To check the fuel pressure on a 2007 Dodge Charger, you will need to use a fuel pressure gauge. You can rent one from most auto parts stores. The fuel pressure gauge will need to be attached to the fuel rail service valve. This valve looks like a valve cap on the fuel rail or feed line. The fuel rail is located on the passenger side of the engine. Once the gauge is attached, turn the ignition key to the 'on' position and check the pressure reading. If the pressure is below specifications, further testing may be required.

| Characteristics | Values |

|---|---|

| Fuel pressure gauge connection location | Not equipped with a fuel pressure test port. |

| Fuel pressure test | T into the line at the fuel rail line connection. |

| Baro reading from the Manifold Absolute Pressure (MAP) sensor | Should be within 0.5" of normal atmospheric pressure for the area. |

| Fuel system | Under constant high pressure even with the engine off. |

| Fuel pressure regulator | Not holding pressure (leaking down) when the engine is off. |

| Fuel pressure | 58 psi (± 5 psi) |

What You'll Learn

Check the barometric reading from the Manifold Absolute Pressure (MAP) sensor

To check the barometric reading from the Manifold Absolute Pressure (MAP) sensor, you will need to perform a physical test and a multimeter test.

Physical Test

- Check the manifold pressure sensor wiring for loose connections or damage.

- Ensure the manifold vacuum is within specifications by comparing the MAP sensor output against the voltage chart from the owner's manual.

- Disconnect the sensor and inspect the pins; they should be straight and clean.

- Check for signs of contamination or damage in the vacuum hose. Ensure that the hose is tightly connected to the sensor.

Multimeter Test

- Set the multimeter to voltage settings and turn the ignition switch on.

- Connect the multimeter’s red lead to the MAP sensor’s power wire.

- Connect its black lead to the battery’s ground terminal.

- Check if the voltage reads around 5V.

- Keep the ignition switch on and turn the multimeter to the continuity tester.

- Connect both leads of the multimeter together.

- Connect the multimeter’s red lead to the MAP sensor’s ground wire and the black lead to the battery’s ground terminal.

- If you hear a beep sound, the ground wire is working properly.

- Set the multimeter to voltmeter settings.

- Now connect the multimeter’s red lead to the signal wire and the black lead to the ground.

- The signal wire should show a reading around 5V when the ignition switch is on, and the engine is off (as there’s no air pressure.)

- The multimeter should ideally read around 1-2V with the engine on.

- Keep the multimeter in voltmeter settings and the ignition switch on.

- Next, connect the multimeter’s red lead to the IAT sensor and the black lead to the MAP sensor’s ground.

- The IAT sensor reading would show around 1.6V.

Other Information

The MAP sensor data helps diagnose throttle performance issues and can be used to check for a vacuum leak in the intake manifold. It can also be used to convert the MAP sensor signal into air mass data by using engine speed and Intake Air Temperature (IAT) sensor data.

Fuel Pressure Requirements for Optimum Chevy 350 Performance

You may want to see also

If the reading is lower than normal, check the 5-volt reference signal

If the reading is lower than normal, you should check the 5-volt reference signal. This is because the 5-volt reference flows through a sensor with a resistance that varies according to changes in temperature, pressure or position. The foundational concept is simple: a 5-volt reference flows through a sensor containing a resistance that varies according to changes in temperature, pressure or position. Due to this variable resistance, the signal return voltage to the ECM is always less than the reference voltage.

Most engine management sensors are two-wire circuits that contain a 5-volt reference and a signal return wire or three-wire circuits that contain a 5-volt, signal return and auxiliary ground wire. In the case of a 2007 Dodge Charger, the engine management data like intake air temperature (IAT), engine coolant temperature (ECT), throttle position (TP), mass air flow (MAF), barometric pressure (BARO), oxygen sensor (O2), crankshaft position (CKP), camshaft position (CMP), variable valve timing (VVT), fuel level and other OBD II-related engine sensors are used to control an engine’s spark, fuel and throttle maps.

The engine management system can also gather indirect data from the ABS (vehicle speed) and transmission modules (gear range) to help make spark, fuel and throttle position calculations. The ECM detects sensor failures and sets codes by comparing or “rationalizing” input data among related sensors. For example, data from the coolant, ambient air, battery temperature, engine oil and transmission fluid sensors should be nearly equal following an overnight “cold-soak.” If one sensor is out of range due to faulty calibration, the ECM will set a code for that sensor by comparing it to the remaining three or four data inputs.

To check the 5-volt reference signal, you will need a voltmeter. You can also use a fuel pressure test adapter.

Testing Fuel Pressure on Your 2007 Subaru: A Step-by-Step Guide

You may want to see also

If the signal is fine, replace the MAP sensor

If the signal is fine, you may need to replace the MAP sensor. This is generally a quick and easy task. The manifold absolute pressure (MAP) sensor will typically be on or adjacent to the intake manifold, and the fastener may be a screw or clip.

To replace the MAP sensor, start by locating it. It is typically found on or around the intake manifold. Once located, simply unscrew or unclip the sensor. Be careful not to damage the sensor while working.

Next, insert the new MAP sensor into the same position and secure it with the screw or clip. After replacing the sensor, review the sensor data to confirm that the issue has been resolved. Reset any related codes while driving.

You can almost certainly replace a MAP sensor yourself. They typically have one electrical connector that can be a little tricky to remove on some models. Protecting the sensor while working is also important.

Mounting Fuel Pressure Regulators: The Right Spot Matters

You may want to see also

Check the fuel pressure regulator

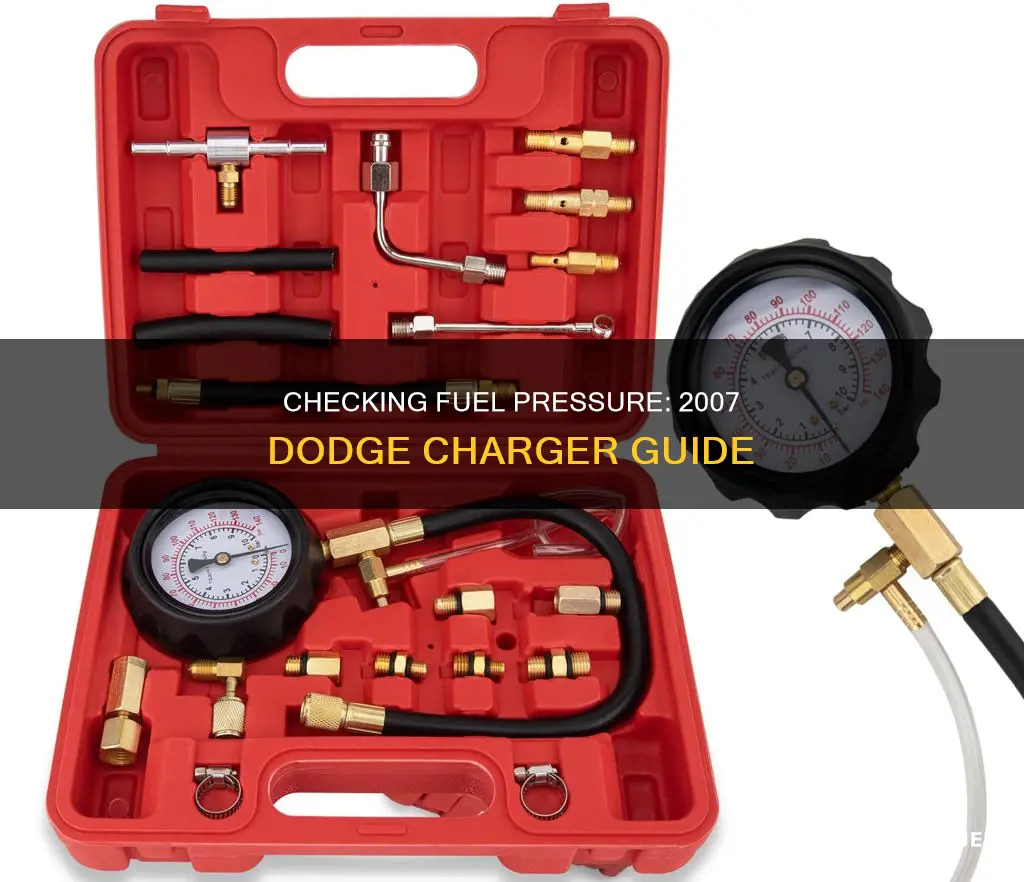

To check the fuel pressure regulator, you will need to install an adapter kit to attach a fuel pressure gauge. This will need to be installed between the fuel line and the fuel rail.

You can also use a DiabloSport Trinity and connect it to the car's OBD2 port to look at the real-time fuel pressure readings. Standard OBD2 PIDs include Fuel Pressure (PID 10) and Fuel Rail Pressure (PID 34). PID 10 is gauge pressure. PID 34 is relative to manifold vacuum. There's also Fuel Rail Pressure (PID 35). It's also gauge pressure but it's only supported on diesel and gasoline direct injection engines.

If you are checking the fuel pressure in-line just after the fuel pump, you will need a fuel pressure test adapter.

Testing Fuel Pressure: 95 Powerstroke Edition

You may want to see also

Check the fuel pump

To check the fuel pump, you will need to test the fuel pressure.

Firstly, relieve the fuel system pressure. To do this, remove the fuel cap, pull the fuel fuse, and connect the fuel pressure device to the testing port.

Next, put the fuel fuse back in, put the gas cap back on, reset the gauge to zero, and turn the key to 'ON'. The needle should jump to 50 psi, then decrease to 40 psi, and slowly decrease to 38 psi.

If the pressure is below specifications, test the system as follows:

- Perform the fuel pressure release procedure.

- Install a fuel gauge and fuel adapter in the fuel supply line between the tank and the fuel filter.

- Place the ignition key in the 'ON' position.

- If the pressure is at least 5 psi or higher than the reading recorded, replace the fuel filter.

- If no change is observed, gently squeeze the return hose. If the pressure increases, replace the pressure regulator. If the gauge reading does not change when the return hose is squeezed, the problem is either a plugged inlet strainer or a defective fuel pump.

- If the fuel pressure reading was above the specifications, test the system as follows:

A. Perform the pressure release procedure.

B. Install a fuel pressure gauge and adapter in the fuel supply line between the fuel tank and the fuel filter.

C. Remove the fuel return line hose from the pump at the tank. Connect a pressure test adapter to the return line. Place the other end of the adapter into an approved gasoline container.

D. Place the ignition key in the 'ON' position.

- If the pressure is now correct, replace the fuel pump.

- If the pressure is still above specifications, remove the fuel return hose from the chassis fuel tubes (at the engine) and attach a fuel pressure test adapter to the return tube. Place the other end of the hose in the clean container, repeat the test. If the pressure is now correct, check for a restricted fuel return line. If there is no change observed, replace the fuel pressure regulator.

Using a Fuel Pump Pressure Gauge: A Step-by-Step Guide

You may want to see also

Frequently asked questions

You will need to purchase or rent a fuel pressure gauge kit. You will then need to connect the gauge to the fuel rail service valve. If you are testing the pressure between the pump and the filter, you will need to install the gauge and a fuel adapter in the fuel supply line between the tank and the filter.

The fuel rail service valve looks like a valve cap on the fuel rail or feed line.

The fuel pressure should be between 46 and 58 psi.

If the fuel pressure is low, the fuel filter may need to be replaced. If that doesn't work, you may need to replace the pressure regulator.

No, you can buy one at an auto parts store such as Pep Boys or Auto Zone.