Checking a vehicle's diesel fuel pressure is a complex process that should only be performed by suitably qualified personnel. The fuel system of a modern direct petrol injection engine consists of a low-pressure system and a high-pressure circuit. The low-pressure circuit, regulated by the engine control unit, is responsible for sucking fuel from the tank and conveying it to the high-pressure pump. The high-pressure circuit then pumps the fuel through high-pressure fuel lines into the fuel distribution pipe, supplying it to the relevant cylinders. The engine control unit monitors and adjusts the fuel pressure in the high-pressure circuit according to the system configuration. Checking fuel pressure involves testing both the low-pressure and high-pressure circuits, and it is important to follow safety precautions and seek professional support when performing these checks.

| Characteristics | Values |

|---|---|

| System pressure in the low-pressure circuit | Up to 6.0 bar |

| System pressure in the high-pressure circuit | 50 to 350 bar |

| Pre-supply pressure in normal operation | 4.0 bar |

| Pre-supply pressure for cold or hot start | 7.0 bar |

| Target value for the fuel system high pressure | 40-120 bar |

What You'll Learn

Check for fuel leaks

Checking for fuel leaks in a diesel engine can be done in several ways. One way is to pressurise the fuel tank to around 4-5 lbs and then inspect for leaks. This can be done by fitting an old fuel cap with a nipple and an air regulator.

Another method is to pressurise the fuel line from the engine back to the tank, as this is the quickest and easiest way to identify a leak. An isolation tap on the tank can be used to achieve this. It is important to note that only a small amount of pressure is needed to find the leak, around 2-6 psi.

If there is no diesel leak apparent, it may be an air leak. To find an air leak, you can try to block off the tank vents, fill point, and heater pickup. This can be tricky, but it is possible to put slight pressure on the supply pipework.

Additionally, it is recommended to check the spill pipes (from the injectors) for damp spots, as these can indicate a return line leak.

Finally, it is worth noting that clear plastic hoses in the fuel system should be replaced with proper marine-grade fuel hoses and fittings.

Testing Ford Focus Fuel Rail Pressure Sensors

You may want to see also

Check the fuel pressure sensor

Checking the fuel pressure sensor is an important part of maintaining your diesel engine. A faulty fuel rail pressure sensor can cause a range of issues, including poor fuel economy, engine hesitation or stalling when accelerating, and can even cause your car to run lean, using too much fuel.

To check the fuel pressure sensor, you will need to compare the fuel pressure in the rail to published known good values. This can be done by reading the scan tool data. If the pressure is too low, the sensor or the high-pressure pump may be to blame. It is worth noting that the high-pressure system is often over 1000 psi, and there is no test port or Schrader valve to mechanically test the system. As such, if the pressure is too low, you will need to decide whether to replace the sensor or the pump first. The sensor is usually the cheaper and easier option to try replacing first.

To test the fuel rail pressure sensor with a multimeter, follow these steps:

- Locate the fuel rail pressure sensor, usually found on the fuel injector rail.

- Disconnect the sensor electrical connector.

- Set the multimeter to the ohms setting.

- Place the multimeter probes on the sensor terminals. If there is no continuity, the sensor is faulty and needs to be replaced.

- Reconnect the sensor electrical connector.

- Start the engine and check for proper operation. If the engine runs erratically or fails to start, the sensor may be faulty.

If you suspect that your fuel rail pressure sensor is failing, it is recommended to consult a professional mechanic for further diagnosis and repair.

Fuel Pressure and Throttle: What's the Relationship?

You may want to see also

Check the fuel pump

Checking the fuel pump is an important step in diagnosing fuel pressure issues. Here is a detailed guide on how to check the fuel pump of your diesel engine:

Locate the Fuel Pump and Prepare the Area

Park your vehicle and engage the parking brake. Turn off the engine and allow it to cool down completely. This step is crucial for safety reasons. Once the engine is cool, locate the fuel pump. In most modern vehicles, the fuel pump is located inside the fuel tank.

Before assuming the fuel pump is faulty, it's important to check the power supply to the pump. Refer to your owner's manual to locate the fuse box. Identify the fuse associated with the fuel pump and remove it for inspection. If the fuse is blown, you will notice that it is broken or burned. If the fuse is intact, move on to the next step.

Check Voltage at the Pump

Even if the fuse is intact, there may be an issue with the voltage reaching the pump. Consult your vehicle's service manual to determine the correct procedure and location for checking the voltage. Test for source voltage to ensure that the charge from the fuse is reaching the pump. If there is no power at the fuel pump, the issue may lie with the fuel pump relay circuit or a faulty relay.

Perform a Drop Test with a Voltmeter

To further diagnose electrical issues, perform a drop test using a voltmeter. Check the power wire for the full voltage and verify that the grounding wire is properly grounded. If this test reveals no problems, it is likely that your fuel pump needs to be replaced. However, for a more comprehensive diagnosis, it is recommended to proceed with a fuel pressure test.

Eliminate the Filter as a Possible Cause

Sometimes, a clogged fuel filter can cause symptoms similar to a faulty fuel pump. To check the filter, remove it from the vehicle and drain any excess fuel. Use a short rubber hose on the filter inlet and blow through it, paying attention to the resistance. If the resistance is high, inspect the screen for debris and consider replacing the filter.

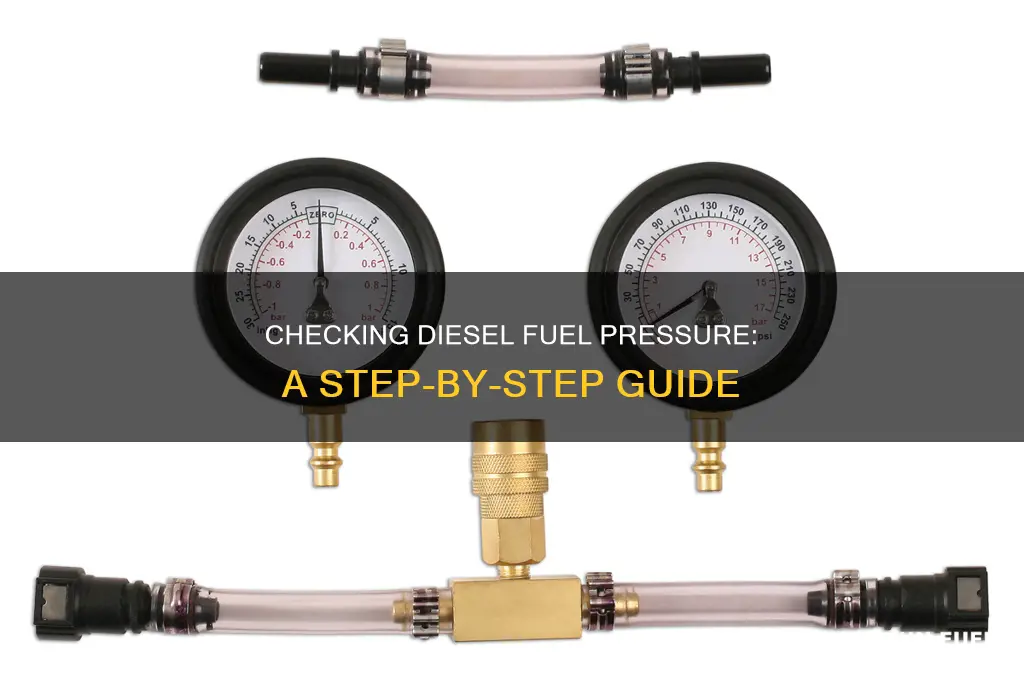

Perform a Fuel Pressure Test

Purchase or borrow a fuel pressure gauge from an auto parts store or a machine shop. Locate the fuel pump test point, usually near the fuel injectors, and find the point where the pump connects to the filter injector rail. Attach the pressure gauge to the separation joint or test port.

With the engine slightly warmed up, ask an assistant to rev the engine while you monitor the gauge. Check the pressure at idle speed and at the rated speed specified in your pump specifications. If the pressure does not match the specifications or fails to increase with engine revving, it indicates that your fuel pump and filter need replacement.

Testing Fuel Rail Pressure Sensor High Input: DIY Guide

You may want to see also

Check the fuel filter

Checking the fuel filter is an important step in diagnosing fuel pump issues. A clogged fuel filter can cause problems with acceleration and engine performance, so it's important to ensure it is clear of debris.

To check the fuel filter, start by locating it in your vehicle. The fuel filter is usually found near the fuel injectors, and there should be a separation joint or test port where you can attach a pressure gauge. If you are having trouble locating it, consult your vehicle's service manual.

Once you have located the fuel filter, remove it from the vehicle and drain any excess fuel. Use a short piece of rubber hose on the filter inlet to blow through and check for resistance. There should only be minimal resistance, and you can inspect the screen for any debris that may be causing a blockage. If the filter is clogged, replace it.

If you are experiencing issues with fuel pressure, you can also perform a pressure test on the fuel filter. Attach a fuel pressure gauge to the test port at the fuel filter. Start the engine and check the pressure level on the gauge. If the pressure is low, it could indicate a clogged fuel filter.

It is important to note that different vehicles will have different fuel filter designs, so it is always best to refer to your vehicle's service manual for specific instructions on checking and replacing the fuel filter.

Finding the Fuel Pressure Regulator in '08 Nissan Sentra

You may want to see also

Check the fuel lines

Checking the fuel lines is an important step in diagnosing fuel pressure issues. If you're experiencing problems with your diesel engine's fuel pressure, here's a detailed guide to help you inspect the fuel lines:

- Initial Troubleshooting: Before delving deeper, it's advisable to perform a visual inspection of the fuel lines. Check for any signs of leaks or defects in the lines. This initial check can often reveal issues that may be causing abnormal fuel pressure readings.

- Checking for Kinks or Blockages: If there's an issue with the fuel pressure, one of the first things to inspect is the fuel lines for any kinks or blockages. Kinks in the lines can restrict fuel flow, leading to inadequate fuel pressure. Ensure that the lines are not bent or crushed, allowing for uninterrupted fuel delivery.

- Fuel Line Connections: Inspect all the connections and fittings associated with the fuel lines. Ensure that they are secure and properly attached. Loose or faulty connections can lead to fuel leaks and affect fuel pressure.

- Fuel Filter Inspection: The fuel filter plays a crucial role in ensuring clean fuel is delivered to the engine. Over time, filters can become clogged with contaminants, restricting fuel flow. Locate the fuel filter and check if it needs to be replaced. Refer to your vehicle's maintenance schedule or consult a mechanic to determine the recommended replacement intervals for the fuel filter.

- Tank Ventilation Check: Proper tank ventilation is essential for the fuel system to function correctly. Ensure that the tank ventilation system is not blocked or restricted. This system helps regulate the pressure within the fuel tank and ensures an uninterrupted fuel supply to the engine.

- Fuel Delivery Unit: The fuel delivery unit, also known as the fuel pump, is responsible for supplying fuel from the tank to the engine. If there's an issue with the fuel pressure, it could be due to a faulty fuel delivery unit. In some vehicles, you may need to remove the fuel tank to access and inspect this component.

Remember, working on fuel systems can be dangerous due to the presence of flammable fuel and high pressure. Always exercise caution, wear protective gear, and refer to manufacturer guidelines or seek professional assistance if you're uncomfortable performing these checks.

Fuel Pressure Gauge: Lincoln Navigator Connection Point

You may want to see also

Frequently asked questions

The fuel pressure sensor for low pressure is installed in the feed line to the high-pressure pump. To check the fuel pressure, connect a pressure gauge to the fuel supply line to the high-pressure pump. Then, let the engine run in idling mode. The fuel pressure should be between 4.0 and 7.0 bar.

Connect a pressure gauge to the fuel supply line, start the engine until operating pressure is reached, and then switch it off. Close the hose pipes to the high-pressure pump and check the pressure gauge after about 10 minutes. The pressure should be approximately 3.0 bar.

Loosen and close the fuel supply line on the high-pressure pump and place it in a measuring cup. Disconnect the electrical connection on the pre-feed pump and set up a separate power supply. Switch on the pump and start measuring once the pressure is built up. After 30 seconds, the target quantity of approximately 600 ml should be reached.