system. It ensures that the fuel pump delivers the right amount of fuel at the right pressure to the engine, optimizing performance and fuel efficiency.

Now, to locate the fuel pressure regulator on your 2006 WRX:

- Consult the Owner's Manual: Start by referring to your vehicle's owner's manual. It should have a section dedicated to the engine and fuel system, which may include a diagram or schematic showing the location of the fuel pressure regulator. This can provide you with a visual guide to help you identify its exact position.

- Check Under the Hood: Open the hood of your 2006 WRX and familiarize yourself with the engine bay. Look for the fuel rail, which is a metal tube that carries fuel from the fuel pump to the fuel injectors. The fuel pressure regulator is typically located near or attached to the fuel rail. It may be a small, cylindrical device with fuel lines connected to it.

- Model-Specific Location: The location of the fuel pressure regulator can vary depending on the specific model of your 2006 WRX. For example, on some Subaru WRX models, the fuel pressure regulator is located underneath the intake manifold. You may need to remove or lift the manifold to access it. In other models, it may be located near the fuel filter or the fuel tank.

- Online Resources and Forums: If you're having trouble locating the fuel pressure regulator, online resources and forums specific to your vehicle can be a great help. Search for forums dedicated to the 2006 WRX, where experienced owners and mechanics may provide detailed guidance on locating the regulator and performing fuel pressure tests.

- Consult a Mechanic: If all else fails, consider consulting a professional mechanic, especially one specializing in Subaru vehicles. They will have the knowledge and experience to quickly locate the fuel pressure regulator and provide advice on any necessary repairs or maintenance.

Remember, working on your vehicle's fuel system can be complex and should be approached with caution. Always refer to reliable sources and consult professionals when needed to ensure the safety and proper functioning of your vehicle.

The High-Pressure Fuel Pump: Powering Your Car's Performance

You may want to see also

Identifying the three fuel lines

To identify the three fuel lines on a 2006 WTRX, you need to locate the attachment point at the intake manifold. From top to bottom, the first line is the feed, the second is the return, and the third, smaller line is the evap line, which goes to the charcoal canister at the passenger side rear of the car.

The feed line is the fuel supply, the return line is the fuel that is leftover after passing through the injectors, and the evap line is the evaporation line. You can identify the return line by squeezing it and observing whether the pressure increases on the gauge. Squeezing the evaporation line will not increase the pressure.

Another way to identify the evap line is by tracing it back to the intake manifold, where it connects to the evap purge.

Finding the Fuel Pressure Sensor in Your Taurus

You may want to see also

Using a T-adaptor to test fuel pressure

To test the fuel pressure of a 2006 WRX, you will need to use a T-adaptor to connect your fuel pressure tester to the fuel rail line connection. This is because the engine is not equipped with a fuel pressure test port. Most fuel test pressure kits come with the T-adaptor required to do this.

To begin, identify the three fuel lines as they attach to the intake manifold. The top line is the feed, the bottom is the return, and the middle is the evap line.

Next, install the gauge on the top line. You can then squeeze the return line and you should see the pressure increase on the gauge. Alternatively, you can trace the evap line back to the intake manifold.

Once you have connected the fuel pressure tester, you can start the engine and take a reading. The pressure should be around 33-38 psi at idle and around 43 psi with the vacuum line to the pressure regulator removed.

If the pressure is too high or too low, you may need to replace the pressure regulator or the fuel filter.

Checking Fuel Pressure: Testing the Schrader Valve

You may want to see also

Checking the baro reading from the Manifold Absolute Pressure (MAP) sensor

To check the barometric (BARO) reading from the Manifold Absolute Pressure (MAP) sensor, you will need to follow a few steps. The MAP sensor measures the pressure inside the intake manifold and sends this information to the Powertrain Control Module (PCM), which uses it to adjust the fuel delivery and ignition timing.

First, you will need to locate the MAP sensor. It is usually found on the intake manifold or air cleaner assembly. Once you have located it, disconnect the electrical connector from the sensor.

Now, you can measure the sensor's resistance using a multimeter. Compare this reading to the manufacturer's specifications. If the reading is out of range, you will need to replace the MAP/BARO sensor.

Additionally, you can also check for any loose or damaged wires and connections in the MAP/BARO sensor circuit. Inspect the air intake system for any leaks or blockages, and examine the vacuum hoses for any cracks or damage. If you find any issues, repair or replace the affected components.

It is important to note that attempting to fix the problem yourself without proper knowledge can lead to further damage to your vehicle and may even be dangerous. Therefore, if you are not familiar with automotive repair, it is recommended to seek assistance from a qualified mechanic.

Troubleshooting Erratic Fuel Pressure Gauge on Sniper EFI

You may want to see also

Testing fuel pressure with a scan tool

First, it is important to note that the diagnostic process for fuel pumps has evolved over time. In the past, most fuel pump-related issues could be solved with a pressure gauge and voltmeter. However, modern vehicles have become more complex, and a scan tool is now the most important tool for diagnosing fuel supply problems.

With a scan tool, you can verify if the modules controlling the fuel pump are receiving the correct data, such as oil pressure, crank position, and key position. Some late-model imports have even turned the fuel pump into its own module or node on a high-speed serial data bus, allowing it to share data like fuel level and tank pressure with the instrument cluster module and the ECM.

Before connecting the scan tool, perform a visual inspection of the vehicle and verify the customer's complaint to ensure that the vehicle indeed has a no-start condition or hard-starting issue. "Noid" lights are not recommended for modern vehicles as they can lead you down a diagnostic black hole. If you feel the need to prove that the injectors are pulsing, use a scope instead.

Now, it's time to connect the scan tool. Pull the codes and ensure that the modules are communicating on their communication buses. Some low-end generic tools may not be able to communicate with all the modules, so you might need an enhanced or factory scan tool for this step. These enhanced scan tools can perform a "health check" and pull codes and parameters from the vehicle's modules with just one click. They can also automatically test and bi-directionally control components to confirm their operation.

After pulling the codes, you can develop diagnostic strategies and further tests to resolve the no-start condition. Service information is critical at this stage, just like a pressure gauge. Every fuel system has a set of parameters that must be met for the pump to be energised, such as a crank sensor signal, oil pressure, and a check with the vehicle theft deterrent module.

If the vehicle has any "loss of communication" codes like U1000, resolve those issues first before diagnosing or replacing the fuel pump. These codes may seem unrelated to the fuel pump, but a dead module or short in the serial bus can cause a no-start condition.

Finally, after performing the checks with your scan tool and confirming with service information that the fuel pump is likely causing the no-start condition, you can proceed with physical tests to confirm the condition of the fuel pump.

Checking Fuel Pressure in Your 2000 Subaru Outback

You may want to see also

Frequently asked questions

You can test your fuel pressure by creating a temporary "T" adaptor to fit the gauge you are using. Stick it between the fuel filter out and the fuel rail in.

With the vacuum line disconnected and plugged from the regulator, you should see 43.5 psi at idle.

I'm not sure, but I can tell you that the fuel pressure can exceed 10k psi.

The regulator should be around the fuel rail at the top. Look for a single fuel line coming to the fuel rail or, if there are two lines, look where the return line comes out of the rail.